A 1/8 inch carbide end mill is an excellent choice for machining stainless steel, offering precision and durability for achieving a mirror finish, especially when equipped with a 10mm shank.

Working with stainless steel on a milling machine can feel a bit daunting, especially when you’re just starting out. It’s a tough material, and using the wrong tools can lead to frustration, broken bits, and less-than-perfect results. You might find yourself battling chatter, slow progress, or a surface finish that’s anything but smooth. But what if I told you there’s a simple, effective tool that can make a huge difference? That’s where a small but mighty tool like a 1/8 inch carbide end mill comes into play. In this guide, we’ll explore how this specific end mill can be your secret weapon for tackling stainless steel with confidence. Get ready to discover how this little tool can help you achieve amazing results, even in your home workshop.

Why a 1/8 Inch Carbide End Mill Excels with Stainless Steel

Stainless steel is known for its strength and resistance to corrosion, which also makes it a challenge to machine. It’s tough, galls easily (meaning it tends to stick to the cutting tool), and dissipates heat poorly. Traditional high-speed steel (HSS) end mills can struggle with these properties, leading to premature wear, tool breakage, and a poor surface finish. This is where carbide, and specifically a small 1/8 inch carbide end mill, shines.

Carbide is significantly harder and more rigid than HSS. This means it can withstand higher cutting temperatures and pressures, which are common when machining stainless steel. For a 1/8 inch end mill, this hardness is crucial. Even though it’s small, its carbide construction allows it to cut cleanly through tough materials without deforming or overheating as quickly as HSS would. This results in:

- Improved Tool Life: Carbide holds its edge much longer under demanding conditions.

- Faster Cutting Speeds: Its rigidity allows for potentially higher feed rates and spindle speeds, increasing efficiency.

- Better Surface Finish: A sharp, rigid carbide edge cuts cleanly, reducing the likelihood of burrs and a rough surface.

- Reduced Galling: Proper carbide tooling, especially when coated, is less prone to material sticking to its flutes.

The Importance of Shank Size: 10mm Shank Advantages

When we talk about a 1/8 inch carbide end mill, we’re referring to the cutting diameter. But the shank, the part that holds the end mill in the collet or tool holder, is also important. For machining tougher materials like stainless steel, a 10mm shank often provides a significant advantage over smaller shanks, even for a 1/8 inch cutting diameter. Here’s why:

- Increased Rigidity: A larger shank diameter, like 10mm, offers more stability and resistance to bending or deflection. This is especially helpful when dealing with the forces involved in cutting stainless steel.

- Better Torque Transfer: A larger shank can handle more torque without slipping in the collet or tool holder, ensuring consistent cutting action.

- Reduced Runout: A well-secured 10mm shank contributes to lower runout (wobble) of the tool, leading to more accurate cuts and a better finish.

- Compatibility: Many common milling machine collet systems are designed to accommodate standard shank sizes like 10mm, making it readily usable.

While a 1/8 inch end mill’s cutting edge is small, the rigidity provided by a 10mm shank makes it a much more capable tool for stainless steel compared to a similarly sized end mill with, say, a 6mm shank. It’s this combination of a small cutting diameter for fine detail and a robust shank for stability that makes it so effective.

Choosing the Right 1/8 Inch Carbide End Mill for Stainless Steel

Not all carbide end mills are created equal, especially when targeting stainless steel. Here are key features to look for:

Number of Flutes

The number of cutting edges (flutes) on an end mill affects how it cuts and evacuates chips:

- 2 Flutes: Generally preferred for aluminum and softer materials. They offer more chip clearance, which is good for sticky materials.

- 3 Flutes: A good all-rounder. They provide a balance between chip clearance and cutting edge engagement. Suitable for many metals, including some stainless steels, when cutting speeds are managed.

- 4 Flutes: Typically best for harder materials like hardened steels and stainless steels. The extra flute provides more cutting edges for a smoother cut and better heat dissipation, but requires good chip evacuation. For stainless steel, 4 flutes are often recommended for a good balance of performance and tool longevity.

For stainless steel, a 4-flute end mill is often the go-to. It allows for more consistent engagement with the material and helps spread the cutting forces over more edges, which can reduce chatter and improve surface finish when paired with appropriate speeds and feeds.

Coating

Coatings on end mills add a layer of protection, increasing hardness, reducing friction, and improving heat resistance:

- Uncoated: The most basic. Good for softer metals but will wear quickly in stainless steel.

- TiN (Titanium Nitride): A common, general-purpose coating. Adds some hardness and lubricity.

- TiCN (Titanium Carbonitride): Harder than TiN and offers better abrasion resistance. Good for stainless steel.

- AlTiN (Aluminum Titanium Nitride) / TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications and very hard materials like stainless steel. They form a protective oxide layer at high heat. This is often your best bet for stainless steel.

- ZrN (Zirconium Nitride): Offers good lubricity and is often used for non-ferrous metals, but can also perform well on some steels.

For machining stainless steel, a coating like AlTiN or TiAlN is highly recommended. These coatings are designed to handle the high heat generated when cutting stainless steel, providing superior performance and tool life.

Helix Angle

The helix angle is the angle of the flutes along the cutting edge:

- Low Helix Angle (e.g., 30°): B getMaxximum cutting edge engagement, good for harder materials, but can lead to more axial thrust and potential chatter.

- Standard Helix Angle (e.g., 45°): A good balance for general-purpose machining.

- High Helix Angle (e.g., 60°+): Provides smoother cutting action, reduces chatter, and offers better chip evacuation. This is often beneficial for softer materials or when aiming for a superior finish.

While a standard 30-45 degree helix is common, some specialized end mills for stainless steel might feature a variable helix or a higher angle for enhanced performance. For a 1/8 inch dedicated stainless steel bit, look for something offering a good balance of rigidity and chip control, often a standard to moderate helix angle is suitable, but always check manufacturer recommendations.

End Mill Geometry

The shape of the end and the cutting edges matters:

- Square End: Creates sharp 90-degree corners. Ideal for pockets and slots.

- Corner Radius: Often called “ball nose” or “round nose” if the entire end is rounded, or “bull nose” if there’s a small radius at the corner of a square end. A small corner radius can add strength to the cutting edge and help reduce stress risers, leading to longer tool life and a better finish, especially in stainless steel.

- Ball Nose: For creating contours and 3D shapes.

For general milling of stainless steel, a square end mill with a small corner radius (e.g., 0.010″ or 0.25mm) can be a good choice. This radius adds a bit of strength to the cutting edge and can help produce a slightly improved surface finish compared to a perfectly sharp square corner.

Mirror Finish Considerations

Achieving a “mirror finish” with end milling, especially on stainless steel, is a high bar and often requires additional post-processing (like polishing). However, the right end mill minimizes the sanding and polishing required. Look for end mills specifically marketed for high-finish applications. These often have:

- Polished Flutes: Reduce friction and prevent material buildup.

- Precise Tolerances: Ensure a consistent cutting diameter and geometry.

- Specific Geometries: Designed to leave a very smooth surface.

The keyword “mirror finish” in your search usually implies tools designed for precision and surface quality. A high-quality, sharp carbide end mill with a polished flute and potentially an AlTiN coating is your best starting point for this goal.

Essential Tools and Setup for Milling Stainless Steel

Before you even think about cutting, ensure you have the right setup. Milling stainless steel requires more than just a good end mill.

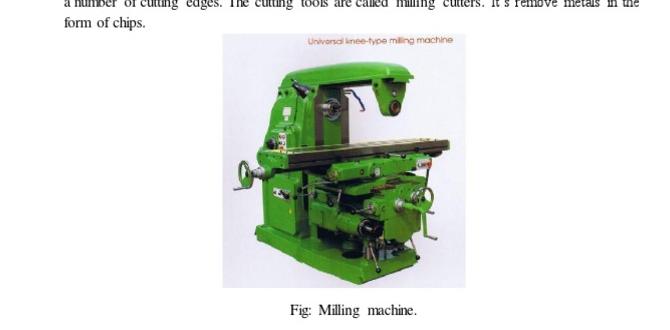

Your Milling Machine

A sturdy, well-maintained milling machine is paramount. For hobbyist use, a benchtop milling machine can work, but it needs to be rigid enough. Ensure:

- No Play: Check for excessive slop in the leadscrews or table ways.

- Good Spindle Taper: A clean and well-fitting spindle taper is crucial.

- Sufficient Power: Stainless steel requires more force to cut.

Workholding

This is critical for safety and accuracy:

- Vise: A robust milling vise securely clamped to the machine table. Use a hardened vise if possible.

- Clamps: If not using a vise, use T-nuts and clamps to firmly secure the workpiece to the table. Ensure all clamping points are solid. Never rely on just one clamp.

- Parallel Stock: If clamping directly to the table, use parallels under your workpiece to lift it for clearance and ensure the vise jaws grip the desired area.

A 1/8 inch end mill is small, so workholding needs to be precise to hold both the workpiece and the tool securely. A small, but very strong, machinist vise is usually the best option.

Collet System

For a 1/8 inch end mill with a 10mm shank, you’ll need a collet system that can grip both sizes accurately. Common setups include:

- R8 Collets: Very common on bridgeport-style mills.

- ER Collets: Extremely versatile and accurate, often used in smaller mills and high-precision machines. You’ll need an ER collet chuck that accepts 10mm shanks and an appropriately sized ER collet for the 1/8″ (3.175mm) shank of the end mill itself, if it had a smaller shank, but since we are specifying a 10mm shank, you need a 10mm end mill holder or a 10mm ER collet. If the shank is 10mm, you would use a 10mm collet to hold the end mill.

- Morse Taper (MT) Holders: Less common for small end mills but possible.

Using the correct size collet and ensuring it’s clean is vital for preventing the end mill from slipping.

Coolant/Lubrication

Stainless steel generates a lot of heat. Proper lubrication is not optional; it’s essential for:

- Cooling: Prevents the tool and workpiece from overheating.

- Lubrication: Reduces friction, which helps prevent galling and improves chip formation.

- Chip Evacuation: Helps wash chips away from the cutting zone.

Suitable lubricants include:

- Cutting Fluid: Specifically formulated for metal cutting.

- Cutting Paste/Stick: Concentrated lubricants that are easy to apply.

- General Purpose Cutting Oil: Can work, but dedicated fluids are usually better.

- Molly-based lubricants: Good for extreme pressure.

For hand-feeding or manual milling, a cutting paste or stick applied directly to the cutting edge is very effective. For CNC applications, a flood coolant system is ideal.

Measuring Tools

Precision is key. You’ll need:

- Calipers: For measuring stock, finished part dimensions, and checking alignment.

- Micrometers: For higher precision measurements.

- Depth Gauge: To accurately set cutting depths.

- Edge Finder: To accurately locate the edge of your workpiece relative to the spindle.

Step-by-Step: Milling Stainless Steel with a 1/8 Inch Carbide End Mill

Now let’s get to the actual machining. Remember, patience and careful setup are your best friends when working with stainless steel.

Step 1: Safety First!**

Before anyone turns a crank or presses a button:

- Eye Protection: Always wear safety glasses or a face shield. Metal chips can fly unexpectedly.

- Appropriate Clothing: No loose clothing, jewelry, or long hair that could get caught.

- Gloves: Wear cut-resistant gloves when handling sharp tools or rough stock, but REMOVE them when operating the machine to avoid getting them caught.

- Understand Your Machine: Know the emergency stop and how to control spindle speed and feed.

Step 2: Prepare the Workpiece

Ensure your stainless steel stock is clean, deburred, and securely held in your vise or fixturing. Check that it’s perfectly square and won’t shift during machining.

Step 3: Mount the End Mill

Clean your collet and the end mill’s 10mm shank. Insert the end mill into the correct collet and then into the collet chuck or tool holder. Tighten securely. Mount the tool holder into your milling machine spindle. If using an R8 spindle, for example, insert the tool holder and tighten the drawbar.

Step 4: Set Zero and Depth

Use an edge finder to accurately locate the desired starting point on your workpiece (e.g., X0, Y0). This is crucial for precise cuts. Then, set your Z-zero. This could be the top surface of your workpiece, or a specific datum. Carefully approach the surface with the end mill until you just feel it touch. Set your Z-axis DRO (Digital Readout) to zero.

If you’re planning to machine a pocket or slot, you’ll need to calculate your cutting depth. Always approach this conservatively. For initial cuts, aiming for a shallower depth than intended is safer.

Step 5: Determine Speeds and Feeds

This is a critical point for stainless steel. Here’s a general guideline for a 1/8 inch carbide end mill in stainless steel, recognizing that specific types of stainless steel and exact tool geometry will vary. Always consult the tool manufacturer’s recommendations if available!

For a general-purpose 1/8 inch, 4-flute carbide end mill (with AlTiN coating, for example) in 304 stainless steel:

- Surface Speed (SFM): Start around 150-250 SFM (Surface Feet per Minute). Convert this to RPM using the formula:

RPM = (SFM 3.82) / Diameter (inches)

For a 1/8 inch (0.125 inch) diameter end mill:

RPM = (200 SFM 3.82) / 0.125 inches = 6112 RPM

So, aim for an RPM in the range of 4,000 – 7,000 RPM, depending on your machine’s capabilities and the specific stainless steel alloy.

- Feed Rate (IPM): Start conservatively. A common starting point for a 1/8 inch carbide end mill in stainless steel is around 0.001 to 0.003 inches per revolution (IPR).

Feed Rate (IPM) = RPM Feed per Revolution (IPR)

Using our example RPM of 6112 and starting with 0.002 IPR:

Feed Rate (IPM) = 6112 0.002 = 12.22 IPM

This translates to about 12 inches per minute. You’ll likely need to adjust this based on how the cut feels and sounds.

Step 6: Apply Lubrication

Before you start the spindle, apply your chosen cutting fluid or paste generously to the area where the end mill will be cutting. Keep it flowing throughout the cut.