Tired of that annoying chatter when milling G10 with a 1/8-inch carbide end mill? This guide shows you exactly how to stop it. Learn simple, step-by-step methods to achieve smooth, precise cuts every time, even with tricky materials like G10. Get ready for cleaner finishes and more efficient machining!

Carbide End Mill 1/8 Inch: Proven G10 Chatter Reduction Techniques

Hate that high-pitched whine and vibration when your end mill touches G10? You’re not alone! Chatter is a common frustration for machinists, especially when working with hard, brittle materials like Garolite (commonly known as G10). It leaves rough surfaces, dulls your tools faster, and can even shake your workpiece loose. But don’t worry! With the right approach and a few simple adjustments, you can conquer G10 chatter and achieve beautifully smooth cuts. This article will guide you through proven techniques using a 1/8-inch carbide end mill, transforming your milling experience.

We’ll break down exactly what causes chatter, why it’s so common with G10, and most importantly, how to eliminate it. Get ready to dive into practical, easy-to-follow steps that will boost your confidence and your finished parts.

Understanding Chatter: The Grinding Grin

Imagine your cutting tool vibrating rapidly against the material. That’s pretty much what chatter is. It’s a self-excited vibration that occurs during machining. Think of it like a skipping record – the stylus jumps out of the groove. In milling, when the cutting edge of the end mill engages the workpiece, it attempts to remove material. If the forces involved cause the tool or workpiece to flex, it can snap back, and then engage the material again, but slightly out of sync. This repetitive cycle of engagement and disengagement creates vibration, which we hear and feel as chatter. This uncontrolled vibration leads to:

- Rough Surface Finish: The wavy, uneven surface left behind looks terrible and often requires extra finishing steps.

- Increased Tool Wear: Constant jarring action hammers your cutting edges, significantly shortening the life of your carbide end mill.

- Workpiece Damage: The vibrations can be strong enough to crack brittle materials like G10 or even loosen workholding.

- Noise and Inaccuracy: It’s an unpleasant experience and makes it impossible to achieve precise dimensions.

Why G10 is a Chatter Magnet

G10 is a fantastic material. It’s strong, electrically insulating, and resistant to heat and chemicals. It’s made by layering fiberglass cloth with an epoxy resin. This composition makes it incredibly durable but also quite brittle and abrasive. These properties contribute significantly to chatter:

- Brittleness: Unlike softer metals, G10 doesn’t deform gracefully. It tends to fracture. When a vibrating tool engages brittle G10, it’s more likely to chip away erratically rather than cut a clean chip.

- Abrasiveness: The glass fibers in G10 act like tiny bits of sandpaper against the cutting edge. This friction generates heat and can dull the end mill quickly, exacerbating chatter.

- Resin Hardness: The epoxy matrix that binds the fibers can also be hard and contribute to cutting forces.

When you combine the inherent tendencies of G10 with the dynamics of milling, especially with small tools like a 1/8-inch end mill, chatter becomes a common nemesis. Even a perfectly tuned machine can struggle.

Choosing the Right 1/8-Inch Carbide End Mill for G10

Not all 1/8-inch end mills are created equal, especially when tackling something like G10. You need a tool specifically designed for the job to minimize chatter from the start. When selecting your 1/8-inch carbide end mill for G10, look for these features:

- High-Quality Carbide: This is non-negotiable. Look for solid carbide, ideally with a fine grain structure for better edge retention against abrasive materials.

- Number of Flutes: For G10, you generally want more flutes. While a 2-flute end mill is common for softer materials, a 3-flute or 4-flute end mill can provide a smoother cut on G10. More flutes mean smaller chip load per flute, distributing the cutting force more evenly.

- Coating: Certain coatings like ZrN (Zirconium Nitride) or AlTiN (Aluminum Titanium Nitride) can improve lubricity, reduce friction, and increase tool life, all of which help combat chatter.

- Geometrical Design: Some end mills are specifically designed for composites or plastics. These might have optimized rake angles and sharper edge geometries to shear the material cleanly rather than rub against it.

- Helix Angle: A moderate to high helix angle (often around 30-45 degrees) can help shear the material more effectively and evacuate chips.

The “Extra Long Shank” Consideration

You might see “extra long shank” mentioned. While this can be useful for reaching into deep pockets, for G10 milling with a 1/8-inch end mill, it’s often best to avoid excessively long tools when possible. A longer tool creates a more flexible cutting system (tool stick-out). This increased flexibility is another contributor to chatter because the tool can deflect more easily. For most G10 operations with a 1/8-inch end mill, a standard length or stub-length end mill provides a more rigid setup and is preferable for chatter reduction.

Key Strategies for G10 Chatter Reduction

Once you have the right tool, it’s time to talk about how you use it. Chatter is a symptom of an unstable cutting process. We need to make the process as stable and smooth as possible. Think of it like tuning a guitar – every string (parameter) needs to be just right.

1. Spindle Speed (RPM) – Finding the Sweet Spot

Spindle speed is crucial. Too fast, and you’ll generate excessive heat and potentially rub rather than cut. Too slow, and you might not get proper chip formation, leading to increased vibration. For a 1/8-inch carbide end mill in G10, you’re generally looking for relatively high spindle speeds, but it often requires experimentation.

A good starting point for a 1/8-inch carbide end mill in G10 might be between 15,000 and 25,000 RPM. However, this depends heavily on your specific machine, the end mill’s geometry, and the rigidity of your setup. A general rule for carbide in harder materials is higher speeds but lighter depths of cut.

Tip: Listen to your machine. A high-pitched squeal often indicates it’s too fast. A chattering, vibrating sound means it’s likely misaligned with your feed rate.

2. Feed Rate – The Gentle Approach

Feed rate is how fast the tool moves through the material. This is often the most impactful parameter for chatter. You want a feed rate that allows the end mill to take a proper chip without being overloaded or taking too shallow a bite.

A common mistake is feeding too slowly. When you feed too slowly, the end mill will rub the material for an extended period before taking a substantial chip. This rubbing generates heat and can cause burrs and a poor finish. You’re looking for a feed rate that creates a consistent, fine chip.

For a 1/8-inch carbide end mill in G10, a good starting point for feed rate might be in the range of 10-30 inches per minute (IPM). This is a VERY general starting point. A more precise way to think about it is Chip Load.

Understanding Chip Load

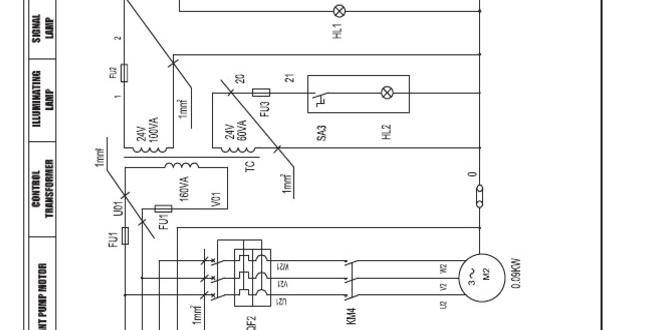

Chip load is the thickness of the material removed by each cutting edge of the end mill per revolution. A typical target chip load for a 1/8-inch carbide end mill in G10 might be between 0.001 to 0.003 inches per flute. You can calculate your desired feed rate using this formula:

Feed Rate (IPM) = Spindle Speed (RPM) × Number of Flutes × Chip Load (inches/flute)

Example:

- Spindle Speed: 20,000 RPM

- Number of Flutes: 3

- Chip Load: 0.002 inches/flute

- Feed Rate = 20,000 × 3 × 0.002 = 120 IPM

This calculated feed rate is your starting point. You might need to adjust it up or down based on the sound and vibration you experience.

3. Depth of Cut (DOC) – Go Shallow, Go Smooth

Depth of cut refers to how deep the end mill plunges into the material. For hard and brittle materials like G10, and especially when using smaller end mills, shallow depths of cut are essential to reduce cutting forces and prevent chatter.

Trying to mill G10 with a 1/8-inch end mill at a 1/4-inch depth of cut is a recipe for disaster. You’ll likely experience excessive chatter, tool breakage, or material cracking.

General Guidelines for Depth of Cut with a 1/8-inch Carbide End Mill in G10:

- Slotting (Full Width): Start with a DOC of no more than 0.020″ to 0.050″.

- Contouring/Profiling: Start with a DOC of no more than 0.050″ to 0.100″.

- Finishing Passes: For a final, clean pass, a very shallow DOC (e.g., 0.005″ to 0.010″) can greatly improve surface finish after an initial heavier cut.

Remember, it’s always better to take multiple shallow passes than one deep, problematic pass. This also helps with chip evacuation.

4. Stepover – How Much to Cut Sideways

Stepover is the distance the tool moves sideways for each pass when milling a larger area (like clearing out a pocket or profiling a larger shape). A large stepover means the end mill is taking aggressive cuts sideways, increasing the load and the likelihood of chatter.

For G10, you’ll generally want a smaller stepover to ensure a smoother finish and less chatter. For finishing passes or when chatter is a persistent issue, a stepover of 20-40% of the tool diameter (i.e., 0.025″ to 0.050″ for a 1/8″ tool) is a good starting point.

For roughing, you might be able to push this closer to 50%, but always monitor for chatter.

5. Workholding – Rock-Solid Stability

Your workpiece needs to be held as rigidly as possible. Any movement or vibration in your vise, clamps, or fixture will directly translate into milling chatter. G10 can be unforgiving, and a loose part can easily get damaged.

- Use the Right Vise: Ensure your milling vise is in good condition, with no excessive play.

- Clamping Technique: Clamp G10 on its strongest areas, avoiding areas where you’ll be milling. Use appropriate clamping pressure – enough to hold it firm but not so much that you crack the material. Consider using soft jaws for G10 if its surface finish is critical.

- Support: For larger or thinner pieces of G10, consider using support blocks or a vacuum table if available to prevent flex.

- Clean Surfaces: Ensure the mating surfaces between the workpiece, vise jaws, and machine table are clean and free of chips or debris.

A vibrating workpiece is just as bad as a vibrating tool!

6. Tool Stick-Out – Short and Sweet

The distance the end mill extends from the collet or tool holder (tool stick-out) is a major factor in rigidity. The more stick-out, the more the tool can vibrate and deflect. For milling G10 with a 1/8-inch end mill, minimize your tool stick-out as much as possible while still allowing you to achieve the necessary cut depth. Ideally, aim for a stick-out just slightly longer than your desired depth of cut.

This is where opting for a standard length or stub-length end mill over an “extra long” one pays dividends for chatter reduction in this specific application.

7. Climb Milling vs. Conventional Milling

This is a critical distinction for G10 and chatter:

- Conventional Milling: The cutter rotates against the direction of feed. This tends to lift the material and can cause rubbing, especially on harder materials. It’s often more prone to chatter in these scenarios.

- Climb Milling: The cutter rotates in the same direction as the feed. The cutting edge engages the material at its thickest point and effectively “climbs” over it. This results in a cleaner cut, better chip formation, and significantly reduced chatter, particularly on G10.

Recommendation for G10: Always aim to use climb milling whenever your CAM software or manual milling strategy allows. You’ll notice a dramatic improvement in cut quality and a reduction in chatter.

Important Note: Climb milling requires backlash-free movement in your machine’s axes. Older manual machines with worn leadscrews might not be suitable for effective climb milling without modifications or careful backlash compensation. If you’re unsure, stick to conventional milling and focus on other parameters.

8. Air Blast and Chip Evacuation – Keep it Clean

G10 produces fine, abrasive dust. If this dust isn’t cleared away from the cutting zone, it can get recut, leading to increased friction, tool wear, and chatter. An effective air blast directed at the cutting zone is essential.

Proper chip evacuation also helps prevent heat buildup. For G10, you want to ensure chips aren’t packing up around the end mill flutes. This is particularly important when slotting.

For inspiration on shop-made solutions for air blast systems, check out resources on industrial dust collection and air assist setups from organizations like the National Institute for Occupational Safety and Health (NIOSH) (www.cdc.gov/niosh/topics/dust), which offers guidance on controlling airborne contaminants in industrial settings, relevant to fine dust.

9. Coolant/Lubrication – A Slick Defense

While not always strictly necessary for G10 (especially if you’re using a good coating and managing speeds/feeds well), a mist coolant or a bit of cutting fluid can help reduce friction, dissipate heat, and improve chip formation. This can make a noticeable difference in reducing chatter and extending tool life.

For G10, flood coolant isn’t typically required. A spray mist system or even a simple brush-on lubricant like a wax stick can provide enough lubrication for a cleaner cut. Avoid excessive coolant if it can cause issues with your machine or the G10 itself (e.g., potential for delamination if coolant soaks in excessively without proper support).

10. Material Quality and Preparation

Sometimes, G10 itself can be problematic. Inconsistent resin content, voids, or delamination issues within the material can cause unpredictable cutting forces and lead to chatter, even with perfect machine setup.

If you’re consistently getting chatter on multiple identical pieces, consider if there’s an issue with your G10 stock. Visually inspect both sides for any obvious flaws before you start.

Practical Steps: Milling G10 with a 1/8-Inch Carbide End Mill

Let’s put it all together:

Step 1: Machine Setup and Workholding

- Ensure your milling machine is clean and well-maintained.

- Securely clamp your G10 workpiece in a rigid vise, ensuring it’s flat and stable.

- Select your 1/8-inch, 3 or 4-flute carbide end mill. For G10, a specialized composite end mill or one with a high-performance coating like AlTiN is ideal.

- Install the end mill in your collet and ensure it’s seated properly.

- Set tool stick-out to be the minimum necessary for your cut depth (e.g., 1/2″ reach for a 3/8″ depth of cut).

Step 2: Setting Machining Parameters (Example for a typical CNC Mill)

These are starting points. Adjust based on your observations.

| Parameter | Setting for G10 Milling (1/8″ 3-Flute Carbide) | Notes |

|---|---|---|

| Spindle Speed (RPM) | 20,000 RPM | Listen for any high harmonics.

|