Carbide end mills with specialized designs dramatically improve chip evacuation, preventing tool breakage and ensuring smoother cuts, especially when milling tricky materials like cast iron with reduced neck and 6mm shank models.

Hey folks, Daniel Bates here from Lathe Hub! Ever find yourself wrestling with chips flying everywhere, gumming up your mill, or worse, causing your end mill to overheat and break? It’s a common frustration, especially when you’re just starting out with milling or tackling materials that love to cling. Those tiny metal shavings, called chips, can cause all sorts of headaches if they aren’t cleared away efficiently. This can lead to poor surface finish, premature tool wear, and even broken tools. But what if I told you there’s a “genius” way to handle these pesky chips? We’re going to dive deep into how the design of carbide end mills, particularly those with specific features for chip evacuation, can make your milling projects a whole lot smoother and more successful. Get ready to learn how to keep your cuts clean and your tools happy.

Understanding Chip Evacuation: Why It Matters More Than You Think

When you’re cutting metal with an end mill, you’re essentially shaving off tiny pieces of material. These pieces are called chips. For your milling operation to work well, these chips need to get out of the way. This process is called chip evacuation. If chips don’t clear properly, they can get trapped between the cutting edges of the end mill and the workpiece. This trapped material can:

- Cause Heat Buildup: Trapped chips act like insulation, preventing heat generated by the cutting action from escaping. Overheating leads to tool wear and can soften the workpiece material.

- Increase Cutting Forces: Fighting against packed chips requires more force, which can lead to tool chatter, inaccurate cuts, and even damage to your milling machine.

- Lead to Poor Surface Finish: Chips getting recut can leave rough marks and a poor-looking surface on your workpiece.

- Result in Tool Breakage: The combination of heat, increased forces, and chip recutting is a recipe for disaster, often ending with a snapped end mill – a costly and frustrating experience for any machinist.

Think of it like trying to dig a trench while also having to constantly push the dirt you’ve removed back into the hole. It’s inefficient and makes the job much harder than it needs to be. Effective chip evacuation is therefore not just a nicety; it’s a fundamental requirement for successful and economical machining.

Carbide End Mills: The Material Advantage

Before we get into the nitty-gritty of chip evacuation design, it helps to understand why carbide is such a popular material for end mills, especially in demanding applications. While high-speed steel (HSS) end mills are great for many tasks and are more forgiving, carbide end mills offer significant advantages, primarily their ability to withstand higher temperatures and maintain their hardness. This means they can:

- Cut Faster: Because they don’t soften as easily at high temperatures, you can often run carbide tools at higher surface speeds.

- Handle Harder Materials: Carbide excels at machining materials that would quickly dull or deform HSS tools, such as hardened steels, stainless steels, and exotic alloys.

- Last Longer: When used correctly and under the right conditions, carbide tools generally have a much longer tool life than HSS.

However, carbide is also more brittle than HSS. This means it can chip or fracture if subjected to excessive shock or vibration, which is precisely where good chip evacuation plays a critical role. It helps ensure that the forces on the tool are consistent and that it’s not subjected to the kind of shock loads that can lead to catastrophic failure.

The “Genius” of Chip Evacuation Design in Carbide End Mills

So, what makes a carbide end mill “genius” at evacuating chips? It’s all about the geometry and how the tool is designed to interact with the material and the coolant/air blast used during machining. The goal is to break the chips into small, manageable pieces that can easily flow away from the cutting zone.

Here are the key design features that contribute to superior chip evacuation:

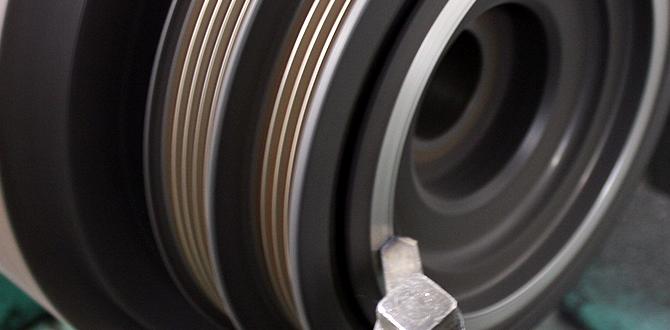

1. Flute Design: The Pathways for Chips

The flutes are the helical grooves that run along the body of the end mill. Their primary job, besides providing cutting edges, is to act as channels to carry chips away. For effective chip evacuation, flute design is paramount:

- Number of Flutes:

- 2-Flute End Mills: These are generally considered excellent for chip evacuation. With fewer cutting edges engaged at any one time, there’s more open space within the flutes for chips to exit. They are ideal for deep cuts, slotting, and pocketing where chip packing is a major concern.

- 4-Flute End Mills: These offer better stability and surface finish in general milling operations and are often suitable for materials that don’t produce long, stringy chips (like cast iron). While they offer more cutting edges, the flute spacing is tighter, meaning chip evacuation can be more challenging compared to 2-flute versions if the chips are voluminous.

- Helix Angle: This is the angle of the flute relative to the end mill’s axis.

- High Helix Angles (e.g., 30° – 45°): These angles help to curl and break chips into smaller pieces, and the steeper angle “lifts” the chips out of the flutes more effectively. This is particularly beneficial for softer, stringier materials like aluminum or mild steel.

- Standard Helix Angles (e.g., 30°): A good all-around compromise.

- Low Helix Angles (e.g., 15°): Less aggressive, can be useful for some materials for better surface finish but generally not the first choice for aggressive chip evacuation.

- Flute Depth/Openness: Deeper, more open flutes provide larger volumes for chips to travel. This is critical in materials that produce large chip loads. For example, an end mill designed specifically for high-volume chip evacuation might have noticeably deeper and wider flutes than a general-purpose end mill.

- Polished or Coated Flutes: Flutes with a highly polished surface finish, or those treated with specific coatings (like TiAlN or ZrN, though less common for chip evacuation focus itself), reduce friction between the chips and the flute wall. This allows chips to slide out more easily and prevents chip welding.

2. Reduced Neck Feature: Clearing the Way for the Cut

A “reduced neck” feature is an area behind the cutting flutes where the diameter of the end mill shaft is slightly smaller than the cutting diameter. This might sound counterintuitive, but it’s a brilliant design for chip evacuation, especially in interrupted cuts or when cutting deep pockets.

Here’s why it’s genius:

- More Room for Chips: The reduced neck provides an extra “escape route” for chips. As the end mill cuts, chips that have been cleared up the flutes can even exit through the gap created by the neck, preventing them from getting jammed at the back of the cutting head.

- Reduced Friction: In deeper cuts, the non-cutting shank of the end mill can rub against the walls of the pocket or slot, generating heat and friction. The reduced neck minimizes this contact area, further aiding in heat dissipation and preventing chip buildup.

- Strength Considerations: While it sounds like it might weaken the tool, this feature is carefully engineered. The reduction is typically only slight, and the core strength of the carbide still provides ample rigidity for most applications. It’s a trade-off that prioritizes chip evacuation and cutting performance.

This feature is particularly beneficial when slotting or pocketing materials that produce stubborn chips, as it offers a secondary, less obstructed path for chip removal.

3. Shank Diameter: Matching Your Needs

The shank is the part of the end mill that grips into the collet or tool holder. For chip evacuation, the consideration is often whether the shank diameter is standard or if it’s a specific size that aids functionality. For instance, a 6mm shank is a common size in metric systems, and when paired with specific flute designs and a reduced neck, it contributes to overall tool performance. A smaller shank diameter, relative to the flute diameter, can also offer more clearance for chip flow in certain setups, though tool rigidity becomes a more significant factor with smaller shanks supporting larger cutting diameters.

Consider the precise dimensions: an end mill advertised with a “6mm shank” means the gripping portion is 6mm in diameter. If it also has a “reduced neck,” that reduced area will be slightly larger than 6mm but still smaller than the 8mm or 10mm cutting diameter it might be paired with. This design aims to facilitate chip removal in a compact tool size.

4. End Mill Coatings: Protecting and Assisting

While not directly part of the geometry for chip evacuation, specialized coatings can indirectly assist by making the surface of the end mill slicker. This reduces friction, making it harder for chips to stick or weld to the cutting edges and flutes. Common coatings like TiN (Titanium Nitride) or ZrN (Zirconium Nitride) can offer some benefit, but for aggressive chip evacuation, the focus remains on geometry. More advanced coatings might also play a role, but it’s secondary to the flute and neck design.

5. Coolant Holes: The Internal Flow

High-performance end mills, especially those designed for tough materials or high-speed machining, often feature through-coolant holes. These are small passages that run through the center of the end mill, exiting at the cutting edge. High-pressure coolant is then directed through these holes.

- Internal Lubrication and Cooling: Coolant delivered directly to the cutting zone cools the tool and workpiece, reducing heat and improving tool life.

- Chip Flushing: The high-pressure jet of coolant exiting the flutes helps to forcefully push chips away from the cutting area and out of the flutes. This is incredibly effective for clearing even stubborn chips, especially in deep pockets where external coolant can have trouble reaching.

For more on the importance of coolant and lubrication in machining, check out resources like these from the National Institute of Standards and Technology (NIST), which often publish research and guidelines related to manufacturing processes.

End mills with through-coolant holes are often marked with “ICEF” (Internal Coolant Ejector Flutes) or similar designations. These are typically used with CNC machines that have a through-spindle coolant system, but they represent the cutting edge in chip evacuation technology.

Carbide End Mill for Cast Iron: A Case Study in Chip Evacuation

Cast iron is a fantastic material to machine in many ways – it’s relatively stable, doesn’t warp easily, and often leaves a good surface finish. However, it has a tendency to produce abrasive, granular chips. These chips can be hard on cutting edges and, if not cleared effectively, can cause premature wear and a dull finish.

When you’re milling cast iron, especially with an end mill like a carbide end mill with a 1/8 inch (or 6mm shank) and a reduced neck for chip evacuation, here’s why it’s a “genius” pairing:

- Granular Chips: Cast iron doesn’t produce long, stringy chips like softer metals. Instead, it produces smaller, abrasive particles. While these are easier to clear in terms of volume, their abrasive nature means they can quickly dull a cutting edge if they stay in the cutting zone. Efficient evacuation removes these abrasive particles away from the cutting edge rapidly.

- Tool Wear: The abrasive nature of cast iron means a tool that doesn’t evacuate chips well will wear out much faster. A design optimized for chip evacuation helps keep the cutting edges cleaner and cooler, extending tool life.

- Reduced Neck in Cast Iron: For features like pockets or slots in cast iron, the reduced neck becomes invaluable. It ensures that even if some of the granular cast iron dust tries to pack up, it has a clearer path to escape, preventing the tool from binding or overheating.

- 6mm Shank Considerations: A 6mm shank end mill with a reduced neck for chip evacuation is often chosen for smaller, more intricate parts or when working with less rigid setups where maintaining tool engagement and chip control is crucial without over-stressing the machine or the tool. The reduced neck helps maintain tool clearance while supporting the cutting edges effectively.

Choosing an end mill with features specifically designed for chip evacuation when working with cast iron will pay dividends in terms of speed, tool life, and finish quality.

Choosing the Right Carbide End Mill for Chip Evacuation

When you’re at the tool supplier or browsing online, what should you look for? Here’s a simple guide:

Key Features to Look For:

- Number of Flutes: For most chip evacuation challenges, especially with materials that produce stringy chips, a 2-flute end mill is often the best starting point. For harder materials or when surface finish is paramount and chip formation is less of an issue, 3 or 4 flutes might be adequate.

- Helix Angle: A moderate to high helix angle (30-45 degrees) is generally preferred for better chip curling and evacuation.

- Flute Form: Look for descriptions that mention “deep flutes,” “open flute design,” or “optimized for chip removal.”

- Reduced Neck: If you’re doing slotting, pocketing, or working with materials that tend to pack chips, definitely consider end mills with a reduced neck feature.

- Material and Coating: Ensure it’s carbide for harder materials and higher speeds. Coatings can be a bonus.

- Through Coolant: If your machine supports it and you’re dealing with difficult materials or deep cavities, through-coolant is a game-changer.

When NOT to Prioritize Extreme Chip Evacuation Features:

While great for many situations, extreme chip evacuation designs (like very deep flutes or very high helix angles) might sometimes compromise other aspects of performance:

- Surface Finish: In some materials, slightly less aggressive flute geometry can lead to a better surface finish because the chips are broken differently or the flute doesn’t interfere as much.

- Tool Strength/Rigidity: Very deep flutes can mean thinner walls and less rigid cutting edges, making the tool more prone to deflection or breaking under heavy radial loads.

- Slotting vs. General Profiling: If you’re primarily doing shallow profiling, extreme chip evacuation might be overkill and a more robust, standard flute design could be a better choice.

The key is to match the end mill design to your specific material, machine capabilities, and the type of operation you’re performing. For a beginner, starting with a good quality 2-flute carbide end mill with a standard or moderately high helix angle is a safe and effective bet for many applications.

Practical Tips for Maximizing Chip Evacuation

The best end mill design in the world won’t perform optimally if you don’t use it correctly. Here are some practical tips:

- Set the Right Cutting Parameters:

- Feed Rate: You need to feed the tool into the material fast enough to create a chip of sufficient thickness. Too slow a feed rate, and you get rubbing and heat without effective cutting or chip formation. Too fast, and you overload the tool. A good rule of thumb for chip evacuation is to aim for a chip load that feels substantial but doesn’t chatter. Refer to manufacturer’s guidelines or online calculators as a starting point.

- Spindle Speed (RPM): This, combined with feed rate, determines the chip load. Adjust to match the material and tool.

- Depth of Cut (DOC) and Width of Cut (WOC): For materials that produce difficult chips, use shallower depths and widths of cut (or employ strategies like Wasp or High-Efficiency Machining – HEM) to reduce the chip load per tooth and give chips more space to escape. This is where you might make multiple lighter passes instead of one heavy one.

- Use Adequate Coolant/Lubrication:

- Stream/Flood: A steady stream or flood of coolant is essential for cooling and flushing.

- Air Blast: For materials like aluminum or cast iron, a powerful air blast, especially directed into the flutes, can be extremely effective at blowing chips away. Many small mills have a nozzle you can position.

- Mist Coolant: A good compromise for cooling and lubrication without excessive mess.

- Proper Tool Engagement:

- Climb Milling vs. Conventional Milling: Climb milling (where the cutter rotates in the same direction as the feed) generally produces a thinner chip at the start of the cut and can help “peel” the material off, often resulting in better chip evacuation. Conventional milling cuts against the feed direction and can produce thicker chips that are harder to evacuate. For materials prone to chip issues, climb milling is often preferred.

For an in-depth look at climb vs. conventional milling, consider resources from organizations like the Society of Manufacturing Engineers (SME).</