Carbide end mills, especially the 1/8-inch size with a 10mm shank, are your secret weapon for a mirror finish when machining mild steel. They offer precision, speed, and durability, making them essential for achieving professional results even for beginners. Get ready to cut clean, shiny steel!

Working with mild steel can sometimes leave you with rough edges or an uneven surface. It’s a common challenge for many who are new to milling or looking to refine their technique. You might find that your tools aren’t quite cutting as cleanly as you’d hoped, or perhaps you’re spending too much time on post-machining cleanup. Don’t worry, this is a perfectly normal part of the learning curve! The good news is that with the right tool and a few key techniques, you can easily achieve that coveted smooth, almost reflective finish on mild steel. We’re going to dive into the world of the 1/8-inch carbide end mill. This little powerhouse is incredibly versatile and, when used correctly, can unlock amazing precision and surface quality. Stick around, and we’ll walk you through everything you need to know to make mild steel work for you, creating beautiful, clean cuts every time.

Why the 1/8-Inch Carbide End Mill is Your Mild Steel Best Friend

When you’re starting out with milling, especially on a machine like a benchtop mill or a more robust industrial one, choosing the right cutting tool is crucial. For mild steel, the 1/8-inch carbide end mill, often paired with a 10mm shank for stability, stands out for several compelling reasons. It’s not just about the size; it’s about what carbide brings to the table, and how that 1/8-inch diameter lets you tackle intricate work and achieve superior finishes.

The Magic of Carbide

Carbide, short for tungsten carbide, is a composite material renowned for its extreme hardness and heat resistance. This makes it an excellent choice for cutting metals like mild steel, which can be tough on softer tools. Unlike High-Speed Steel (HSS) cutters, carbide tools can:

- Cut at much higher speeds without dulling quickly.

- Withstand higher temperatures generated during machining.

- Maintain their sharpness for longer, providing more consistent results.

- Offer a superior finish on many materials, including mild steel.

Small Diameter, Big Advantages

The 1/8-inch (approximately 3.175mm) diameter of this end mill might seem small, but it offers significant advantages, especially for beginners and those aiming for detailed work or a mirror finish:

- Intricate Detail: This size is perfect for cutting fine grooves, small slots, and detailed profiles that larger end mills simply can’t achieve.

- Reduced Cutting Forces: Smaller diameter tools generally require less force to cut, which is beneficial for less rigid machines and helps prevent deflection, leading to more accurate parts.

- Surface Finish Potential: A smaller diameter, when used with appropriate feeds and speeds, can often produce a smoother surface finish. It takes smaller, more controlled “bites” out of the material.

- Material Removal for Fine Work: While not for hogging out large amounts of material, it’s ideal for the finishing passes that refine your part’s surface and dimensions.

The 10mm Shank: Stability Matters

The 10mm shank is a common size that provides a good balance of rigidity and compatibility with many collet systems on milling machines. A larger shank diameter (compared to a 1/8-inch shank) generally means:

- Increased Rigidity: It’s less prone to vibration and deflection, which is critical for maintaining accuracy and achieving a good surface finish, especially with smaller diameter tools.

- Secure Clamping: A larger shank provides more surface area for the collet to grip, ensuring the end mill stays firmly in place during operation.

When you combine the hardness and heat resistance of carbide with the precision a 1/8-inch diameter offers, and then secure it with a robust 10mm shank, you have a tool perfectly engineered for achieving that sought-after mirror finish on mild steel.

Choosing Your 1/8-Inch Carbide End Mill: What to Look For

Not all 1/8-inch carbide end mills are created equal. To ensure you get the best results and a true mirror finish on your mild steel projects, consider these important features:

Number of Flutes

The flutes are the helical cutting edges on the end mill. For milling mild steel and aiming for a premium finish, the number of flutes is a critical consideration.

- 2 Flutes: Excellent for slotting and general milling. They offer good chip clearance, which is vital when cutting softer metals like mild steel that can produce long, stringy chips. The fewer flutes also mean larger chip gullets, helping to prevent chip recutting and overheating. For a mirror finish, 2-flute end mills are often favored because they can be run at higher speeds and potentially lower chip loads than 4-flute cutters, leading to a smoother cut.

- 4 Flutes: Better for finishing operations where a very smooth surface is desired and chip evacuation is less of a concern, or when using flood coolant. The multiple flutes provide more cutting edges, which can lead to a finer surface finish if chip evacuation is managed properly. For high-quality finishing passes on mild steel, especially with good coolant, 4-flute can also be very effective.

Recommendation for Mirror Finish on Mild Steel: Start with a 2-flute end mill. They generally offer superior chip evacuation for mild steel and can be run at speeds conducive to a good finish without packing chips. If you have excellent coolant delivery, a 4-flute can also achieve a great finish.

Coating

Coatings on end mills are like armor for the cutting edges. They improve performance, longevity, and surface finish.

- Bright (Uncoated): Often used for softer metals and plastics where adhesion and heat build-up are less of an issue. While common, they won’t offer the same benefits as coated options for high-performance steel milling.

- AlTiN (Aluminum Titanium Nitride): A very popular and versatile coating. It’s excellent for high-temperature applications and provides good wear resistance, making it a solid choice for machining steels.

- TiN (Titanium Nitride): A more traditional gold-colored coating. It offers good lubricity and wear resistance, extending tool life and improving chip flow. It’s a good all-around choice for mild steel.

- ZrN (Zirconium Nitride): Offers good lubricity and is excellent for stainless steels and nickel alloys, but also performs well on mild steel.

Recommendation for Mirror Finish on Mild Steel: Look for an AlTiN or TiN coated 1/8-inch carbide end mill. These coatings enhance lubricity and heat resistance, crucial for achieving a smooth, chip-free cut on mild steel and preventing built-up edge.

End Mill Geometry

The shape of the tip and the helix angle also matter.

- Square End: The most common type. Ideal for general milling, slotting, and creating square corners. For a mirror finish, you’ll be relying on light finishing passes.

- Corner Radius: A slight radius on the tip can add strength to the cutting edge and help prevent chipping. It also creates a slightly rounded corner in your machined features, which can be desirable.

- Helix Angle: A higher helix angle (e.g., 30-45 degrees) generally provides a smoother cut and better chip evacuation, which is excellent for mild steel. Lower helix angles (e.g., 20 degrees) can be more robust but might produce a slightly rougher surface.

Recommendation for Mirror Finish on Mild Steel: A standard square 1/8-inch carbide end mill with a 30-45 degree helix angle is a great starting point.

Material Compatibility

Always double-check that the end mill is specifically designed or recommended for machining mild steel. While carbide is versatile, some end mills are optimized for specific material groups.

By considering these factors—flute count, coating, geometry, and material suitability—you can select a 1/8-inch carbide end mill that will perform exceptionally well on mild steel and help you achieve that elusive mirror finish.

Setting Up for Success: Machine and Workpiece Preparation

Before you even touch the start button, a few crucial setup steps will dramatically improve your results and ensure safety. Think of this as laying the foundation for a perfect cut.

Securing the Workpiece

A solid grip on your workpiece is non-negotiable. Any movement or vibration during the cut will ruin your finish and can be dangerous.

- Use a Vise: A sturdy milling vise is your best friend. Ensure the vise jaws are clean and have good contact with the workpiece. For best results, use parallels under the workpiece so the vise jaws clamp on the sides, keeping the top surface accessible and clear for milling.

- Clamping: For larger or irregularly shaped parts, consider using T-nuts and clamps directly on the machine table. Ensure there are no gaps under the workpiece where chips could accumulate and cause lifting.

- Alignment: For critical dimensions, consider indicating the workpiece square to the machine’s axes. This ensures your cuts are straight and true.

Tool Holder and Collet

The connection between the spindle and the end mill is vital.

- Collet Chuck: Using a high-quality collet chuck (like a qualidade ER collet system with a 10mm collet) is highly recommended. This provides the most concentric and rigid grip on the end mill shank.

- Cleanliness: Ensure the collet, collet nut, and the end mill shank are perfectly clean and free of oil, chips, or debris. Contamination can lead to runout (wobble), poor finish, and tool breakage.

- Proper Tightening: Tighten the collet nut firmly according to the manufacturer’s recommendations. Over-tightening can damage the collet, while under-tightening is a recipe for disaster.

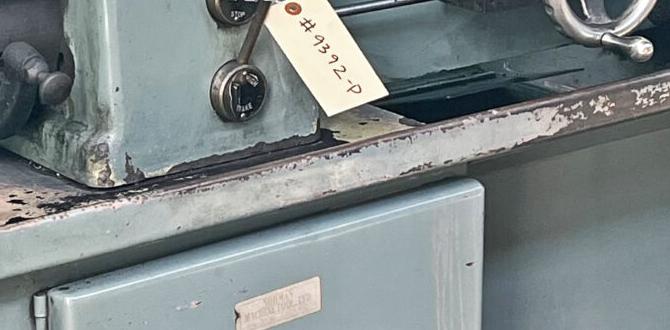

Machine Spindle Check

A quick check of your milling machine’s spindle can save a headache later.

- Runout: If you have an indicator, check the spindle runout with a precision test bar or gauge pin. Minimal runout (ideally less than 0.0005 inches or 0.01mm) is essential for a good finish.

- Bearings: Listen for any unusual noises from the spindle bearings. They should run smoothly and quietly.

Lubrication and Coolant

Mild steel can generate a lot of heat and produce sticky chips. Proper lubrication and cooling are key to a good finish and tool life.

- Cutting Fluid: Use a good quality cutting fluid or mist coolant. This does several things:

- Cools the cutting edge, preventing premature tool wear and reducing the risk of the workpiece expanding.

- Lubricates the interface between the tool and the workpiece, reducing friction and allowing for a cleaner cut.

- Helps to evacuate chips away from the cutting zone, preventing them from being recut.

- Application: A spray mist system or a flood coolant system is ideal. For very light operations, a brush-on cutting fluid or even a cutting paste can be used, but ensure the tool and workpiece are adequately lubricated.

- Chip Evacuation: For light cuts, you might need to periodically retract the tool and clear chips manually with a brush or compressed air (wear eye protection!).

With your work securely clamped, your tool holder clean and ready, and a means for cooling and lubrication in place, you’re well on your way to achieving that professional mirror finish on mild steel.

Feeds and Speeds: The Golden Ratio for Mild Steel

This is often the trickiest part for beginners, but it doesn’t need to be. Finding the right balance of cutting speed (how fast the spindle rotates) and feed rate (how fast the tool moves through the material) is crucial for any machining operation, especially when aiming for a superior surface finish on mild steel with a 1/8-inch carbide end mill.

Understanding the Basics

- Surface Speed (SFM/SMM): This refers to the speed at which the cutting edge of the tool is moving relative to the workpiece. For carbide tools on mild steel, this is typically much higher than for HSS. A good starting range for 1/8-inch carbide end mills on mild steel is often between 300-600 Surface Feet per Minute (SFM) or 100-200 Surface Meters per Minute (SMM).

- Spindle Speed (RPM): This is what you control on your machine. You calculate it from the Surface Speed using the tool diameter. The formula is:

- RPM = (Surface Speed [SFM] 3.25) / Tool Diameter [inches]

- Or, RPM = (Surface Speed [SMM] 1000) / (Diameter [mm] π)

- Feed Rate (IPM/MM/min): This is how fast you push the tool into the material. It’s often expressed in Inches Per Minute (IPM) or Millimeters per Minute (MM/min). The feed rate determines the chip load.

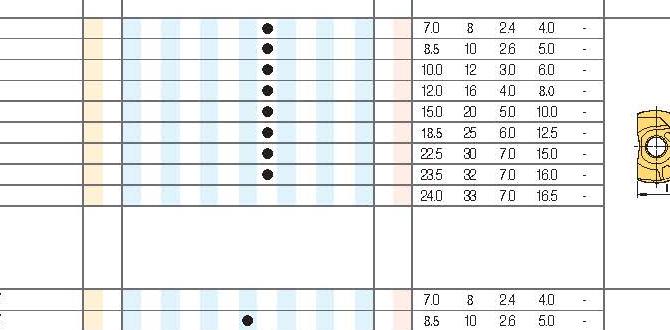

- Chip Load (IPT/MMT): This is the thickness of the chip being removed by each cutting edge (flute) of the end mill. A proper chip load prevents the tool from rubbing, reduces heat, and ensures efficient cutting. For a 1/8-inch carbide end mill, a good starting chip load is typically in the range of 0.001 to 0.003 inches per tooth (IPT) or 0.03 to 0.08 mm per tooth (MMT).

Calculating for Your 1/8-Inch End Mill

Let’s plug in some typical numbers for a 1/8-inch (0.125 inch) carbide end mill on mild steel.

Example Calculation:

Assume we want to use a surface speed of 400 SFM.

- RPM = (400 SFM 3.25) / 0.125 inches = 10400 RPM

This is a very high RPM for many common benchtop mills. This illustrates why understanding your machine’s capabilities is important. Let’s try a lower surface speed that might be more achievable on a wider range of machines, say 300 SFM.

- RPM = (300 SFM 3.25) / 0.125 inches = 7800 RPM

If your machine tops out at 5000 RPM, you’d be using a lower surface speed, which is perfectly fine. The key is to find parameters that your machine can achieve reliably.

Now, let’s consider chip load. For a 2-flute end mill, aiming for a chip load of 0.002 IPT:

- Feed Rate (IPM) = RPM Number of Flutes Chip Load per Tooth

- Feed Rate = 7800 RPM 2 Flutes 0.002 IPT = 31.2 IPM

For a 4-flute end mill with the same RPM and chip load:

- Feed Rate = 7800 RPM 4 Flutes * 0.002 IPT = 62.4 IPM

Key Adjustments for a Mirror Finish

To achieve that smooth, reflective surface, consider these adjustments:

1. Finishing Pass: The absolute key to a mirror finish is a dedicated finishing pass. This is a light cut made after the bulk of the material has been removed.

- Depth of Cut (DOC): Make this very shallow. For finishing, aim for a DOC between 0.002 to 0.005 inches (0.05 to 0.12 mm).

- Stepover: This is the amount the end mill overlaps on each pass across the surface. For a good finish, use a relatively small stepover, typically between 20-50% of the tool diameter. For a 1/8-inch end mill, this would be 0.025 to 0.06 inches (0.63 to 1.5 mm). A smaller stepover means more passes, but a much smoother surface.

- Feed Rate for Finishing: Often, you’ll want to increase your feed rate slightly for finishing. This can help the tool “glide” rather than “shave” the material. A common recommendation is to increase the feed rate by 20-50% for the finishing pass, or to target a chip load at the higher end of the recommended range.

2. Climb Milling vs. Conventional Milling: