Quick Summary: A carbide end mill is your go-to for precision machining of materials like PEEK, especially for tight tolerances and intricate designs. Choosing the right size, like a 1/8 inch with a 3/8 shank and long reach capability, ensures efficient material removal and a superior finish. This guide simplifies selecting and using these powerful tools for your projects.

Hey there, fellow makers! Daniel Bates from Lathe Hub here. Ever found yourself staring at a piece of material, maybe some tough PEEK or a tricky metal, and feeling a bit stuck on how to get that perfectly clean, accurate cut? You’re not alone! Machining can sometimes feel like tiptoeing through a minefield of potential errors. One tool that can make a huge difference, turning those frustrating moments into satisfying triumphs, is the humble yet mighty carbide end mill. Specifically, when you need to reach into tight spots or achieve incredibly fine detail, a specialized carbide end mill can feel like a secret weapon. We’re going to peek behind the curtain and show you exactly how to wield this precision instrument to achieve those genius-level results in your projects.

Carbide End Mills: Your Secret Weapon for Precision Machining

When you’re working on a project that demands accuracy, especially with materials like PEEK (Polyetheretherketone) or other advanced plastics and metals, the right cutting tool makes all the difference. That’s where the carbide end mill shines. Unlike HSS (High-Speed Steel) tools, carbide offers superior hardness and heat resistance, meaning it can cut faster, last longer, and maintain sharper edges, even in tough materials that tend to gum up or wear down other tools. For beginners, this translates to fewer mistakes, cleaner cuts, and a more enjoyable machining experience from the get-go. Let’s dive into why these specialized end mills are such a game-changer.

Why Carbide? The Hard Truth About Cutting Tools

Think of your cutting tool as your primary interface with the material you’re shaping. Its performance directly impacts the quality of your finished part. Here’s a quick rundown of why carbide is often the superior choice, especially for demanding applications:

- Hardness: Carbide is significantly harder than HSS. This means it can maintain its cutting edge for much longer, allowing for more parts to be machined without tool changes or resharpening.

- Heat Resistance: Machining generates heat. Carbide can withstand much higher temperatures before softening, which is crucial when working with materials that generate a lot of friction or have high melting points. This reduces the risk of the tool deforming or losing its edge.

- Rigidity: Carbide is also more brittle than HSS, but its overall rigidity allows for more aggressive cuts and higher feed rates without excessive tool deflection. This is key for achieving tight tolerances.

- Tool Life: Due to its hardness and heat resistance, carbide tools generally have a significantly longer lifespan than their HSS counterparts, offering better value in the long run.

Understanding the “Genius Peek” – When and Why

The term “Genius Peek” in our title refers to a specific scenario where a carbide end mill excels: achieving precise cuts and details in hard-to-reach areas or working with challenging materials where standard tools might struggle. This often involves:

- Tight Tolerances: When your design calls for incredibly precise dimensions and minimal deviation, a sharp, rigid carbide end mill is essential.

- Complex Geometries: Cutting intricate shapes, shallow pockets, or detailed features requires a tool that can hold its edge and deliver a clean cut without chipping or breaking.

- Difficult Materials: PEEK, for example, is known for its excellent mechanical properties, but it can be “gummy” and generate heat. A carbide end mill is ideal for tackling these materials efficiently and cleanly.

Choosing the right end mill for these tasks isn’t just about picking one off the shelf; it’s about understanding the specific features that make it suitable for the job. Let’s explore the critical specifications to look for.

Key Specifications Explained: Finding Your Perfect Carbide End Mill

When you start looking for carbide end mills, you’ll see a lot of numbers and terms. Don’t let it overwhelm you! Understanding a few key specifications will help you pick the exact tool you need. For our “Genius Peek” scenario, especially with materials like PEEK, we’re often looking at specific sizes and configurations. Let’s break down what matters most.

1. Material: Carbide is Non-Negotiable Here

We’ve already covered why carbide is king, but it’s worth reiterating. For high-performance machining of tough materials and achieving tight tolerances, you absolutely want a solid carbide end mill or at least a carbide-tipped one. Solid carbide offers the best rigidity and edge retention.

2. Diameter: Smaller Can Be Mighty

The diameter of the end mill is its cutting width. For intricate work or getting into small cavities, smaller diameters are crucial. A common size for detailed work is a 1/8 inch end mill. This size is perfect for creating fine details, engraving, or machining small parts where larger tools simply won’t fit or would remove too much material.

3. Shank Diameter: Strength and Stability

The shank is the part of the end mill that goes into your tool holder or collet. While you can find end mills with various shank diameters, a common standard for many milling machines and routers is 3/8 inch. A 3/8 inch shank provides a good balance of strength and compatibility with most common tool holding systems. For a 1/8 inch cutting diameter, a 3/8 inch shank offers excellent rigidity, reducing deflection and vibration for cleaner cuts.

4. Reach and Length: Getting Where You Need to Go

This is where the “long reach” aspect comes into play. Standard end mills have a certain length, but for deep pockets or reaching into recessed areas, you need an end mill with an extended reach. A “long reach” end mill has a longer flute length and/or a longer overall length, allowing the cutting edges to access deeper parts of your workpiece. When combined with a smaller cutting diameter like 1/8 inch, a long-reach end mill enables you to machine deep, narrow slots or internal features that would be impossible with standard tools.

5. Number of Flutes: Balancing Chip Clearance and Finish

Flutes are the helical grooves on the cutting edges of an end mill. The number of flutes affects how well the tool clears chips and the quality of the surface finish. For general-purpose machining, 2 or 4 flutes are common.

- 2 Flutes: Excellent for softer materials and plastics like PEEK. They provide good chip clearance, reducing the chance of the material melting and clogging the flutes.

- 4 Flutes: Better for harder metals and provide a smoother finish in many applications. However, they can sometimes clog more easily with softer, “gummy” materials.

For PEEK and similar plastics, a 2-flute end mill is often the preferred choice to ensure good chip evacuation and prevent melting.

6. Coating: Extra Protection for Tough Jobs

Some end mills come with coatings, such as Titanium Nitride (TiN) or Titanium Carbon-Nitride (TiCN). These coatings can further enhance hardness, reduce friction, and increase tool life. For demanding materials or long production runs, a coated carbide end mill can be a wise investment.

Selecting the Right “Carbide End Mill 1/8 Inch 3/8 Shank Long Reach for PEEK Tight Tolerance”

Now, let’s put these specifications together to find that perfect tool. When you’re looking for a “carbide end mill 1/8 inch 3/8 shank long reach for PEEK tight tolerance,” you’re describing a very specific, high-precision instrument. Here’s what to expect and look for:

| Specification | Why it Matters for PEEK & Tight Tolerances | Ideal Choice Example |

|---|---|---|

| Material | Carbide’s hardness and heat resistance are crucial for PEEK’s properties and maintaining sharp edges for precision. | Solid Carbide |

| Cutting Diameter | A 1/8 inch diameter allows for intricate details and precise feature milling. | 1/8 inch (0.125″) |

| Shank Diameter | A 3/8 inch shank provides excellent rigidity, minimizing deflection, which is vital for tight tolerances. | 3/8 inch (0.375″) |

| Reach / Length | “Long Reach” means extended flute length, enabling access to deeper features without special setups. | Look for end mills with significantly longer flute lengths than standard (e.g., 1/2 inch or 3/4 inch flute length for a 1/8″ dia tool). |

| Flute Count | 2 flutes are generally best for PEEK to manage chip load and prevent melting/clogging. | 2 Flutes |

| End Type | Square end is standard for pockets and slots. Ball nose for radiused features. For general “peek” work, square is often most versatile. | Square End |

| Coating | Optional, but coatings like TiN can further improve performance and tool life. | Uncoated or TiN Coated |

When you search for these, you’ll often find them listed as “2 Flute Long Reach Single End Carbide End Mill.” Pay close attention to the flute length specification versus the overall length; for reach, flute length is usually the key metric.

Preparing for Success: A Step-by-Step Approach

Getting the most out of your specialized end mill requires a bit of preparation. It’s not just about having the right tool; it’s about using it correctly. Here’s how to set yourself up for that “genius peek” moment:

Step 1: Secure Your Workpiece Meticulously

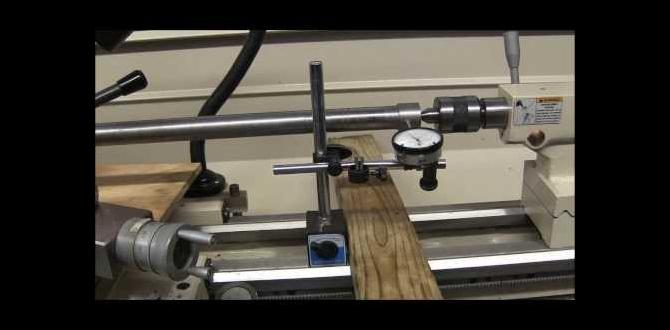

This is non-negotiable for precision machining. Your material must be clamped down so it cannot shift, vibrate, or move at all. Use appropriate clamps, vises, or fixtures. For PEEK, which can be slightly flexible, ensure you have firm, even clamping pressure. A stray vibration can ruin a tight tolerance. You can learn more about workholding best practices from resources like Tooling University’s guide on workholding.

Step 2: Set Up Your Machine Correctly

Ensure your spindle is clean and that the end mill is properly seated in the collet or tool holder. Overtightening can damage the shank, while undertightening can lead to runout and tool breakage. Use the correct torque if you have a torque wrench for your collets.

Step 3: Determine Your Cutting Parameters

This is where the magic happens, and it requires a bit of research or experience. For PEEK and a fine 1/8 inch end mill, you’ll want relatively high spindle speeds (RPM) and conservative feed rates. The goal is to get the tool spinning fast enough to cut cleanly without melting the plastic, while feeding just fast enough to create chips, not dust.

Here’s a general starting point for PEEK with a 1/8 inch solid carbide 2-flute end mill. Always consult with the end mill manufacturer’s recommendations if available. These are guidelines and may need adjustment based on your specific machine, setup, and coolant:

- Spindle Speed (RPM): 15,000 – 30,000 RPM (Higher RPM is generally better for PEEK with carbide to create a sharp cutting action and minimize friction heat.)

- Feed Rate (IPM – Inches Per Minute): 5 – 15 IPM (Start low and increase gradually. Aim for nice, clean chips, not fine powder which indicates too slow a feed or too much heat.)

- Depth of Cut (DOC): 0.010″ – 0.030″ per pass (For PEEK and small end mills, shallow depths of cut are crucial for accuracy and preventing tool breakage.)

- Stepover: 20% – 50% of diameter (0.025″ to 0.060″ for a 1/8″ end mill) for contouring. For pocketing, a wider stepover can be used if the depth of cut is controlled well.

Important Note: These are starting points. Always listen to your machine and look at your chips. If the PEEK starts melting or smoking, your RPM is too low, or your feed rate is too high, or your depth of cut is too aggressive. Conversely, if you’re getting chatter, your feed rate might be too high, or your DOC too deep.

Step 4: Implement Your Cutting Strategy

For tight tolerances and precision, think about how you’re approaching the cut.

- Climb Milling vs. Conventional Milling: For most CNC operations with modern machines, climb milling is preferred. The tool rotates in the same direction as the feed, which puts less stress on the spindle and often results in a better finish. However, conventional milling can sometimes be better for preventing chatter with very flexible materials or very light cuts. Experiment is key!

- Multiple Passes: Never try to take too much material off in one go. For precise features, plan on multiple shallow passes. This significantly reduces heat buildup, tool deflection, and improves the final accuracy.

- Coolant/Lubrication: For PEEK, a good air blast or a minimal amount of specialized plastic machining lubricant can help manage heat and improve chip evacuation. Avoid flood coolants if possible, as they can sometimes make the plastic swell.

Step 5: Monitor and Adjust

During the machining process, keep a close eye and ear on what’s happening. Listen for any unusual sounds (chatter, grinding). Watch for smoke or excessive heat buildup. If possible, measure critical dimensions periodically to ensure you’re staying within tolerance. Be prepared to pause or stop the operation if something doesn’t seem right.

PEEK Specific Machining Challenges and Solutions

PEEK is a fantastic material, but it does have its quirks when it comes to machining. Understanding these will help you appreciate why the right tool and technique are so important.

The “Gummy” Nature of PEEK

PEEK can be somewhat “gummy” or “stringy” when cut. This means it can melt slightly under friction and stick to the cutting tool, leading to chip recasting and tool buildup. This significantly degrades the cutting edge and surface finish.

- Solution: High spindle speeds with sharp carbide tools (like our 1/8″ 2-flute long reach) are excellent for this. They create a shearing action rather than rubbing, and the high speed helps the tool move through the material quickly, minimizing heat buildup on the tool face. Good chip evacuation is paramount, which is why 2 flutes are often preferred.

Thermal Expansion

While PEEK has good thermal stability, it can still expand and contract with temperature changes. If you are machining parts that need to fit precisely at a specific operating temperature, you may need to factor this in.

- Solution: Machine the parts at or near their expected operating temperature. If this isn’t feasible, make your final passes very shallow and at a lower feed rate to achieve the final dimension when the part is at room temperature, understanding that it might grow or shrink slightly in use.

Tool Wear

Even with carbide, PEEK can be abrasive enough to cause wear over time, especially if dust is generated instead of clean chips. This wear can lead to loss of tolerance, rougher finishes, and increased heat.

- Solution: Use appropriately chosen cutting parameters, ensure good chip evacuation, and consider coatings for extended tool life on high-volume jobs. Regularly inspect your tool for wear. A slight radius on the cutting edge, even on a “square” end mill, is normal wear. Excessive wear means it’s time for a new tool.

Beyond PEEK: Other Applications for Your “Genius Peek” End Mill

While PEEK is a prime candidate, this specialized carbide end mill isn’t limited to just one material. Its precision and reach make it invaluable in many other scenarios:

- Aluminum Alloys: For intricate shrouds, small model parts, or detailed engraving on aluminum. The high speeds possible with carbide work well here too.

- Delrin (Acetal): Similar to PEEK in its “gummy” nature, Delrin benefits from the same high-speed, sharp-cutting approach enabled by a good carbide end mill.

- Brass and Mild Steels: For very small, detailed parts or shallow engraving where a larger tool would be too aggressive.

- Mold Making and Pro