A 1/8 Inch Carbide End Mill is Crucial for Effective Chip Evacuation, Especially in Tough Materials, Ensuring Smooth Machining and a Cleaner Workspace.

Ever found yourself wrestling with a machining job, only to be bombarded by stubborn chips hindering your progress? It’s a common frustration for anyone working with metal or even some harder woods and plastics. You’re aiming for precision, but the material just isn’t cooperating. The good news? There’s a specific tool designed to tackle this head-on, and understanding it is key to smoother cuts and a more efficient workflow. We’re diving deep into the world of the 1/8 inch carbide end mill, explaining why it’s a hidden gem for clearing out those pesky chips. Get ready to learn how this small but mighty tool can make a big difference in your workshop.

Why Chip Evacuation Matters

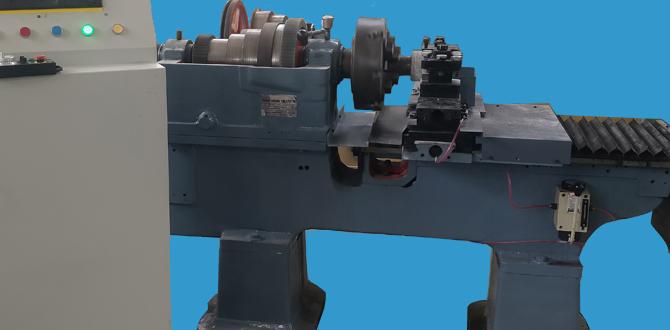

In any machining operation, whether it’s on a metal lathe, a milling machine, or even a high-precision CNC, effectively removing chips is paramount. Think of chips as the waste material produced when your cutting tool shaves away at your workpiece. If these chips aren’t cleared away quickly and efficiently, they can cause a whole host of problems.

Imagine trying to paint a wall while someone keeps smearing wet paint back over where you just painted. That’s kind of what happens when chips aren’t evacuated effectively. They can:

- Cause Tool Damage: Chips can get recut or packed around the cutting edge of your tool, leading to premature wear, chipping, or even catastrophic failure. This is especially true for delicate tools like a 1/8 inch carbide end mill.

- Degrade Surface Finish: When chips interfere with the cutting process, they can scratch and mar the surface of your workpiece, leaving behind a rough, undesirable finish.

- Overheat the Workpiece and Tool: Trapped chips act like insulation, preventing coolant or air from reaching the cutting zone. This leads to increased heat, which can soften the material being cut and further damage the tool.

- Reduce Cutting Efficiency: A tool that’s constantly fighting through packed chips won’t be able to cut effectively, slowing down your process and increasing the strain on your machine.

- Create Safety Hazards: Loose, sharp chips can fly off unexpectedly, posing a risk to the operator and others nearby.

For materials like Inconel 718, known for its toughness and high-temperature resistance, effective chip evacuation isn’t just a convenience—it’s a necessity. Neglecting it can render an otherwise precise operation unusable.

Introducing the 1/8 Inch Carbide End Mill

When we talk about end mills, we’re referring to rotary cutting tools that are used in milling operations to create slots, pockets, and contours. They have cutting edges on their end and flutes that run up the body of the tool, which are crucial for chip evacuation. A carbide end mill, specifically, is made from tungsten carbide, a material renowned for its extreme hardness and ability to withstand high temperatures and wear.

Why the focus on a 1/8 inch size? This particular diameter is incredibly versatile. It’s small enough for detailed work, intricate pockets, and precise slotting, making it a staple in precision machining. When we add the characteristic of a “long reach” for a tool this small, it means the cutting flutes extend further up the shank, allowing access into deeper cavities or for machining features that require a longer reach without excessive setup.

The keyword “carbide end mill 1/8 inch 6mm shank long reach for inconel 718 chip evacuation” highlights a very specific, high-performance application. Inconel 718 is a superalloy used in extreme environments (like aerospace engines and chemical processing) because of its strength and heat resistance. Machining it is notoriously difficult, and that’s where the advantages of a specialized carbide end mill truly shine. The combination of carbide’s hardness, the small diameter for detailed control, the long reach for access, and the design optimized for chip evacuation is critical for success when working with such demanding materials.

What Makes Carbide Special?

- Hardness: Carbide is significantly harder than high-speed steel (HSS), allowing it to cut harder materials and maintain its edge longer.

- Heat Resistance: It can operate at much higher cutting speeds without losing its temper, crucial for materials like Inconel that generate a lot of heat.

- Wear Resistance: This translates to longer tool life and more consistent performance.

The Role of the 6mm Shank

The “6mm shank” specifies the diameter of the part of the end mill that fits into the tool holder of your milling machine. For smaller end mills, especially those in the 1/8 inch (which is approximately 3.175mm) range, using a precisely sized shank like 6mm is common on many small-to-medium sized milling machines and CNCs. It ensures a secure fit and proper runout, which is critical for the precision required when using such small tools.

The Significance of Long Reach

A “long reach” end mill has an extended flute length compared to its overall length. This feature is vital when:

- Machining deep pockets or slots.

- Needing to clear obstructions around the feature being machined.

- Achieving a specific depth of cut without requiring excessive setup or multiple tool changes.

For a 1/8 inch end mill, a long reach design needs to be carefully manufactured to maintain rigidity. Too much overhang can lead to chatter and poor surface finish, but when engineered correctly, it opens up possibilities for more complex geometries.

Chip Evacuation Strategies for Small End Mills

For a small-diameter tool like a 1/8 inch carbide end mill, especially one designed for difficult materials like Inconel, effective chip evacuation relies on a combination of tool geometry and machining techniques. The flutes of the end mill are the primary pathways for chip removal. The more efficient these pathways are, the better the tool and the material will perform.

Tool Geometry Matters

Manufacturers design end mills with chip evacuation in mind. For a 1/8 inch carbide end mill intended for materials like Inconel:

- Number of Flutes: While 2-flute end mills are excellent for chip evacuation as they offer more space between flutes, 3-flute or 4-flute are also used for increased rigidity and better surface finish in harder materials. For Inconel and critical chip evacuation, a 2-flute end mill is often preferred.

- Helix Angle: A steeper helix angle can help “screw” chips up and out of the flutes more effectively.

- Core Thickness: The central core of the end mill (the part without flutes) influences rigidity. For small end mills, a robust core is crucial to prevent deflection.

- Surface Finish of Flutes: Polished or coated flutes reduce friction, allowing chips to slide out more easily.

Machining Techniques

Even with an optimized tool, how you use it significantly impacts chip evacuation:

- Appropriate Spindle Speed and Feed Rate: This is a delicate balance. Too slow a feed rate per tooth can lead to chips packing in the flutes, while too fast can overload them. High spindle speeds are often used with carbide to achieve efficient material removal, but they must be paired with appropriate feed rates.

- Peck Drilling and Ramping: For pockets, rather than plunging straight down, techniques like peck drilling (where the tool retracts periodically to clear chips) or ramping (where the tool enters the material at an angle) can greatly improve chip flow.

- Coolant/Lubrication: Using a high-pressure coolant system or mist coolant is vital. It not only cools the cutting zone but also flushes chips away from the tool and workpiece. For Inconel, specialized cutting fluids are often necessary.

- Air Blast: A strong blast of compressed air can help dislodge chips, especially in dry machining or when a conventional coolant system isn’t feasible.

- Up-milling vs. Down-milling: In some cases, the direction of cut can influence how chips are managed.

Challenges of Machining Inconel 718 with Small Tools

Inconel 718 is a workhorse material in high-stress industries like aerospace and energy. Its remarkable properties—high tensile strength, corrosion resistance, and excellent performance at high temperatures—make it ideal for turbine blades, engine components, and rocket motors. However, these very properties make it a nightmare to machine.

When machining Inconel 718, particularly attempting intricate features with a 1/8 inch carbide end mill, machinists face several significant challenges:

- Work Hardening: Inconel 718 has a tendency to work harden significantly. This means the material directly beneath the cutting surface becomes harder with every pass, making subsequent cuts more difficult and increasing tool wear.

- Low Thermal Conductivity: While it performs well at high temperatures, Inconel 718 doesn’t dissipate heat well. This leads to a high concentration of heat at the cutting edge, accelerating tool wear and potentially causing thermal damage to the workpiece.

- Gummy and Abrasive Nature: It can behave somewhat “gummy,” leading to chip welding onto the cutting tool, and it’s also abrasive, causing rapid flank wear on the end mill.

- Excessive Cutting Forces: Machining Inconel requires higher cutting forces, which can lead to tool deflection and vibration, especially with small-diameter tools.

- Chip Packing: As mentioned previously, the combination of heat, gummy texture, and tendency to work harden makes chip evacuation extremely critical. Chips can easily become recut or fuse to the tool if not cleared immediately.

This is where a well-designed 1/8 inch carbide end mill, with features optimized for chip evacuation (like a 2-flute design with polished flutes and a suitable flute length), becomes indispensable. Its hardness and heat resistance combat the material’s properties, while its geometry actively fights chip-related problems.

Selecting the Right 1/8 Inch Carbide End Mill

Not all 1/8 inch carbide end mills are created equal, especially when you’re aiming for precision and dealing with tough materials. Here’s a breakdown of what to look for:

Material and Coating

- Substrate: Look for a micro-grain carbide substrate suitable for the hardness of Inconel. Your supplier can provide guidance on the best carbide grade.

- Coatings: Coatings like TiAlN (Titanium Aluminum Nitride) or AlCrN (Aluminum Chromium Nitride) are excellent for high-temperature applications and wear resistance when machining superalloys like Inconel. They help reduce friction and prolong tool life.

Flute Design

- Number of Flutes: For tough materials and superior chip evacuation, a 2-flute end mill is often the best choice. The larger flute volume allows for better chip clearance.

- Helix Angle: A steeper helix angle (e.g., 30-45 degrees) can aid in chip evacuation by helping to “screw” chips out of the cut more effectively.

- Chip Breakers: Some end mills have small notches or chip breakers ground into the cutting edges of the flutes. These help to break long, stringy chips into smaller, more manageable pieces, improving evacuation.

Shank and Length

- Shank Tolerance: Ensure the shank is manufactured to tight tolerances (e.g., H6) for accurate clamping in your tool holder.

- Reach: A “long reach” end mill is important for specific applications, but be mindful of rigidity. For very deep cuts, you might need a tool with a slightly shorter flute length for better stability, or employ harmonic dampeners if available for your machine.

Manufacturer Reputation

Reputable tool manufacturers invest heavily in R&D to optimize their end mills for specific materials and applications. Consulting their catalogs or contacting their technical support can provide invaluable insights. For example, companies like Sandvik Coromant, Iscar, and Kennametal are leaders in tooling for demanding applications.

Practical Application Example

Let’s consider a scenario where you need to mill a small internal slot with a width of approximately 1/8 inch (3.175mm) and a depth of 0.5 inches (12.7mm) in a block of hardened Inconel 718. You’re using a small CNC milling machine with a 6mm collet system. This is where our specialized 1/8 inch carbide end mill comes into play.

The Tool: A 1/8 inch (3.175mm) diameter, 2-flute, long-reach carbide end mill with a TiAlN coating, a 30-degree helix angle, and polished flutes. The shank is 6mm. The flute length might be around 1/2 inch or slightly more, with an overall length allowing for machine clearance.

The Challenge: To machine this slot accurately without overheating the tool, work hardening the Inconel excessively, or packing chips in the narrow flutes, which would lead to tool breakage or a poor surface finish.

The Solution:

- Setup: Secure the Inconel block firmly and ensure the end mill is correctly seated in a high-quality 6mm collet for minimal runout.

- Coolant: Utilize a high-pressure coolant system, with the nozzle directed precisely at the cutting zone to flush chips and cool both the tool and workpiece.

- Machining Strategy: Instead of direct plunging, use a spiral ramping motion to enter the material. This reduces the initial cutting load and helps clear chips.

- Cutting Parameters (Example – Always consult tool manufacturer recommendations!):

- Spindle Speed: 8,000 – 12,000 RPM (Carbide can handle high speeds, but Inconel needs careful management).

- Feed Rate per Tooth: 0.0005 – 0.001 inches/tooth (0.0127 – 0.0254 mm/tooth). This is a very conservative feed rate, crucial for managing forces and heat in Inconel.

- Stepdown (Plunge/Ramp Diameter): Start with a 0.050 inch (1.27mm) diameter to enter via spiral interpolation for the first pass, then use trochoidal milling or helical interpolation for the slot walls.

- Depth of Cut per Pass: For the wall, 0.010 – 0.020 inches (0.254 – 0.508 mm). This light depth of cut is essential to manage heat and cutting forces.

- Engagement Type: Use high-feed milling or trochoidal milling strategies to maintain a consistent chip load and avoid dwelling in the material, which generates heat.

- Monitoring: Listen to the sound of the cut. A smooth, consistent sound indicates good chip formation and evacuation. Any chattering or screaming suggests an issue. Visually inspect chips if possible—they should be small and well-formed, not long and stringy.

- Post-Machining: After the slot is milled, the debris should be easily cleared with the coolant flow. The clean flutes of the fresh end mill prevent recutting during the final passes.

This careful approach, enabled by the specialized 1/8 inch long-reach carbide end mill, allows for precise machining of demanding features in difficult alloys.

Maintenance and Care for Your End Mill

Even the best tools need proper care to perform optimally. For your valuable 1/8 inch carbide end mills, especially those used in demanding applications, follow these guidelines:

- Cleaning: After each use, thoroughly clean the end mill. Remove all chips, coolant residue, and any sign of material buildup.