Carbide end mills make cutting PVC easy and fast, offering excellent results with minimal effort, boosting productivity and precision for your projects.

Working with PVC can sometimes feel like a wrestling match. You want clean cuts, smooth finishes, and efficient production, but PVC can chip, melt, or leave a rough edge if you’re not using the right tools and techniques. It’s a common frustration for makers, hobbyists, and even seasoned professionals. But what if there was a tool that made cutting PVC feel almost… effortless? There is! In this guide, we’ll dive into why a carbide end mill is your new best friend for PVC projects and how to use it effectively. Get ready to cut through your PVC challenges like never before!

Why Carbide End Mills Are Your PVC Cutting Champion

When you’re looking at cutting plastics, especially something like PVC, you need a cutting tool that can handle the material’s properties without causing problems. PVC, or polyvinyl chloride, is a common and versatile plastic, but it has a tendency to melt under friction and can be prone to chipping or melting if the wrong tool is used. This is where the humble carbide end mill shines.

The Magic of Carbide

Carbide, specifically tungsten carbide, is an incredibly hard and durable material. It’s significantly harder than high-speed steel (HSS), which is often used for other cutting tools. This hardness translates directly to several key advantages when cutting PVC:

- Heat Resistance: PVC can get hot during machining, leading to melting and gumming up your cutting tool. Carbide’s superior heat resistance means it stays sharp and effective for longer, even when working with plastics that generate significant friction.

- Wear Resistance: Because it’s so hard, carbide resists wear much better than HSS. This means your end mill will maintain its cutting edges for many more cuts, providing consistent results over time.

- Sharpness Retention: The superior hardness also means carbide edges stay sharper for longer. A sharp edge is crucial for clean cuts, minimal tear-out, and preventing melting, all vital when working with PVC.

End Mills vs. Other Cutters for PVC

While saws and routers can cut PVC, end mills offer a level of precision and control that’s often unmatched, especially when CNC (Computer Numerical Control) machining is involved. Unlike a saw blade designed for straight cuts, an end mill can create intricate shapes, slots, pockets, and holes within a piece of PVC. For CNC routing or milling, especially for detailed work or repeatable production, an end mill is the go-to tool.

The “Extra Long” Advantage

The keyword “carbide end mill 1/8 inch 1/2 shank extra long for pvc high mrr” points to a specific type of end mill that’s particularly beneficial for PVC. An “extra long” end mill, often with a 1/2-inch shank for stability, allows for deeper cuts in a single pass or lets you reach into deeper cavities without needing to extend the tool excessively from its holder. This depth capability is fantastic for creating features that go deep into the material or for projects where you need to mill out significant material.

Understanding High MRR (Material Removal Rate)

High MRR means the tool can remove a large volume of material quickly and efficiently. For PVC, this is desirable because machining it too slowly or with dull tools can lead to melting. A well-chosen carbide end mill, combined with appropriate speeds and feeds, can achieve a high MRR, cutting cleanly and quickly without overheating the plastic. This leads to faster project completion and a better finish.

Types of Carbide End Mills for PVC

When selecting a carbide end mill for PVC, you’ll encounter different types, primarily distinguished by the number of flutes (the cutting edges) and the geometry of those flutes. For PVC, you generally want fewer flutes to help with chip evacuation and prevent melting.

Flute Count Matters

There are typically 2, 3, or 4 flutes on an end mill. For plastics like PVC, which can be “gummy” and prone to melting:

- 2-Flute End Mills: These are often the preferred choice for plastics. With fewer flutes, there’s more open space for chips to clear out. Good chip evacuation is critical to prevent heat buildup and melting. The two flutes provide enough cutting action for efficient material removal.

- 3-Flute End Mills: While sometimes usable, 3-flute end mills have less chip room than 2-flute. They can work well if you’re taking lighter cuts or have excellent chip evacuation systems, but they carry a slightly higher risk of melting or clogging.

- 4-Flute End Mills: Generally not recommended for soft plastics like PVC. The reduced chip clearance space with four flutes significantly increases the risk of melting and tool clogging.

Uncoated vs. Coated Carbide

Most general-purpose carbide end mills are uncoated. For PVC, an uncoated carbide end mill is usually sufficient. If you encounter PVC with additives that are particularly abrasive or if you’re doing very high-volume production, you might consider a specialized coating (like TiCN or ZrN), but for most hobbyist and beginner applications, uncoated carbide is cost-effective and performs very well.

Corner Radius vs. Square End Mills

- Square End Mills: These have a flat end and are used for general milling, pocketing, and facing operations. They leave a sharp corner.

- Ball Nose End Mills: These have a rounded tip, ideal for 3D contouring and creating curved surfaces.

- Corner Radius End Mills: These are like square end mills but have a small radius on the corners. This helps to strengthen the cutting edges and can reduce stress on the workpiece at sharp internal corners. For PVC, a square end mill or one with a slight corner radius is most common for general fabrication.

Key Specifications for PVC Cutting

Let’s break down the “carbide end mill 1/8 inch 1/2 shank extra long for pvc high mrr” to understand what each part means for your PVC projects.

| Specification | Meaning for PVC | Recommendation |

|---|---|---|

| Material | Tungsten Carbide. Extremely hard and heat-resistant. | Essential for clean, non-melting cuts in PVC. |

| Diameter | 1/8 inch (3.175 mm). A smaller diameter allows for fine detail work and is suitable for thinner PVC sheets or smaller features. | Ideal for detailed cuts, small slots, and thin materials. |

| Shank Diameter | 1/2 inch (12.7 mm). A larger shank provides much more rigidity and reduces vibration compared to smaller shanks. | Provides stability and reduces chatter, leading to cleaner cuts. Essential for deeper cuts. |

| Length | Extra Long. Refers to the overall length and/or the effective cutting length (flute length). Allows for deeper milling or reaching into recesses. | Enables deeper cuts in fewer passes, or allows milling in deeper cavities. |

| Number of Flutes | (Implicitly 2 for plastics) More flutes mean less chip clearance. | Recommend 2-flute for PVC to maximize chip evacuation and minimize heat. |

| Coating | None specified, usually uncoated for general plastic work. | Uncoated is typically fine for PVC. |

| Type | End Mill. Suitable for milling operations (profiling, pocketing, slotting). | Standard for CNC routers and milling machines. |

Setting Up Your Machine for PVC

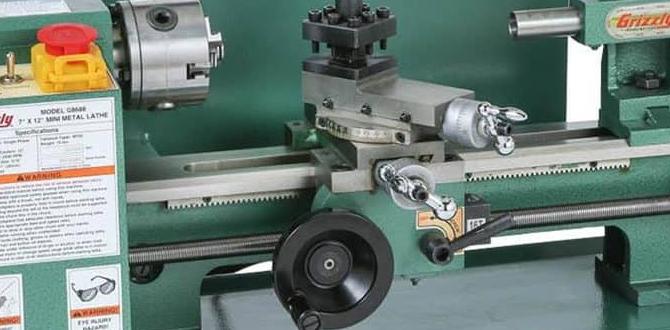

Choosing the Right Machine

A carbide end mill can be used on various machines:

- CNC Router: This is where end mills truly shine with PVC. The automated, precise movements ensure consistent results for intricate designs, batch production, or repeatability. A 1/8-inch diameter end mill is perfect for detailed work on a CNC router.

- Milling Machine (Manual or CNC): For more traditional machining operations on thicker PVC stock or for more robust applications, a milling machine offers immense capability. The 1/2-inch shank provides the necessary rigidity for heavier cuts.

- Drill Press (with limitations): While not ideal for complex milling, a drill press can use end mills for simple drilling of holes or shallow counterbores. Ensure you have a very secure way to hold the workpiece and control the depth. Caution: Drill presses are not designed for lateral forces that milling puts on the spindle, so use light pressure and don’t try to mill large areas.

Workholding: Keeping PVC Stable

Secure workholding is paramount for safe and accurate cuts. PVC can shift if not properly secured, leading to inaccuracies or dangerous situations.

- Clamps: Use C-clamps, F-clamps, or specialized hold-down clamps around the edges of your PVC sheet. Ensure the clamps don’t interfere with the cutting path.

- Vacuum Table: For CNC routers, a vacuum table is an excellent option for holding down flat sheets of PVC securely and evenly.

- Double-Sided Tape (for light work/CNC): High-strength double-sided tape can work for smaller pieces or less aggressive cuts on a CNC router, especially when combined with other fastening methods.

- Fixtures: If you’re doing production runs, custom fixtures can hold the PVC precisely in place.

Always ensure your clamps or fixtures are positioned so they don’t get hit by the spinning end mill. A broken clamp or a bit going wild can cause significant damage.

Choosing Your Speed and Feed Rate

This is arguably the most crucial part of cutting PVC effectively with an end mill. Too fast (in terms of feed) or too slow (in terms of spindle speed) can lead to melting, poor finish, or tool breakage.

Understanding “Speeds and Feeds” is key. Here’s a simplified breakdown:

- Spindle Speed (RPM): How fast the end mill spins. For PVC, a balance is needed. Too slow, and you won’t cut effectively; too fast, and you’ll melt it.

- Feed Rate (IPM or mm/min): How fast the tool moves through the material. This is directly related to “chip load” – the thickness of the material each cutting edge removes per revolution.

General Guidelines for PVC with a 2-Flute Carbide End Mill:

| Parameter | Typical Range for PVC | Notes |

|---|---|---|

| Spindle Speed (RPM) | 10,000 – 20,000 RPM | Higher RPMs work well with faster feed rates. Start in the middle and adjust. |

| Feed Rate (IPM) | 20 – 60 IPM (500 – 1500 mm/min) | Depends heavily on the diameter and depth of cut. A 1/8″ bit will be on the lower end. |

| Chip Load (per flute) | 0.002″ – 0.005″ (0.05 – 0.13 mm) | This is a critical value. Calculate your feed rate using: Feed Rate = RPM x Number of Flutes x Chip Load. Example: 18,000 RPM x 2 flutes x 0.003″ chip load = 108 IPM. |

| Depth of Cut (DOC) – Per Pass | 0.050″ – 0.150″ (1.27 – 3.81 mm) | For a 1/8″ bit, don’t try to cut too deep at once. For thicker PVC, take multiple passes. |

| Stepover (Width of Cut) | 30% – 70% of diameter | For profiling/outer cuts, 100% of the diameter is used. Pockets can use less. |

Important Note on Speeds and Feeds: These are starting points. Always perform test cuts on scrap material. Listen to the sound of the cut, watch for melting or chip buildup, and observe the cut quality. Adjust one variable at a time.

For more in-depth information on speeds and feeds, consult resources like Machinery Parts Depot’s guide or your machine’s manual.

Cooling and Lubrication (Minimal Needed for PVC)

PVC can melt, but it doesn’t typically require aggressive coolant like metal. In fact, too much coolant can sometimes make a mess and hinder chip evacuation if not managed properly.

- Air Blast: A directed stream of compressed air is often the best cooling/chip clearing method for PVC. It helps to blow chips away from the cutting zone and cool the bit.

- Mist Coolant: A fine mist of coolant sprayed at the cutting zone can be very effective. It cools the bit and the material, and the moisture helps to clear chips.

- Water: In a pinch, a light spray of water can offer some cooling.