A standard-length 1/8-inch carbide end mill with a 1/4-inch shank is a reliable choice for machining Inconel 625, offering excellent performance when minimizing deflection. This guide will show you how to select and use it effectively for best results.

Hello there, fellow makers and machinists! Daniel Bates here from Lathe Hub. Ever stare at a piece of Inconel 625 and wonder how to tackle it? It’s a tough nut, no doubt about it! Especially when you’re just starting out with milling. The thought of using a tiny 1/8-inch end mill on something so strong can feel daunting. But don’t worry, because a quality carbide end mill with a 1/4-inch shank can be your best friend here. We’re going to walk through exactly how to choose the right one and make it work wonders, even minimizing that pesky deflection. Get ready to machine Inconel 625 with confidence!

Why Inconel 625 is a Machining Challenge

Inconel 625 is a superalloy, which means it’s designed to be incredibly strong, resist corrosion, and handle extreme temperatures. These same properties make it a real challenge to machine. It work-hardens quickly, meaning the more you cut into it, the harder it becomes. This can lead to tools wearing out fast, chatter, and inaccurate parts if you’re not careful. For beginners, this can be frustrating, but with the right approach and tools, you can achieve great results.

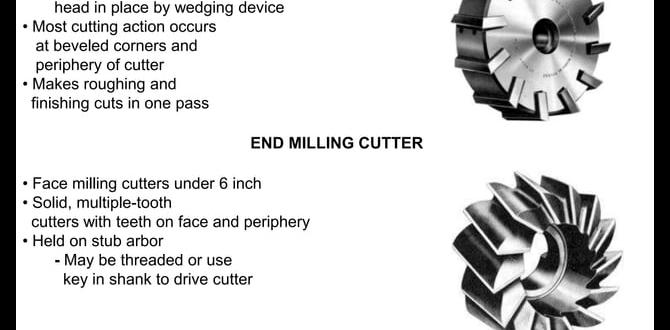

The Humble Hero: 1/8 Inch Carbide End Mill with 1/4 Inch Shank

When you’re facing the challenge of Inconel 625, especially for smaller or more intricate work, a 1/8-inch carbide end mill with a 1/4-inch shank is often the go-to tool.

Carbide: This material is incredibly hard and can withstand the high temperatures and forces involved in cutting tough alloys. It stays sharp longer than high-speed steel (HSS) if used correctly.

1/8 Inch Diameter: This small diameter is perfect for creating detailed features, slots, or pockets. It’s also less likely to put extreme stress on your machine compared to larger tools.

1/4 Inch Shank: The 1/4-inch shank offers a good balance. While a larger shank generally provides more rigidity and reduces deflection, a 1/4-inch shank is common, readily available, and still offers decent support for a 1/8-inch cutting diameter, especially when used with a suitable collet.

Minimizing Deflection: The Key to Success

Deflection is when your tool bends or moves away from its intended path due to cutting forces. With a small diameter end mill cutting a tough material like Inconel 625, this is a major concern. Even a tiny bit of deflection can ruin your workpiece or break your tool.

Here’s why a standard-length 1/8-inch, 1/4-inch shank end mill is often recommended for minimizing deflection in Inconel:

Balance of Tool Length: A “standard length” end mill is designed to have a reasonable flute length and overall length. Too long, and it will flex more. Too short, and you might not be able to reach your desired depth of cut or it might not have enough engagement with the workpiece. A standard length strikes a good balance for general Inconel machining.

Shank Rigidity: While not as robust as a 1/2-inch shank, a 1/4-inch shank on a quality carbide tool provides sufficient rigidity when properly held in a tight collet. The key is to minimize the amount of unsupported tool sticking out of the collet.

Selecting Your 1/8 Inch Carbide End Mill for Inconel 625

Not all carbide end mills are created equal, especially when it comes to superalloys. Here’s what to look for:

Material and Coating

Sub-micron Carbide: Look for end mills made from high-quality, sub-micron grade carbide. This provides a harder, tougher base material.

Coating: A PVD (Physical Vapor Deposition) coating is crucial for Inconel. Common coatings like TiN (Titanium Nitride) are okay for general use, but for Inconel, you want something more advanced.

TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications like Inconel. It forms a protective aluminum oxide layer at high temperatures, which resists wear.

AlTiN (Aluminum Titanium Nitride): Similar to TiAlN, offering great heat resistance.

ZrN (Zirconium Nitride): Offers good lubricity and can help reduce built-up edge.

Geometry

Number of Flutes: For Inconel, it’s generally recommended to use end mills with fewer flutes.

2-Flute: This is often the best choice for Inconel. The lower flute count provides more chip clearance, which is vital for removing the tough, gummy chips produced by Inconel. It also allows for a more aggressive feed rate, which can help break chips.

3-Flute: Can be used, but chip evacuation becomes more critical. It offers a bit more rigidity than a 2-flute at the same diameter.

4-Flute: Generally avoided for roughing Inconel as chip clearance is very limited, leading to re-cutting chips and tool breakage. They are better suited for finishing operations in softer materials.

Corner Radius: Some end mills have a sharp corner, while others have a small corner radius. A small corner radius (e.g., 0.010″ or 0.020″) can help strengthen the cutting edge and reduce the tendency for chipping, which is beneficial for Inconel.

Tool Holder and Runout

High-Quality Collet Chuck or Collet: This is non-negotiable. A precision collet chuck (like a CAT 40 or BT 40 spindle holder with a collet) or a high-quality ER collet system is essential. Ensure the collet you use is sized correctly for the 1/4-inch shank.

Minimize Runout: Runout is the wobble or eccentricity of the cutting tool. Even a few tenths of a thousandth of an inch of runout can drastically increase cutting forces, cause chatter, and lead to premature tool failure, especially with a small 1/8-inch end mill. Invest in the best tool holding you can afford. Aim for less than 0.0005″ runout at the cutting edge.

Setting Up Your Machine for Success

Before you even think about cutting, proper machine setup is paramount.

Rigidity of the Machine Tool

This is perhaps the most important factor after the tool itself. A small 1/8-inch end mill can still chatter or deflect if the milling machine isn’t rigid enough.

Mill Type: A Bridgeport-style manual milling machine can work, but it needs to be in good condition with minimal play in the ways and the spindle. A small, rigid CNC mill designed for metalworking will generally provide a more stable platform.

Table and Spindle Vibration: Ensure there’s no perceived vibration from the table or spindle when the machine is running without the tool. Loose gibs, worn ways, or a shaky spindle will amplify any cutting forces.

Workholding

Your part must be held absolutely securely.

Vise: Use a good quality, hardened vise. Ensure the vise jaw inserts are clean and provide good contact. Using parallels under your workpiece in the vise is standard practice to lift it off the vise jaws and allow for a full depth cut.

Clamping: If not using a vise, use T-nuts and clamps to secure your workpiece directly to the mill table. Ensure clamps are positioned to resist the cutting forces and do not obstruct the tool path.

Vibration Dampening: For very thin or flexible Inconel parts, consider using a dampening material underneath. However, for most applications, a rigid hold is sufficient.

The Machining Process: Step-by-Step

Let’s get down to business. Here’s how to approach milling Inconel 625 with your 1/8-inch carbide end mill.

Step 1: Determine Your Cutting Parameters

This is where research meets practical application. Finding the exact “perfect” parameters can sometimes require a little experimentation, but we can start with solid recommendations. These are just starting points; always listen to your machine and tool.

| Operation | Material | Tool | Diameter | Flutes | Feed (IPM) | Speed (SFM) | Depth of Cut (DOC) | Width of Cut (WOC) | Coolant/Lube |

| :————— | :——————- | :———————— | :——- | :—– | :——— | :———- | :—————– | :—————– | :—————– |

| Roughing | Inconel 625 | 1/8″ Carbide End Mill | 0.125″ | 2 | 3-8 | 50-100 | 0.020″ – 0.040″ | 0.060″ – 0.100″ | Flood, Mist, or Paste |

| Finishing | Inconel 625 | 1/8″ Carbide End Mill | 0.125″ | 2 | 5-15 | 75-125 | 0.005″ – 0.010″ | 0.060″ – 0.100″ | Flood, Mist, or Paste |

Note: IPM = Inches Per Minute, SFM = Surface Feet Per Minute, DOC = Depth of Cut, WOC = Width of Cut.

Explanation of Parameters:

Speed (SFM): This is how fast the cutting edge is moving. For Inconel and carbide, a moderate speed is best. Too high, and you’ll burn up the tool. Too low, and you’ll rub and build up heat. The coating plays a big role here.

Feed (IPM): This is how fast the tool is advanced into the material. A good chip load (feed per tooth) is crucial. For Inconel, aim for a higher chip load that is still manageable for your machine’s rigidity. For a 1/8″ diameter, 2-flute end mill, a chip load of 0.003″ to 0.005″ is a good starting point. So, Feed (IPM) = Speed (SFM) 12 / (Tool Diameter Pi) Chip Load. (Example: 80 SFM 12 / (0.125 3.14) 0.004 = ~9.8 IPM).

Depth of Cut (DOC): How deep the end mill cuts into the material vertically. For Inconel and smaller end mills, shallow depths are key to controlling forces and heat.

Width of Cut (WOC): How wide the end mill cuts horizontally into the material. For Inconel, taking less than half the tool diameter (50% = 0.0625″ for a 1/8″ tool) is often best to avoid excessive side loading and heat.

High-Quality Machining Resources: For more on machining parameters for Inconel and other hard-to-machine materials, check out resources from organizations like the National Tooling and Manufacturing Association (NTMA) which often provide valuable data. Another excellent source for machining data is the Machinery’s Handbook, a comprehensive reference for machinists.

Step 2: Coating Your End Mill (Figuratively!)

As discussed, a good coating is essential. Ensure your chosen end mill has a suitable coating like TiAlN or AlTiN.

Step 3: Achieving a Precise Tool Length

The less your end mill sticks out of the collet, the more rigid the setup.

Measure Tool Stick-Out: Before inserting the end mill into the collet, measure how much of the cutting length you expect to need.

Minimize Projection: Aim to have the cutting flutes as close to the collet as possible while still achieving your desired depth. For a 1/8-inch end mill, try to keep the projection to 1/2 inch or less if your work allows.

Step 4: Cutting Strategy

Climb Milling vs. Conventional Milling:

Climb Milling: The tool rotates in the same direction as the feed. This is generally preferred for Inconel because it reduces cutting forces and heat. The downward force of the cutting edge pushes the chip away, and it’s less likely to drag. This is especially beneficial for minimizing cutter deflection.

Conventional Milling: The tool rotates against the direction of the feed. This tends to create more friction and heat, and can push the tool away from the workpiece. Use this only if climb milling proves problematic due to machine backlash.

Tip: If using a manual mill, you may need to take steps to eliminate back lash in the X or Y axis to effectively climb mill.

Step-Overs: For pocketing or contouring, don’t try to do it all in one pass.

Roughing Passes: Use the recommended DOC and WOC. Take multiple shallower passes rather than one deep, aggressive pass.

Finishing Passes: For accuracy and surface finish, make a final, light finishing pass. Use a lower DOC (e.g., 0.005″) and a similar WOC or slightly larger if possible, with an appropriate feed rate.

Step 5: Coolant and Lubrication

Machining Inconel 625 generates a lot of heat. Proper cooling and lubrication are critical for tool life, chip evacuation, and preventing thermal shock to the workpiece.

Flood Coolant: A robust flood coolant system is ideal. It provides excellent cooling and chip flushing.

Mist Coolant: A mist/lubricant system can be effective, especially on smaller machines. It delivers a fine spray of coolant and lubricant directly to the cutting zone.

Cutting Paste/Fluid: For very small operations or where flood/mist isn’t feasible, a high-quality cutting paste or fluid specifically designed for superalloys can be used sparingly. Apply it directly to the tool or the workpiece.

Through-Spindle Coolant (TSC): If your machine has TSC, it’s a huge advantage for removing chips from the flutes and keeping the cutting zone cool.

Step 6: Chip Evacuation

This cannot be stressed enough. Helical chips from Inconel can weld themselves to the cutting edges, leading to tool failure.

Use 2-Flute Tools: As mentioned, this provides excellent chip clearance.

Manage Feed Rates: Ensure your feed rate is high enough to produce a distinct chip, not a dust or powder.

Peck Drilling/Milling: For deep pockets, engage peck cycles (if CNC) or manually retract the tool during milling to clear chips.

Common Issues and How to Solve Them

| Problem | Possible Cause | Solution |

| :——————- | :————————————————- | :——————————————————————————————————————————————————————————————- |

| Chatter/Vibration| Loose machine components, incorrect speeds/feeds, tool overload, tool deflection, insufficient rigidity. | Tighten gibs, check tool holder for runout, adjust speeds/feeds for chip load, reduce DOC/WOC, use Climb Milling, ensure workpiece is rigidly clamped, try a shorter tool projection. |

| Tool Breakage | Excessive feed/speed, insufficient coolant, poor chip evacuation, shock loading, worn tool. | Reduce DOC/WOC, ensure proper chip clearance, use adequate coolant, check for machine backlash issues, replace worn tools immediately, use climb milling. |

| Poor Surface Finish| Incorrect speeds/feeds, worn tool, insufficient coolant, tool deflection. | Optimize feed rate (often faster for finish), use a sharp finishing tool, ensure good coolant flow, take a light finishing pass with reduced DOC. |

| Work Hardening | Machining too slowly, not removing material quickly enough, insufficient cut depth. | Ensure you are taking a sufficient depth and width of cut (within rigidity limits), maintain appropriate feed rates to create a good chip, use climb milling. |

Safety First! Always.

Working with metal and machinery involves inherent risks. Never compromise on safety.

Eye Protection: Always wear safety glasses or a face shield.

Hearing Protection: For extended milling operations, use earplugs or earmuffs.

Clothing: Avoid loose clothing, jewelry, or long hair that could get caught in rotating machinery.

Machine Guarding: Ensure all machine guards are in place and functional.

Tool Handling: Be careful when changing tools, as they can be sharp and hot.

Emergency Stops: Know the location of your machine’s emergency stop button and ensure it is functional.

Read Manuals: Familiarize yourself with the operating manuals for your milling machine and any accessories you are using. The Occupational Safety and Health Administration (OSHA) provides valuable general safety guidelines applicable to workshop environments.

Frequently Asked Questions (FAQ)

Q1: Can I use a 1/8 inch carbide end mill with a 1/4 inch shank for aluminum?

A1: Yes, you absolutely can, and it will perform very well in aluminum. However, aluminum is much softer than Inconel 625, so you can use much higher speeds and feed rates, and often a