A 1/8-inch carbide end mill is your secret weapon for precise, dry cutting in various materials like aluminum, plastics, and even some composites. It’s a versatile tool for detailed work and hobbyist projects where a standard mill might be too large or complex to set up for dry machining.

When you’re working on intricate projects, especially with softer metals or plastics, getting the right tool for the job is key. That’s where a 1/8-inch carbide end mill shines, particularly when you need to perform “dry cutting.” This might sound a bit confusing at first – isn’t cutting supposed to involve coolant? Well, for certain materials and specific applications, dry cutting is not only possible but often preferred. It simplifies your setup, reduces mess, and can be just as effective with the right technique and tooling. However, choosing the wrong end mill or pushing it too hard can lead to frustrating results like tool breakage or poor surface finish. Don’t worry, though! In this guide, we’ll break down exactly what you need to know about using a 1/8-inch carbide end mill for essential dry cutting, step-by-step, so you can achieve clean, accurate results with confidence. We’ll cover everything from selecting the right mill to setting your machine and ensuring safe operation.

Why Choose a 1/8-Inch Carbide End Mill for Dry Cutting?

You might be wondering why this specific size and type of tool are so popular for dry cutting. It all comes down to a few key advantages that make it a go-to for many makers and machinists.

Precision and Detail: The 1/8-inch (or sometimes 3mm or 10mm shank for compatibility) diameter is perfect for creating fine details, small slots, pocketing intricate areas, and achieving sharp corners. This size is ideal for tasks that require a high degree of accuracy found in model making, electronics enclosures, or delicate component machining.

Material Versatility: Carbide is a hard and wear-resistant material, making it excellent for cutting a range of materials without coolant. This is particularly true for softer metals like aluminum, brass, and copper, as well as plastics like acrylic, ABS, and polycarbonate. These materials often don’t require a coolant flood to prevent overheating or chip welding when using the correct speeds and feeds.

Simplified Setup (Dry Cutting): What is “dry cutting” exactly? It means performing machining operations without the use of a liquid coolant. For certain materials and with carbide tools, this is perfectly viable. It significantly simplifies your setup: no need for coolant pumps, reservoirs, or dealing with waste coolant disposal. This is a huge advantage for small workshops, home hobbyists, or when working on projects where coolant could damage the workpiece or surrounding equipment.

Carbide Properties: Carbide (tungsten carbide) is much harder than High-Speed Steel (HSS). This hardness allows it to maintain its cutting edge at higher speeds and temperatures, which is crucial for dry machining where heat dissipation relies more on chip evacuation. Its brittleness means it can chip if abused, but when used correctly, it provides excellent tool life.

Cost-Effectiveness for Hobbyists: While carbide tools can be more expensive upfront than HSS, their longer lifespan and ability to perform these specific dry-cutting tasks without additional coolant systems can make them more cost-effective for frequent DIYers and hobbyists.

When is Dry Cutting a Good Option?

Dry cutting is best suited for materials that don’t have a high tendency to “gum up” or stick to the cutting edge, and where thermal expansion isn’t a major concern for dimensional accuracy. Metals like aluminum, copper, and brass are excellent candidates. Many plastics also machine well dry. The key is to manage the heat generated through proper speeds, feeds, and effective chip evacuation.

Selecting Your 1/8-Inch Carbide End Mill

Not all 1/8-inch carbide end mills are created equal. For dry cutting, especially in materials like copper where you might be looking for a “1/8 inch carbide end mill 10mm shank long reach for copper dry cutting” setup, there are specific features to consider.

Key Features to Look For:

Number of Flutes: This refers to the number of cutting edges on the end mill.

2 Flute: These are generally preferred for dry cutting and softer materials like aluminum and plastics. The increased chip clearance helps evacuate chips more effectively, reducing the risk of chip welding and overheating. They often have a center-cutting tip, allowing you to plunge straight into the material.

4 Flute: While often used for harder steels and with coolant, a 4-flute end mill can sometimes be used for dry cutting in materials like aluminum if speeds and feeds are meticulously controlled to manage heat and chip evacuation. However, for beginners focusing on general dry cutting, 2-flutes are usually the safer bet.

Coating: While not strictly essential for every dry cutting task, certain coatings can significantly improve performance and tool life.

Uncoated: Good for general purposes, especially in softer materials.

TiN (Titanium Nitride): A common and cost-effective coating that adds some hardness and lubricity, helping to reduce friction and heat.

AlTiN (Aluminum Titanium Nitride): Offers excellent thermal stability and wear resistance, often preferred for slightly tougher materials or higher temperatures encountered in dry cutting.

Helix Angle: This is the angle of the flutes.

Standard Helix (30°): Suitable for a wide range of materials.

High Helix (45°+): Provides excellent chip evacuation and can reduce cutting forces, making it beneficial for dry cutting softer metals. This is a good option if available.

End Cut Type:

Flat End: The most common type, creating flat bottoms in pockets. Make sure it has a sharp corner radius or is a square end for precise corners.

Center Cutting: Essential if you need to plunge the end mill directly into the material to start a cut, like drilling a hole or creating a pocket from scratch. Most 2-flute end mills for general machining will be center-cutting.

Shank Diameter: You mentioned “10mm shank.” While 1/8 inch refers to the cutting diameter, the shank is the part that grips the collet or tool holder. Ensuring your shank diameter (e.g., 1/8 inch for very small machines, 1/4 inch, or metric sizes like 6mm, 8mm, or 10mm) matches your collet system is crucial for proper clamping. A 10mm shank is common on many CNC machines and can often accommodate a 1/8-inch cutting end.

Reach: For “long reach” applications, you’ll need an end mill with an extended flute length. This allows you to machine deeper pockets or reach features that are further down in your workpiece. Be aware that longer reach tools are more prone to deflection, so rigidity is important.

Example Product Search Term:

If you’re looking online, a good search might be: `”1/8 inch carbide end mill 2 flute 4mm shank aluminum” or `”1/8 inch end mill 10mm shank long reach for copper dry cutting”` to find what you need.

Setting Up for Successful Dry Cutting

Proper setup is paramount for any machining operation, and even more so when you’re omitting coolant. It’s all about managing heat and ensuring the chips get out of the way.

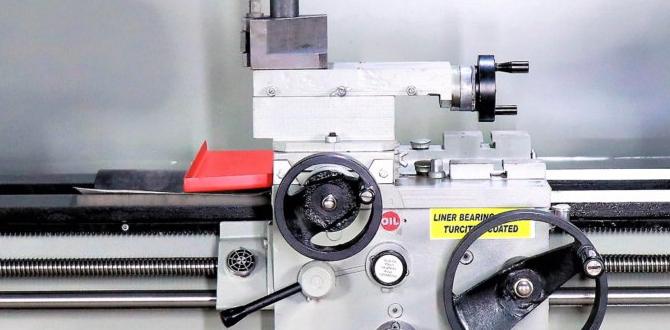

1. Machine Preparation:

Cleanliness is Key: Ensure your milling machine (whether it’s a small desktop CNC, a manual mill, or even a router with an appropriate spindle) is clean. Remove any dust, debris, or old cutting fluids that could interfere with the cut quality or clog chip evacuation.

Rigidity: Make sure your workpiece is securely clamped. Any movement or vibration will drastically reduce the quality of your cut and can lead to tool breakage. Use appropriate vices, clamps, or fixtures.

Spindle/Tool Holder: Install your 1/8-inch carbide end mill into a clean collet or tool holder that fits your machine’s spindle. Ensure it’s seated correctly and tightened securely. A runout indicator can help confirm your tool is spinning true.

2. Understanding Speeds and Feeds:

This is the heart of successful dry cutting. You need to spin the tool fast enough to cut efficiently but slow enough to avoid excessive heat, yet feed it fast enough to create chips that can be cleared.

Spindle Speed (RPM): Carbide generally likes to run faster than HSS. For a 1/8-inch end mill in aluminum or plastic, you might start in the range of 15,000 to 30,000 RPM, depending on your machine’s capabilities and the specific material. Higher speeds help achieve a better surface finish and can sometimes help with chip evacuation if the feed is appropriate.

Feed Rate (IPM – Inches Per Minute or mm/min): This is how fast the tool moves through the material. For small end mills, especially in dry cutting, you want to maintain a consistent chip load. A good starting point for 1/8-inch carbide in aluminum might be between 5 to 15 IPM. For plastics, it could be similar or slightly lower. Always consult manufacturer recommendations for your specific end mill if available.

Chip Load: This is the thickness of the chip being removed by each flute. For a 1/8-inch, 2-flute end mill in aluminum, you’re aiming for a chip load around 0.001 – 0.003 inches per flute. If chips are too small and powdery, you’re not feeding fast enough or spinning too slow (leading to rubbing and heat). If chips are too large, or you hear screaming, you might be feeding too fast or spinning too slow.

Depth of Cut (DOC) and Width of Cut (WOC): For dry cutting with small end mills, conservative depths and widths are crucial.

DOC: Start shallow, perhaps 0.010″ to 0.030″ (0.25mm to 0.75mm), especially when plunging or starting out. You can increase this if the machine and setup are rigid and chip evacuation is good.

WOC: For full slotting (cutting a slot the full diameter of the end mill), use a WOC equal to the end mill diameter (0.125″). For profiling or pocketing, you might use a smaller WOC, like 0.050″ to 0.100″ (1.25mm to 2.5mm), for better control and to reduce side load.

Important Note: Always start with conservative speeds and feeds and make adjustments based on the sound of the cut, the appearance of the chips, and the surface finish. A good rule of thumb is to listen to the machine and the tool; it will often tell you if something isn’t right.

3. Chip Evacuation:

This is your primary cooling mechanism in dry cutting.

Air Blast: Using a directed stream of compressed air can help blow chips away from the cutting zone and cool the area slightly. This is very common on CNC machines.

Vacuum: A shop vacuum positioned to suck chips away from the cutting zone can also be effective, especially for lighter materials like plastic.

Peck Drilling/Clearing Cycles: For pockets or deep features, program “peck” moves. This involves plunging in a small amount, retracting to clear chips, and then continuing to plunge. This is vital to prevent chips from packing up.

Clearing Passes: For pockets, make an initial pass with a 100% WOC (slotting) to clear out the bulk, then subsequent passes with less WOC to finish the walls.

Tooling Considerations for Specific Materials:

Aluminum: Aluminum is prone to chip welding. Use a high helix angle, 2-flute end mill with good chip clearance. Keep speeds and feeds dialed in to create a continuous chip. Sometimes a tiny bit of isopropyl alcohol can be misted on (very sparingly!) but for true dry cutting, focus on speed, feed, and clearance.

Copper: Similar to aluminum but can be “gummy.” Use a sharp, 2-flute end mill. High RPM and a moderate feed rate are key for small chip loads. A good quality uncoated or TiN coated end mill is usually sufficient.

Plastics (Acrylic, ABS, Polycarbonate): These can melt if too much heat is generated due to a slow feed rate or rubbing. Single-flute or two-flute end mills designed for plastics are ideal. High RPMs and relatively aggressive feed rates (to create a proper chip and avoid melting) are often used. Always test on scrap first!

Step-by-Step: Performing a Dry Cut with Your 1/8-Inch Carbide End Mill

Let’s walk through a typical operation, like cutting out a profile from a piece of aluminum.

Step 1: Design and CAM Programming

1. Create Your Design: Use your CAD software to create the 2D profile or 3D model you want to machine.

2. Generate Toolpaths (CAM): In your CAM software (like Fusion 360, Vectric, etc.), select your 1/8-inch end mill.

Choose the appropriate operation (e.g., Pocket, Profile, Contouring).

Input your material type (e.g., Aluminum, Plastic).

Enter your desired spindle speed (e.g., 24,000 RPM).

Enter your feed rate based on recommendations or calculations (e.g., 10 IPM).

Set your Depth of Cut (e.g., 0.020″ per pass).

Set your Width of Cut (e.g., 0.100″ for profiling, or 0.125″ for slotting).

Enable chip-thinning if your software supports it, which adjusts feed rate for small DOC/WOC.

Ensure your toolpath strategy includes lead/lag moves suitable for profiling and chip clearance moves for pockets (like helical ramping if possible, or multiple plunge/retract cycles).

Step 2: Machine and Workpiece Setup

1. Secure the Workpiece: Clamp your material firmly to the machine bed. Ensure you have enough material for your part plus a small margin.

2. Set Z-Zero: Accurately set your Z-zero point. This is usually the top surface of your material. Use a touch probe, edge finder, or an indicator.

3. Set X/Y Zero: Define your starting point for the toolpath in the X and Y axes. This is often a corner of your material or a specific datum point.

Step 3: Pre-Run Checks

1. Air Cut (Highly Recommended!): Before cutting material, run your entire program with the spindle OFF. Watch the tool move through the air to ensure the toolpaths are correct and there are no unexpected collisions.

2. Spindle Check: Turn the spindle ON and let it come up to speed. Listen for any odd noises.

3. Air Blast/Vacuum: Ensure your chip evacuation system is active and positioned correctly.

Step 4: The First Cut

1. Engage Toolpath: Start the machining program.

2. Monitor Closely: ESPECIALLY for the first few passes.

Listen: Does it sound like it’s cutting smoothly, or is it chattering, screaming, or rubbing?

Watch Chips: Are they coming off as small, powdery chips (too fine, rubbing/heating)? Are they long, stringy chips (possible welding)? Or are they well-formed, manageable chips being cleared away?

Look/Feel (Carefully!): Is the tool overheating? Is the workpiece getting excessively hot? (Use caution; a hot workpiece can cause burns). Is the surface finish looking good?

3. Adjust as Needed: If you encounter issues:

Too loud/chattering: Reduce feed rate, or slightly decrease DOC/WOC.

Rubbing/Melting (plastics) / Excessive Heat: Increase feed rate slightly, or increase Z-depth of cut slightly (if the machine is rigid enough), or ensure better chip evacuation.

Poor Surface Finish: Adjust feed rate, or check tool condition. A dull or chipped tool will always produce a poor finish.

Step 5: Completing the Job

Continue Passes: Let the machine complete all the programmed passes.

Final Inspection: Once the job is done, carefully inspect your part. Check dimensions with calipers or a micrometer. Examine the surface finish.

Clean Up: Remove your part, clean the machine, and dispose of chips properly.

Essential Tools and Accessories for Dry Cutting

Beyond the end mill itself, a few other items will make your dry cutting experience much more successful and safer.

Must-Have Items:

Accurate Collets/Tool Holders: A good quality collet set or tool holder system is vital. An arbor or incorrectly sized collet will lead to runout, poor finish, and tool breakage. For a 1/8-inch end mill, you’ll need collets that can hold it securely (e.g., 1/8″ collet, or a metric equivalent if using a 10mm shank that steps down).

Calipers and Micrometers: For accurate measurement of your workpiece and the finished part.

Feeler Gauges or Touch Probe: For precise setting of Z-zero.

End Mill Holder: A dedicated holder can provide better rigidity than a basic collet chuck for some machines.

Safety Glasses: Non-negotiable. Always wear safety glasses when operating any machinery or cutting tools.

Ear Protection: Milling can be noisy.

* Dust Mask or Respirator: When cutting plastics, fine dust can be generated. Even with metals