Get a mirror finish on Peek with a 1/8-inch carbide end mill. Learn the exact settings and tips to achieve a smooth, polished surface every time.

Ever stared at a machined Peek part and wished for that perfectly smooth, almost reflective finish? Getting a “peek finish” can feel a bit like chasing a ghost. It’s frustrating when your milling work looks good but just isn’t quite there. Don’t worry! With the right approach and a few simple tricks, you can achieve that stunning mirror-like sheen on Peek – and it’s more achievable than you might think. This guide will walk you through everything you need to know, from choosing the right tool to setting up your machine for success. Let’s get that perfect shine!

What is Peek and Why is it Tricky to Machine?

PEEK, or Polyetheretherketone, is a high-performance thermoplastic. It’s known for its amazing strength, stiffness, excellent chemical and thermal resistance, and good wear properties. Because of these traits, it’s used in demanding applications like aerospace, automotive, medical devices, and electronics.

However, PEEK can be a bit temperamental at the machining stage. It has a relatively low glass transition temperature (around 140-160°C or 284-320°F) compared to its melting point. This means it can soften and melt easily if too much heat is generated during machining. If it gets too hot, it can melt, smear, and clog your cutting tools, leading to poor surface finish and tool damage. This is why achieving that desired “peek finish” requires careful attention to detail, especially when it comes to heat management and cutting parameters.

Why a 1/8 Inch Carbide End Mill for a Mirror Finish?

When aiming for a mirror finish, especially on a material like PEEK, the tool choice is critical. A 1/8-inch carbide end mill offers several advantages:

- Precision: The small diameter allows for intricate detailing and smooth contours, essential for achieving a uniform reflective surface.

- Carbide Material: Carbide is much harder and more heat-resistant than High-Speed Steel (HSS). This means it can maintain its cutting edge at higher speeds and temperatures, while also reducing tool wear, which is vital for consistent finishing.

- Controlled Chip Load: A smaller diameter, combined with appropriate settings, allows for a very fine chip load. This means the cutter is taking off tiny amounts of material with each pass, which is key to reducing heat buildup and preventing material smearing on PEEK.

- Specific Geometries: Many 1/8″ carbide end mills are designed with high flute counts (e.g., 4 or 6 flutes) and polished flutes. These features help to further reduce friction and evacuate chips efficiently, both crucial for a good finish.

The phrase “peek finish” specifically refers to the highly polished, mirror-like surface often desired on PEEK components. Achieving this isn’t just about the tool; it’s about how you use it. For PEEK, we’re often looking for a specific type of 1/8″ carbide end mill – often a stub length with a polished flute for optimal performance.

Key Considerations for Achieving a Peek Finish

Getting that glassy surface requires a combination of the right end mill, precise machine settings, and good manufacturing practices. Here’s what you need to focus on:

1. Tool Selection

Not all 1/8-inch carbide end mills are created equal for this task. Look for these characteristics:

- Material: Solid carbide is a must for its hardness and heat resistance.

- Flute Count: For finishing PEEK, a higher flute count (4 or 6 flutes) is generally preferred. More flutes mean a smaller chip load for a given feed rate, which translates to less heat and a smoother cut.

- Helix Angle: A 30-degree helix angle is a good all-around choice for finishing. Steeper helix angles (like 45 degrees) can sometimes lead to chatter, while very shallow angles might not provide enough cutting action for PEEK.

- Coatings: While not always necessary for PEEK, some coatings like TiCN (Titanium Carbonitride) can offer a bit of added lubricity and wear resistance. However, for PEEK, a polished, uncoated carbide tool often performs excellently.

- Polished Flutes: This is a significant factor. End mills with polished flutes reduce friction and improve chip evacuation, leading to a cleaner cut and a better surface finish.

- Stub Length: For general finishing and to improve rigidity, a stub length end mill (where the cutting length is closer to the diameter, e.g., 1/4″ to 1/2″ cutting length for a 1/8″ diameter) is often beneficial. Less overhang means less vibration and better tool stability.

- Corner Radius: A sharp corner edge can be prone to chipping. A slight corner radius (e.g., 0.010″ or 0.25mm) can improve tool life and surface finish by preventing edge fraying. For a true mirror finish, a sharp corner might be preferred if you have the rigidity to support it, but a small radius is often more forgiving and easier to manage.

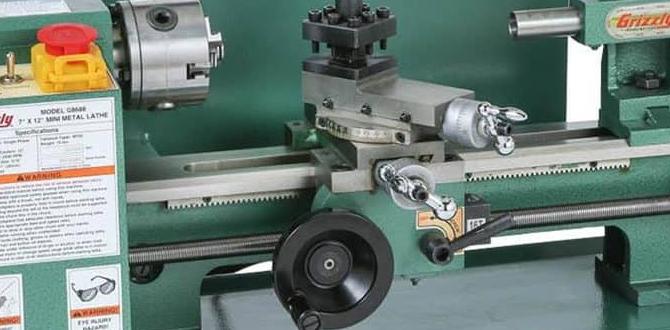

2. Machine Rigidity and Condition

A shaky machine is the enemy of a good finish. Ensure your machine is:

- Rigid: A stiff machine with minimal play in the axes and spindle will prevent chatter and vibration.

- Clean and Well-Lubricated: Proper maintenance ensures smooth operation.

- Spindle Trueness: A spindle that runs true is critical. Any runout will translate into an uneven cut and a poor finish.

3. Cutting Fluid and Lubrication

Proper cooling is paramount when machining ANY plastic, especially PEEK. The goal is to remove heat rapidly without submerging the part in a fluid that could cause swelling or material changes.

- Mist Coolant: A fine mist coolant system is ideal. It provides targeted cooling directly at the cutting zone with minimal fluid. This is far superior to flood coolant for plastics.

- Air Blast: A strong air blast aimed at the cutting area can also help a lot, especially if mist coolant isn’t an option. This helps to cool the workpiece and clear chips.

- Lubricants: Sometimes, a specialized plastic machining spray or a light, dry lubricant can be used. Avoid heavy oils. For PEEK, a high-quality mist coolant is generally the best bet.

You can find excellent mist coolant systems from many industrial suppliers. For example, companies like Engmatic offer a range of systems that can be adapted to most milling machines.

4. Cutting Parameters: The Sweet Spot

This is where the magic happens. Finding the right balance of spindle speed (RPM) and feed rate is crucial. Too fast a feed or too slow a speed generates heat. Too slow a feed or too fast a speed can tear the material or cause chatter.

For a 1/8-inch carbide end mill on PEEK aiming for a mirror finish, you’ll typically use higher spindle speeds and moderate to high feed rates, focusing on a very small chip load. These are starting points, and you’ll likely need to fine-tune them. It’s always better to start on the conservative side and increase.

Recommended Starting Parameters for 1/8″ Carbide End Mill (4-6 Flute, Polished) on PEEK:

| Parameter | Typical Value for PEEK (1/8″ End Mill) | Notes |

|---|---|---|

| Spindle Speed (RPM) | 7,000 – 20,000 RPM | Higher speeds help reduce friction per revolution. |

| Feed Rate (IPM or mm/min) | 15 – 30 IPM (380 – 760 mm/min) | Adjust based on chip load calculation. |

| Chip Load per Tooth (IPT) | 0.0005″ – 0.001″ (0.013 – 0.025 mm) | This is the most critical factor. Keep it small! |

| Axial Depth of Cut (DOC) | 0.010″ – 0.020″ (0.25 – 0.50 mm) | Light passes are key for finishing. |

| Radial Depth of Cut (WOC) | 0.010″ – 0.050″ (0.25 – 1.25 mm) | Consider a light scallop or a full slotting pass with careful feed adjustment. A light finish pass with a small scallop can give a great finish. |

| Cooling | Mist Coolant / Air Blast | Essential for PEEK. |

Calculating Feed Rate from Chip Load: You can calculate your desired feed rate using the formula:

Feed Rate = RPM × Number of Flutes × Chip Load per Tooth

For example, using 10,000 RPM, a 4-flute end mill, and a chip load of 0.001″ IPT:

Feed Rate = 10,000 × 4 × 0.001 = 40 IPM.

This calculated feed rate is a target. You’ll then adjust it based on what the machine is doing – listening to the sound and observing the chips.

5. Finishing Passes

Often, the best way to achieve a mirror finish is with a dedicated finishing pass. After roughing out your part, you might:

- Lighten the Load: Make a final pass with very light axial and radial depths of cut.

- Increase Feed Rate Slightly: Sometimes, a slightly higher feed rate on the finishing pass (while maintaining a low chip load) can help “polish” the surface.

- Reduce Spindle Speed Slightly: Experiment with a slightly lower RPM during the finishing pass if you find the material is heating up too much.

For an absolute mirror finish, especially on curved surfaces, a toolpath that uses a very small step-over (e.g., 1-10% of the tool diameter) and a high feed rate at a light depth of cut is often used. Think of it like painting with a light, sweeping motion.

Step-by-Step Guide to Achieving a Peek Finish with a 1/8″ End Mill

Let’s break down the process into actionable steps:

-

Select Your Tool Wisely:

- Choose a 1/8-inch solid carbide end mill, preferably 4- or 6-flute, with polished flutes and a stub length. A slight corner radius (0.010″) is recommended for PEEK.

- Ensure the tool is sharp and in good condition. A dull or damaged tool will never achieve a mirror finish.

-

Set Up Your Machine:

- Mount your workpiece securely. Use appropriate workholding that won’t deform the PEEK during clamping.

- Check that your spindle runs true.

- Ensure your cooling system (mist coolant is ideal) is ready to go.

-

Determine Your Starting Parameters:

- Consult the table above and your tool manufacturer’s recommendations.

- Calculate your initial feed rate based on your desired chip load per tooth. For a 1/8″ end mill on PEEK, aim for a chip load between 0.0005″ and 0.001″.

- Start with a moderate spindle speed, such as 10,000 RPM.

- Set very light axial and radial depths of cut (e.g., 0.010″ axial, 0.020″ radial).

-

Perform a Test Cut:

- On a scrap piece of PEEK, or an inconspicuous area of your workpiece, perform a light test cut.

- Ensure the mist coolant is flowing correctly during the entire operation.

- Listen to the sound of the cut. It should be a consistent, light “hissing” or “crunching” sound, not a loud shrieking or chattering.

- Observe the chips. They should be small, consistent, and not melting or smearing. If they look like melted plastic, your feed rate is too slow or your spindle speed is too high, generating excessive heat.

-

Adjust and Refine:

-

If the tool is chattering or not cutting cleanly:

- Increase machine rigidity if possible.

- Check for tool holder runout or wear.

- Slow down your spindle speed slightly.

- Keep your depth of cut very light.

-

If the material is smearing or melting:

- Increase your feed rate.

- Ensure adequate cooling.

- You might need to increase your spindle speed slightly if the feed rate can’t go high enough to maintain chip load.

-

If the surface finish is good but not mirrored:

- Consider a lighter radial depth of cut for a finishing pass.

- You may need to increase your feed rate slightly for the finishing pass to “polish” the surface.

- Ensure your tool path is smooth and continuous, avoiding abrupt changes in direction.

-

If the tool is chattering or not cutting cleanly:

-

Execute the Finishing Pass:

- Once you have dialed in the parameters on your test cut, perform the final finishing pass on your actual part.

- Use the lightest possible axial and radial depths of cut. For a true mirror polish, the radial depth of cut (step-over) should be as small as your CAM software allows and your machine’s rigidity can handle (often 1-10% of tool diameter for a high-quality surface finish). The axial depth of cut should be superficial, just enough to remove any slight imperfections.

- Maintain consistent feed and speed throughout the pass.

-

Clean and Inspect:

- Carefully remove the part from the machine.

- Clean it thoroughly to remove any coolant or debris.

- Inspect the surface under good lighting to confirm your mirror finish.

Common Problems and Troubleshooting

Even with the best intentions, you might run into snags. Here’s how to overcome them:

-

Problem: Smearing or Melting of PEEK

- Cause: Excessive heat generated due to low feed rate, high spindle speed, insufficient cooling, or dull tool.

- Solution: Increase feed rate, ensure coolant is applied effectively, use a sharper tool, or slightly reduce spindle speed. Make sure your chip load per tooth is appropriate and not too small for the RPM. For PEEK, you want to get the chips away quickly before they have too much time to transfer heat.

-

Problem: Chatter or Vibration

- Cause: Lack of rigidity in the machine, workpiece, or tool setup. Tool might be dull or have an inappropriate helix angle.

- Solution: Shorten tool overhang, use a stub end mill, improve workholding, reduce spindle speed, lighten the depth of cut, or consider a tool with a different helix angle. Ensure your tool holders are clean and run true.

-

Problem: Surface Finish is Good, But Not Mirrored

- Cause: Insufficient finishing passes, incorrect finishing parameters, or tool wear.

- Solution: Perform a dedicated finishing pass with very light axial and radial depths of cut. Slightly increase feed rate for the finishing pass. Ensure the tool is sharp and use a very small step-over (radial depth of cut).

-

Problem: Tool Wear is Excessive

- Cause: Running too fast, too slow (rubbing), insufficient cooling, or using the wrong type of tool.

- Solution: Experiment with your cutting parameters. Ensure adequate cooling and lubrication. Verify you are using a carbide tool specifically suited for plastics or general purpose.

FAQ: Your Questions Answered

Q