Carbide end mills, especially 1/8″ long reach versions, are a fantastic choice for machining cast iron. They offer precision, longevity, and excellent chip evacuation, making them ideal for detailed work on tough materials.

Working with cast iron can feel a little daunting, especially when you’re just starting out. It’s a strong, durable material, but it can also be challenging to machine if you don’t have the right tools. Many beginners get frustrated when their end mills chatter, break, or just don’t cut cleanly. But there’s a really effective solution: a 1/8-inch long reach carbide end mill. These small but mighty tools are designed to tackle tough materials like cast iron with surprising ease. They can help you achieve incredible detail and smooth finishes without the headaches. In this guide, we’ll walk you through exactly why this specific tool is so brilliant for cast iron and how you can use it to get great results in your workshop. We’ll cover everything from choosing the right one to setting it up for success.

Why a 1/8″ Long Reach Carbide End Mill is Your Cast Iron Best Friend

When you hear “end mill,” you might picture something larger, but don’t let the 1/8-inch size fool you. This little tool packs a serious punch, especially when it comes to cast iron. Carbide is a game-changer here, and the “long reach” aspect adds versatility. Let’s break down why this combination is so effective.

The Magic of Carbide for Cast Iron

Carbide, or tungsten carbide, is a super-hard material made from carbon and tungsten. It’s incredibly tough and can withstand high temperatures, which is crucial when cutting metal.

Hardness: Carbide is significantly harder than High-Speed Steel (HSS). This means it can maintain its sharp edge for much longer, even when cutting abrasive materials like cast iron. For cast iron, which can be tough on tooling, this is a huge advantage.

Heat Resistance: Machining generates heat. Carbide can handle much higher temperatures than HSS before it starts to soften or deform. This allows for faster cutting speeds and longer tool life, reducing the chance of tool failure due to heat.

Wear Resistance: Because it’s so hard, carbide resists wear exceptionally well. It won’t dull as quickly, ensuring consistent cutting performance job after job. This means fewer tool changes and more reliable results for your projects.

Chip Evacuation: While it might seem counterintuitive for a small tool, the geometry of carbide end mills is often optimized for excellent chip control. Good chip evacuation is vital when working with cast iron to prevent the chips from clogging the flutes and causing them to break or overheat.

The Benefits of a “Long Reach” Design

The “long reach” designation refers to the extended length of the cutting portion of the end mill, beyond the shank. For a 1/8-inch end mill, this often means it has a longer flute length relative to its shank diameter.

Accessing Tight Spaces: The longer reach allows you to cut deeper into cavities or access areas that a standard-length end mill might not be able to reach. This is invaluable for intricate machining tasks or when working with parts that have complex geometries.

Reduced Chatter: Sometimes, having a tool that extends further can help dampen vibrations, potentially leading to a smoother cut and less chatter. However, this needs to be balanced with rigidity; excessive length can also be a source of vibration if not used correctly. For a 1/8-inch tool, a controlled long reach can offer access without sacrificing too much rigidity.

Versatility: A long reach end mill can perform both shallower and deeper cuts, offering more flexibility in a single tool. This can be particularly useful in a home workshop where tool variety might be limited.

Why 1/8″ is Perfect for Detailed Cast Iron Work

The 1/8-inch diameter is ideal for creating fine details, slots, pockets, and contours in cast iron. Think of intricate engravings, precise locating features, or small internal features.

Precision: Smaller diameter mills are naturally suited for producing fine details and achieving tight tolerances.

Manageable Chip Load: For a 1/8-inch tool, the chip load (the amount of material removed by each cutting edge per revolution) is typically very small. This is good for hard materials like cast iron, as it reduces the stress on the tool and the machine, leading to a cleaner cut and longer tool life.

Accessibility: This small diameter can fit into very narrow slots and tight corners that larger end mills cannot.

Choosing the Right 1/8″ Long Reach Carbide End Mill for Cast Iron

Not all carbide end mills are created equal, especially when you’re targeting a specific material like cast iron. Here’s what to look for:

Key Features to Consider:

Number of Flutes: For general-purpose machining of cast iron, a 2-flute or 4-flute end mill is usually recommended.

2-Flute: These generally offer better chip clearance and are less prone to packing chips. They are excellent for plunging and slotting in softer materials, but can also work well in cast iron with proper settings and lubrication.

4-Flute: These provide a smoother finish and are often more rigid. They can handle heavier cuts and are very common for general milling. For cast iron, a 4-flute can be effective if chip evacuation is managed well.

Coating: While many uncoated carbide end mills work well for cast iron, certain coatings can significantly enhance performance and tool life.

Uncoated: This is a common and effective option for cast iron. The natural properties of carbide are often sufficient.

TiN (Titanium Nitride): A general-purpose coating that can improve surface finish and wear resistance. It’s a good budget-friendly option.

AlTiN (Aluminum Titanium Nitride): This coating excels in high-temperature applications, making it an excellent choice for machining tough materials like cast iron where heat is a concern. It provides superior oxidation resistance and extended tool life.

End Type:

Square End: The most common type, creating sharp internal corners.

Corner Radius: If you need fillets in your corners to reduce stress risers or for aesthetic reasons, a ball end mill or a square end mill with a small corner radius is the way to go.

Shank: Ensure the shank is properly sized for your collet or tool holder (e.g., 1/8″ shank). Many long reach tools will also have a reduced shank to allow for deeper reach without the shank colliding with the workpiece or fixture.

Material Grade of Carbide:

While you won’t typically see specific “grades” advertised for end mills in the same way you do for solid carbide rods, manufacturers select specific carbide grades and sintering processes for their end mill lines. Generally, a fine-grain carbide offers a good balance of hardness and toughness suitable for cast iron.

Where to Find Reliable Tools:

Look for reputable manufacturers known for quality cutting tools. Some well-regarded brands include Union Tool, OSG, YG-1, and Harvey Tool. For beginner-friendly options, checking out suppliers like McMaster-Carr or Grizzly Industrial can also be beneficial, although always check the specifications.

How to Use Your 1/8″ Long Reach Carbide End Mill on Cast Iron: A Step-by-Step Guide

Now that you’ve got the right tool, let’s talk about how to use it effectively and safely on cast iron. This guide assumes you’re using a milling machine or a CNC machine.

Essential Tools and Setup:

Before you begin, gather these items:

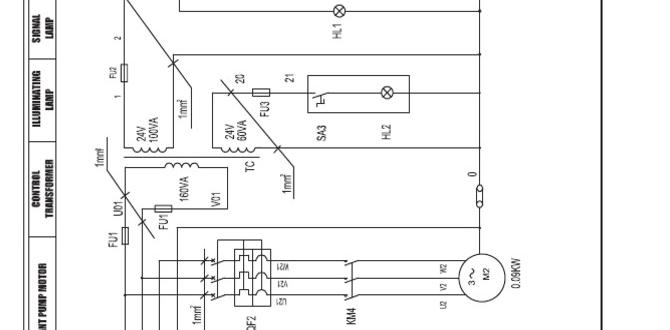

Milling Machine/CNC: Ensure it’s in good working order.

1/8″ Long Reach Carbide End Mill: Coated or uncoated, suitable for cast iron.

Collet Holder: For secure tool holding. A precision collet (e.g., ER series) is best.

Coolant/Lubrication System: Crucial for cast iron.

MQL (Minimum Quantity Lubrication): This is often ideal for carbide tools and cast iron. It uses a fine mist of coolant and air.

Flood Coolant: A constant flow of coolant.

Spray Coolant: A targeted spray.

Cutting Fluid: Specific fluids designed for milling cast iron.

Air Blast: Can help clear chips, especially if liquid coolant is difficult.

Workholding: A sturdy vise or fixture to hold your cast iron part securely.

Safety Glasses & Face Shield: Non-negotiable.

Work Gloves: For handling parts.

Calipers/Measuring Tools: For setting depths and verifying dimensions.

Deburring Tool: For cleaning up edges after machining.

Setting Up Your Machine:

1. Secure the Workpiece: Mount your cast iron part firmly in a vise or fixture. Ensure it’s stable and won’t move during machining. Double-check it’s the most rigid setup possible.

2. Install the End Mill: Insert the 1/8″ long reach carbide end mill into a precision collet and tighten it securely in your machine’s spindle. Make sure the collet is the correct size for the mill’s shank.

3. Set Up Lubrication: If using MQL, set up your system to deliver a fine mist directly to the cutting area. For flood coolant, ensure good flow. If using just an air blast, position it to clear chips effectively from the flutes.

Machining Parameters (Starting Points):

Finding the perfect settings often involves some experimentation, but here are good starting points for a 1/8″ carbide end mill in cast iron. Always consult your tool manufacturer’s recommendations if available.

Spindle Speed (RPM): For carbide in cast iron, you’ll generally use higher speeds than you would with HSS.

Start around 8,000 – 15,000 RPM. Lower speeds can lead to rubbing and heat buildup, while excessively high speeds can cause rapid wear.

Feed Rate (IPM or mm/min): This is how fast the tool moves through the material.

Start around 8 – 20 IPM (inches per minute) or 200 – 500 mm/min.

Chip Load: A good rule of thumb for cast iron with a 1/8″ carbide mill is a chip load between 0.0005″ and 0.002″ per tooth. [(Number of flutes) x (Chip Load per tooth) x (RPM) = Feed Rate (IPM)].

For a 2-flute mill at 0.001″ chip load and 10,000 RPM: 2 0.001 10,000 = 20 IPM.

For a 4-flute mill at 0.0008″ chip load and 10,000 RPM: 4 0.0008 10,000 = 32 IPM. (This might be a bit aggressive start, adjust down if needed).

Depth of Cut (DOC): For a 1/8″ end mill, you generally want to keep the depth of cut relatively shallow to maintain rigidity and prevent chatter, especially with the long reach.

Start with a radial depth of cut (how much it cuts sideways if slotting) of 0.020″ to 0.040″.

For axial depth of cut (how deep it cuts down), start with 0.060″ to 0.125″. Avoid plunging deeper than approximately 1x the tool diameter unless the tool is specifically designed for it.

The Machining Process:

1. Approach the Surface: Using your machine’s controls, carefully bring the tip of the end mill down to the surface of the cast iron.

2. Set Z-Zero: Once the mill lightly touches the surface, set your Z-axis zero point.

3. Engage and Cut:

Conventional Milling: The tool rotates against the direction of feed. Generally provides a cleaner cut and better chip thinning.

Climb Milling: The tool rotates in the same direction as the feed. Can allow for faster material removal and is less prone to lifting the workpiece, but demands a rigid setup and can sometimes overload the tool if not controlled.

For cast iron, conventional milling is often preferred for its stability, especially with smaller tools.

4. Apply Lubrication: Turn on your coolant or MQL system to coincide with the start of the cut. Ensure good chip evacuation.

5. Monitor the Cut: Listen to the sound of the cut. A smooth, consistent sound is good. Grinding sounds or excessive chatter indicate issues; stop the machine and re-evaluate your settings or setup. Observe the chips – they should be small and consistent, not dusting or stringy.

6. Control Z-Depth: Use your Z-axis control to move the tool to the desired depth. For the long reach, be mindful of tool deflection if you’re cutting deep. It’s often better to take multiple shallow passes than one deep pass.

7. Complete the Operation: Follow your programmed toolpath or manual movements to achieve the desired shape.

8. Retract and Clean: Once done, retract the tool clear of the part. Turn off the coolant and allow the machine to stop.

9. Deburr: After the part is removed from the machine, use a deburring tool to clean up any sharp edges or burrs left by the machining process.

MQL – The Genius Solution for Cast Iron and Carbide

Minimum Quantity Lubrication (MQL) is a highly effective way to machine cast iron with carbide tools. It uses a very small amount of specialized cutting fluid mixed with compressed air.

Benefits of MQL for Cast Iron:

Excellent Cooling and Lubrication: The mist provides targeted cooling right at the cutting edge.

Superior Chip Evacuation: The air blast helps blow chips away, preventing them from re-cutting or clogging the flutes.

Reduced Coolant Usage: Minimal fluid means less mess and lower disposal costs.

Improved Surface Finish: Often results in a smoother finish than dry machining.

Extended Tool Life: Effective cooling and lubrication reduce wear on the carbide.

Setting up an MQL system involves a small reservoir for the fluid, an air line, and a nozzle that delivers the mist precisely to the tool tip. These systems are widely available and can be a worthwhile investment for anyone frequently machining tough materials.

Sample Machining Parameters for Cast Iron

These are starting points and may need adjustment based on your specific machine rigidity, tool condition, and desired finish. Always prioritize safety and listen to your machine.

| Operation | Tool | Material | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (Axial) | Depth of Cut (Radial) | Lubrication |

|---|---|---|---|---|---|---|---|

| General Milling/Facing | 1/8″ 2-Flute Carbide Long Reach End Mill | Cast Iron (Gray) | 10,000 – 12,000 | 10 – 18 | 0.060″ – 0.100″ | 0.020″ – 0.040″ | MQL or Flood Coolant |

| Pocketing/Slotting | 1/8″ 4-Flute Carbide Long Reach End Mill | Cast Iron (Ductile) | 8,000 – 10,000 | 15 – 25 | 0.100″ – 0.125″ | 0.030″ – 0.060″ | MQL or Flood Coolant |

| Finishing Pass (Optional) | 1/8″ 4-Flute Carbide Long Reach End Mill | Cast Iron | 12,000 – 15,000 | 15 – 20 | 0.020″ – 0.040″ | 0.010″ – 0.020″ | MQL or Flood Coolant |

Troubleshooting Common Issues

Even with the right tools, you might encounter problems. Here’s how to tackle them:

Chatter/Vibration:

Cause: Machine rigidity, worn tool, incorrect speeds/feeds, workpiece not held securely.

Solution: Decrease depth of cut, increase coolant flow, check tool for wear, ensure workpiece is firmly clamped, experiment with different speeds and feeds (often slightly higher RPM with a slightly lower feed can help). Ensure your spindle runout is minimal.

Tool Breakage:

Cause: Too aggressive depth of cut, poor chip evacuation, plunging too deep too fast, worn tool, sudden impact.