Quick Summary: A 1/8 inch carbide end mill is your Go-To tool for HRC60 steel, offering precision and durability for hardened metal tasks.

Hey there, fellow makers and machinists! Daniel Bates here from Lathe Hub. Ever stared at a piece of tough, hardened steel and wondered how to even begin shaping it in your workshop? You’re not alone. It can feel like trying to carve granite with a butter knife. The good news is, with the right tool, it’s entirely achievable. Today, we’re diving deep into a small but mighty hero of the machining world: the 1/8 inch carbide end mill, especially when you’re tackling materials hitting that tough HRC60 mark. We’ll break down why this specific tool is essential and how to use it effectively, turning those challenging projects into triumphs.

Why Your Workshop Needs a 1/8 Inch Carbide End Mill for HRC60 Steel

When you’re upgrading your machining toolkit, selecting the right cutting tools can feel like a maze. You’ve got different materials, different shapes, and different jobs. For anyone venturing into machining hardened steel, especially those rated at HRC60 (which is quite tough!), one tool stands out: the 1/8 inch carbide end mill. But why this specific size and material for such a demanding task?

Understanding Hardness: What HRC60 Means

First off, let’s quickly touch on HRC60. This refers to the Rockwell Hardness scale, a common way to measure how resistant a material is to scratching or indentation. An HRC60 rating means the steel is very hard. Think of it like this: standard mild steel might be around HRC10-20, while tool steel can push past HRC50. HRC60 is in the realm of high-grade tool steels, often used for applications requiring extreme wear resistance and durability. Machining this without the correct tools is like trying to cut diamonds with a plastic knife – it just won’t work effectively and will likely damage your tools.

Carbide: The Secret Weapon

Now, let’s talk about carbide. Unlike High-Speed Steel (HSS) tools, carbide is a much harder and more brittle material. This might sound like a disadvantage, but in machining, its superior hardness translates to incredible performance, especially on hard metals.

- Heat Resistance: Carbide can withstand much higher temperatures than HSS. When you’re cutting hard materials, friction generates a lot of heat. Carbide doesn’t soften or lose its edge as easily under these conditions.

- Wear Resistance: Because it’s so hard, carbide resists wear significantly better than HSS. This means your cutting edges stay sharp for longer, leading to cleaner cuts and a longer tool life, especially on tough materials like HRC60 steel.

- Rigidity: Carbide is also a more rigid material. This means less flex and vibration during cutting, which is crucial for precision work and preventing tool breakage.

The 1/8 Inch Advantage

So, why a 1/8 inch size specifically? This small diameter offers several key benefits for precision machining and tight spaces:

- Detail Work: A 1/8 inch end mill is perfect for intricate details, small slots, chamfering small edges, or working in confined areas where larger tools simply won’t fit.

- Reduced Cutting Force: Smaller diameter tools require less cutting force. This is important when machining hard materials, as it puts less stress on both the tool and your machine, helping to prevent breakage.

- Accuracy: For fine features and miniature projects, a smaller diameter tool allows for greater control and accuracy.

- Versatility: While small, a 1/8 inch carbide end mill can be used for a range of tasks from light milling to creating small pockets and contours.

When you combine the toughness of carbide with the precision of a 1/8 inch diameter, you get a tool that’s not just capable, but essential for anyone regularly working with or needing to machine HRC60 steel. It’s the perfect tool for detailed work on challenging materials.

Key Features to Look for in a 1/8 Inch Carbide End Mill for HRC60

Not all 1/8 inch carbide end mills are created equal, especially when you’re aiming for the best performance on HRC60 steel. Cutting through hardened materials demands specific features to ensure efficiency, durability, and safety. Here’s what to keep an eye out for:

Material Composition and Coating

As we’ve discussed, carbide is the base material. However, the specific grade of carbide (e.g., Tungsten Carbide) matters. For HRC60 steel, you want a high-performance carbide grade. Beyond that, coatings play a vital role:

- TiN (Titanium Nitride): A very common coating that offers good lubricity, heat resistance, and wear resistance. It adds a golden color to the tool.

- TiCN (Titanium Carbonitride): Offers superior hardness and wear resistance compared to TiN, especially useful for dry machining or higher speeds. Usually has a greyish or purplish hue.

- TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications, making it ideal for cutting hard steels. It forms a protective aluminum oxide layer at high temperatures, providing exceptional thermal stability. This is often black or dark grey.

- DLC (Diamond-Like Carbon): Provides extreme hardness and low friction, excellent for abrasive materials and reducing built-up edge.

For HRC60 steel, a TiAlN or a high-quality TiCN coating is often recommended. Always check the manufacturer’s specifications for the intended application.

Number of Flutes

The flutes are the helical grooves that run along the cutting edge of the end mill. The number of flutes affects chip evacuation and the tool’s ability to cut efficiently.

- 2 Flutes: Generally preferred for milling softer materials and for plunging or slotting. They offer better chip clearance, which is good for preventing chip recutting.

- 3 Flutes: A good all-around choice. They offer a good balance between chip clearance and cutting rigidity.

- 4 Flutes: Provide the most rigidity per diameter and are excellent for finishing passes and for milling harder materials where chip load per tooth is smaller. For HRC60 steel, 4 flutes are often a great choice for stability and a good surface finish.

For milling HRC60 steel, especially with a small 1/8 inch diameter, you will likely find 2 or 4-flute options most effective. 2-flute gives better chip evacuation in deep cuts, while 4-flute offers more rigidity and better surface finish when you’re not going too deep.

End Type

The shape of the cutting end is also important:

- Square End: The most common type. It creates sharp 90-degree corners, ideal for pockets and profiling.

- Ball Nose: Has a hemispherical tip. Used for creating rounded shapes, fillets, and 3D contouring.

- Corner Radius (Bull Nose): A hybrid between square and ball nose, featuring a small radius on the corners. This strengthens the cutting edge and can improve surface finish when cutting corners.

For general-purpose machining of HRC60 steel, a square end mill is highly versatile. If you’re creating fillets or need to avoid sharp internal corners, a ball nose or corner radius end mill would be more appropriate.

Shank Diameter and Length

While the cutting diameter is 1/8 inch, the shank diameter can vary. Common shank sizes for 1/8 inch cutters include:

- 1/8 inch (3.175mm) Shank: Matches the cutting diameter, suitable for very small machines or specific holders.

- 1/4 inch (6.35mm) Shank: A more robust option, offering more rigidity and easier gripping in standard collets and holders.

- 6mm or 8mm Shank: Common metric sizes that offer good rigidity for the tool size.

The length of the end mill (overall length and flute length) is also a consideration. You’ll find standard lengths and “extra long” or “stubby” versions. For most general work on HRC60, a standard flute length is sufficient. If you need to reach into deep pockets or need extra clearance, an extended length might be necessary, but be mindful of increased deflection and vibration.

Manufacturer and Quality

Investing in end mills from reputable manufacturers is crucial. High-quality tools are made with tighter tolerances, better carbide grades, and superior coatings, leading to better performance and longevity. Brands known for precision cutting tools often invest more in R&D and quality control. A quick search might point you towards brands commonly used in professional settings for their reliability.

When shopping, look for descriptions like “for hardened steel,” “HRC60+,” or “high-performance carbide.” These indicators signal that the end mill is engineered for the demanding task ahead.

Essential Setup: What You Need Before You Cut

Before you even think about bringing that 1/8 inch carbide end mill anywhere near your workpiece, a proper setup is absolutely critical. Machining hardened steel is unforgiving, and cutting corners here can lead to broken tools, damaged workpieces, or even safety hazards. Think of this as your pre-flight checklist – it ensures everything is ready for a smooth and successful operation.

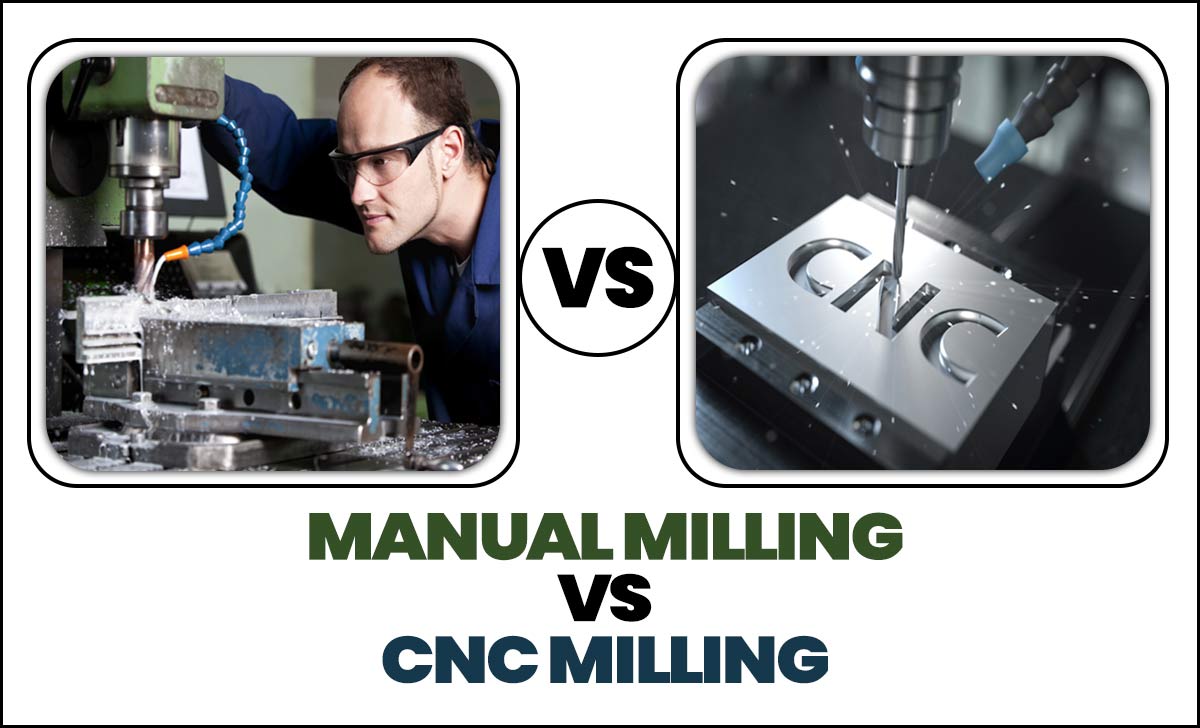

The Milling Machine

You’ll need a milling machine capable of handling the forces involved, even with a small tool. This could be:

- Desktop CNC Mill: Many hobbyists use these. Ensure yours has a rigid frame and a spindle that can accurately hold smaller collets and run at appropriate speeds.

- Benchtop Mill: A more traditional option, offering good rigidity for its size.

- Larger Vertical or Horizontal Mill: If you have access to these, they provide even more power and stability.

Regardless of the machine, ensure it’s properly maintained, with no excessive play in the ways or spindle bearings. A stable machine is your best friend when cutting hard materials.

Spindle and Tool Holding

This is where precision is paramount. You need to securely hold that 1/8 inch end mill.

- Collet System: The best way to hold end mills, especially small ones. A high-quality ER collet chuck or a dedicated end mill holder with the correct size collet (e.g., 1/8 inch or a metric equivalent like 3mm or 3.175mm) is essential. Make sure the collet is clean and properly seated.

- Runout: Minimize runout (the wobble of the tool in the spindle). Excessive runout will lead to chatter, poor surface finish, and premature tool failure. Test your setup if you suspect issues.

Workholding: Securing the HRC60 Steel

Your workpiece needs to be absolutely rock-solid. Any movement will ruin the cut and be dangerous.

- Vise: A sturdy milling vise is the most common method. Ensure the jaws are clean and provide ample grip. For HRC60 steel, consider using hardened vise jaws if you’re doing extensive work, as softer jaws can get damaged.

- Clamps: If a vise isn’t suitable, use toe clamps or strap clamps to secure the workpiece firmly to the machine table. Ensure clamping doesn’t interfere with your desired cutting path.

- Supports: For larger or awkwardly shaped pieces, use parallels or supports under the workpiece to keep it stable and prevent it from rocking.

Coolant or Lubrication

While some carbide end mills are designed for dry machining, using a coolant or lubricant significantly extends tool life, improves surface finish, and helps manage heat when cutting HRC60 steel.

- Flood Coolant: If your machine is equipped, this is ideal. It flushes away chips and cools the cutting zone effectively.

- Mist Coolant: A good alternative, spraying a fine mist of coolant and air directly at the cutting zone.

- Cutting Fluid/Lubricant: For smaller operations, you can manually apply a specialized cutting fluid designed for hard metals. Use a brush or a specialized dispenser. Look for lubricants specifically formulated for steel machining.

Remember to check the manufacturer’s recommendations for the specific end mill and material. Some modern coatings on carbide tools are designed for dry milling, but even then, a little lubrication can help.

Measuring Tools and Safety Gear

Don’t forget the basics:

- Calipers and Micrometers: For accurate measurements of your workpiece and depths of cut.

- Safety Glasses: Non-negotiable. Always wear ANSI-approved safety glasses or a face shield.

- Gloves: Wear appropriate gloves when handling sharp tools and workpieces.

- Hearing Protection: Milling can be loud, especially with harder materials.

Having the right setup ensures you’re working safely and effectively. It prepares you to get the most out of your 1/8 inch carbide end mill when tackling that HRC60 steel.

Step-by-Step Guide: Milling HRC60 Steel with a 1/8 Inch Carbide End Mill

Alright, with your setup ready and your tool chosen, let’s get down to the actual machining. Milling hardened steel like HRC60 requires a methodical approach. We’ll break it down into manageable steps. Remember, patience and precision are key here.

Step 1: Prepare Your Workpiece and Machine

Before you start anything, ensure your HRC60 steel workpiece is securely clamped in the milling vise or by clamps. Double-check that nothing can shift during the cutting process. Make sure your end mill is tightly secured in the collet and the collet is seated correctly in the spindle. Clean any debris from the machine table and your workpiece.

Step 2: Set Your Zero Point (Work Coordinate System)

This is crucial for accuracy, especially with CNC machines. For manual machines, it’s about setting your reference point.

- X and Y Axis: Use an edge finder or a probe to accurately locate the edge of your workpiece for your X and Y zero points. Many machinists prefer to set X0 and Y0 to a specific corner or the center of a feature.

- Z Axis: Carefully bring the end mill down until it just kisses the top surface of your workpiece. Many digital readouts (DROs) have a “go-to” function, or you can use a feeler gauge. Set your Z0 at this point. It’s often a good practice to slightly move past Z0 (just a few thousandths of an inch) so the tool isn’t rubbing on the surface before it starts cutting.

Step 3: Determine Your Cutting Speeds and Feeds

This is one of the most critical parts when machining hardened steel. Using incorrect speeds and feeds can rapidly break your end mill.

- Consult Charts: Always start by checking manufacturer recommendations or using online calculators for carbide end mills on hardened steel. Websites like Machinery & More offer helpful tools.

- Starting Parameters (General Guideline for 1/8″ Carbide on HRC60):

- Spindle Speed (RPM): You’ll generally want to run carbide tools at higher RPMs than HSS, but for hard materials, it might be slightly lower than for softer steels. A good starting point could be anywhere from 5,000 to 15,000 RPM, depending on the rigidity of your setup and the specific end mill.

- Feed Rate (IPM or mm/min): This is the speed at which the tool moves through the material. For a 1/8 inch carbide end mill on HRC60, you’re looking at a relatively low chip load per tooth. This means a slower feed rate. Aim for a chip load of around 0.0005 to 0.001 inch per tooth. If you have a 4-flute end mill, multiply that by 4 for your feed rate per revolution.

- DOC (Depth of Cut – Axial): How deep you cut into the material along the Z-axis. For HRC60 steel, use small depths of cut. Start with perhaps 0.010″ to 0.020″ (0.25mm to 0.5mm).

- WOC (Width of Cut – Radial): How wide a bite you take across the material (e.g., when cutting a slot or pocket). For full slotting (WOC = 1/8″), you might need to be more conservative. For profiling, a WOC of 0.050″ to 0.100″ is often a good starting point.

- Listen and Observe: Your ears are your best tool. If you hear screaming, ch