A 1/8 inch carbide end mill can offer exceptional tool life when machining brass, thanks to its hardness and specific geometries designed for non-ferrous metals. Proper speeds, feeds, cooling, and application are key to maximizing its longevity and achieving precise results.

Ever wrestled with a sharp tool that just didn’t seem to last? You’re not alone. Many of us in the home workshop dream of precision cuts and tools that stay sharp, especially when working with softer metals like brass. It can be frustrating when a brand new bit starts showing wear after just a few projects. But what if I told you there’s a way to get incredible longevity from even small tools like a 1/8 inch carbide end mill, specifically when you’re machining brass? It’s not magic; it’s about understanding a few key principles and using the right tool for the job. We’ll explore how to make your carbide end mills sing when cutting brass, ensuring you get more done with less wear and tear. Get ready to unlock superior tool life and cleaner cuts.

Understanding Your 1/8 Inch Carbide End Mill for Brass

When we talk about machining brass, we’re dealing with a material that’s relatively soft but also quite “gummy.” This gummy nature can cause chips to stick to the cutting edges of tools, leading to premature wear and poor surface finish. This is where a small but mighty tool, the 1/8 inch carbide end mill, shines, especially when it’s designed with brass in mind.

Carbide, as a material, is incredibly hard. This hardness is crucial for resisting wear. However, not all carbide end mills are created equal, and their geometry plays a huge role in how they perform with specific materials. For brass, we often look for end mills with specific features:

High Helix Angle: A higher helix angle (often 30-45 degrees or more) helps to curl the chips tightly and evacuate them more efficiently. This is vital for preventing material buildup on the cutting edge.

Polished Flutes: Smooth, polished flutes reduce friction and further assist in chip evacuation. Less friction means less heat and less chance of that gummy brass sticking.

Number of Flutes: For brass, a lower number of flutes (like 2 or 3) is often preferred. Fewer flutes mean larger chip gullets, allowing for better chip clearance and preventing chip recutting, which is a major cause of tool wear.

Coating: While not always necessary for brass, certain coatings can enhance lubricity and wear resistance. However, for many brass applications, an uncoated, high-quality carbide with polished flutes is often sufficient and cost-effective.

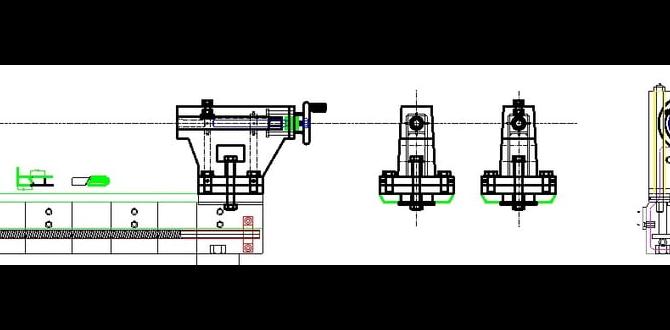

The ‘1/8 inch’ refers to the diameter of the cutting head, a common size for intricate work, engraving, or machining small parts. The ’10mm shank’ is a standard size for many milling machine collets and holders, providing a secure grip. The “extra long” description in the keyword suggests an extended reach, which is useful for getting into deeper features or clearing workholding. However, longer tools can also be more prone to chatter or vibration, so proper machining practices become even more critical.

Why Brass Demands Special Attention

Brass is a copper alloy, and its machinability varies depending on its specific composition. Common brass alloys like yellow brass (e.g., UNS C26000) are relatively easy to machine, but they can still create long, stringy chips that don’t break apart easily. When these chips pack into the flutes of an end mill, they can:

Dull the cutting edges: Stuck chips act like abrasives.

Cause surface finish issues: Chips can be recut, leading to a rough finish.

Increase cutting forces and heat: Leading to tool breakage or premature wear.

Overload the machine: As cutting forces increase.

This is precisely why a well-chosen carbide end mill, with its inherent hardness, combined with a geometry optimized for brass, can deliver that “genius” tool life.

SEO-Optimized Keywords and Concepts

To make sure this guide reaches everyone who needs it, we’ll weave in important terms naturally. When searching for tools and information, beginners often use phrases like:

“1/8 inch carbide end mill for brass”

“best end mill for brass”

“long tool life milling brass”

“brass machining tips”

“DIY CNC brass parts”

“small end mill for hobby milling machine”

“how to improve tool life”

Understanding these search queries helps us create content that’s not only informative but also easily discoverable. The “extra long” feature in the keyword is also important for users who need to reach deeper features, and the “10mm shank” is a common specification for many milling setups.

Essential Machining Parameters for Brass with a 1/8″ Carbide End Mill

Getting the most life out of your 1/8 inch carbide end mill when machining brass isn’t just about the tool itself; it’s about how you use it. Setting the right speeds, feeds, and using appropriate cutting fluids are critical. Let’s break down what you need to know.

Speeds and Feeds: The Foundation of Tool Life

This is arguably the most critical aspect. Too fast, and you’ll overheat the tool and the workpiece, leading to rapid wear. Too slow, and you might rub the cutting edge instead of cutting, also causing wear and poor finish. For brass and a 1/8 inch carbide end mill, here are some general guidelines.

Surface Speed (SFM – Surface Feet per Minute):

Carbide tools can generally run much faster than High-Speed Steel (HSS) tools. For brass with carbide, a common starting point is between 200-500 SFM. The exact speed depends on the specific brass alloy, the rigidity of your setup, and the quality of the end mill.

Calculating Spindle Speed (RPM):

You’ll need to convert SFM to RPM for your milling machine. The formula is:

RPM = (SFM × 3.25) / Diameter (inches)

Let’s do an example for a 1/8 inch (0.125 inch) carbide end mill:

At 300 SFM:

RPM = (300 × 3.25) / 0.125 = 7800 RPM

At 400 SFM:

RPM = (400 × 3.25) / 0.125 = 10400 RPM

So, a spindle speed between roughly 7,800 RPM and 10,400 RPM is a good starting range. Always aim for the lower end of this range when starting and listen to the machine and the cut. Vibration or a high-pitched squeal often indicates you need to adjust.

Feed Rate (IPM – Inches per Minute):

The feed rate determines how quickly the tool advances through the material. This is closely related to chip load.

Chip Load: This is the thickness of the chip being removed by each cutting edge (tooth) of the end mill. For small end mills in brass, a chip load of 0.0005″ to 0.0015″ per tooth is a good range.

Calculating Feed Rate:

Feed Rate (IPM) = Chip Load (inches/tooth) × Number of Flutes × Spindle Speed (RPM)

Let’s use our example speeds and a 2-flute end mill with a chip load of 0.001″ per tooth:

At 7800 RPM (using 300 SFM):

Feed Rate = 0.001″ × 2 flutes × 7800 RPM = 15.6 IPM

At 10400 RPM (using 400 SFM):

Feed Rate = 0.001″ × 2 flutes × 10400 RPM = 20.8 IPM

So, a feed rate between 15-25 IPM is a reasonable starting point.

Important Considerations for Speeds and Feeds:

Rigidity: A very rigid setup (e.g., a sturdy bridge mill with minimal spindle runout) can handle higher speeds and feeds. A less rigid setup (e.g., a hobby CNC with a wobbly spindle or a very long extension on a manual mill) will require slower speeds and feeds to avoid vibration.

“Extra Long” Shank: If your 1/8 inch end mill has a significantly long shank (e.g., 3-4 inches or more), you will likely need to reduce your speeds and feeds. The longer the tool, the more it can flex and vibrate. Try reducing speeds by 10-20% and feeds by 20-30% as a starting point.

Listen and Observe: The best indicator is your ears and eyes. If the cut sounds “chattery,” the tool is screaming, or you see excessive smoke/chips packing, slow down your feed rate first. If the finish is poor or you’re getting rubbing, slightly increase your feed.

Coolant/Lubrication: While high-speed machining of brass can sometimes be done dry, using a cutting fluid or lubricant will significantly improve tool life and surface finish by reducing heat and friction.

Cutting Fluids and Lubrication

For brass, you don’t necessarily need heavy-duty metalworking coolants. Often, a light mist of a specialized cutting fluid or even a simple spray of WD-40 or a dedicated CNC lubricant can make a world of difference.

Purpose: They help carry chips away from the cutting zone, reduce friction, lubricate the cutting edge, and cool the tool and workpiece.

Types:

Mist Coolant: A fine spray of oil or synthetics. Excellent for chip evacuation and cooling.

Cutting Paste/Stick: Solid lubricants that can be applied directly. Good for manual machining or where a mist isn’t feasible.

Light Oils: Such as Kroil, LPS, or even a light mineral oil.

Application: Apply the lubricant directly to the cutting area. For CNC, a misting system is ideal. For manual mills, you can apply it periodically.

Machining Strategies for Optimal Brass Turning

How you approach the cutting path can dramatically influence tool life and the quality of your brass parts. Different applications will call for different strategies.

1. Plunge Milling (Drilling into Material)

If you need to create a pocket or hole, you might need to plunge the end mill straight down.

Use Appropriate End Mills: Tools designed for plunging (often with chipbreaker features on the end cut) are best, but many standard end mills can do it if done carefully. For brass, a 2-flute end mill with a good chip evacuation path is preferable.

Slow Plunge Rates: Plunge significantly slower than your typical feed rate – perhaps 25-50% of your radial feed rate. This reduces the force on the cutting edges as they engage the material on the end.

Pecking: For deeper holes, retracting the tool periodically (like drilling with a peck cycle) can help clear chips and prevent overheating.

2. Pocketing (Removing Material from an Area)

When machining a pocket, the goal is to remove material efficiently without overloading the tool.

Conventional vs. Climb Milling:

Conventional Milling: The cutter rotates against the feed direction. This tends to create larger chips and can lead to rubbing, especially in gummy materials like brass. It’s generally less preferred for fine finishes.

Climb Milling: The cutter rotates in the same direction as the feed. This produces smaller, thinner chips and generates less heat and friction at the cutting edge. It often results in a better surface finish and is usually the preferred method for brass.

Stepover: The amount the tool moves sideways for each pass. For efficient pocketing, a stepover of 30-50% of the tool diameter is common. For finishing passes, a smaller stepover (e.g., 10-20%) will yield a smoother surface.

Depth of Cut: For a 1/8 inch end mill, it’s generally best to keep the depth of cut conservative. A radial depth of cut (how much material is removed sideways in one pass) of 30-50% of the diameter is good. For axial depth of cut (how deep it cuts into the material vertically), especially in a pocket, it’s wise to take several shallower passes rather than one deep pass. For example, if you need to pocket 1/4 inch deep, consider taking two passes of 1/8 inch or three passes of ~0.085 inches.

3. Contour/Profile Machining (Cutting Around an Edge)

When cutting the outside of a part or a slot.

Climb Milling: Again, climb milling is generally preferred for the best surface finish and tool life.

Lead Angle: For very tight contours, you might need to adjust your lead angle (the angle at which the tool approaches the cut). However, for simple profiles, standard approach angles are usually fine.

Finishing Passes: For critical dimensions and surface finish on the outer profile, a final finishing pass with a very small depth of cut (e.g., 0.002″ – 0.005″) and a small stepover (e.g., 10% of tool diameter) at a slightly slower feed rate can produce a mirror-like finish.

Table: Recommended Cutting Parameters (Starting Points)

This table provides a starting point for machining brass with a 1/8 inch (0.125″) 2-flute carbide end mill. Always adjust based on your specific machine, setup, and audible feedback.

| Operation | Material | End Mill Diameter | Flutes | Surface Speed (SFM) | Spindle Speed (RPM) | Chip Load (per tooth) | Feed Rate (IPM) | Axial Depth of Cut (inches) | Radial Depth of Cut (inches) | Notes |

| :———————— | :————— | :—————- | :—– | :—————— | :—————— | :——————– | :————– | :————————– | :————————— | :——————————————— |

| Pocketing (Roughing) | Brass (e.g. C360)| 1/8″ (0.125″) | 2 | 300 – 450 | 7,800 – 11,500 | 0.0007 – 0.0012 | 11 – 28 | 0.050 – 0.125 (multiple passes) | 0.050 – 0.0625 (30-50%) | Climb milling, mist coolant recommended |

| Pocketing (Finishing) | Brass | 1/8″ (0.125″) | 2 | 300 – 450 | 7,800 – 11,500 | 0.0005 – 0.0008 | 8 – 18 | 0.002 – 0.005 | 0.010 – 0.025 (10-20%) | Climb milling, lighter feed, consider lubricant |

| Contour/Profile (Rough) | Brass | 1/8″ (0.125″) | 2 | 300 – 450 | 7,800 – 11,500 | 0.0007 – 0.0012 | 11 – 28 | Depends on feature depth | 0.050 – 0.0625 (30-50%) | Climb milling, steady feed |

| Contour/Profile (Finish) | Brass | 1/8″ (0.125″) | 2 | 300 – 450 | 7,800 – 11,500 | 0.0005 – 0.0008 | 8 – 18 | Depends on feature depth | 0.010 – 0.025 (10-20%) | Climb milling, very light cut |

| Slotting (Full Slotting) | Brass | 1/8″ (0.125″) | 2 | 250 – 350 | 6,400 – 8,900 | 0.0005 – 0.0010 | 6 – 18 | 0.125 (or less if needed) | 1.0 (full slot width) | Slower speeds, lower chip load, peck if deep |

| Engraving/Detail | Brass | 1/8″ (0.125″) | 2 | 300 – 500 | 7,800 – 12,800 | 0.0002 – 0.0005 | 3 – 10 | Varying (small stepdown) | 0.005 – 0.020 | Light cuts, use lubricant, focus on precision|

Note: For end mills with extra-long shanks, a reduction in speeds and feeds by 10-30% is often necessary due to increased flex and vibration potential.

Tool Geometry Matters: Choosing the Right End Mill

As mentioned earlier, the geometry of your 1/8 inch end