CARBIDE END MILL 1/8 INCH: PROVEN INCONEL DRY CUTTING MADE SIMPLE

Cutting tough materials like Inconel with a small 1/8-inch carbide end mill might seem daunting, especially when aiming for dry cuts. This guide will show you the best methods and tips to achieve accurate, frustration-free results. We’ll cover everything from choosing the right tool to setting up your machine safely and effectively, making this challenging task achievable for any home workshop enthusiast.

Mastering the 1/8 Inch Carbide End Mill for Inconel: A Beginner’s Guide to Dry Cutting

Hey there, workshop adventurers! Daniel Bates here from Lathe Hub. Today, we’re tackling something that sounds a bit intimidating but is totally doable: cutting Inconel, a super strong metal, using a small 1/8-inch carbide end mill, and doing it dry. Think of Inconel like the super-durable armor of the metal world – it’s tough to cut! Many beginners get worried about this because Inconel fights back, and a tiny tool like a 1/8-inch end mill needs careful handling. But don’t sweat it! We’re going to break it all down, step-by-step, so you can confidently make precise cuts without needing flood coolant. Get ready to learn the tricks that make this process smooth and successful.

Why is Cutting Inconel So Tricky?

Inconel is a nickel-chromium superalloy known for its incredible strength, resilience, and resistance to high temperatures and corrosion. These amazing properties, which make it perfect for jet engines and other extreme environments, also make it notoriously difficult to machine. It work-hardens quickly, meaning it becomes even tougher the more you try to cut it. This can lead to tools breaking, poor surface finish, and tons of frustration, especially for beginners.

The Role of the 1/8 Inch Carbide End Mill

When we talk about machining, the tool is key. A 1/8-inch carbide end mill is a very small but incredibly precise cutting tool. Carbide is favored for tough materials because it’s harder and can withstand higher temperatures than high-speed steel (HSS). A 1/8-inch size is perfect for intricate details, small parts, or when you need to achieve fine features. For Inconel, using a high-quality, specifically designed carbide end mill is crucial. The “1/8 inch carbide end mill 10mm shank extra long for inconel 718 dry cutting” is a mouthful, but it tells us exactly what we need: a small diameter (1/8 inch), made of strong carbide, often with a larger shank (10mm) for rigidity, an extended length for reach, and designed specifically for dry cutting Inconel 718.

Why “Dry Cutting” Matters

Dry cutting means machining without using any liquid lubricant or coolant. For most softer metals, coolants are essential to keep the tool from overheating and to wash away chips. However, Inconel and specific carbide tools are designed to handle the heat generated during dry cutting, especially at slower speeds and with careful chip evacuation. Dry cutting simplifies your setup – no need for coolant systems, pumps, or mess. It’s often preferred for Inconel because the high temperatures can sometimes be better managed with air cooling alone, and specialized carbide geometries help with this.

Choosing the Right 1/8 Inch Carbide End Mill for Inconel

Not all carbide end mills are created equal, especially when you’re aiming for Inconel. Here’s what to look for:

Key Features to Consider:

- Material: High-quality solid carbide is a must. Look for mills with a high binder content (like 6% cobalt) for added toughness, which helps resist chipping and fracturing.

- Number of Flutes: For Inconel, especially in smaller diameters like 1/8 inch, two-flute end mills are generally preferred for dry cutting. Fewer flutes help evacuate chips more effectively and reduce friction. Four-flute mills can sometimes pack chips in small slots, leading to tool breakage. Elite high-performance mills might use specialized flute counts, but for beginners, two flutes are a safe bet.

- Coatings: While not always necessary for dry cutting, certain coatings can enhance performance. A TiAlN (Titanium Aluminum Nitride) or AlTiN (Aluminum Titanium Nitride) coating can improve heat resistance and lubricity, helping the tool stand up to the demands of Inconel.

- Geometry: Look for end mills designed for high-temp alloys or tougher materials. This often means a more robust cutting edge, a specific helix angle, and sometimes a slight radius or chamfer on the cutting edge to prevent chipping.

- Shank Diameter: As often seen in the “10mm shank” specification, a larger shank diameter relative to the cutting diameter (like 10mm for a 1/8 inch cutter) provides significantly more rigidity. This is crucial for small tools to prevent chatter and deflection, which can quickly lead to tool failure.

- Length: An “extra long” designation means the tool has a longer reach. Be cautious with very long tools at small diameters, as they are more prone to vibration. Ensure your machine’s rigidity can support the tool engagement depth you plan.

Specific Recommendations for Inconel 718:

Inconel 718 is a workhorse in aerospace and other demanding industries. It requires tools that can handle its extreme hardness and tendency to work-harden. For a 1/8 inch end mill on Inconel 718 dry cutting:

- Opt for a 2-flute, solid carbide end mill.

- Consider one with a high-performance coating like TiAlN or AlTiN.

- Ensure it’s specifically marketed for “high-temperature alloys,” “superalloys,” or “difficult-to-machine materials.”

- Look for a tool with a strong, slightly larger shank (e.g., 6mm or 10mm) for better toolholding and rigidity.

Reputable manufacturers often provide specific cutting data recommendations for Inconel. Always check their technical sheets if available. For more information on materials like Inconel, resources like Key to Metals offer comprehensive data on their properties and applications.

Setting Up Your Machine for Success

Even with the perfect tool, your machine setup is critical for successful dry cutting of Inconel with a small end mill.

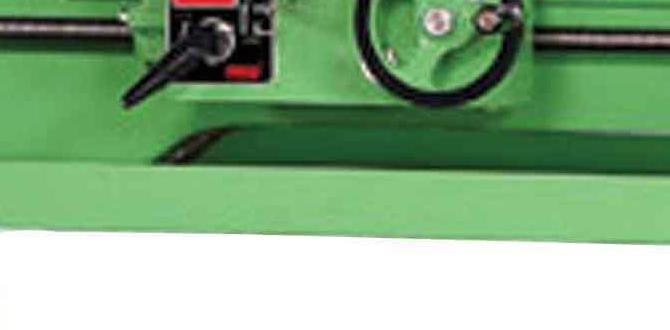

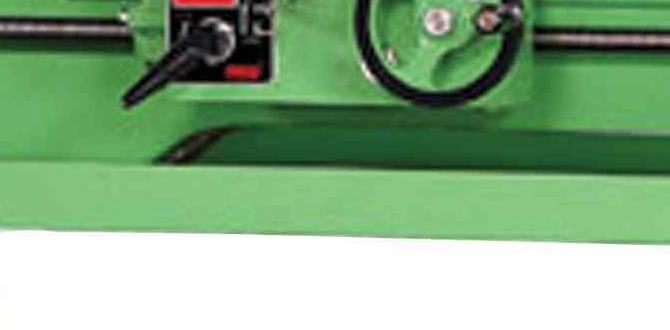

Rigidity is King: Machine and Tool Holding

- Machine Rigidity: A stiff, well-maintained milling machine is essential. Any flex in the machine frame, spindle, or table will be amplified with a small tool and tough material, leading to chatter and breakage. Ensure your machine is properly secured and any play in the axes is minimized.

- Tool Holder: Use the best tool holder you have. A precision collet chuck or a high-quality end mill holder is far superior to a standard drill chuck for milling. A 10mm shank often means using a holder designed for that shank size, providing far better grip and concentricity than a holder for a smaller shank.

- Workholding: Secure your Inconel workpiece VERY firmly. Use robust clamps and ensure the part cannot move or vibrate. A loose part is a recipe for tool failure. If possible, mill towards a positive stop.

Spindle Speed and Feed Rate: The Delicate Balance

This is where most beginners struggle. For Inconel with a 1/8-inch carbide end mill, you’re operating in a zone that requires careful attention to Surface Feet per Minute (SFM) and chip load.

- Surface Feet per Minute (SFM): This is the speed at which the cutting edge of your tool is moving through the material. For carbide cutting Inconel dry, typically you’ll be in the range of 50-200 SFM, but this varies greatly by tool coating, geometry, and the specific Inconel grade.

- Spindle Speed (RPM): This is calculated from SFM and your tool diameter. The formula is:

RPM = (SFM × 12) / (π × Diameter in inches)

So, for a 1/8-inch (0.125 inch) end mill:

RPM = (SFM × 12) / (3.14159 × 0.125)

RPM ≈ SFM × 30.56

For 100 SFM, this would be around 3056 RPM. Start on the lower end of recommended SFM and adjust upwards if you’re not making good chips.

- Chip Load: This is the thickness of the chip being removed by each cutting edge (or flute). For small diameter tools like a 1/8-inch end mill in Inconel, the chip load per tooth is very small, often in the range of 0.0005 to 0.0015 inches per tooth.

- Feed Rate: This is the speed at which the tool advances into the material. It’s calculated from chip load, number of flutes, and spindle RPM:

Feed Rate (IPM) = Chip Load (IPR) × Number of Flutes × RPM

If your Machining calculator gives you Chip Load per Tooth (CLPT), use that directly with the number of flutes. If it gives you Chip Load per Revolution (CLPR), use that. Assuming a 2-flute mill and a chip load of 0.001″ per tooth:

Feed Rate (IPM) = 0.001 × 2 × 3056 ≈ 6.11 IPM

It’s crucial to use a machining calculator or lookup table for these values. Starting too fast on feed rate is a common way to break small end mills.

Chip Evacuation: Keeping It Clean

Without coolant, chips can build up and re-cut, causing excessive heat and tool wear. For dry cutting Inconel:

- Air Blast: Use a powerful air blast directed at the cutting zone. This helps blast chips away and provides some cooling.

- Peck Drilling/Ramping: When plunging (drilling into the material vertically), always use a peck depth. Start with a shallow peck (e.g., 0.010″ to 0.020″) and retract to clear chips. For slotting or pocketing, consider spiraling or ramping into the material rather than plunging straight down whenever possible.

- Tool Path Strategy: Optimize your CAM tool paths to break up long channels of cutting action. If possible, use climb milling, which generally produces better surface finishes and chip control.

Depth of Cut (DOC): Go Slowly!

With a 1/8-inch end mill in Inconel, you cannot take aggressive depths of cut. For dry cutting, especially with a small diameter:

- Radial Depth of Cut (Side Milling): For slotting or pocketing, the radial depth of cut (how much width you take per pass) should typically be no more than half the tool diameter, often less (e.g., 0.030″ to 0.050″ for a 1/8″ tool). You might need several passes to achieve the full width.

- Axial Depth of Cut (Plunging/Slotting): The depth you cut down into the material per pass. For Inconel, this needs to be conservative. Start with very shallow passes, perhaps 0.050″ to 0.100″ depending on your machine’s rigidity and tool holder setup. You might need multiple passes to reach your target depth. Always prioritize tool life and finish over speed.

Step-by-Step: Dry Cutting Inconel with a 1/8 Inch Carbide End Mill

Let’s walk through the process. Imagine you need to mill a small slot in a piece of Inconel 718.

Step 1: Preparation and Safety First

- Read Tool Documentation: If your end mill came with any recommended speeds or feeds, review them.

- Wear PPE: Always wear safety glasses, hearing protection, and appropriate work clothing.

- Secure Workpiece: Clamp the Inconel block _very_ firmly to your milling machine table. Ensure it cannot move.

- Select Correct Tool Holder: Insert your 1/8-inch end mill into a high-quality collet or end mill holder. Ensure the shank is seated correctly and tighten it securely.

- Mount Tool Holder: Insert the tool holder into the spindle.

Step 2: Machine Setup

- Zero Axes: Carefully jog your machine to find the top surface of your Inconel workpiece and one edge. Set your X, Y, and Z zero points in your CNC controller or on your DRO (Digital Readout).

- Program/Set Speeds and Feeds: Based on recommended SFM for Inconel and your tool diameter (e.g., 1/8″ or 0.125″), calculate your spindle RPM. Then, determine your feed rate based on an appropriate chip load per tooth (e.g., 0.001″ per tooth for a 2-flute mill) and your RPM.

- Example: For 100 SFM on a 0.125″ end mill, RPM is ~3056.

- With a 0.001″ CLPT, Feed Rate = 0.001″ x 2 flutes x 3056 RPM = 6.11 IPM.

It’s often better to start with a slightly conservative feed rate (maybe 5-7 IPM) and ramp it up if the cut is too light.

- Set Depth of Cut (DOC): For the first pass, plan a shallow axial DOC (e.g., 0.050″) and a conservative radial DOC (e.g., 0.030″ – no more than 50% of the tool diameter).

- Enable Air Blast: Ensure your air blast system is ready to activate.

Step 3: Performing the Cut

- Jog to Position: Jog the spindle to the planned start of your cut, a few tenths of an inch above the workpiece surface.

- Engage Air Blast: Turn on your air blast.

- Start the Spindle: Bring the spindle up to your programmed RPM.

- Initiate Feed: Carefully feed the end mill into the Inconel. If plunging, use a peck drilling cycle with a very short peck depth and a retraction to clear chips. If approaching from the side or ramping, feed into the material.

- Monitor the Cut: Listen to the sound of the tool. A smooth, consistent hum is good. A high-pitched squeal or uneven chattering indicates a problem (tool rubbing, chatter, or chips building up). Watch the chips – they should be small, consistent, and flying away from the cut. If they are large, stringy, or re-entering the cut, adjust your feed rate, peck depth, or clearance.

- Make Passes: Completing the slot will require multiple passes.

- Axial Passes: After each pass at your set depth, retract the tool, advance to the next depth (e.g., another 0.050″), and repeat the milling process. Always ensure chips are cleared between passes.

- Radial Passes (if slotting wider): After reaching the desired depth, you may need to take multiple side passes to widen the slot to the final dimension. Again, keep radial depth of cut conservative (e.g., 0.030″ to 0.050″).

- Cool Down (Optional but Recommended): For very long cuts or many passes, allow the tool and workpiece brief moments to cool between operations. This helps extend tool life.

- Final Pass: For the final depth pass, consider taking a lighter cut (e.g., 0.020″) with a slightly increased feed rate to improve surface finish.

Step 4: Post-Cut Inspection

- Retract Tool: Once the cut is complete, retract the end mill clear of the workpiece.

- Stop Spindle and Air Blast: Turn off the spindle and air blast.

- Inspect: Examine the cut surface for finish and accuracy. Check the end mill for signs of excessive wear or chipping.