Quick Summary: A 1/8 inch carbide end mill is a fantastic tool for achieving high Material Removal Rates (MRR) in many materials, especially when used correctly. This guide will show you how to select, use, and maximize its potential for efficient machining.

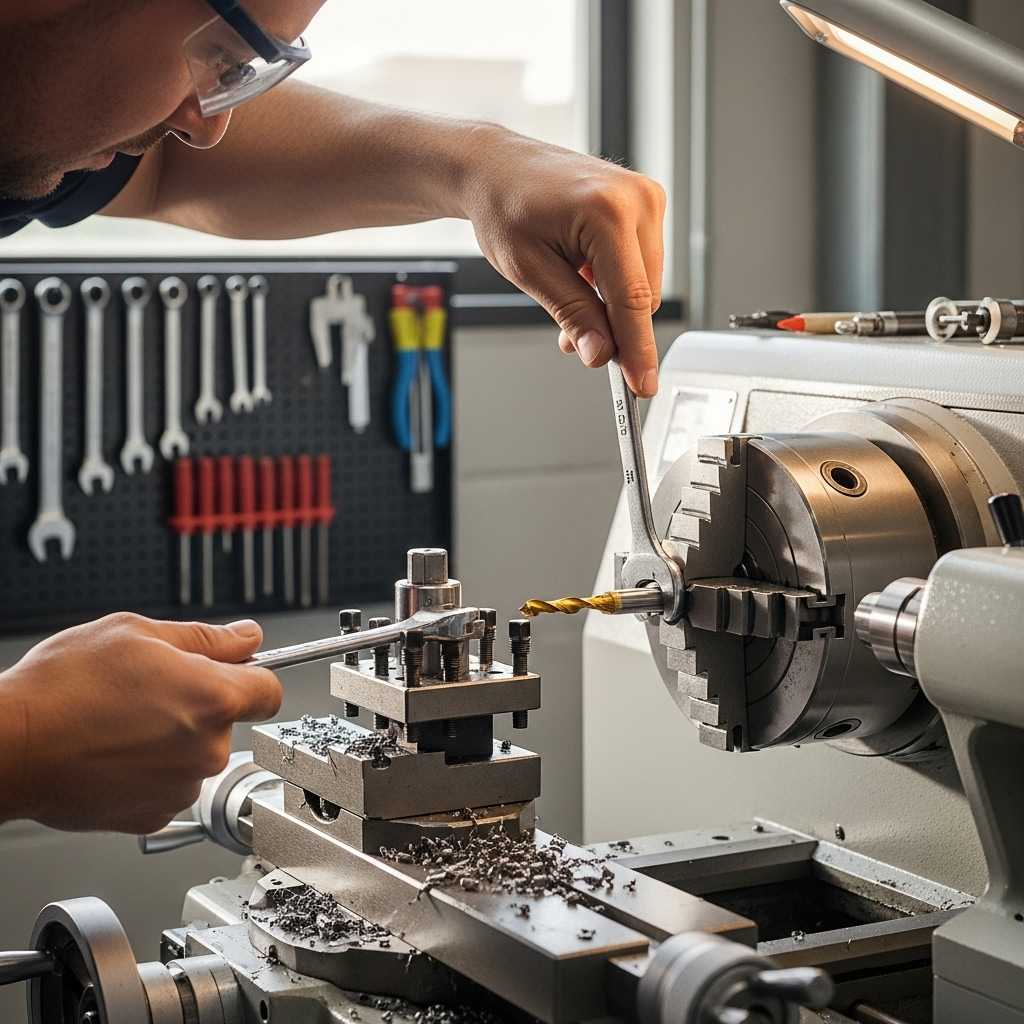

Hey there, fellow makers and machinists! Daniel Bates here from Lathe Hub. Ever feel like you’re wrestling with your milling machine, just inching along when you want to be making real progress? That’s a common feeling, especially when you start dealing with tougher materials or larger cuts. You look at your tools, wondering if there’s a better way. Well, today, we’re going to dive into a small but mighty tool that can make a big difference: the 1/8 inch carbide end mill. We’ll explore how this specific tool, when used right, can significantly boost your Material Removal Rate (MRR) and get your projects done faster and cleaner. Stick around, and let’s unlock its potential together!

Unlock Faster Machining: Your 1/8 Inch Carbide End Mill Guide

When it comes to milling, efficiency is key. We all want to spend less time at the machine and more time enjoying the finished product. The “Material Removal Rate” (MRR) is a fancy term for how much material you can cut away in a given time. Higher MRR means faster work! While giant end mills often get the spotlight for this, even a small 1/8 inch carbide end mill can be a powerhouse for specific tasks. It’s all about choosing the right tool for the job and knowing how to use it to its fullest. Let’s get into what makes this little guy so effective and how you can harness its power.

Why Carbide for Your 1/8 Inch End Mill?

Carbide, specifically tungsten carbide, is a super hard material known for its toughness and ability to withstand high temperatures. Unlike High-Speed Steel (HSS) tools, carbide can cut faster and for longer periods without losing its sharp edge. For a 1/8 inch end mill, this means you can push it harder, take deeper cuts, and achieve that coveted high MRR, even in demanding materials. Think of it as giving your small tool a big punch!

Understanding “High MRR” with Small End Mills

Before we go too deep, let’s clarify what “high MRR” means in the context of a 1/8 inch end mill. It’s not about removing massive chunks like a 1-inch end mill. Instead, it’s about achieving the most efficient material removal possible for its size. This often translates to:

- Taking wider, shallower passes rather than very deep, narrow ones.

- Using the right feed rates and spindle speeds to let the tool work efficiently without overheating or breaking.

- Machining materials where smaller tools are necessary for detail or access, but still wanting to get the job done relatively quickly.

- Achieving a good surface finish along with reasonable cutting speed.

What the “1/8 Inch” and “10mm Shank” Mean

You’ll often see “1/8 inch carbide end mill 10mm shank.” Let’s break that down:

- 1/8 Inch: This refers to the diameter of the cutting flutes – the sharp edges that do the cutting. So, it’s an eighth of an inch across.

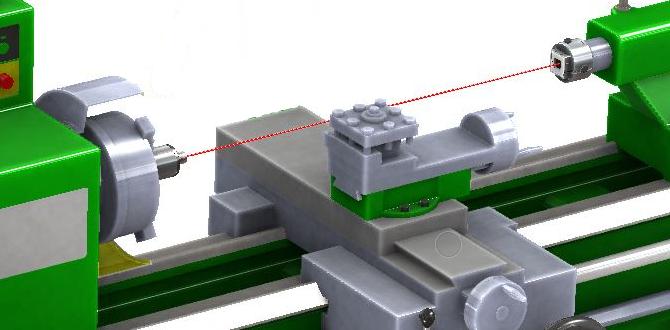

- 10mm Shank: The shank is the part that goes into your tool holder (like a collet chuck or end mill holder). A 10mm shank is a common size for many milling machines, especially smaller ones or those using metric tooling. This dimension is crucial for ensuring your tool holder can grip the end mill securely. A good fit prevents runout (wobble) and ensures accurate cuts.

Having a 10mm shank means you need a tool holder that can accept a 10mm shank. This is a common size, so finding compatible holders shouldn’t be too difficult.

“Standard Length” Considerations

The “standard length” usually refers to the overall length of the end mill. While there isn’t one single “standard,” it generally means it’s not an extra-long or extra-short version. Standard lengths are designed to provide a good balance between reach into a workpiece and rigidity. For a 1/8 inch end mill, standard overall lengths might range from 2 to 4 inches. This length is important for planning your machining setup and ensuring you can reach your target cutting area without needing special extensions.

Choosing the Right 1/8 Inch Carbide End Mill for High MRR

Not all 1/8 inch carbide end mills are created equal when it comes to MRR. Here are key features to look for:

Number of Flutes

This is a big one! The number of cutting edges (flutes) on an end mill directly impacts its cutting performance and chip evacuation capabilities.

- 2-Flute End Mills: These are generally the best choice for high MRR, especially in softer materials like aluminum or plastics. With fewer flutes, there’s more open space between them (larger chip gullets). This allows for larger chip loads and better chip evacuation, preventing chips from clogging up the flutes and causing overheating or tool breakage. They are also good for plunging and slotting.

- 4-Flute End Mills: While great for finishing and machining harder materials where you need more support and a smoother finish, 4-flute end mills have smaller chip gullets. This can limit the chip load and MRR, especially in gummy materials. They generate more heat due to more friction but offer better rigidity and surface finish in demanding applications. For pure MRR in softer metals, 2-flutes often win.

So, for maximizing MRR with a 1/8 inch end mill, a 2-flute design is typically your go-to.

Coating

Coatings add a tough, slick layer to the carbide, increasing its hardness, wear resistance, and heat tolerance. This allows for higher cutting speeds and feeds, directly contributing to higher MRR.

- Uncoated: Basic, good for general-purpose use, and often cheaper. Best suited for non-ferrous materials or lower-duty cycle.

- TiN (Titanium Nitride): A good all-around coating, adds hardness and reduces friction. Good for steels and cast iron.

- TiCN (Titanium Carbonitride): Harder than TiN, good for abrasive materials and higher speeds.

- TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications, especially in steels and superalloys. It forms a protective oxide layer at high heat, extending tool life considerably. This is often a top choice for demanding MRR applications in harder metals.

- ZrN (Zirconium Nitride): Good for aluminum and other non-ferrous metals, providing a slick surface that prevents material buildup.

For maximizing MRR in metals, especially tougher ones, a TiAlN or similar high-performance coating can make a significant difference by allowing you to push the tool harder and faster.

Material and Geometry

- Solid Carbide: This is what you want for strength and heat resistance.

- End Geometry: Most 1/8 inch end mills will have flat ends, suitable for general pocketing and profiling. Ball-nose or corner-radius end mills are for specific shapes and surface finishes.

- Helix Angle: Standard helix angles (around 30-45 degrees) offer a good balance of cutting force and chip evacuation. Steeper helix angles can provide a smoother cut but might deflect more, while shallower angles might pack chips. For high MRR, a moderate to slightly steeper helix can be beneficial.

Machining Inconel 625 with a 1/8 Inch Carbide End Mill (High MRR Focus)

Ah, Inconel 625. This nickel-chromium superalloy is notoriously tough, gummy, and heat-resistant. Machining it is a challenge, and achieving a decent MRR requires careful attention. Using a 1/8 inch carbide end mill for Inconel 625 might seem counterintuitive for high MRR due to the material’s nature and the small tool size. However, for certain detailed work or when restricted by machine capability, it’s possible to optimize for better-than-expected removal rates.

Here’s how to approach it:

- Tool Selection: You absolutely need a high-quality, solid carbide end mill specifically designed for high-temperature alloys. Look for:

- 2 or 3 flutes: While 4 flutes are common for finishing in tougher materials, for maximizing MRR in Inconel with a small diameter, fewer flutes offer better chip clearance. A 3-flute might offer a bit more rigidity than a 2-flute while still clearing chips well enough.

- High-performance coating: TiAlN or advanced AlTiN coatings are essential for handling the heat generated.

- Robust geometry: A strong core and optimized helix angle are crucial to prevent breakage.

- Precise dimensions: A true 1/8 inch diameter with a securely fitting 10mm shank is vital.

- Cutting Parameters (The Crucial Part): This is where you’ll see the biggest impact on MRR. For Inconel 625 with a 1/8 inch end mill, expect these parameters to be conservative compared to softer metals, but optimized for the best possible rate. These are starting points and will require fine-tuning.

| Parameter | Recommendation for 1/8″ Carbide End Mill in Inconel 625 | Notes |

|---|---|---|

| Spindle Speed (RPM) | 2,000 – 4,000 RPM | Lower speeds help manage heat. Higher speeds can increase MRR but risk tool failure if not managed properly. Adjust based on machine power and coolant. |

| Feed Rate (IPM or mm/min) | 0.001 to 0.002 inches per revolution (IPR) / 0.025 to 0.05 mm/rev | This translates to 4-8 IPM (100-200 mm/min) at 2000 RPM. Always aim for a chip load that produces a visible chip, not dust. Feeds and speeds calculators are invaluable here. |

| Depth of Cut (Axial DOC) | 0.020 – 0.050 inches / 0.5 – 1.2 mm | Keep depth of cut relatively shallow. Too deep will overload the small tool. |

| Width of Cut (Radial WOC) | 10% – 30% of diameter (0.012 – 0.036 inches) | For slotting, use a full indicator width (100% WOC with a 2-flute end mill). For pocketing, use lighter radial engagement to reduce cutting forces. “Steep and Shallow” or trochoidal milling strategies can improve MRR significantly while minimizing cutting forces. |

| Coolant/Lubrication | High-pressure Minimum Quantity Lubrication (MQL) or Flood Coolant (oil-based) | Essential for heat management and chip evacuation. Extended reach through-the-tool coolant is ideal if available. |

Key MRR Strategy for Inconel 625: Use high-performance CAD/CAM software with advanced milling strategies. Trochoidal milling (also known as dynamic milling or high-speed milling) is excellent for pocketing. It uses a consistent, light radial engagement and a high axial depth of cut, keeping the cutter engaged in a sweeping motion. This strategy maintains a consistent chip load, reduces heat buildup in one spot, and allows for higher feed rates while respecting the tool’s limits, thereby maximizing MRR.

For more on machining materials like Inconel, resources from organizations like MetalForming Magazine or manufacturers of these alloys often provide valuable insights into best practices.

General Tips for Maximizing MRR with Any 1/8 Inch Carbide End Mill

Whether you’re milling aluminum, steel, or Inconel, these tips will help you get the most out of your 1/8 inch carbide end mill:

- Rigidity is King: Ensure your machine spindle is rigid, your tool holder is high quality (e.g., a good ER collet chuck or hydraulic holder), and the tool is seated correctly. Any flex or runout will significantly reduce your effective MRR and tool life.

- Use Proper Coolant/Lubrication: Whether it’s a spray mist, MQL, or flood coolant, using the right fluid is critical. It cools the cutting zone, lubricates the cut, and helps clear chips. For aluminum, a specific aluminum-cutting fluid or even simple isopropyl alcohol can work wonders. For steel, a dedicated cutting fluid or oil is recommended.

- Chip Evacuation Matters: Always ensure chips can easily exit the flutes. If you’re slotting, take multiple shallow passes rather than one deep one to avoid packing chips. For pocketing, consider climb milling (where appropriate) and ensuring your WOC isn’t too high.

- Feed Rate is Your Friend: Don’t be afraid to push the feed rate, provided you are maintaining a proper chip load. This is the chip thickness per flute. Too low, and you get rubbing and heat; too high, and you risk tool breakage. Listen to the cut!

- Spindle Speed for Heat Management: While higher RPMs can sometimes increase MRR, it also dramatically increases heat. Balance RPM with feed rate to keep the cutting edge from overheating. Carbide can take heat better than HSS, but it’s not invincible.

- Feeds and Speeds Calculators: Use online calculators or software from tool manufacturers (like Guhring, Sandvik Coromant, etc.) as a starting point. However, always be prepared to adjust based on your specific machine, workpiece material condition, and tool wear. MachineryParts.com offers a handy calculator as an example resource.

- Utilize Advanced CAM Strategies: For automated machines, strategies like dynamic milling excel at maintaining consistent chip load and maximizing MRR, especially in pockets and contours. This is often the best way to leverage a small end mill’s MRR potential.

- Tool Length Matters: Use the shortest effective flute length possible. The longer the tool extends from its holder, the more it’s prone to deflection and vibration, reducing your maximum MRR and surface finish quality.

Common Pitfalls to Avoid

Even with the right end mill, mistakes can happen. Here are common pitfalls that hinder MRR:

- Rubbing instead of Cutting: This happens when feed rates are too low. The tool rubs against the material, generating excessive heat and poor chip formation, which kills MRR and tool life.

- Chip Recutting: Chips aren’t clearing properly and get re-cut by the tool. This is a major cause of premature tool failure and dramatically reduces efficiency.

- Overly Deep Cuts: Trying to take too much material at once with a small tool leads to excessive force, deflection, and potential breakage.

- Insufficient Coolant: Not enough cooling leads to rapid tool wear and the potential for the workpiece material to weld to