A 1/8-inch carbide end mill is key to controlling deflection when machining PMMA, ensuring clean cuts and preventing tool breakage. Proper selection and machining techniques are vital for precise results in your projects. Let’s dive in!

Working with plastics like PMMA (also known as acrylic) on a mill can sometimes feel like a wrestling match. You want a clean cut, but instead, you get chatter, chipping, or worse, the tool bends and breaks. A big culprit behind this frustration is deflection – the unwanted bending of the cutting tool. For hobbyists and beginners especially, understanding and controlling this can seem tricky. But what if I told you a simple tool, the 1/8-inch carbide end mill, could be your secret weapon? It’s true! In this guide, we’ll explore exactly why this specific tool excels at PMMA and how you can use it to achieve stellar results. Get ready to say goodbye to frustrating cuts and hello to perfectly machined acrylic!

Understanding Deflection in PMMA Machining

Deflection is a common challenge when machining any material, but it’s particularly noticeable when working with softer, more flexible plastics like PMMA. Imagine trying to cut through a thick, slightly rubbery sheet with a very thin, bendy knife – that’s kind of what’s happening when your end mill deflects. It bends away from the intended cutting path, leading to:

- Poor Surface Finish: The cut edges become rough, uneven, or develop unsightly burrs.

- Inaccurate Part Dimensions: Because the tool isn’t cutting where you want it to, your finished part won’t match your CAD design.

- Tool Breakage: Excessive flexing can stress the end mill, leading to premature wear or snapping it entirely.

- Chatter Marks: Pulsating vibrations can create a wavy or ribbed surface on the workpiece.

Several factors contribute to deflection:

- Tool Diameter: Smaller diameter tools are inherently more flexible.

- Tool Length: The longer the flute (cutting edge) sticking out from the collet, the more it can bend.

- Cutting Forces: The force applied by the material as the tool cuts. This is influenced by feed rate, depth of cut, and the material itself.

- Material Properties: PMMA, while rigid, is less stiff than metals. It can deform under cutting pressure.

- Spindle Speed (RPM): Incorrect speeds can cause vibrations that exacerbate deflection.

- Machine Rigidity: A wobbly mill frame or loose spindle will magnify any deflection.

For beginners, it’s easy to get discouraged when these issues pop up. But with the right approach and tools, you can overcome them. That’s where our hero, the 1/8-inch carbide end mill, comes into play for PMMA.

Why a 1/8-Inch Carbide End Mill is Your PMMA Ally

When it comes to machining PMMA, a 1/8-inch carbide end mill offers a fantastic balance of cutting ability and control. Let’s break down why it’s so effective, focusing on the keywords: “carbide end mill 1/8 inch 10mm shank standard length for pmma minimize deflection.”

Carbide Material: Durability and Heat Resistance

End mills are made from various materials, but carbide reigns supreme for machining plastics, especially for precise work. Here’s why:

- Hardness: Carbide is significantly harder than High-Speed Steel (HSS). This means it maintains its sharp edge longer, even when cutting tough materials or at higher speeds.

- Heat Resistance: Machining generates heat. Carbide can withstand much higher temperatures than HSS before softening, which is crucial for a clean cut in plastics that can melt.

- Rigidity: Carbide is a stiffer material, which helps resist deflection better than more flexible materials like HSS.

For PMMA, which can gum up and melt if cut improperly, the hardness and heat resistance of carbide help ensure a clean, chip-free cut rather than a melted mess.

1/8-Inch Diameter: The Sweet Spot for Detail and Control

The 1/8-inch (or approximately 3mm) diameter is often the sweet spot for detailed work in PMMA:

- Reduced Cutting Forces: A smaller diameter tool takes a smaller bite of material. This means less force is exerted on the tool, directly reducing deflection.

- Access to Details: It allows you to machine intricate shapes, tight corners, and fine details that larger tools simply can’t reach.

- Manageable Chip Load: The amount of material removed by each cutting edge (chip load) is easier to manage with a smaller tool. This is key to preventing melting and chatter.

The 10mm Shank: Stability and Compatibility

You’ll often see end mills specified with a shank diameter. A 10mm shank is a common size that offers good stability for a 1/8-inch cutting diameter:

- Secure Grip: A 10mm shank fits securely in many common collet sizes (like R8, ER collets, or specific CNC holders), providing a strong, rigid connection between the tool and the spindle.

- Reduced Runout: A well-gripped shank minimizes “runout” – the wobble or eccentricity of the tool. Low runout is essential for predictable cutting.

- Compatibility: Many beginner-friendly milling machines and hobby CNCs come equipped with collet systems that readily accept 10mm shank tools.

Standard Length: Balancing Reach and Rigidity

“Standard length” end mills strike a balance. While longer tools offer more reach, they are more prone to deflection. A standard length 1/8-inch end mill typically has flute lengths that are a few times the diameter. This provides enough cutting edge to engage the material effectively without excessive overhang, which helps keep deflection to a minimum. For most PMMA projects, a standard length is perfect.

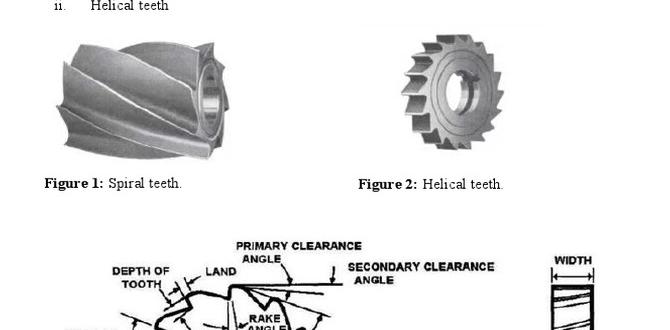

PMMA-Specific “O-Flute” or “Plastic” End Mills

While not explicitly in the keyword phrase, it’s worth mentioning that for PMMA and other plastics, you’ll often find end mills designed specifically for them. These are commonly called “O-flute” (meaning single straight flute) or “plastic” end mills. They feature:

- Highly Polished Flutes: This reduces friction and prevents plastic from sticking to the tool.

- Sharp, Up-Acting or Straight Helix: Up-acting flutes push chips upwards, which can help clear them from the cut more effectively in plastics to prevent melting. Straight flutes are also common and very effective.

- Fewer Flutes: Often 1 or 2 flutes. Fewer flutes mean larger chip pockets and less chance of the flutes clogging with melted plastic.

If you can find a 1/8-inch carbide O-flute end mill specifically designed for plastics, that’s often the best choice. However, a good quality, sharp, standard 1/8-inch 2-flute carbide end mill will also perform admirably.

Choosing the Right 1/8-Inch Carbide End Mill for PMMA

Not all 1/8-inch carbide end mills are created equal, especially when working with PMMA. Here’s what to look for:

Key Features to Consider:

- Number of Flutes: For PMMA, 1 or 2 flutes are generally best. Single-flute (O-flute) end mills are excellent for plastics as they provide maximum chip clearance and a clean cut. Two-flute end mills are also very common and effective, offering a good balance between cutting action and chip evacuation. Avoid end mills with 3 or 4 flutes for PMMA, as they tend to clog and create more heat.

- Helix Angle: A high helix angle (e.g., 30-45 degrees) can help lift chips out of the cut more effectively, reducing the risk of melting and re-cutting. However, extremely high helix angles can sometimes lead to chatter. For PMMA, a standard helix (around 30 degrees) is usually a safe bet.

- Coating: While not always necessary for PMMA, some coatings can improve performance and tool life. For plastics, uncoated carbide is often preferred because the polished surface naturally prevents sticking. If coated, look for very smooth coatings that don’t add much friction.

- Specific “Plastic” or “O-Flute” Design: If you see end mills marketed specifically for plastics, they usually have a highly polished flute and optimized geometry for this material. These are ideal.

- Brand Reputation: Stick with reputable tool manufacturers. Quality control matters, especially for smaller diameter tools where precision is paramount.

What to Avoid:

- General-Purpose End Mills with Many Flutes: As mentioned, 3 or 4 flutes are not ideal for plastics.

- Tools with Poor Surface Finish: Rough flutes will snag the plastic and cause a bad cut.

- Hogging End Mills: These are designed for aggressive material removal and might be too robust, generating too much heat or force for delicate PMMA work.

Setting Up Your Mill for Success with a 1/8-Inch End Mill on PMMA

Getting the machine settings right is just as crucial as having the right tool. This is where we prevent deflection before it even starts.

Spindle Speed (RPM) and Feed Rate

This is the most critical part! You need to find the “sweet spot” where the tool cuts efficiently without melting or deflecting.

General Guidelines:

For a 1/8-inch carbide end mill in PMMA, a good starting point for spindle speed is quite high.

- Spindle Speed: Start around 12,000 to 18,000 RPM. Many small CNC routers and hobby mills can achieve these speeds. If your machine can’t go that high, you’ll need to adjust your feed rate significantly.

- Feed Rate: This is how fast the tool moves through the material. For a 1/8-inch end mill in PMMA, a conservative starting feed rate might be between 10-30 inches per minute (IPM), or about 250-750 mm/min.

The “Chip Load” Concept:

A more advanced way to think about this is chip load – the thickness of the material each cutting edge removes per revolution. For plastics like PMMA with a 1/8-inch carbide end mill, you want a small to moderate chip load, typically in the range of 0.001 to 0.003 inches per edge.

You can calculate your feed rate using this formula:

Feed Rate (IPM) = Spindle Speed (RPM) × Number of Flutes × Chip Load (inches per tooth)

Example: For a 1/8-inch, 2-flute end mill at 15,000 RPM with a chip load of 0.002 inches/tooth:

Feed Rate = 15,000 × 2 × 0.002 = 60 IPM.

Now, this is just a starting point. You must listen to your machine and watch the cut. If you hear squealing or see melted plastic, your feed rate is too slow, or your RPM is too low. If you see excessive vibration or hear a loud clatter, your feed rate might be too high, or your depth of cut is too aggressive.

Depth of Cut and Stepover

Depth of Cut (DOC):

This is how deep the end mill cuts in a single pass. For PMMA and a 1/8-inch end mill, it’s crucial to use shallow depths of cut. This minimizes the cutting forces and thus deflection.

- Recommended DOC: Start with a depth of cut equal to or less than the diameter of the end mill (e.g., 0.125 inches or 3mm). For very fine detail or to maximize precision, you might go even shallower, like half the diameter (0.0625 inches or 1.5mm).

- Multiple Passes: It’s always better to machine a feature in several shallow passes than one deep pass. This significantly reduces the stress on the tool and your machine, leading to less deflection and a better finish.

Stepover:

This is the amount the end mill moves sideways between each cutting pass when milling a pocket or contour. A smaller stepover results in a smoother finish but takes longer.

- For Pockets: A stepover of 40-60% of the end mill diameter is common. For a 1/8″ end mill, this would be around 0.05″ to 0.075″ (1.2mm to 1.9mm).

- For Contours: You can achieve a very smooth surface finish with a small stepover, sometimes as low as 10-20% of the end mill diameter (0.0125″ – 0.025″).

Workholding: Securely Holding Your PMMA

How you hold your PMMA is critical. It needs to be clamped down firmly without distorting or cracking the material. Ensure your clamps are not placing excessive pressure on one area.

- Clamps: Use clamp types that distribute pressure. F-style clamps or specialized plastic clamps work well.

- Double-Sided Tape: For smaller parts or delicate operations, strong double-sided tape specifically made for machining can be an excellent, non-marring option.

- Fixturing: A sacrificial spoilboard (like MDF or plywood) is essential. Clamping directly to the machine bed or a stout fixture plate provides a solid base.

- Support: Ensure the PMMA is well-supported from beneath, especially where the end mill will be cutting.

Safely Machining PMMA: Step-by-Step Guide

Let’s walk through a typical process for milling PMMA with your 1/8-inch carbide end mill, keeping deflection control and safety in mind.

Step 1: Design and Preparation

- Design: Create your part in CAD software. For beginners, keep shapes relatively simple.

- Tool Selection: Choose your 1/8-inch carbide end mill. Ensure it’s sharp and clean. An O-flute or 2-flute designed for plastics is preferred.

- CAM Software: Generate your toolpaths in CAM software (e.g., Fusion 360, Easel, VCarve). Apply the settings discussed:

- Tool: 1/8″ Carbide (1 or 2 flute)

- Spindle Speed: Start around 15,000 RPM

- Feed Rate: Start around 20-30 IPM (adjust based on RPM and chip load)

- Depth of Cut: Start at 0.1″ (2.5mm) or less

- Stepover: 40-50% for pockets, 10-20% for contour passes

- Engraving/Pencil Passes: Consider adding a final shallow finishing pass (e.g., depth 0.01″) with a slow feed rate for a super smooth edge.

- Machine Setup: Ensure your end mill is securely held in the collet. Check that the collet nut is tightened properly according to your machine’s recommendations.

Step 2: Workholding

- Securely clamp your PMMA sheet to the machine bed or a jig. Ensure there are no gaps between the PMMA and the support surface. Place clamps strategically so they don’t interfere with the toolpath.

- If using double-sided tape, ensure the surface is clean and dry for maximum adhesion.

Step 3: Setting the Zero (Origin Point)

- Carefully find the X and Y zero points where your toolpath should start. Use a touch probe, edge finder, or manual methods.

- Set the Z zero. This can be done by touching the top surface of the PMMA, the spoilboard, or by using a Z-probe. Make sure your CAM software zero setting matches your physical setup.

Step 4: The First Cut (Test Cut Recommended!)

- Air Cut: If possible, run your entire program with the spindle OFF, just to watch the toolpath and ensure everything looks correct.

- Shallow Test: Before committing to a full depth, perform a shallow test cut in a non-critical area or a scrap piece. This allows you to verify your feed rate, spindle speed, and listen for any issues.

- Listen and Observe: Start the actual cut. Pay close attention to the sound.

- A clean, consistent whirring or light cutting sound is good.

- High-pitched squealing means the feed rate is likely too slow for the RPM, causing rubbing instead of cutting. Increase