A 1/8 inch carbide end mill is a versatile and affordable cutting tool perfect for detailed work on various materials. It’s essential for precise cuts in hobbyist projects, small-batch production, and intricate CNC machining, offering durability and clean finishes without breaking the bank.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Ever stared at a tiny piece of material, dreaming up a detailed project, only to realize your cutting tools just aren’t up to the task? It’s a common puzzle for anyone diving into milling or CNC work. That’s where the humble, yet mighty, 1/8 inch carbide end mill comes in. It’s a go-to tool for precision, especially when you need to make those super fine cuts or engrave delicate details. But with so many options out there, especially when you start looking at things like 1/2 inch shanks or extra-long versions for specific jobs like MDF, it can feel a bit overwhelming. Don’t worry, though! We’re going to break it all down, making it super simple to understand why this little tool is a powerhouse in any workshop. Get ready to unlock some new creative possibilities!

Why the 1/8 Inch Carbide End Mill is Your New Best Friend

When you’re starting out in machining, whether it’s with a metal lathe, a milling machine, or even a CNC router, the right tools make all the difference. The 1/8 inch carbide end mill is one of those tools that punches way above its weight. Why? Because it’s all about precision and versatility. Think of it as the fine-tipped pen of the cutting tool world. It allows you to create intricate designs, cut small grooves, and machine detailed parts that larger tools simply can’t manage.

Unlocking Precision in Your Workshop

The beauty of a diameter this small (1/8 inch, or roughly 3.175mm) is the level of detail you can achieve. For hobbyists working on intricate models, jewelers creating detailed components, or even DIY enthusiasts tackling small batch production, this size is often exactly what’s needed. It’s perfect for engraving text, creating fine slots, or profiling small, complex shapes. No more struggling to make a larger bit do a job it wasn’t designed for!

Durability for the Long Haul

Carbide is the star of the show here. Unlike High-Speed Steel (HSS) bits, carbide is incredibly hard and can withstand much higher temperatures. This means it stays sharp for longer, cuts through tougher materials more effectively, and generally lasts a lot longer, especially when used correctly. For beginners, this translates to fewer tool changes, less frustration with dull bits, and a more consistent cutting performance.

Affordability Without Compromise

While high-quality tooling can get expensive, the 1/8 inch carbide end mill, especially in common configurations, is surprisingly affordable. This makes it an accessible entry point for beginners and home workshop enthusiasts. You can invest in a few different types without draining your budget, allowing you to experiment and tackle a wider range of projects. It’s that sweet spot where performance meets budget.

Understanding the Basics: Anatomy of a 1/8 Inch Carbide End Mill

Before we get too deep into using it, let’s quickly look at what makes up this essential tool. Understanding its parts will help you appreciate its function and make better choices when buying.

- Versatile material for a wide range of applications.

- Exceptional hardness for long-lasting sharpness.

- Reliable for both soft and hard materials.

- Yields clean cuts with minimal burrs.

- Suitable for intricate detailing and small-scale work.

Key Features to Look For

When you’re shopping for a 1/8 inch carbide end mill, you’ll notice a few variations. Knowing what they mean will help you pick the right one for your project.

Number of Flutes

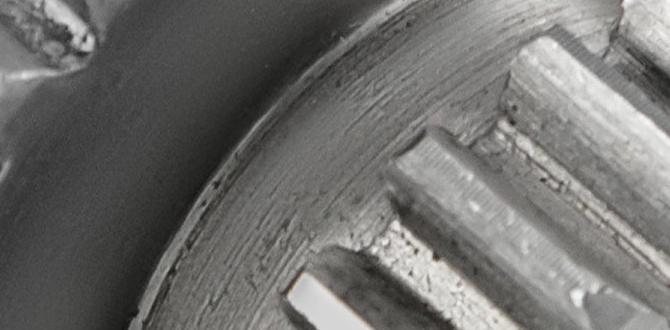

Flutes are the spiral grooves that run up the cutting end of the mill. The number of flutes affects how well the end mill clears chips and the finish quality. For a 1/8 inch end mill, you’ll most commonly find:

- 2 Flutes: Generally best for softer materials like plastics and wood. They offer a more aggressive cut and better chip clearance, which is important for these materials.

- 4 Flutes: Good for harder materials like aluminum and some plastics. They provide a smoother finish than 2-flute bits and can handle the heat generated better. They are also more rigid.

For general-purpose use on a home CNC or milling machine, starting with a 2-flute is often a good bet for versatility across wood and plastics. If you’re planning on working with metals like aluminum, a 4-flute is a better choice.

Shank Diameter

The shank is the part that fits into your milling machine’s collet or tool holder. While we’re talking about a 1/8 inch cutting diameter, the shank diameter can vary. You’ll most commonly find:

- 1/8 Inch Shank: This matches the cutting diameter. It’s common for smaller routers or CNC machines where rigidity isn’t the primary concern for such a small diameter.

- 1/4 Inch Shank: A more common and robust option, even for a 1/8 inch cutting diameter. This larger shank provides more rigidity and strength, reducing the chance of deflection or breakage, especially when cutting deeper or at higher feed rates. This is often preferred for stability.

- 1/2 Inch Shank: While less common for a 1/8 inch cutting diameter, some specialized holders or machines might use this. However, generally, a 1/8 inch cutting head would be paired with a 1/4 inch shank for optimal balance of rigidity and tool availability. If you see “1/8 inch cutting diameter, 1/2 inch shank,” it usually implies the holder or collet system is designed to accommodate a larger shank for overall machine rigidity, though the cutting portion remains small.

For most hobbyists and beginners using standard collets, a 1/8 inch or 1/4 inch shank end mill is what you’ll encounter. The 1/4 inch shank offers better rigidity, which is always a plus.

Length

End mills come in various lengths, and “extra long” is a category that helps with deeper cuts or reaching into specific areas. For a 1/8 inch end mill:

- Standard Length: Good for general surfacing, profiling, and pocketing where Z-depth isn’t excessive.

- Extra Long: These have a much longer reach beyond the shank. They are useful for creating deep pockets, chamfering edges that are far down on a workpiece, or when your setup requires the tool to extend further from the spindle for clearance. However, longer tools are less rigid, so you need to be more careful with feed rates and depth of cut.

Coating

Some end mills have coatings (like TiN, TiCN, or AlTiN) that improve performance, hardness, and heat resistance. For a basic 1/8 inch general-purpose bit, an uncoated carbide is often sufficient and more affordable. If you plan to work with tougher materials or push your machine a bit harder, a coated end mill can be a worthwhile upgrade.

Applications: What Can You Do with a 1/8 Inch Carbide End Mill?

The versatility of a 1/8 inch carbide end mill means it can be your do-it-all tool for many projects. Let’s explore some of its most common and effective uses.

Precision Engraving and Lettering

This is where the 1/8 inch end mill truly shines. Whether you’re personalizing a gift, adding labels to your workshop projects, or creating signage, its small diameter allows for incredibly crisp and clear lettering. You can engrave fine fonts and intricate logos that would be impossible with larger tools.

Detailed Profiling and Outline Cutting

Need to cut out a complex shape with tight corners or sharp details? A 1/8 inch end mill is perfect for profiling intricate parts. It can navigate tight curves and create smooth, clean edges that require minimal post-processing. This is invaluable for creating custom gaskets, stencils, or detailed decorative elements.

Small Pocketing and Slotting

Creating shallow pockets for inlays, small compartments, or precise slots for mechanical parts is a breeze. The small diameter allows for accurate placement and control over the depth and width of these features, ensuring a perfect fit for components.

Working with Specific Materials

While versatile, this end mill is particularly well-suited for certain materials:

- MDF (Medium-Density Fiberboard): For projects involving MDF, a sharp carbide end mill is crucial. MDF can be abrasive and prone to tear-out. A 1/8 inch bit, especially an extra-long one if needed for depth, can provide clean cuts and detailed work without splintering the surface.

- Plywood and Softwoods: While often cut with larger bits, a 1/8 inch end mill can be used for fine details, inlays, or smaller projects where precision is key.

- Plastics: Acrylics, ABS, and other plastics machine well with carbide. A 2-flute end mill is often recommended for good chip evacuation and to prevent melting.

- Aluminum: With the right feed and speed settings, a 4-flute 1/8 inch carbide end mill can also tackle soft metals like aluminum for smaller, detailed parts.

It’s important to always check the manufacturer’s recommendations for specific materials and tool usage. For instance, The National Institute of Standards and Technology (NIST) provides valuable resources on machining best practices and material properties that machinists of all levels can benefit from. You can often find their publications on machining parameters and material data by searching their website.

Choosing the Right 1/8 Inch End Mill for Your Project

Now that you know what it is and what it can do, how do you pick the perfect one? It’s not just about the size; it’s about matching the tool to your task and material.

Material Considerations

As mentioned, your primary material will heavily influence your choice:

- Wood/MDF: A 2-flute uncoated carbide is often a good starting point. For MDF, look for bits designed to minimize dust and tear-out. An extra-long option might be necessary for deeper cuts.

- Plastics: Again, 2-flute is generally preferred for better chip clearance and to avoid melting. Single-flute plastic-cutting bits also exist and are excellent for some plastics.

- Aluminum: A 4-flute uncoated or specially designed aluminum-cutting end mill (often with a polished flute) is recommended for better surface finish and preventing material buildup.

- Metals (Steel, Brass): While 1/8 inch is small for general steel milling, if you’re doing very light work or small brass parts, a 4-flute end mill is typically used. Material-specific coatings (like AlTiN) are beneficial here.

Project Requirements

Think about the depth of cut, the complexity of the shape, and the required finish:

- Deep Pockets: You might need an extra-long end mill. Be mindful of rigidity; a smaller depth of cut per pass is essential.

- Intricate Details: The 1/8 inch diameter is the star here. For very fine details, ensure your CNC machine has the precision and rigidity to handle such a small tool.

- Surface Finish: For smoother finishes, more flutes (like 4) can help, as can specific coatings or designs like polished flutes.

Rigidity vs. Reach

This is a common trade-off. A shorter, thicker end mill (like a 1/4 inch shank with a 1/8 inch cutting head) will be much more rigid than a long, thin one. Rigidity is crucial for preventing chatter and achieving accurate cuts, especially in harder materials or when taking deeper passes. If you need reach, be prepared to reduce your feed rates and depth of cut to compensate for reduced rigidity.

Essential Setup & Safety Practices

Using any cutting tool, especially a small but sharp carbide end mill, requires careful setup and a commitment to safety. As Daniel Bates, I can’t stress this enough: your safety and the longevity of your tools depend on it!

Secure Workholding is Paramount

No matter what you’re cutting, your workpiece must be held securely. For milling operations, this often means using clamps, vises, or other fixturing methods. A workpiece that moves during cutting is an accident waiting to happen and will ruin your part. Ensure your clamps are positioned so they don’t interfere with the tool path.

Proper Collet Selection and Installation

The collet grips the end mill’s shank and holds it in the spindle. Using the correct size collet for your shank diameter is crucial. A 1/8 inch end mill with a 1/8 inch shank needs a 1/8 inch collet. If you have a 1/8 inch end mill with a 1/4 inch shank, you’ll need a 1/4 inch collet.

Here’s why it matters:

- Too Loose: A collet that’s too large won’t grip the shank properly, leading to runout (wobble), poor cuts, and potentially the tool being ejected from the spindle – very dangerous!

- Too Tight: A collet that’s too small might not allow the shank to seat fully, or it could even damage the shank. Make sure the entire bearing surface of the shank is seated within the collet.

Always insert the end mill into the collet before inserting the collet into the spindle. Tighten the collet nut securely, but avoid overtightening, which can damage the collet and spindle. For CNC machines, ensure the collet seating is clean and free of debris.

Understanding Feed Rate and Spindle Speed (RPM)

These are the two critical numbers that control how fast your end mill cuts. Getting them right is key to good results and tool life.

- Spindle Speed (RPM): How fast the tool spins.

- Feed Rate: How fast the tool moves through the material (e.g., inches per minute or millimeters per minute).

For a 1/8 inch carbide end mill:

- Carbide generally likes to spin faster than HSS. For small bits, typical spindle speeds can range from 10,000 RPM up to 24,000 RPM or even higher on some CNC routers.

- Feed rate depends heavily on material, depth of cut, and number of flutes. Start conservatively! For example, in MDF, you might start with a feed rate of around 20-40 inches per minute (IPM) and a depth of cut of 0.1 inch. In aluminum, you’d use a slower feed rate and a much smaller depth of cut.

Rule of Thumb: Chip Load. This is the thickness of the material being removed by each cutting edge of the rotating tool. A good chip load is like shaving a thin layer, not gouging. For a 1/8 inch carbide end mill, you’re typically looking for chip loads between 0.001 to 0.004 inches per tooth. You can calculate your feed rate using the formula: Feed Rate = Tool Diameter × Number of Flutes × Chip Load × Spindle Speed (RPM).

Tip: Always consult machining forums, manufacturer’s charts, or software like Fusion 360 or CAMotics (for simulation) for recommended starting parameters. For example, learn about spindle speed and feed rate recommendations from organizations like the Manufacturing Technology magazine website, which often features articles and guides on machining best practices.

Depth of Cut (DOC)

This is how deep the end mill cuts into the material on each pass. For a small 1/8 inch end mill, especially at longer reach, you’ll want to keep the DOC conservative. A common recommendation is to take a DOC of no more than 25-50% of the tool diameter for general cutting, and sometimes even less for harder materials or longer tools. For example, on a 1/8 inch end mill, a DOC of 0.03 to 0.06 inches per pass is often a good starting point.

Chip Evacuation

As the tool cuts, it creates chips. If these chips aren’t removed, they can recut, clog the flutes, overheat the tool, and lead to a poor finish or tool breakage. Ensure good air blast or vacuum for dust collection, especially with MDF and plastics.

Eye Protection is NON-NEGOTIABLE

Flying chips, debris, or even broken tool fragments are a serious hazard. Always wear safety glasses or a full face shield when operating any machining equipment. Make it a habit!

Optimizing Performance & Extending Tool Life

A tool is only as good as how you use it. Here are some tips to get the best results from your 1/8 inch carbide end mill and keep it cutting effectively for