1/8 inch carbide end mills are an excellent choice for cutting carbon steel, offering durability and precision essential for beginners working with this material.

Working with carbon steel can be a bit daunting for newcomers to machining. It’s a tough material that demands the right tools and techniques to get clean, precise cuts without bending or breaking your bits. One of the most essential tools you’ll reach for is a 1/8-inch carbide end mill, especially when dealing with detailed work on carbon steel. It might seem small, but this tiny tool packs a big punch for accuracy. If you’ve struggled to get smooth finishes or found your tools wearing out too quickly on metal, you’re in the right place. We’re going to break down exactly why the 1/8-inch carbide end mill is your new best friend for carbon steel projects and how to use it effectively.

Why a 1/8″ Carbide End Mill is Key for Carbon Steel

When it comes to machining carbon steel, especially for intricate details or small parts, the 1/8-inch carbide end mill is an absolute workhorse. Carbon steel is known for its strength and hardness, which means it can be tough on tooling. This is where carbide shines. Unlike high-speed steel (HSS), carbide is significantly harder and more rigid, allowing it to maintain its cutting edge at higher temperatures and speeds. This translates to less tool wear, cleaner cuts, and the ability to achieve tighter tolerances – all crucial when you’re learning.

The 1/8-inch size is particularly versatile. It’s small enough to get into tight corners and create fine details, making it perfect for engraving, slotting small parts, or performing delicate profiling. For beginners, this means fewer opportunities for catastrophic tool failure due to chatter or overloading a larger, less manageable tool. It allows you to practice your feeds and speeds on a smaller scale, building confidence before moving to larger diameters.

Understanding Carbide End Mills

Before we dive into using them, let’s quickly touch on what makes carbide special. Carbide, or tungsten carbide, is a composite material formed by combining tungsten carbide particles with a binder, usually cobalt. This creates an incredibly hard and wear-resistant material. However, carbide is also more brittle than steel. This means you need to be mindful of your machining parameters. You can’t just push it as hard as you might an HSS tool. The key is to leverage its hardness for precision and speed, while respecting its brittleness to avoid chipping or breaking.

When you’re looking for a 1/8-inch end mill for carbon steel, you’ll encounter a few key features:

- Number of Flutes: For general-purpose machining of steel, 2-flute and 4-flute carbide end mills are most common.

- 2-Flute: These offer better chip evacuation, which is crucial when machining steel as it can produce long, stringy chips. The wider flutes mean more space for chips to escape, reducing the risk of clogging and overheating. They are excellent for slotting and pocketing.

- 4-Flute: These provide a smoother finish and are better suited for finishing passes and side milling operations. They have less chip clearance but offer more cutting edges, leading to a better surface finish.

- Coating: While uncoated carbide is common, specialized coatings can further enhance performance on steel.

- TiN (Titanium Nitride): A general-purpose coating that adds hardness and lubricity, improving tool life and chip flow.

- TiCN (Titanium Carbonitride): Offers even greater hardness and abrasion resistance, making it excellent for harder steels and high-wear applications.

- AlTiN (Aluminum Titanium Nitride): Ideal for high-temperature applications, including machining steels. It forms a protective aluminum oxide layer at high cutting temperatures, further extending tool life.

For beginners working with carbon steel, a TiN or AlTiN coated 1/8-inch end mill is often a great starting point.

- Helix Angle: This refers to the angle of the cutting edges. A standard helix angle is typically around 30 degrees. Higher helix angles (e.g., 45 degrees) can provide a smoother cutting action and better chip evacuation, but may be less rigid.

- Shank Type: Most 1/8-inch end mills will have a standard round shank, often 1/4-inch or 1/8-inch. Ensure it matches your collet or workholding. For increased rigidity and to prevent slippage, a Weldon flat (or “shank flat”) on the side of the shank is beneficial.

- Reach: The “reach” is the length of the cutting flutes. For general work, standard reach is fine. For deeper pockets, you might consider “long reach” or “extended reach” end mills, but these can also be less rigid. For a 1/8″ end mill, stick to standard or shorter reach for better stability unless absolutely necessary.

Selecting Your Carbide End Mill for Carbon Steel

When you’re at the tool supplier, or browsing online, keep these factors in mind for your 1/8-inch carbide end mill, specifically for carbon steel:

- Material: Always look for “Carbide” or “Tungsten Carbide.”

- Diameter: Clearly “1/8 inch.”

- Number of Flutes: Start with a 2-flute for better chip clearance when roughing or slotting. A 4-flute can be used for finishing passes if you’re not experiencing chip packing.

- Coating: For carbon steel, an AlTiN or TiCN coating is highly recommended for extended tool life and better performance. If budget is a concern, a good quality uncoated carbide or TiN coated mill will work, but may require more careful control of feeds/speeds and coolant.

- “For Steel” or “Steel Mill”: Many manufacturers label their end mills for specific materials. Look for ones designed for machining steels.

- Shank: A standard 1/4″ shank is very common for 1/8″ end mills and offers good rigidity. A 1/8″ shank end mill will be less rigid. If your machine has a very small spindle taper or collet system, a 1/8″ shank might be necessary, but be extra cautious with cutting forces. A Weldon flat is a bonus for secure clamping in some holders.

- “Low Runout”: This is a critical keyword to look for, especially for precision work. Low runout means the cutting edges run very true to the spindle axis, leading to more accurate dimensions and a better surface finish. This is especially important for small diameter end mills where any wobble is amplified.

A good example of a suitable tool might be described as: “1/8″ 4-Flute AlTiN Coated Carbide End Mill, 1/4″ Shank, Standard Length.” Or for slotting: “1/8″ 2-Flute TiCN Coated Carbide End Mill, 1/4″ Shank, Square End.”

Safety First: Working with End Mills and Carbon Steel

Machining, especially with sharp tools and hard materials, requires a strong focus on safety. Always:

- Wear Safety Glasses: This is non-negotiable. Metal chips can fly with surprising force. A full face shield offers even better protection if available.

- Secure Your Workpiece: Ensure your carbon steel workpiece is firmly clamped in a vise or held securely to your machine table. This prevents it from spinning or moving during the cut, which could cause serious injury or tool breakage.

- Use Appropriate Workholding: For milling, this usually means a milling vise. For lathe operations using an end mill, ensure it’s held rigidly in the tool post or gang tooling.

- Understand Your Machine’s Limits: Don’t try to take too aggressive of a cut. Start conservatively and gradually increase your depth of cut or feed rate as you gain confidence and observe the cutting action.

- Keep Hands Clear: Never hold small workpieces by hand while milling. Keep your hands well away from the spinning tool and the cutting area.

- Use Coolant or Lubricant: Machining steel generates heat. Using a cutting fluid or lubricant makes the cut smoother, cools the tool and workpiece, and helps with chip evacuation. This significantly prolongs tool life and improves surface finish. For 1/8″ end mills and carbon steel, a mist coolant system or a quality cutting fluid is highly beneficial.

- Inspect Your Tool: Before each use, check your end mill for any signs of damage, chipping, or excessive wear. A damaged tool can lead to poor results and can be more dangerous.

- Proper Chip Removal: Don’t let chips build up. Use a brush or a vacuum designed for chip removal (not compressed air, which can blow chips into your face and the machine).

You can find excellent resources on machining safety from organizations like OSHA (Occupational Safety and Health Administration) or university extension programs that offer manufacturing or fabrication courses. For instance, Canadian Centre for Occupational Health and Safety provides comprehensive guidance on machine shop safety.

Setting Up Your 1/8″ Carbide End Mill

Proper setup is crucial for getting the best performance and longevity from your 1/8″ carbide end mill.

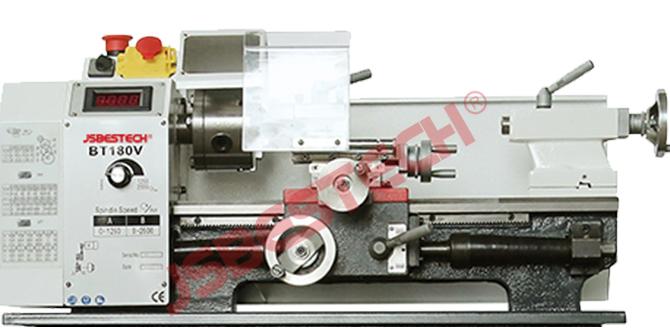

In a Milling Machine

- Select the Right Collet: You’ll need a collet that precisely matches the shank diameter of your end mill. For a 1/8″ end mill with a 1/4″ shank, you’ll need a 1/4″ collet. For a 1/8″ shank end mill, you’ll need a 1/8″ collet. Using a collet that’s too large will result in poor runout and probable workpiece or tool damage.

- Insert the End Mill: Clean the collet and the spindle taper. Insert the end mill into the collet. Ensure the proper cutting length is exposed. For 1/8″ end mills, you generally don’t want to expose more fluting than necessary to maintain rigidity. A good rule of thumb is to have no more than 2-3 times the diameter of the tool exposed. So, for a 1/8″ tool, that’s about 1/4″ to 3/8″ of flute exposure.

- Tighten the Collet: Secure the end mill in the collet using the appropriate wrench. Ensure it’s snug, but avoid overtightening, which can damage the collet or the tool shank.

- Secure the Workpiece: Clamp your carbon steel stock firmly in the milling vise. Ensure it’s parallel to the machine table or at the desired angle.

- Set Your Zero (Origin): Use your machine’s DRO (Digital Readout) or CNC controller to establish your X, Y, and Z zero points. For Z zero, this is typically the top surface of your workpiece.

On a Lathe for Side-Milling or Drilling Operations

Using an end mill on a lathe is often referred to as “off-center drilling” or “milling.” This requires a specific setup:

- Rigid Workholding is Paramount: The workpiece must be incredibly secure in the lathe chuck or between centers with a driving dog.

- Tool Holder: The 1/8″ end mill needs to be held in a tool holder that fits the lathe’s tool post. This could be a dedicated milling attachment, a boring bar holder that can grip an end mill, or a specialized gang tooling setup.

- Positioning the Tool: The end mill will typically be held tangentially to the workpiece’s rotation, or mounted in a vertical milling attachment. For drilling holes off-center, the end mill is usually aligned to approach the workpiece surface at an angle.

- Spindle Speed: This is often done with the lathe’s spindle rotating at a slow speed, feeding the tool into the rotating workpiece. Alternatively, some setups allow the spindle to be stationary while the end mill is rotated in its own holder (often powered by a separate motor).

- Feeds and Speeds: This is more complex on a lathe and depends heavily on your specific setup and machine capabilities. Always refer to machining handbooks or online calculators and err on the side of caution.

Calculating Feeds and Speeds for Carbon Steel with a 1/8″ Carbide End Mill

This is where many beginners get stuck. Fortunately, there are resources to help. Feeds and speeds are crucial for preventing tool breakage, achieving a good finish, and ensuring efficient machining. They are determined by:

- Material Being Cut: Carbon steel is harder than aluminum, so it requires slower speeds and potentially lower feed rates.

- Tool Material: Carbide has different optimal speeds than HSS.

- Tool Diameter: Smaller tools require higher spindle speeds (RPM) but slower feed rates (in/min or mm/min) to avoid deflection and breakage.

- Number of Flutes: Affects chip load.

- Depth of Cut (DOC) and Width of Cut (WOC): The amount of material being removed.

- Machine Rigidity and Power: A less rigid machine or one with lower power will require more conservative settings.

- Presence of Coolant.

A good starting point for 1/8″ carbide end mills on medium carbon steel (like 1018 or 1045) might be:

- Surface Speed (SFM – Surface Feet per Minute): For carbide on steel, this can range from 150-350 SFM. Let’s aim for a conservative 200 SFM for 4-flute.

- RPM Calculation: RPM = (SFM 3.82) / Diameter (inches).

RPM = (200 3.82) / 0.125 = 6112 RPM.

Many smaller machines might not reach this, so adjust accordingly. If your machine tops out at 4000 RPM, you’ll need to compensate with feed rate. - Chip Load (CL – Inches per Tooth): For a 1/8″ 4-flute carbide end mill in steel, a chip load might be around 0.0008″ to 0.0015″ per tooth. Let’s use 0.001″ per tooth.

- Feed Rate (IPM – Inches per Minute): Feed Rate = RPM Number of Flutes Chip Load.

Using our calculated 6112 RPM:

Feed Rate = 6112 4 0.001 = 24.45 IPM.

If your machine is limited to 4000 RPM:

Feed Rate = 4000 4 0.001 = 16 IPM. - Depth of Cut (DOC): For a 1/8″ end mill, a conservative radial depth of cut (how much of the diameter is engaged) is often 50% (0.0625″). For axial depth of cut (how deep into the material you’re cutting), start very shallow, perhaps only 0.020″ to 0.040″ for steel.

Important Disclaimer: These are starting points! Always listen to your machine and the sound of the cut. If it’s chattering or sounding stressed, reduce your feed rate or depth of cut. If the chips are tiny and dusty, you might be able to increase your chip load or depth of cut slightly.

Online calculators are invaluable. Websites like the Machinewizard or tools provided by end mill manufacturers (like G-Wizard or even Autodesk’s Fusion 360 CAM software) can help you dial in these settings more precisely. Searching for “carbide end mill calculator steel” will give you many options.

| Parameter | Example Value |

|---|