For fiberglass projects needing high material removal rates, a 1/8 inch carbide end mill with a 1/2 inch shank is a specialized tool. This guide will walk you through its selection and best practices for efficient and safe use in machining fiberglass.

Carbide End Mill 1/8 Inch 1/2 Shank Extra Long for Fiberglass High MRR: A Deep Dive

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Today, we’re tackling a tool that might sound super specific, and honestly, it is! We’re talking about a Carbide End Mill, specifically a 1/8 inch one with a 1/2 inch shank and extra length, designed for cutting fiberglass at a high material removal rate (MRR). Now, I know what you might be thinking: “What does a tiny, specialized cutting tool have to do with anything else?” Well, in the world of precise fabrication, especially with materials like fiberglass, the right tool makes all the difference. It’s not about just cutting; it’s about cutting efficiently, cleanly, and safely.

If you’ve ever struggled with cutting plastics or composites, you know it can be a messy, frustrating business. Chipping, melting, or just plain slow progress can derail even the best projects. That’s where understanding tools like this specific end mill comes in. It’s engineered to get the job done right the first time. Stick with me, and we’ll break down exactly why this tool is so special, what it’s good for, and how to use it to get fantastic results in your fiberglass projects.

Why This Specific End Mill is a Game-Changer for Fiberglass

Let’s zoom in on what makes this particular end mill stand out. When we talk about a “Carbide End Mill 1/8 inch 1/2 shank extra long for fiberglass high mrr,” we’re describing a very precise set of characteristics that are crucial for working with fiberglass.

Carbide: This is the material the cutting edges are made from. Carbide is incredibly hard and durable, meaning it can cut through tough materials like fiberglass much better and for longer than high-speed steel (HSS). It stays sharper and resists wear, which is vital when dealing with abrasive composites.

1/8 Inch Diameter: This small diameter allows for intricate detailing and precise cuts. It’s perfect for smaller features or when you need to mill out tight spaces.

1/2 Inch Shank: The shank is the part of the tool that gets held by the collet or tool holder in your milling machine. A 1/2 inch shank is a common size, offering good rigidity and stability for the tool. It ensures the end mill is held securely, reducing vibration and improving cut quality.

Extra Long: This feature gives you increased reach. It’s essential for milling deeper pockets or chamfering features that are further down into your workpiece without needing to reposition. It can simplify your machining setup.

For Fiberglass: Fiberglass is a notoriously abrasive and brittle material. Standard end mills can struggle, leading to rapid tool wear, poor surface finish, and chipping. Tools designed for fiberglass often have specific flute geometry and coatings to handle these challenges.

High MRR (Material Removal Rate): This refers to how quickly the tool can cut away material. An end mill designed for high MRR in fiberglass will have a geometry that allows for faster feed rates and deeper cuts without overheating or damaging the material.

So, while the keyword might seem a mouthful, each part describes a critical feature that makes this end mill exceptionally suited for its intended purpose.

Understanding the Basics: What is an End Mill?

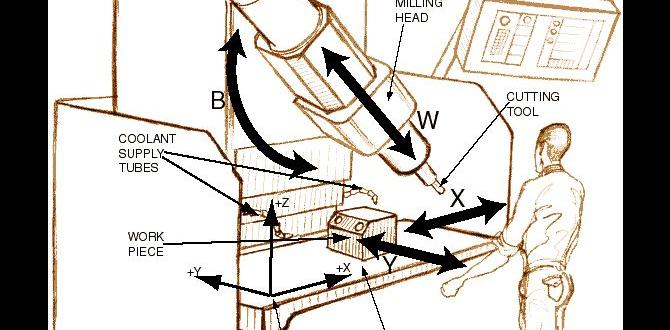

Before we dive deeper into fiberglass specifics, let’s quickly cover what an end mill is in the first place. Think of an end mill as a specialized drill bit that can also cut horizontally. Unlike a drill bit that primarily cuts downwards, an end mill has cutting edges on its sides and tip, allowing it to cut into a material and move sideways. This makes them incredibly versatile for creating slots, pockets, profiles, and even 3D shapes on a milling machine.

They come in various materials (like HSS and carbide), diameters, lengths, and with different numbers of “flutes” (the spiral grooves that clear away material). Choosing the right end mill for your specific job is key to achieving good results, extending tool life, and maintaining a safe working environment.

Fiberglass Machining Challenges

Fiberglass reinforced plastic (FRP) presents unique challenges for machining:

Abrasiveness: The glass fibers are hard and abrasive. They quickly dull standard cutting tools.

Brittleness: Fiberglass can chip or delaminate if cut improperly. This means aggressive or blunt tools can cause surface damage.

Dust and Debris: Machining fiberglass creates fine, irritating dust. Proper dust collection and personal protective equipment (PPE) are non-negotiable.

Heat: While not as prone to melting as some softer plastics, excessive heat can degrade the resin binder, weakening the material and potentially causing discoloration or fume release.

Resin Variations: different resins (epoxy, polyester, vinyl ester) can have slightly different machining characteristics.

This is precisely why a specialized tool like the carbide end mill we’re discussing is so valuable. It’s designed to overcome these hurdles.

Why Carbide is King for Fiberglass

Carbide’s superiority for fiberglass work isn’t by accident. Here’s why:

Hardness: Carbide is significantly harder than HSS. This means it can cut through the glass fibers with less effort and wear.

Hot Hardness: Carbide retains its hardness at higher temperatures, which is beneficial as machining generates heat.

Edge Retention: It holds a sharp edge for much longer, ensuring consistent cuts and a better finish over the life of the tool.

Predictable Wear: While carbide can be more brittle than HSS and is prone to chipping if used improperly, its wear is often more predictable, giving you a clearer indication of when it needs replacing.

For materials as demanding as fiberglass, investing in carbide is usually the most cost-effective and efficient choice in the long run, especially for high-volume production or frequent use.

The Role of End Mill Geometry in Fiberglass Machining

Beyond the material, the specific geometry of the end mill plays a crucial role. For fiberglass and high MRR, you’ll typically look for:

Number of Flutes:

2-Flute: Generally preferred for plastics and composites. The fewer flutes mean larger chip gullets (the space between flutes), which are essential for efficiently clearing the abrasive dust and preventing it from clogging the tool. Good for high feed rates and deep cuts.

3-4 Flute: Can be used, but might require slower feed rates or more attention to chip evacuation in very abrasive materials.

Helix Angle: A steeper helix angle (e.g., 45-60 degrees) can provide a smoother cut and better chip evacuation. A lower helix angle might be more rigid but can chatter more in softer or fibrous materials.

Rake Angle: A positive rake angle helps create a shearing action, reducing cutting forces and heat.

Coatings: Some specialized end mills for composites come with coatings (like TiAlN or DLC – Diamond Like Carbon) that further enhance hardness, reduce friction, and improve tool life.

Our specific end mill, designed for high MRR, likely incorporates these geometric features to aggressively yet cleanly remove material.

Selecting Your 1/8 Inch Carbide End Mill for Fiberglass

When you go to select an end mill that fits the description “carbide end mill 1/8 inch 1/2 shank extra long for fiberglass high mrr,” here are the key specifications to confirm:

Key Specifications to Look For:

| Feature | Specification | Importance for Fiberglass & High MRR |

| :——————– | :——————————————— | :————————————————————————————————————————————————- |

| Material | Solid Carbide | High hardness and wear resistance crucial for abrasive fiberglass. |

| Diameter | 1/8 inch (0.125″) | Allows for fine details and tight machining, suitable for various project complexities. |

| Shank Diameter | 1/2 inch | Provides good rigidity and tool holding capacity in most standard milling machine collets. Ensures secure grip and minimizes runout. |

| Overall Length | Extra Long (specific length will vary) | Enables milling deeper features or pockets without tool changes or complex setups. Check the length – it’s a defining feature! |

| Number of Flutes | 2 or 3 (2 often preferred for composites) | 2 flutes offer better chip clearance for abrasive dust; 3 flutes can offer a smoother finish but might pack chips more. |

| Coating | Optional but beneficial (e.g., uncoated, TiAlN) | Uncoated carbide is good, but specialized coatings can further enhance performance, reduce friction, and extend tool life in abrasive composites. |

| End Type | Square/Flat End | Standard for general milling, profiling, and pocketing. Ball nose or corner radius ends are for specific shapes. |

| Designed for | Plastics, Composites, Fiberglass | Look for manufacturers that specify suitability for these materials. They often have optimized flute geometry and edge preparation. |

Example Scenario: You might find an item listed as “2 Flute Carbide End Mill, 1/8″ Dia, 1/2″ Shank, 4″ OAL, Uncoated, for Composites.” This matches your description perfectly. The “4” OAL” (Overall Length)” indicates it’s significantly longer than a standard end mill, providing that extra reach.

Where to Buy: Reputable industrial supply companies, specialized tooling websites, and even some larger online marketplaces (like Amazon, McMaster-Carr, MSC Industrial Supply, G&J Tool & Supply) will carry these types of end mills. Always check the specs carefully.

Best Practices for Using Your End Mill with Fiberglass

Using this specialized tool correctly will maximize its benefits and ensure a safe, productive machining session.

1. Machine Setup and Work Holding

Secure Your Workpiece: Fiberglass must be clamped down firmly to prevent movement during machining. Use clamps, a vise, or a dedicated jig. Any shifting can lead to errors or dangerous tool loading.

Rigid Machine Setup: Ensure your milling machine is in good working order. A stable Z-axis and a collet that holds the tool securely with minimal runout are essential. As this is an extra-long end mill, it’s more prone to chatter if not held properly.

Zero Z-Axis Accurately: Precisely setting your Z-zero point is critical for controlling depth of cut and preventing the end mill from plunging too deep, which can overload it.

2. Machining Parameters (Feeds and Speeds)

This is where “high MRR” really comes into play. However, “high” is relative and depends on your specific machine, the type of fiberglass, and the end mill’s exact geometry.

Spindle Speed (RPM): For 1/8 inch carbide end mills, speeds can range from 10,000 RPM to 25,000 RPM or even higher, depending on the machine. Start conservatively and listen to the cut.

Feed Rate (IPM – Inches Per Minute): This is how fast you move the tool through the material. For high MRR, you’ll want a relatively aggressive feed rate.

Chip Load: A key concept is chip load, which is the thickness of the chip each cutting edge is removing. For a 1/8 inch end mill, a typical chip load for plastics/composites might range from 0.001″ to 0.004″ per flute. Calculate your feed rate by: `Feed Rate = Chip Load × Number of Flutes × Spindle Speed (in Revolutions per Minute)`.

Example Calculation: For a 1/8″ 2-flute end mill, a chip load of 0.003″ per flute, running at 15,000 RPM: `Feed Rate = 0.003″ × 2 × 15,000 = 90 IPM`. You would then adjust based on the sound and feel of the cut.

Depth of Cut (DOC): For effective MRR, aim for a reasonable DOC. For a 1/8″ end mill, this might be anywhere from 1/8″ to 1/4″ (or even more) per pass, especially if the end mill is designed for it and your machine is rigid.

Climb Milling vs. Conventional Milling: For fiberglass, climb milling is generally preferred. In climb milling, the cutter rotates in the same direction as the feed movement. This results in a shearing action that produces smaller chips, reduces cutting forces, and often yields a better surface finish. Conventional milling, where the cutter rotates against the feed direction, can drag the material and cause more chipping.

A Starting Point for Parameters:

| Parameter | Value Range (Approximate) | Notes |

| :————– | :——————————————————————————————————— | :——————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————- |

| Spindle Speed | 15,000 – 25,000 RPM | Start on the lower end and increase if the cut is clean and the machine sounds happy. Higher speeds generally mean higher feed rates can be used. |

| Feed Rate | 60 – 150 IPM (adjust based on chip load) | This is critical for high MRR and chip evacuation. Listen carefully! If you hear rubbing or feel excessive drag, reduce the feed rate. If you’re getting fine dust instead of chips, you might increase the feed rate or DOC. |

| Depth of Cut| 0.125″ – 0.250″ | This depends heavily on the rigidity of your machine, the type of fiberglass, and the end mill’s flute length. For a 1/8″ diameter, this is a significant cut per pass. You can make multiple passes if needed. |

| Stepover | 25% – 50% of tool diameter (for pocketing/contouring) | Controls the width of the tool’s path in a single pass when milling an area. Smaller stepovers give smoother walls but take longer. For maximum MRR, you might push this higher, but it can affect surface finish. |

| Coolant/Lube| Air blast or minimal mist coolant is often sufficient. Avoid flooding. | Fiberglass dust combined with fluids can create a very messy situation. An air blast helps evacuate dust. If using a mist, keep it minimal to assist in chip evacuation and cooling without excessive mess. |

Rule of Thumb: Always start with conservative settings and increase them gradually while monitoring the cut. A good cut sounds like a consistent “hiss” or light “shush,” not a screeching or grinding noise.

3. Dust Management and Safety

This cannot be stressed enough. Fiberglass dust is a serious respiratory irritant and can get everywhere.

Personal Protective Equipment (PPE):

Respirator: A high-quality N95 or P100 respirator is mandatory. Regular dust masks are insufficient.

Safety Glasses/Face Shield: Protect your eyes.

Gloves: Protect your skin from fiberglass itch.

Long Sleeves: Minimize skin exposure.

Dust Collection:

Vacuum System: Connect your milling machine’s dust port to a shop vac with a good filter.

Enclosure: Consider a small enclosure around your work area to contain the dust.

Ventilation: Ensure good airflow in your workshop.

Clean Up: Thoroughly clean the machine and surrounding area after each session.

For more information on safe machining practices, the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) provides extensive resources on workplace safety. You can often find specific guidelines for composite materials and dust control on their website: osha.gov.

4. Tool Life and Maintenance

Listen to Your Tool: If the cutting noise changes or you start seeing a rougher finish, it’s a sign the tool might be getting dull.

Inspect for Wear: Periodically check the cutting edges for chipping, excessive wear, or damage.

Keep it Clean: Remove any accumulated dust or debris from the flutes immediately after use.

Replace When Necessary: Don’t push a dull or damaged end mill. Replacing it before it breaks is far cheaper and safer than dealing with a catastrophic tool failure that can damage your workpiece or machine.

When to Use an Extra-Long End Mill

The “extra long” feature of this end mill is key for specific applications:

Machining Deep Pockets: If you need to mill a cavity that is deeper than a standard end mill’s flute length, the extra length provides the necessary reach without needing multiple tool changes or specialized holders.

Chamfering or Deburring Incess: For features that require a chamfer or to clean up edges deep within a part, the extended length allows you to reach these areas.