Quick Summary

This article is about machining bronze efficiently and safely using a carbide end mill. We’ll cover selecting the right mill, machine setup, cutting parameters, and best practices for high Material Removal Rates (MRR) to achieve excellent results in your workshop.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. It’s no secret that when you’re working on a project, especially with metal, you want to get the job done right, safely, and with the best possible finish. Sometimes, it feels like choosing the right tool for the job can be a bit of a puzzle, right? Especially when you’re aiming for speed and efficiency. That’s where understanding the specifics of your cutting tools, like a carbide end mill, comes into play. We’re going to dive deep into how to pick and use the perfect 1/8 inch carbide end mill with a 1/2 inch shank—specifically the extra-long kind—for high material removal rates when machining bronze. Stick with me, and we’ll demystify this, making your machining tasks smoother and more productive. Let’s get those chips flying!

Unlocking Bronze Machining Potential with the Right End Mill

Working with bronze can be incredibly rewarding. It’s a versatile metal that machines beautifully, offering a great balance of strength and machinability. However, to really unlock its potential, especially when you’re trying to achieve a high Material Removal Rate (MRR), you need the right tools and techniques. This is precisely where a specialized carbide end mill comes into play. We’re talking about that specific tool: a 1/8 inch carbide end mill with a 1/2 inch shank, designed to be extra-long. Why is this particular combination so important for cutting bronze fast and effectively?

The answer lies in how these features combine to tackle bronze. A carbide end mill is naturally suited for harder metals like bronze due to its superior hardness and heat resistance compared to high-speed steel (HSS). The 1/8 inch diameter gives you precision for detailed work or smaller features, while the 1/2 inch shank provides a robust connection to your machine’s collet or tool holder, reducing deflection. The “extra-long” aspect is key for reaching into deeper pockets or features without needing special extensions, allowing for more comfortable machining and potentially better tool access. When all these elements are optimized, you can push your machine to achieve a high MRR, meaning you remove metal quickly and efficiently. This translates to saved time, increased productivity, and a more enjoyable machining experience. Let’s break down what makes this tool choice work so well and how you can use it to its fullest.

Understanding the Carbide End Mill: Anatomy and Benefits

Before we start cutting, let’s get to know our star player: the carbide end mill. Understanding its components and why they matter will empower you to make better decisions and achieve superior results, especially when targeting high MRR in bronze.

What is Carbide?

Carbide, more formally called tungsten carbide, is a compound composed of tungsten and carbon atoms. It’s renowned for its extreme hardness, wear resistance, and ability to withstand high temperatures. This makes it an ideal material for cutting tools that need to perform under demanding conditions, such as machining metals like bronze at high speeds.

Key Features of Our Specialized End Mill

- Material: Tungsten Carbide. This is the powerhouse behind the tool’s ability to cut through tough materials like bronze without quickly dulling or degrading. It also handles the heat generated during aggressive cutting much better than HSS.

- Diameter: 1/8 inch. This small diameter is crucial for intricate work. It allows for fine detail milling, cutting narrow slots, and machining smaller features. For a 1/8 inch mill, achieving high MRR means optimizing speed and feed rates carefully.

- Shank Diameter: 1/2 inch. A larger shank diameter, like 1/2 inch, generally means greater rigidity. It provides a more secure grip in the collet or tool holder, leading to less vibration and deflection during cutting. This increased stability is vital for accurate machining and for pushing the limits on MRR without sacrificing surface finish or tool life.

- Length: Extra Long. This feature is all about reach. An extra-long end mill allows you to access deeper cavities, mill features that are far from the workpiece surface, or simply provide more clearance between your tool holder and the workpiece. For high MRR operations, having adequate reach without compromising rigidity can be a significant advantage.

- Flute Count: While not explicitly stated in the keyword, flute count is critical. For general-purpose milling of a material like bronze, 2-flute or 4-flute end mills are common. 2-flute tools are often preferred for slotting and higher feed rates as they offer better chip evacuation, which is key for high MRR. 4-flute tools can be used for peripheral milling and offer a better surface finish. For bronze and high MRR, a 2-flute might be your go-to if chip evacuation is a concern.

- Coating: Some carbide end mills come with coatings (like TiN, TiAlN, or ZrN). These coatings can further enhance lubricity, reduce friction, improve heat resistance, and extend tool life, allowing for even higher cutting speeds and feeds. For bronze, uncoated or a simple ZrN coating can work well.

Why This Combination is Superior for Bronze at High MRR

- Heat Dissipation: Carbide’s inherent ability to handle heat means less tool wear during aggressive cuts.

- Rigidity: The 1/2 inch shank minimizes tool chatter and deflection, allowing us to push the cutting forces higher, which is fundamental for MRR.

- Reach: The extra length provides accessibility without sacrificing rigidity as much as a long, small-shanked tool would.

- Precision: The 1/8 inch diameter allows for controlled material removal while still being able to achieve complex shapes.

- Chip Evacuation: Proper flute design (especially in a 2-flute) is critical for clearing chips quickly, preventing re-cutting, and maintaining a good surface finish, all crucial for sustained high MRR.

Setting Up for Success: Machine and Workpiece Preparation

Getting your machine and workpiece ready is just as important as choosing the right tool. A solid setup is the foundation for achieving high MRR safely and effectively. Let’s make sure everything is rock solid before we even think about touching off.

Machine Readiness: The Foundation of High MRR

- Spindle Speed (RPM): Ensure your machine’s spindle can achieve the necessary RPMs for efficient cutting. For a 1/8 inch end mill, you might be looking at higher RPMs, so verify your machine can comfortably handle this.

- Rigidity of the Machine: A rigid machine that doesn’t flex under load is paramount. Check that your machine’s ways, table, and spindle are in good condition. Any wobble or play will limit your cutting parameters and prevent high MRR.

- Spindle Runout: Minimize spindle runout (wobble) as much as possible. Excessive runout will cause chatter, poor surface finish, and premature tool wear, all of which are enemies of high MRR. A good collet chuck system is your friend here.

- Coolant/Lubrication: Bronze can benefit from lubrication to reduce friction and help clear chips. Ensure your coolant system is functioning correctly, delivering a steady stream to the cutting zone. Flood coolant is ideal, but a good quality cutting fluid applied directly can also work. For information on machining fluids, resources like Metal Forming Magazine offer insights into suitable options.

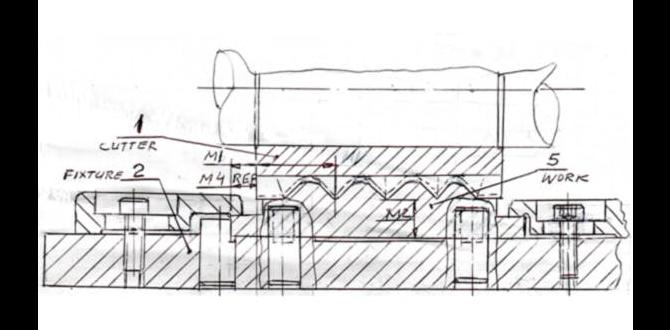

Workpiece Clamping: Rock Solid Is the Only Option

This is non-negotiable. If your workpiece moves even slightly, you risk tool breakage, poor finish, and serious injury. For high MRR operations, forces are significant.

- Vise: A high-quality, rigid milling vise is essential. Ensure the vise jaws are clean, and the workpiece is seated firmly against the fixed jaw. Use hardened or soft jaws appropriate for your material.

- Workholding Devices: Depending on the part geometry, consider using clamps, toe clamps, or an angle plate. The goal is to secure the workpiece so it cannot lift, shift, or vibrate under the cutting forces.

- Indicator Check: After clamping, use an indicator to check that your workpiece is stable. Gently tap it to ensure there’s no movement.

- Clean Mounting Surfaces: Ensure the surface of your workpiece and the vise/machine table are clean and free of debris. A small burr or chip can cause the workpiece to sit unevenly, leading to instability.

Tool Holder and Collet: The Critical Connection

The connection between the machine spindle and your end mill is a chain – its strength is only as good as its weakest link.

- Quality Collet Chuck: Use a high-quality tool holder and collet. For this setup, a 1/2 inch shank end mill will fit into a 1/2 inch collet. A balanced tool holder will also reduce vibration at higher speeds.

- Proper Collet Engagement: Ensure the end mill shank is inserted sufficiently into the collet to provide maximum support. For extra-long tools, this engagement depth is even more critical to prevent cantilevered forces from causing deflection or breakage.

- Cleanliness: Both the collet and the end mill shank must be perfectly clean. Any oil, coolant residue, or chips on the shank or inside the collet will prevent a tight grip and lead to runout or slippage.

Optimizing Cutting Parameters for High MRR in Bronze

Now for the fun part: dialed-in cutting parameters! This is where we balance speed, feed, and depth of cut to remove material efficiently while keeping the tool and workpiece happy. For high MRR, we’re aiming to push these values, but always with an eye on surface finish and tool life.

Understanding MRR

Material Removal Rate (MRR) is the volume of material removed per unit of time. It’s typically measured in cubic inches per minute (in³/min) or cubic centimeters per minute (cm³/min). The formula for MRR is often approximated as:

MRR = Cutting Speed × Depth of Cut × Width of Cut × Chip Load × Flutes

While this equation is simplified, it highlights the key variables: increasing any of these factors (while maintaining balance) will increase MRR. For a 1/8 inch end mill with a 1/2 inch shank, we leverage rigidity and speed.

Key Cutting Parameters Explained:

- Cutting Speed (Surface Speed, SFM/SMM): This is the speed at which the cutting edge of the tool moves across the workpiece surface. For carbide end mills in general, typical speeds for bronze can range from 200-600 SFM (surface feet per minute) or even higher, depending on the specific alloy, tool coating, and coolant.

- Spindle Speed (RPM): This is directly calculated from cutting speed and tool diameter:

RPM = (Cutting Speed [SFM] × 12) / (π × Tool Diameter ["])For a 1/8″ (0.125″) end mill and let’s say you aim for 400 SFM:

RPM = (400 × 12) / (3.14159 × 0.125) ≈ 12,190 RPMThis highlights why a high-speed spindle is beneficial for smaller diameter tools to achieve optimal cutting speeds and thus high MRR. However, if your machine is slower, you will need to adjust to find the sweet spot.

- Feed Rate (IPM): This is how fast the tool moves into the material (or across it) per revolution of the spindle. Chip load (the thickness of the chip removed by each cutting edge) is a critical component here.

Feed Rate [IPM] = Chip Load [IPT] × RPM × Number of FlutesThe chip load for a 1/8 inch carbide end mill in bronze might start around 0.001 – 0.003 inches per tooth (IPT). So, for a 2-flute end mill at 12,190 RPM aiming for a 0.002 IPT:

Feed Rate = 0.002 × 12,190 × 2 ≈ 48.76 IPMYou’ll likely need to experiment. Start conservatively and increase the feed rate until you hear the cut becoming more efficient without excessive chatter or tool strain.

- Depth of Cut (DOC): This is how deep the end mill cuts into the material in a single pass. For high MRR with a 1/8″ end mill, aggressive radial DOC might not be feasible due to the small diameter. Axial DOC (how deep the tool plunges) is more controllable.

Axial DOC: For high MRR in bronze with a 1/8″ end mill, you’ll want to maximize this as much as your stepover allows and your machine rigidity permits. This could be anywhere from 0.25 to 0.5 inches (or more) if plunging, or a portion of the diameter during contouring. However, for delicate features or to maintain surface finish, you might take lighter passes.

Radial DOC (Stepover): This is the amount the tool moves sideways between passes when milling a pocket or contour. A large stepover (e.g., 50% of the tool diameter) provides faster clearing but can lead to a poorer surface finish (scalloping). A smaller stepover (e.g., 20-30%) gives a better finish but takes longer. For maximizing MRR without sacrificing cut integrity, aim for a balance. Often, it’s more effective to use a larger axial DOC with a moderate stepover.

Table of Recommended Starting Parameters (Bronze Alloy – e.g., C63000/Aluminum Bronze)

These are starting points. Always listen to your machine and make adjustments!

| Parameter | Typical Range for 1/8″ Carbide End Mill in Bronze | Notes |

|---|---|---|

| Cutting Speed (SFM) | 300 – 500 | Adjust based on specific bronze alloy, tool coating, and coolant. |

| Spindle Speed (RPM) @ 0.125″ Dia. | ~9,000 – 15,000 | Calculated from SFM. Lower RPMs will require higher feed rates for equivalent MRR. |

| Chip Load (IPT) | 0.001 – 0.003 | Start low and increase. Watch for chatter and chip formation. |

| Feed Rate (IPM) @ 2 Flutes, 10k RPM | ~40 – 120 | Calculated from Chip Load and RPM. |

| Axial Depth of Cut (in) | 0.100 – 0.500+ | Maximize based on rigidity and stability. For full slotting, consider stepped plunging. |

| Radial Depth of Cut (Stepover %) | 20% – 50% | Higher percentage for roughing, lower for finishing. |

| Coolant/Lubrication | Flood or Mist | Essential for heat management and chip evacuation. |

Strategies for Achieving High MRR

To achieve high MRR, we combine these parameters strategically:

- Maximize Axial DOC: If your machine has the power and rigidity, take the deepest axial cut possible per pass. This is often more efficient than taking very shallow, wide cuts.

- Optimize Feed Rate: Once your axial DOC is set, increase the feed rate (IPM) until you hear the cut becoming efficient. If the tool starts chattering or the chips look like dust, back off.

- Smart Stepover: For pockets, use a stepover percentage that balances speed with surface finish. For contours, a moderate stepover is usually best.

- Roughing vs. Finishing: Use dedicated roughing passes to quickly remove bulk material, then a finishing pass (or passes) with a lighter cut and smaller stepover to achieve the desired surface finish and dimensional accuracy.

- Trochoidal Milling: For pockets with tight corners, consider trochoidal milling (also known as dynamic milling or constant scallop milling). This technique uses a larger axial DOC and a small radial stepover, with the tool following a curved path that engages the material evenly. This is excellent for reducing tool stress and heat buildup, allowing for higher MRR in enclosed areas. Many CAM software packages have options for this.

- Take Advantage of Extra Length: Use the extra length to your advantage to reach features without needing multiple tool changes or complex setups, thus maintaining continuity in your machining operations, which contributes to overall efficiency.

Always refer to the tool manufacturer’s recommendations for specific carbide grades and coatings, as these can influence optimal parameters. Reputable sources like <a href="https://www.sandvik.coromant.com/en-gb/knowledge/materials/non-ferrous-metals