A 1/8 inch carbide end mill with a 3/8 inch shank, especially one with a reduced neck, is a brilliant solution for precise cuts, particularly in softer metals like brass, helping to significantly reduce chatter and improve surface finish.

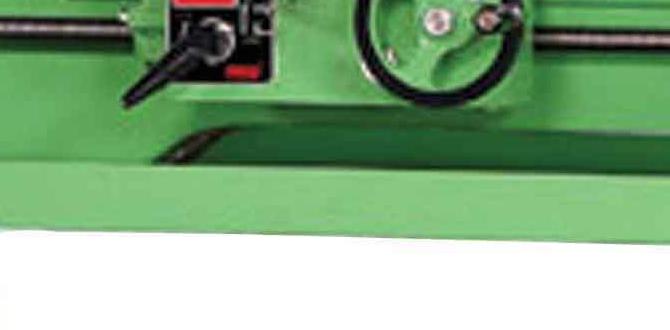

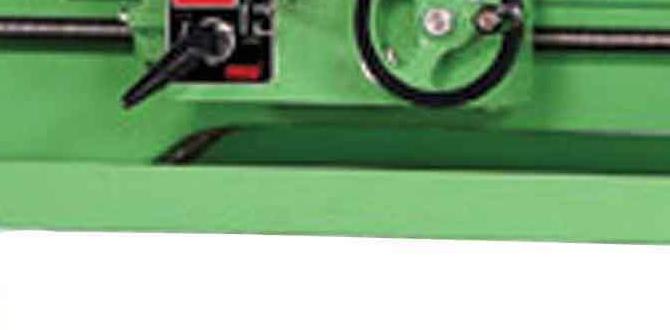

Working with a milling machine can feel a bit intimidating when you’re just starting out. You’ve got this amazing tool that can carve and shape metal with incredible accuracy, but sometimes, holding the right cutting tool can be a puzzle. One question that pops up a lot is about finding the perfect end mill for delicate work, especially when dealing with materials prone to vibration. That’s where a specific type of end mill, the 1/8 inch carbide end mill with a 3/8 inch shank, often with a specialized design, shines! It’s not just another cutting tool; it’s a smart problem-solver for many common milling challenges, particularly that annoying chatter. Stick around, and we’ll break down why this tiny tool is a big deal and how you can use it to achieve amazing results.

Why This Tiny End Mill is a Big Deal

So, you’ve got a project that needs some fine detail work, perhaps in brass or aluminum, and you’re worried about getting a rough finish or hearing that unpleasant vibration from your mill. The 1/8 inch carbide end mill with a 3/8 inch shank is often the answer. Let’s unpack why this specific combination of size and material makes it such a genius solution.

Material Matters: The Power of Carbide

Carbide, or more accurately, tungsten carbide, is a super-hard material. It’s significantly harder and more rigid than high-speed steel (HSS), the other common material for end mills. This hardness offers several key advantages:

Durability: Carbide end mills last much longer than HSS ones, especially when cutting harder materials or at higher speeds. This means fewer tool changes and less downtime.

Heat Resistance: They can handle higher cutting temperatures without getting dull quickly. This allows for faster feed rates and deeper cuts, increasing efficiency.

Precision: Their rigidity helps maintain sharp edges and precise dimensions, leading to more accurate machining results.

For hobbyists and beginners, this means a more forgiving tool that can handle mistakes better and produce cleaner cuts more reliably.

The Shank Advantage: Stability and Tool Holding

The shank is the part of the end mill that gets held by the collet or tool holder in your milling machine. A 3/8 inch shank is a common size for many desktop and benchtop milling machines, offering a good balance of strength and compatibility.

Secure Grip: A larger shank like 3/8 inch provides a more substantial area for your collet or tool holder to grip. This reduces the chance of the end mill slipping or vibrating loose, which is crucial for safety and accuracy.

Reduced Runout: A well-machined shank seated properly in a quality collet minimizes runout – that little wobble a tool can have. Less runout means cleaner cuts and less stress on the cutting edges.

The Cutting Diameter: Precision in Detail

The 1/8 inch cutting diameter is where the magic of detail happens. This small size is perfect for:

Intricate Engraving: Creating fine lines, text, and delicate patterns.

Slotting Small Features: Machining narrow slots for pins, keyways, or other precise components.

Finishing Contours: Smoothing out complex shapes and edges where larger tools can’t reach.

When you combine this small cutting diameter with the strength of carbide and a secure shank, you get a tool that’s exceptionally well-suited for delicate, high-precision work.

The “Genius Solution” Explained: Tackling Chatter

Now, let’s get to the heart of why this setup is often called a “genius solution,” especially with the mention of a “reduced neck.” Chatter is that rhythmic vibration that occurs during machining, leading to a rough surface finish, tool breakage, and even damage to your machine. It’s a common frustration for beginners and experienced machinists alike.

What Causes Chatter?

Chatter is usually an instability in the cutting system. It can be caused by a variety of factors:

Tool Vibration: The cutting tool itself is too flexible or not rigidly held.

Machine Deflection: The spindle, bearings, or overall machine structure flexes under cutting forces.

Workpiece Rigidity: The material being cut is not held securely or is too thin.

Cutting Parameters: Incorrect spindle speed, feed rate, or depth of cut.

Tool Geometry: The design of the end mill’s cutting edges and flute geometry.

How the 1/8″ Carbide End Mill Helps

1. Rigidity: The carbide material itself is inherently rigid, resisting deflection better than HSS. Even though the cutting diameter is small (1/8 inch), its solid construction contributes to stability.

2. Short Stick-Out: To minimize overhang, you generally want to use the shortest flute length possible for the depth of cut. With a 1/8 inch end mill, the overall tool length is often relatively short, meaning less of it extends from the collet. Less overhang equals less vibration.

3. Reduced Neck (The Real Genius!) This is where specialized designs come into play. Many 1/8 inch end mills designed for precision work will feature a “reduced neck.” This means that above the cutting flutes, the body of the end mill tapers down to a smaller diameter before reaching the shank.

Why is this genius? In applications where you need to cut deeper than the flute length, you would normally have to extend the tool further, increasing chatter risk. A reduced neck allows the upper, non-cutting portion of the tool to pass through the workpiece without rubbing. This means you can achieve effective cutting depths that are greater than the flute length while keeping the cutting portion short and rigid, dramatically reducing the chance of chatter. For intricate parts or small workpieces, this feature is invaluable.

The U.S. government’s National Institute of Standards and Technology (NIST) publishes extensive research on machining processes, including studies on cutter geometry and vibration. Understanding these principles can significantly elevate your machining skills.

4. Chip Evacuation: The flutes are designed to efficiently remove chips. Good chip evacuation prevents chip recutting, which can lead to tool damage and poor surface finish.

Perfect for Specific Materials

Brass: Brass is a relatively soft metal that can gum up tools easily if they aren’t sharp or if the cutting parameters are wrong. A sharp carbide end mill with the right geometry cuts brass cleanly. The reduced neck is also excellent for creating detailed features in brass without worrying about the tool body colliding with the workpiece.

Aluminum: Similar to brass, aluminum can be gummy. Carbide excels here, and a small end mill allows for precise contouring and pocketing.

Plastics and Woods: While we’re focusing on metal, these end mills can also perform admirably in certain plastics and hardwoods, offering very clean cuts due to their sharpness and rigidity.

Anatomy of a 1/8 Inch Carbide End Mill

Let’s take a closer look at the components and characteristics of this specialized tool. Understanding these parts will help you choose the right one for your needs and use it effectively.

Key Features to Look For

Material: Tungsten Carbide (often with a binder like Cobalt for toughness).

Shank Diameter: 3/8 inch (0.375 inches).

Cutting Diameter: 1/8 inch (0.125 inches).

Number of Flutes: This is crucial.

2 Flutes: Generally preferred for milling softer materials like aluminum and brass. They have more open flutes for better chip evacuation and are less prone to clogging. They also provide more axial rake, which can help reduce cutting forces.

4 Flutes: Better for harder materials and general-purpose milling. They offer more cutting edges, leading to a smoother finish, but can be more prone to clogging in soft, gummy materials. For a 1/8 inch end mill, especially in brass, 2 flutes are usually ideal.

Flute Length: How far down the tool the cutting edges extend. Shorter flute lengths mean less tool overhang and more rigidity.

Overall Length: The total length of the end mill.

Coating: Some carbide end mills come with coatings (like TiN – Titanium Nitride, TiAlN – Titanium Aluminum Nitride) that can further enhance hardness, reduce friction, and extend tool life, especially at higher speeds or with tougher materials. However, for beginners and soft metals, an uncoated end mill is often sufficient.

Helix Angle: The angle of the flutes. A higher helix angle (e.g., 30-45 degrees) provides a shearing action, which is good for chip evacuation and can reduce cutting forces. A lower helix angle can be more robust.

End Cut Type:

Square End: Creates flat-bottomed slots and profiles. This is the most common type.

Ball Nose: Creates rounded internal corners and features.

Corner Radius: Has a small radius at the corner to add strength and reduce chipping.

Table 1: Common End Mill Configurations for a 1/8 Inch Carbide End Mill

| Feature | Configuration A (Brass/Aluminum Focus) | Configuration B (General Purpose) | Configuration C (High Detail) |

| :—————— | :————————————- | :——————————– | :———————————————————- |

| Material | Tungsten Carbide | Tungsten Carbide | Tungsten Carbide |

| Shank Diameter | 3/8 inch | 3/8 inch | 3/8 inch |

| Cutting Diameter| 1/8 inch | 1/8 inch | 1/8 inch |

| # of Flutes | 2 | 4 | 2 (or sometimes 3 for a balance) |

| Flute Length | Short (e.g., 1/4″ – 3/8″) | Medium (e.g., 1/2″ – 3/4″) | Very Short (e.g., 3/16″ – 1/4″) for max rigidity |

| End Type | Square End | Square End | Square End or Ball Nose (depending on detailed application) |

| Coating | Uncoated or bright (for soft metals) | TiN or TiAlN (optional) | Uncoated or bright |

| Helix Angle | 30 degrees | 45 degrees | 30-45 degrees |

| Special Feature | Standard | Standard | Reduced Neck (essential for chatter reduction in deep cuts) |

Getting Started: Setting Up Your 1/8 Inch End Mill

Using any cutting tool effectively and safely requires proper setup. Here’s a step-by-step guide to getting your 1/8 inch carbide end mill ready for action.

Step 1: Select the Right End Mill

Based on your material and desired outcome, choose the end mill that fits your needs. For brass or aluminum and to specifically combat chatter in deeper cuts or intricate detailed profiling, prioritize a 2-flute end mill with a reduced neck if possible.

Step 2: Inspect the Tool and Machine

End Mill Condition: Before inserting the end mill, check its cutting edges for any damage, chips, or dullness. Even new tools can occasionally have manufacturing defects.

Collet and Holder Cleanliness: Ensure your milling machine’s collet and the tool holder are perfectly clean. Any dirt, oil, or debris can cause the shank to grip unevenly, leading to runout and vibration. Use a clean, lint-free cloth or compressed air.

Spindle Condition: Make sure your milling machine’s spindle bearings feel smooth and don’t have excessive play.

Step 3: Insert the End Mill into the Collet

Loosen the Collet Nut: Ensure the collet nut is loosened sufficiently so the collet can open up.

Insert the Shank: Place the 3/8 inch shank of the end mill into the collet. Push it in until you’ve reached your desired cutting depth or as far as the collet can securely hold it without exceeding the flute length significantly. For a 1/8 inch end mill designed for detail, you often want to minimize the amount of tool exposed.

Tighten the Collet Nut: Hand-tighten the collet nut first to ensure it’s seated correctly. Then, use a wrench to tighten it firmly. Don’t overtighten, as this can damage the collet or the end mill. The goal is a secure grip without deforming the tool or collet.

Check for Runout (Optional but Recommended): If you have a dial indicator, you can mount it to your machine’s table or column and sweep the side of the end mill shank as it rotates slowly (by hand or with the spindle off). Aim for minimal runout (ideally less than 0.001 inches).

Step 4: Secure Your Workpiece

This is critical for preventing chatter and ensuring safety.

Use a Vise: For most small workpieces, a good quality milling vise is essential. Ensure the workpiece is held firmly and squarely in the vise jaws.

Clamping: For larger or irregularly shaped parts, use clamps, T-nuts, and studs to secure the workpiece directly to the milling machine table.

Support: If you’re working with thin material, consider adding a backing plate or support to prevent vibration and deflection.

Step 5: Set Your Cutting Parameters

This is where experience comes in, but for beginners, starting conservatively is key.

Spindle Speed (RPM): The optimal speed depends on the material, the end mill diameter, and the type of cut. For a 1/8 inch carbide end mill in brass, a common starting point might be around 5,000 – 10,000 RPM. Always consult manufacturer recommendations or online calculators.

Surface Speed to RPM Conversion: To calculate RPM, you’ll use the formula:

`RPM = (Surface Speed 3.82) / Diameter`

Where Surface Speed is in SFM (Surface Feet per Minute) and Diameter is in inches. For brass, a surface speed between 150-300 SFM is a good range.

Example for Brass (200 SFM): `RPM = (200 3.82) / 0.125 = 6112 RPM`

Feed Rate: This is how fast the tool moves through the material. Again, start conservatively. For a 1/8 inch end mill, a feed rate of 5-15 inches per minute (IPM) might be appropriate.

Chip Load: A more advanced concept is chip load (the thickness of the chip the tool is removing). For a 2-flute end mill in brass, a chip load of 0.001 to 0.003 inches per flute is a reasonable starting point.

`Feed Rate (IPM) = Number of Flutes Chip Load RPM`

Example: `Feed Rate = 2 0.002 6112 = 24.4 IPM` (This is a bit aggressive for a beginner, so start lower).

Depth of Cut: This should be conservative, especially when learning. For a 1/8 inch end mill, start with a depth of cut around 0.020 inches (half the diameter) for general pocketing or profiling. For very fine detail, you might only go 0.010 inches. For slotting, aim for no more than half the diameter per pass. The reduced neck feature is specifically for situations where you might need to cut deeper, but even then, multiple passes are safer.

Plunge Rate: When feeding the end mill straight down into the material, use a much slower plunge rate than your standard feed rate (e.g., 1/4 to 1/3 of the feed rate) to avoid tool breakage.

Resource: For more detailed guidance on speeds and feeds, resources like the Sandvik Coromant technical data or machinery handbooks are excellent. You can find them through academic institutions or specialized engineering supply sites.

Step 6: Perform a Test Cut

Before diving into your main project, always perform a test cut on a scrap piece of the same material. This helps you:

Check your setup and spindle speed/feed rate settings.

Listen for any signs of chatter.

Verify the surface finish.

Adjust your parameters as needed.

If you hear chatter, try adjusting the spindle speed slightly, slowing down the feed rate, or taking shallower cuts.

Common Milling Operations with This Tool

This specific end mill excels in several common machining tasks, making it a versatile addition to your toolkit.

1. Pocketing

Pocketing involves removing material from an area to create a recessed shape. The 1/8 inch end mill is ideal for small, intricate pockets or for cleaning up corners where larger tools can’t reach (creating a fillet).

How-to:

1. Define the pocket boundaries in your CAD/CAM software or set them up manually on the machine.

2. Set your cutting parameters for pocketing. Often, a zig-zag or spiral milling pattern is used.

3. For best results and to reduce chatter, take multiple shallow passes rather than one deep cut. This is where the reduced-neck feature proves its worth; you can achieve a significant depth by stepping down gradually while the reduced neck prevents the tool body from rubbing.

4. Ensure good chip evacuation, especially in deeper pockets.

2. Profiling (Contouring)

Profiling cuts around the outside or inside perimeter of a shape. This 1/8 inch end mill