Carbide end mills designed for Titanium Grade 5 offer precise cuts, making them ideal for demanding aerospace and medical applications. Choose the right one for your project and achieve flawless finishes.

Working with tough materials like Titanium Grade 5 can be a real challenge, especially when you need pinpoint accuracy. Many beginners find it intimidating, worrying about tool wear, broken bits, and inconsistent results. But what if I told you there’s a specific type of tool that makes this process much simpler and yields incredibly precise outcomes? This guide is all about the carbide end mill, specifically engineered for materials like Titanium Grade 5. We’ll break down exactly what makes them special, how to choose the right one for your needs, and how to use them safely and effectively to achieve those “proven Titanium Grade 5 precision” results you’re aiming for.

What is a Carbide End Mill for Titanium Grade 5?

When we talk about machining Titanium Grade 5, we’re dealing with a material that’s known for its strength, hardness, and tendency to work-harden. This means it’s tough to cut and can quickly dull or break standard milling tools. A specialized carbide end mill for Titanium Grade 5 is designed to overcome these challenges.

Why Carbide is Key

Carbide, or tungsten carbide, is an extremely hard ceramic compound. It’s significantly harder and more rigid than High-Speed Steel (HSS). This superior hardness allows it to:

Cut through tough materials like Titanium Grade 5 with less wear.

Maintain a sharp cutting edge for longer periods.

Withstand higher cutting temperatures, which is crucial when machining titanium.

Specialized Geometry and Coatings

End mills designed for titanium aren’t just made of carbide; they also feature specific design elements:

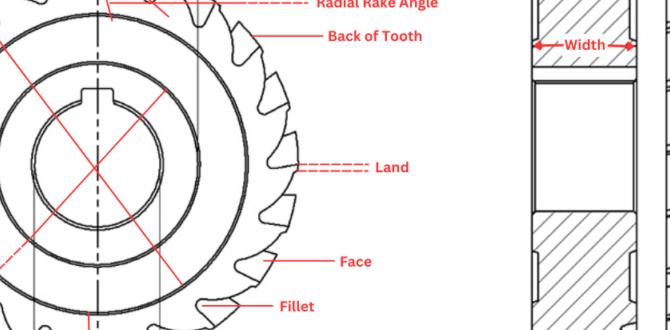

Flute Count: Often have fewer flutes (2 or 3) compared to those for softer metals. This provides more chip clearance, which is vital for managing titanium’s tendency to produce long, stringy chips that can clog the flutes and cause tool failure.

Helix Angle: A steeper helix angle can help to slice through the material more effectively and reduce the cutting forces.

Coatings: Advanced coatings, such as TiAlN (Titanium Aluminum Nitride) or AlTiN (Aluminum Titanium Nitride), add an extra layer of hardness and thermal resistance. These coatings also reduce friction, allowing for faster cutting speeds and extended tool life.

Corner Radii/Chamfers: Often incorporate a small radius or chamfer on the cutting edges to add strength and prevent chipping.

The “Precision” Factor

When the term “precision” is attached to an end mill for Titanium Grade 5, it implies that the tool is manufactured to very tight tolerances. This means:

Accurate Diameter: The actual diameter will be exactly as specified, crucial for achieving exact part dimensions.

Concentricity: The cutting edges will run true to the shank, minimizing vibration and improving surface finish.

Surface Finish: The flutes and cutting edges are polished to a high degree, which further reduces friction and improves chip evacuation, leading to cleaner cuts.

Understanding Key Specifications: Your Buying Guide

Choosing the right carbide end mill involves understanding a few key specifications. Let’s break down what to look for, especially when aiming for “Titanium Grade 5 precision.”

Diameter and Shank Size

The diameter is how wide the cutting portion of the end mill is. For Titanium Grade 5, common diameters range from fractions of an inch (like 1/8 inch) up to several inches.

1/8 inch Diameter: Excellent for intricate details, engraving, or machining smaller features. Be mindful that smaller diameter tools are more fragile and require lower feed rates and shallower depth of cuts.

10mm Shank: This is a metric standard shank diameter. Many CNC machines and collets are designed to accept specific shank sizes. Ensuring your tool holder (collet or chuck) matches the shank size is critical for secure clamping and accurate machining.

Length (Standard vs. Extended Reach)

End mills come in various lengths.

Standard Length: These are more rigid and generally used for parts where the depth of cut isn’t excessive. They are less prone to deflection.

Extended Reach or Long Flute: These allow you to machine deeper pockets or features. However, they are less rigid and require careful machining strategies (lower speeds, reduced depths of cut) to avoid vibration and breakage.

For achieving “proven Titanium Grade 5 precision,” a standard length end mill is often preferred for its rigidity, unless the part geometry specifically demands a longer reach.

Number of Flutes

As mentioned, titanium machining typically benefits from fewer flutes to improve chip evacuation.

2-Flute: Ideal for slotting and roughing operations in titanium. They offer maximum chip clearance.

3-Flute: A good balance for both slotting and some finishing operations. They can offer a slightly better surface finish than 2-flute due to more cutting edges engaging the material.

4-Flute: Generally less ideal for titanium as they have reduced chip clearance. They can be used for light finishing passes in some scenarios if chip evacuation is meticulously managed.

For Titanium Grade 5 precision, a 2-flute or 3-flute carbide end mill with good chip management is typically recommended.

End Type

Square End: The most common type, creating sharp internal corners.

Ball Nose: Creates a radiused, or rounded, end. Excellent for 3D contouring, milling complex surfaces, and creating fillets.

Corner Radius: A square end with a small radius on the corners. This strengthens the cutting edges and helps produce fillets, preventing stress concentrations.

Bull Nose: A larger radius than a corner radius end mill.

For general precision machining of Titanium Grade 5, a square end or a corner radius end mill is often chosen.

Material and Coating Summary Table

| Feature | Recommendation for Titanium Grade 5 Precision | Why it Matters for Titanium Grade 5 |

| :—————- | :——————————————– | :———————————————————— |

| Base Material | Tungsten Carbide | Extreme hardness and heat resistance. |

| Flute Count | 2 or 3 Flutes | Maximizes chip clearance, preventing chip recutting and buildup. |

| Coating | TiAlN, AlTiN, or similar high-performance | Adds hardness, reduces friction, and improves thermal stability. |

| Helix Angle | 30-45 degrees (or specialized for titanium) | Efficient chip evacuation and reduced cutting forces. |

| Corner Style | Square or Corner Radius | Strength and durability, preventing edge chipping. |

| Tolerance | Tight manufacturing tolerances | Ensures dimensional accuracy and consistent performance. |

The “Tight Tolerance” Factor

When you see “tight tolerance” in reference to an end mill for Titanium Grade 5, it means the manufacturer has invested in high-quality grinding processes and stringent quality control. They ensure:

Dimensional Accuracy: The actual diameter of the cutting flutes is held within a very narrow range of the advertised size.

Straightness and Roundness: The tool body and cutting edges are perfectly straight and round.

Surface Finish: The flutes are highly polished to minimize friction and improve chip flow.

This level of precision is essential for applications where your finished part must meet exact specifications, such as in aerospace components or medical implants.

Why is Titanium Grade 5 So Difficult to Machine?

Before we dive into how to use these specialized end mills, it’s helpful to understand why titanium presents such a machining challenge.

1. Low Thermal Conductivity: Titanium doesn’t dissipate heat well. This means heat generated during cutting stays concentrated at the cutting edge, rapidly causing tool wear and potentially leading to tool breakage.

2. High Strength and Hardness: Titanium Grade 5 (Ti-6Al-4V) is a strong and hard alloy, requiring significant force to cut. This puts stress on the cutting tool.

3. Tendency to Work Harden: As titanium is cut, the material near the cut surface becomes harder. This new, hardened layer is even more difficult to machine, exacerbating the problem if not managed correctly.

4. Gummy and Stringy Chips: Titanium tends to produce long, stringy chips. If these chips aren’t cleared effectively from the cutting area, they can re-cut, clog the flutes, and cause catastrophic tool failure.

5. Reactivity: At higher temperatures, titanium can react with cutting tool materials, forming tenacious bonds that can lead to chip welding onto the tool.

Setting Up for Success: Essential Tools and Considerations

To get the most out of your carbide end mill when machining Titanium Grade 5, proper setup is crucial. You’ll need more than just the end mill itself.

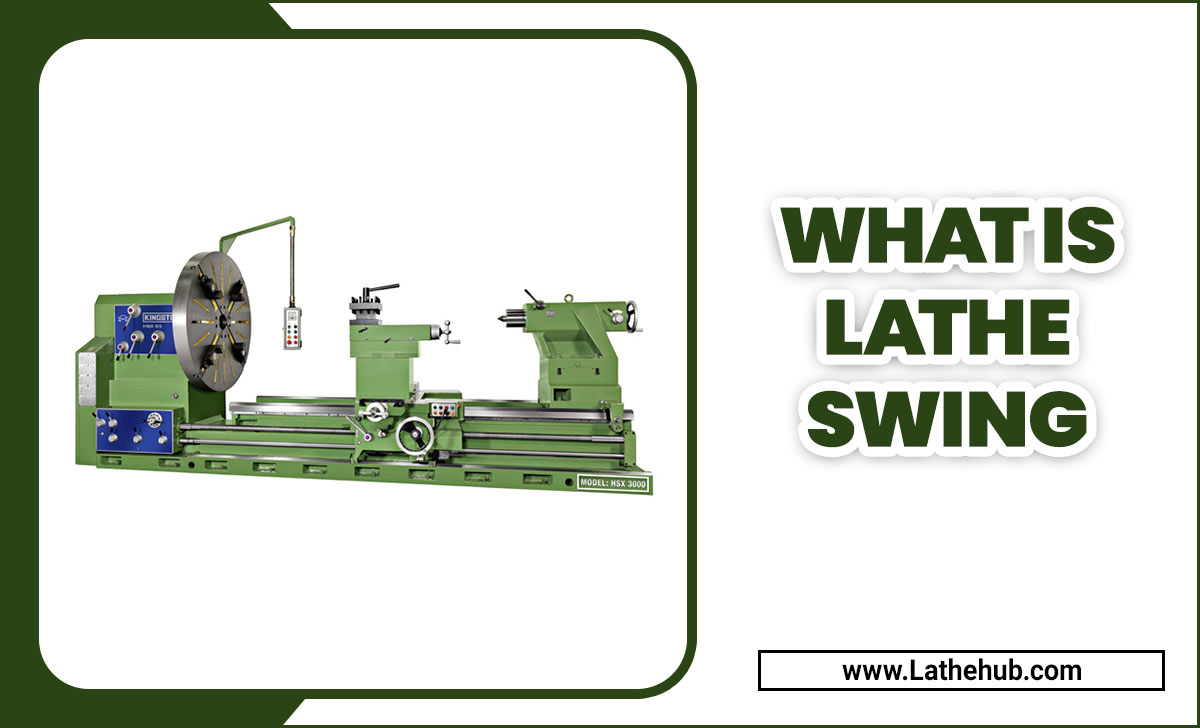

Your Milling Machine and Workholding

Rigid Milling Machine: A machine with a rigid frame and a strong spindle is essential. Vibration is the enemy of precise machining and tool life, especially with tough materials. Ensure your machine is well-maintained.

Accurate Spindle: The spindle should run true with minimal runout.

High-Quality Collets or Tool Holders: AEROSPACE or precise ER collets are highly recommended. A shank that isn’t held securely and concentrically will lead to chatter, poor surface finish, and premature tool failure. Make sure the collet size precisely matches your 10mm shank end mill.

Secure Workholding: The workpiece must be held absolutely rigidly. Clamps, vises, or custom fixtures should be robust enough to prevent any movement during the machining process. For Titanium Grade 5, consider using a vise with hardened jaws or specialized fixturing.

Coolant and Lubrication

Machining titanium generates significant heat. Effective cooling and lubrication are non-negotiable.

Flood Coolant: A high-pressure flood coolant system is ideal. It flushes chips away, cools the cutting edge, and lubricates the cut.

MQL (Minimum Quantity Lubrication): For some machines or specific operations, MQL systems can deliver a fine mist of cutting fluid directly to the cutting zone.

Cutting Pastes/Oils: For manual machining or less sophisticated setups, a good quality cutting paste or heavy-duty cutting oil designed for titanium can make a significant difference when applied directly to the cutting area. Be sure to reapply frequently.

You can find excellent resources on metalworking fluids and their application from organizations like the Society of Manufacturing Engineers (SME), which often publish guides and best practices.

Machine Settings: Speed and Feed Rates

This is where many beginners struggle. Titanium requires significantly slower speeds and optimized feed rates compared to softer metals.

Spindle Speed (RPM): For a carbide end mill machining Titanium Grade 5, speeds are generally much lower than for aluminum or steel. A common starting point might be 20-60 surface feet per minute (SFM). For a 1/8 inch (0.125 inch) diameter end mill, this translates to roughly 500-1500 RPM. Always consult the end mill manufacturer’s recommendations.

Feed Rate: The feed rate determines how fast the tool moves through the material. For titanium, you want a feed rate that is fast enough to ensure the cutting edge “bites” into the material and creates a chip, rather than rubbing and work-hardening the surface. A common starting point might be 0.001 to 0.003 inches per revolution (IPR) for a 1/8 inch end mill.

Depth of Cut: Due to titanium’s hardness and tendency to build heat, shallow depths of cut are recommended. Both axial (depth into the material) and radial (width of the cut) depths of cut should be conservative, especially during initial trials.

Always start with conservative settings and gradually increase them while monitoring tool performance, noise, and chip formation. It’s better to cut slowly and reliably than to break an expensive tool.

Step-by-Step: Machining Titanium Grade 5 with Your Carbide End Mill

Let’s walk through the process of using your specialized carbide end mill. We’ll assume you’re using a modern CNC mill, as this is where precision is most critical.

Step 1: Prepare Your Machine and Workpiece

Cleanliness: Ensure your milling machine, spindle, and tool holder are clean. Any debris can cause runout or damage.

Tool Installation: Insert the carbide end mill into its collet, ensuring the shank is seated correctly. Tighten the collet securely in the spindle. Double-check that the collet size matches the 10mm shank.

Secure Workpiece: Mount your Titanium Grade 5 workpiece firmly in your vise or fixture. Ensure it’s positioned correctly and won’t move.

Coolant/Lubricant Setup: Prepare your coolant system or have your cutting lubricant ready.

Step 2: Set Up the Coordinate System (Work Offset)

Zeroing: Carefully use your chosen method (edge finder, probe, or manual measurement) to establish the X, Y, and Z zero points (work offset) for your part program on the workpiece. For Z zero, it’s common to set it on the top surface of the titanium.

Step 3: Program or Manually Set Tool Parameters

Tool Number and Length Offset: Input the tool number into your CNC controller and set its length offset accurately.

Speeds and Feeds: Program the cutter speeds and feed rates determined in the previous section. It’s always best to start conservatively.

Step 4: Perform a Dry Run (Air Cut)

Safety First: Before cutting into the material, run the program with the spindle off and the Z-axis raised at least an inch above the workpiece. This allows you to visually verify the toolpath and ensure everything is set up correctly and there are no unexpected movements.

Lowering the Z-Axis: Once the dry run looks good, carefully lower the Z-axis (spindle) to just above the workpiece surface where the tool will begin its cut.

Step 5: Initiate the Cut with Coolant

Start Spindle: Turn on the spindle to the programmed RPM.

Start Coolant: Activate your coolant system or begin applying lubricant.

Engage Feed: Initiate the cutting program or manually engage the feed rate.

Observe Closely: Watch and listen as the end mill engages the Titanium Grade 5. Look for:

Chip Formation: You should see healthy, manageable chips being produced, not dust or long, stringy shavings.

Sound: A consistent, smooth cutting sound is good. Any chatter or screeching indicates a problem.

Tool Deflection: Ensure the tool isn’t visibly bending or vibrating excessively.

Coolant Flow: Make sure coolant is reaching the cutting zone effectively and flushing chips.

Step 6: Monitor and Adjust

Chip Evacuation: Continuously monitor chip evacuation. If chips start to build up, the cut is likely too deep or feed too slow. You may need to pause the cut, clear chips, and restart with adjusted parameters.

Tool Temperature: While difficult to directly measure on some machines, you can often infer if the tool is getting too hot by a change in cutting sound or if the workpiece starts to discolor significantly.

Adjustments: If everything looks good but the cutting marks are too light, you can gradually increase the feed rate or depth of cut. If you encounter chatter or excessive heat, reduce speeds and feeds, or try a shallower depth of cut.

Step 7: Complete the Operation and Inspect

Retract Tool: Once the machining is complete, program the tool to retract safely in Z, then X and Y, away from the workpiece.

Turn Off Coolant & Spindle: Once clear of the workpiece, turn off the coolant and spindle.

Inspect: Carefully remove the workpiece and inspect the machined features. Check for:

Dimensional Accuracy: Use calipers or a micrometer to verify that the part meets its specifications.

Surface Finish: Look for a smooth, consistent finish without tool marks or burrs.

Tool Condition: Examine the end mill for excessive wear, chipping, or signs of melting.

Pro Tips for Precision Machining Titanium Grade 5

Achieving that “proven Titanium Grade 5 precision” isn’t just about having the right tool; it’s about the finesse you apply.

Use High-Quality Cutting Fluids: Don’t skimp on lubrication. For titanium, specialized cutting fluids or pastes are designed to handle the extreme pressures and temperatures.

Prioritize Chip Evacuation: This is paramount. If you’re not on a CNC, consider using a vacuum system or compressed air to help blow chips away from the cutting zone. For CNC, program tool paths that facilitate chip removal.

Climb Milling vs. Conventional Milling: For titanium, climb milling (where the cutter rotates in the same direction as its feed) is often preferred. It can reduce cutting forces and provide a better surface finish, but it requires a rigid machine to avoid chatter.

“Peck” Drilling/Milling: For slots or deep pockets, consider implementing a “peck” cycle. This involves plunging the tool into the material, withdrawing slightly to clear chips, and then plunging again.

Tool Path Optimization: For complex 3D shapes, consider using specialized CAM software that can optimize tool paths for titanium machining, ensuring efficient material removal and good surface finish.

Tool Break-In: For new, high-performance carbide end mills, some machinists recommend a brief “break-in” period. This involves running the tool at slightly reduced parameters for a short time to gently hone the cutting edges, which can extend its overall life and improve initial performance.

*