No carbide end mill 1/8 inch 6mm shank reduced neck for brass heat resistant: Proven Essential

Quick Summary

For brass, a 1/8 inch, 6mm shank carbide end mill with a reduced neck designed for heat resistance is essential for precise, clean cuts. This specialized tool prevents melting and ensures smooth operation, making your projects look professional and keeping your tools in top shape.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Ever found yourself wrestling with brass on your milling machine, only to have your end mill get hot, sticky, and leave a messy finish? It’s a common frustration, especially when you’re working with smaller bits like a 1/8 inch or 6mm shank. The heat generated can quickly turn a beautiful piece of brass into a gummy mess, and worse, damage your tool. That’s why I want to talk about a very specific, yet incredibly important tool: the carbide end mill with a reduced neck, designed for heat resistance when working with brass. It might sound niche, but mastering this can make all the difference in your projects. Stick around, and I’ll walk you through why this tool is a proven essential and how to use it to get those crisp, clean cuts you’re aiming for!

Understanding the Challenge: Machining Brass

Brass is a fantastic material to work with. It’s relatively soft, easy to machine, and has a beautiful, warm color. It’s perfect for decorative parts, small components, and even jewelry. However, brass has a lower melting point and can be gummy when cut, especially with standard tooling. This can lead to several problems:

- Chip Welding: The hot chips created during machining can melt and weld to the cutting edges of your end mill. This dulls the tool rapidly and creates a poor surface finish.

- Heat Buildup: Friction is the enemy of precise machining, and brass is particularly prone to generating heat. Too much heat can deform the workpiece, cause tool wear, and make the cutting process unstable.

- Poor Surface Finish: When chips weld to the tool or excessive heat is generated, you end up with a rough, uneven surface that requires a lot of post-machining work.

For beginners, these issues can be incredibly discouraging. You’ve invested in a machine, the material, and setup, only to be met with frustrating results. This is precisely where specialized tooling comes into play.

Why a “Reduced Neck” Carbide End Mill for Brass?

Let’s break down what makes a specific type of end mill so crucial for brass: “carbide,” “1/8 inch 6mm shank,” and “reduced neck for heat resistance.”

Carbide: The Material Matters

Carbide, or tungsten carbide, is an extremely hard and wear-resistant material. Unlike High-Speed Steel (HSS) tools, carbide can withstand higher cutting speeds and temperatures without losing its sharpness as quickly. This is vital for machining tougher or “gummier” materials like brass, where heat is a significant factor.

When you’re milling brass, the friction generates heat. A carbide end mill’s inherent hardness and thermal resistance mean it can handle this without immediately becoming dull or deforming. This translates to longer tool life and more consistent results for you.

1/8 Inch (3mm) and 6mm Shank Size: Precision in Miniature

The mention of “1/8 inch” and “6mm shank” points to smaller diameter end mills. These are often used for detailed work, engraving, or machining small features on brass parts. Why is the shank size important here?

- Tool Holder Fit: Your milling machine’s collet or chuck must match the shank diameter. Common sizes include 1/8 inch (approximately 3.175mm) and 6mm. Ensuring you have the right size means the tool is held securely and runs true.

- Reach and Accessibility: Smaller shank diameters allow the end mill to reach into tighter areas and machine finer details.

- Rigidity: While smaller shank diameters can be less rigid than larger ones, a well-designed end mill compensates for this, especially when used with appropriate cutting parameters.

For intricate brass projects, using the correct shank size ensures that your tool fits securely and allows you to achieve the delicate details required.

Reduced Neck: The “Heat Resistant” Secret Weapon

This is where the real magic happens for brass machining. A “reduced neck” end mill features a section of the shank that is ground down to a smaller diameter just above the cutting flutes. This design is specifically engineered to:

- Reduce Heat Transfer: The reduced neck acts as a thermal barrier. It disconnects the cutting head from the majority of the shank, significantly slowing down the transfer of heat generated during cutting up towards the spindle and collet.

- Prevent Chip Recutting: In some designs, this reduced neck can also help prevent chips from getting recut and re-welded to the tool’s body, especially when machining deep pockets or slots.

- Improve Chip Evacuation: The geometry around the neck can sometimes aid in clearing chips away from the cutting zone more effectively, further reducing heat and preventing buildup.

When machining brass, this feature is invaluable. It helps keep the tool cooler, reduces the likelihood of chip welding, and ultimately leads to a cleaner cut and longer tool life. This is why an end mill with this specific design for brass heat resistance is not just a nice-to-have, but a proven essential for anyone serious about achieving good results.

Choosing the Right End Mill: Key Features to Look For

When you go to purchase your end mill, keep these specific criteria in mind to ensure you get the right tool for brass machining:

1. Material Composition

Look for solid carbide or micro-grain carbide end mills. These offer the best combination of hardness, edge retention, and heat resistance. Avoid HSS for this application if you can, as it will wear out much faster and perform poorly.

2. Flute Count

For softer metals like brass, end mills with fewer flutes are generally preferred. A 1 or 2-flute end mill is ideal. Why? More flutes mean less chip clearance. Brass produces a lot of chips, and with fewer flutes, you give those chips more space to escape. This prevents chip packing, reduces heat, and leads to a smoother cut.

Table: Flute Count vs. Material Type

| Material Type | Recommended Flute Count | Reasoning |

|---|---|---|

| Brass, Aluminum, Plastics | 1 or 2 Flutes | Excellent chip clearance, reduced heat buildup, prevents chip welding. |

| Steels, Stainless Steels | 2, 3, or 4 Flutes | Better for harder materials, more cutting edges for efficient material removal, good for chip breaking. |

| General Purpose (Multi-Material) | 2 or 3 Flutes | A compromise for versatility. |

3. Coating

While not always necessary for casual brass machining, certain coatings can enhance performance. For brass, a basic uncoated carbide end mill is often sufficient. However, if you plan to push speeds or machine for extended periods, a coating like TiN (Titanium Nitride) or AlTiN (Aluminum Titanium Nitride) can add an extra layer of hardness and lubricity, further reducing friction and heat. For brass, TiN is often a good, cost-effective choice.

4. Geometry and Helix Angle

Look for end mills specifically designed for “non-ferrous metals” or “aluminum.” These often have a steeper helix angle (around 30-45 degrees) and polished flutes. A high helix angle helps pull chips up and out of the cut more effectively, reducing the chance of them sticking to the tool. Polished flutes also contribute to better chip flow and less friction.

A reduced neck design, as discussed, is your primary focus for heat resistance. Ensure the specifications clearly state this feature.

5. Shank Diameter

As identified, you need an end mill with a 1/8 inch (approx. 3mm) or 6mm shank diameter. Make sure your collets or tool holders can accommodate this size precisely for a secure grip.

Setting Up Your Milling Machine for Success

Even with the perfect tool, your machining setup is critical. Here’s how to prepare your machine:

1. Secure Your Workpiece

Always use a vise or clamps to hold your brass securely. Even small movements can ruin a detailed cut. Ensure the workpiece is a good distance from your clamp jaws so the end mill doesn’t collide with them.

2. Use the Right Spindle Speed (RPM) and Feed Rate

This is crucial for minimizing heat and achieving good chip formation. For brass using a 1/8 inch or 6mm carbide end mill, start with conservative settings:

- Spindle Speed (RPM): For a 1/8 inch end mill in brass, a good starting point is often between 10,000 to 20,000 RPM. For a 6mm end mill, you might be slightly lower, perhaps 8,000 to 15,000 RPM. Always consult your end mill manufacturer’s recommendations if available. Higher RPMs can generate more heat, but with carbide, they can also create smaller, easier-to-manage chips if fed correctly.

- Feed Rate: This is how fast your machine moves the tool into the material. For small end mills, a light feed rate is key. Aim for a feed per tooth that generates a thin, consistent chip. With a 1/8 inch or 6mm tool, a feed of around 0.001 to 0.003 inches per tooth (or 0.025 to 0.075 mm per tooth) is a good starting point. Too slow a feed will rub instead of cut, generating heat. Too fast will overload the tool.

Note on Feed and Speed: These are starting points. You’ll adjust based on the sound of the cut, the chip formation, and the finish. If chips are melting or the tool is getting hot, slow down your feed rate or increase your spindle speed slightly. If the cut is chattering or the tool is straining, reduce your feed rate or spindle speed.

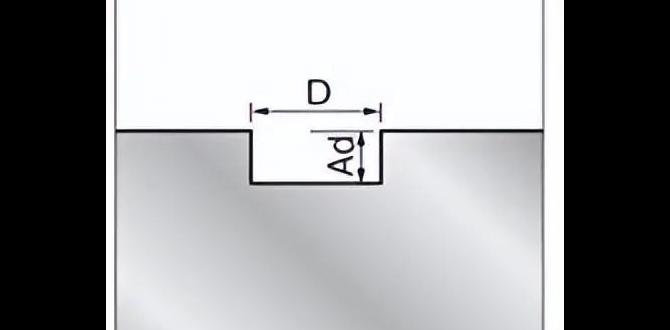

3. Depth of Cut (DOC) and Stepover

Always take light cuts when milling brass with small end mills, especially when starting. This puts less load on the tool and reduces heat.

- Depth of Cut (DOC): For a 1/8 inch or 6mm end mill, start with a DOC of no more than 0.010 to 0.020 inches (0.25mm to 0.5mm). You can gradually increase this if the tool and machine can handle it comfortably.

- Stepover: This is how far the passes overlap. For finishing passes, a small stepover (e.g., 10-20% of the tool diameter) will give a smoother surface. For clearing out material, a larger stepover (e.g., 30-50%) is fine.

4. Coolant or Lubricant

While not always mandatory for brass, a small amount of cutting fluid or a lubricant specifically designed for aluminum and brass can make a significant difference. It helps carry away chips, reduce friction, and further lower the temperature. A spray mist or a few drops applied directly to the cutting area is usually sufficient. Understanding cutting fluids is key to optimizing your machining process.

5. Air Blast

A strong stream of compressed air directed at the cutting zone can help blow away chips and cool the tool and workpiece. This is often an easier and cleaner option than liquid coolants for small home workshop setups.

Step-by-Step: Milling Brass with Your Specialized End Mill

Let’s walk through a typical scenario for milling a simple pocket in brass using your 1/8 inch or 6mm reduced neck carbide end mill.

Tools and Materials Needed:

- Your specialized 1/8 inch or 6mm shank carbide end mill for brass

- Milling machine (benchtop or larger)

- Compatible collet or tool holder

- Secure vise or clamping system

- Piece of brass stock

- Safety glasses and hearing protection

- Cutting fluid or compressed air (optional but recommended)

- Digital Caliper or measuring tools

- Machinist’s chalk or marker (optional, for marking)

The Process:

Step 1: Safety First!

Always wear your safety glasses and hearing protection. Ensure your machine is clean and all guards are in place. Understand your machine’s E-stop and how to use it.

Step 2: Secure the Workpiece

Mount your brass stock securely in the milling vise. Ensure it’s positioned so that the end mill won’t crash into the vise jaws or clamps. Make sure the portion you intend to mill is accessible and at a comfortable height.

Step 3: Install the End Mill

Insert the 1/8 inch or 6mm shank carbide end mill into the appropriate collet or tool holder. Tighten it securely in the spindle. Ensure the shank is properly seated to avoid runout.

Step 4: Set Your Zero Point and Program (if applicable)

If you’re using a CNC mill, load your G-code program. If you’re operating manually, carefully touch off your axes to establish your X, Y, and Z zero points. For manual milling, you might mark your desired pocket outline on the brass with a marker.

Tip: For manual milling, consider using a dial indicator to ensure your workpiece is perfectly square in the vise.

Step 5: Set Cutting Parameters

Program or set your spindle speed (RPM), feed rate, depth of cut, and stepover according to the recommendations for brass and the size of your end mill. Remember to start conservatively!

Step 6: Initial Plunge/Entry

If plunging straight into the material, do so slowly and carefully. Avoid plunging directly downwards if possible; a slight helical (spiral) or ramp entry is often better for small end mills. If manual, use your Z-axis handwheel to slowly lower the tool until it just touches the surface, then set your Z zero. Now, lower it the desired depth for your first pass.

Step 7: Roughing Passes

Begin your milling operation. Let the machine take light, consistent passes.

Monitor your chips:

- If chips are small, curly, and falling away cleanly: You’re likely in a good zone.

- If chips are large, stringy, or melting: You might be feeding too slowly, or your spindle speed is too high for the feed. Try increasing the feed rate slightly or decreasing RPM.

- If the tool is screaming or vibrating excessively: Reduce feed rate or DOC.

Use your cutting fluid or air blast to keep the chips flowing. For milling a pocket, you’ll typically make multiple passes, incrementally increasing the depth until you reach your target depth. A common strategy is to use a 50% stepover for roughing to clear material efficiently.

Step 8: Finishing Pass

Once you’ve reached your final depth, make a final pass with a smaller stepover (e.g., 10-20% of the tool diameter) and potentially a slightly increased feed rate. This pass is about achieving a smooth surface finish. Ensure you have good chip evacuation on this pass as well.

Step 9: Cool Down Period

After the machining is complete, let the workpiece and the end mill cool down before removing them. This prevents any minor deformation and ensures the tool is safe to handle.

Step 10: Inspect and Clean

Carefully remove the workpiece from the vise. Inspect the machined surface for accuracy and quality. Remove any burrs or sharp edges with a deburring tool or file. Clean your end mill and machine to prepare for the next operation.

Troubleshooting Common Issues

Even with the right tool, you might encounter some hiccups. Here’s how to address them:

Problem: Chips are welding to the end mill.

- Cause: Too much heat, feed rate too slow, or spindle speed too fast.

- Solution: Increase feed rate slightly, decrease spindle speed slightly, use a cutting lubricant or air blast, ensure adequate chip clearance (use 1-2 flute end mills).

Problem: Poor surface finish (rough, fuzzy).

- Cause: Dull tool, feeds and speeds are off, excessive vibration, chip recut