Carbide end mills are precision cutting tools designed for creating intricate shapes and achieving exact measurements, making them ideal for tight tolerance work in machining.

Carbide End Mill: Your Essential Tight Tolerance Tool

Ever stared at a project that demands super-precise cuts, where even a tiny wiggle of the tool means disaster? You know, those jobs where the difference between “almost right” and “perfect” is measured in fractions of a millimeter? For many of us in the workshop, myself included here at Lathe Hub, hitting those tight tolerances can feel like a real challenge. It’s easy to get frustrated when your standard tools just can’t keep up. But don’t worry, there’s a specific tool designed to tackle these demanding tasks with ease and accuracy. Get ready to discover your new best friend for precision machining: the humble, yet mighty, carbide end mill.

In this guide, we’ll break down exactly what makes a carbide end mill so special, why they are your go-to for tight tolerances, and how to pick the right one for your needs. We’ll cover everything from understanding their unique properties to practical tips for using them effectively. By the end, you’ll feel confident selecting and using these incredible tools to achieve those exacting results you’ve been aiming for.

What Exactly is a Carbide End Mill?

Let’s start with the basics. An end mill is a type of milling cutter. Think of it like a drill bit, but with a really important difference: it can cut horizontally into material, not just downwards. This makes it incredibly versatile for tasks like cutting slots, creating pockets, profiling edges, and so much more. When we add “carbide” into the mix, we’re talking about the material the cutting edges are made from.

Tungsten carbide, the material used for carbide end mills, is an incredibly hard and wear-resistant compound. It’s formed by combining tungsten and carbon atoms. This process creates a material that is significantly harder than high-speed steel (HSS), the more traditional material for cutting tools. This hardness is the key to why carbide end mills excel.

Because carbide is so hard, it can maintain its sharp cutting edge for much longer, even when working with tough materials or at higher speeds. This superior edge retention means less tool wear and more consistent cutting performance, which is absolutely crucial when you need accuracy down to the thousandth of an inch.

Why Carbide End Mills are Perfect for Tight Tolerances

So, why is this super-hard material so good for “tight tolerance” work? Let’s break it down:

- Exceptional Hardness & Strength: As mentioned, tungsten carbide is one of the hardest materials known. This means it resists deformation and wear much better than traditional materials like HSS. When cutting precisely, you want a tool that doesn’t flex or wear down easily, as this directly impacts the accuracy of your cuts.

- High Wear Resistance: Tight tolerance machining often involves repeated passes or cutting through abrasive materials. Carbide’s resistance to wear ensures that the cutting edge stays sharp and the tool maintains its intended diameter and geometry for longer. This consistency is paramount for achieving and holding precise dimensions.

- Ability to Handle High Speeds: Carbide can withstand higher cutting speeds and temperatures compared to HSS. While this might seem like it’s just about speed, it also contributes to accuracy. Higher speeds can sometimes lead to cleaner cuts and reduced vibration, both of which are beneficial for precision work.

- Rigidity: Carbide end mills are typically very rigid. This rigidity means they can resist deflection under cutting forces. Less deflection equals less chance of cutting a profile that is slightly larger or smaller than intended, which is exactly what you want when chasing tight tolerances.

- Precision Manufacturing: Carbide end mills themselves are manufactured to very high standards of accuracy. Their geometry, flute spacing, and diameter are controlled precisely, ensuring that when you set up your machine correctly, the tool will perform as expected.

For anyone working on components where mating parts need to fit perfectly, or where a specific clearance is critical, a carbide end mill is not just a choice, it’s often a necessity. Think about making parts for a model engine, a custom camera mount, or a precision instrument – these are the kinds of applications where the reliability of a carbide end mill shines.

Understanding the Anatomy of a Carbide End Mill

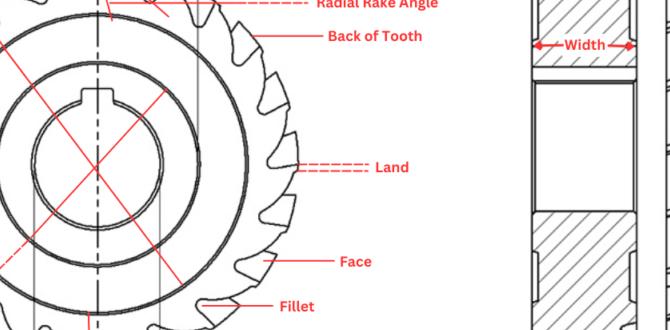

Before we dive into selection, let’s quickly get familiar with the parts of an end mill. This will make understanding different types and features much easier:

- Shank: This is the part of the end mill that gets held by the tool holder in your milling machine’s spindle. It’s usually cylindrical. The size of the shank (e.g., 1/8 inch, 1/4 inch, 6mm, 12mm) is important because it dictates what collets or holders you’ll need.

- Flutes: These are the helical grooves that run along the cutting portion of the end mill. They serve multiple purposes: they create the cutting edges, help to evacuate chips (the material being cut away), and contribute to the tool’s rigidity.

- Cutting Diameter: This is the diameter of the tool at its widest point across the flutes. This is the dimension that will determine the width of slots or the size of pockets you can create.

- Flute Length: This is the length of the portion of the end mill that has flutes – this is where the cutting happens.

- Overall Length: The total length of the end mill, from the tip of the flutes to the end of the shank.

- End Tooth: Some end mills have cutting teeth on their end face, while others do not. This affects their ability to plunge (cut straight down into material) and can influence the surface finish they produce.

Types of Carbide End Mills for Precision Work

While all carbide end mills share that inherent hardness, they come in various designs, each suited for different tasks. For tight tolerance work, you’ll often be looking at specific types:

Square End Mills

These are the most common type. They have flat, square ends with cutting edges that go all the way around the perimeter and on the end face. Their versatility makes them suitable for a wide range of operations, including milling slots, pockets, and facing (creating a flat surface).

Ball End Mills

As the name suggests, these have a rounded, ball–shaped tip. They are fantastic for creating contoured surfaces, 3D pockets, and fillets (rounded internal corners). The radius of the ball tip is a critical dimension for achieving specific shapes and fits.

Corner Radius End Mills

A hybrid between square and ball end mills, these have flat ends but with a small radius ground into each corner where the side meets the end. This radius helps to strengthen the corners, preventing chipping and allowing for slightly cleaner cuts when milling square pockets or slots. They can also leave a small radius in the corner of your workpiece, which can be desirable for stress distribution or easier assembly.

Micro End Mills

When we talk about “tight tolerances,” we often mean very small features. Micro end mills are specifically designed for very small diameter work, often in the range of a few millimeters or less. These are highly specialized and require very rigid machines and fixtures to operate effectively. An articles on micro-milling often highlight the challenges and precision required for these tiny tools.

Choosing the Right Carbide End Mill: Key Factors

Selecting the correct end mill is crucial for achieving tight tolerances and ensuring a good machining process. Here are the key factors to consider:

1. Material of the Workpiece

The material you are cutting significantly influences your choice of end mill. Carbide excels at cutting harder materials like steels, stainless steels, and hardened alloys. However, it can also be used on softer materials like aluminum and plastics. For softer, gummy materials, sometimes end mills with fewer flutes (2 or 3) and polished flutes are preferred to prevent chip buildup. Always check the manufacturer’s recommendations for the best end mill for your specific workpiece material.

2. Number of Flutes

The number of cutting edges (flutes) on an end mill affects its performance:

- 2 Flutes: Generally offers better chip clearance, making it ideal for softer, “gummy” materials like aluminum, copper, and plastics. They are also good for side milling and slotting where chip evacuation is critical.

- 3 Flutes: Offers a good balance between chip clearance and rigidity. They can often handle slightly harder materials than 2-flute end mills and provide a better surface finish than 2-flute tools in some applications.

- 4 Flutes: Provides greater rigidity and a better surface finish on harder materials. They are less effective at chip evacuation, so they are better suited for shallower cuts, finishing passes, or materials that don’t produce long, stringy chips.

- More Flutes (e.g., 5, 6, 7): These are often referred to as “high-performance” or “square type” end mills. They offer maximum rigidity and excellent surface finish but are intended for very shallow depth-of-cut operations, often in hard materials, and typically require specialized machining centers for optimal performance.

For tight tolerance work, a balance between the number of flutes and the material is key. Often, 3 or 4 flutes offer a good compromise for accuracy and versatility.

3. Diameter and Shank Size

This is where we consider specific sizes. For example, if you’re looking for a specific tool like a “carbide end mill 1/8 inch 6mm shank extra long for FR4 tight tolerance,” it breaks down like this:

- Diameter: In this case, it’s 1/8 inch (which is approximately 3.175mm). This small diameter is crucial for creating very fine details and precise slots.

- Shank Size: The shank is specified as 6mm. This means the tool holder or collet you use must be compatible with a 6mm shank.

- “Extra Long”: This refers to the flute length or overall length. An “extra long” end mill allows you to reach deeper into a workpiece or cut deeper slots than a standard length tool. This can be very useful for specific geometries but requires careful consideration of tool deflection, especially with smaller diameters.

- “For FR4 Tight Tolerance”: This is a critical application note. FR4 is a common material for printed circuit boards (PCBs), often made of fiberglass epoxy. It’s a somewhat abrasive material. Machining FR4 for PCBs often involves cutting very fine traces and precise outlines where extremely tight tolerances are paramount. End mills designed for FR4 might have specific coatings or geometries to handle its abrasive nature and achieve clean edges without delamination.

When selecting, always ensure the diameter and shank size match your machine’s capabilities and your tooling. For precision, a tool that is perfectly straight and concentric is vital.

4. Coatings

End mills can be coated to improve their performance. While not always necessary for hobbyists, coatings can offer significant benefits:

- TiN (Titanium Nitride): A common gold-colored coating that increases surface hardness and wear resistance, extending tool life and allowing for higher cutting speeds.

- TiCN (Titanium Carbonitride): A gray/black coating that is harder than TiN and offers better abrasion resistance, especially useful for cutting steels and cast iron.

- TiAlN (Titanium Aluminum Nitride): A dark purple/black coating that is excellent for high-temperature applications and machining of stainless steels and exotic alloys. It forms a protective oxide layer that prevents heat buildup.

- ZrN (Zirconium Nitride): Offers good performance on aluminum and non-ferrous materials, often resulting in a very smooth surface finish.

For FR4, a coating designed to reduce friction and prevent material buildup, like ZrN or specific proprietary coatings, might be beneficial.

5. Helix Angle

The helix angle refers to the angle of the flutes. A standard helix angle is typically around 30 degrees. However, you might find tools with:

- High Helix Angle (e.g., 45-60 degrees): Provides a sharper cutting action, better chip evacuation, and can lead to a smoother finish. However, it also increases the tendency for the tool to “climb” or lift the workpiece if not used correctly (especially in milling aluminum).

- Low Helix Angle (e.g., 15-25 degrees): Offers more rigidity and less tendency to climb.

For general-purpose tight tolerance work, a standard to high helix angle is often preferred for its cutting efficiency.

Using Your Carbide End Mill for Tight Tolerances: Best Practices

Having the right tool is only half the battle. How you use it is just as important for achieving those precise results.

1. Machine Rigidity and Setup

This is non-negotiable for tight tolerances. Ensure your milling machine is in good condition. The ways should be properly adjusted, and there should be minimal play in the lead screws or ball screws. A wobbly machine will result in wobbly cuts. Use a rigid tool holder and a good quality collet that grips the shank securely and concentrically. A runout (wobble) of even a few thousandths of an inch will destroy your precision efforts.

2. Workholding

Your workpiece must be held extremely securely. For precision work, use a vise with hardened jaws, custom fixtures, or clamps that apply force without distorting the part. A workpiece that shifts even slightly during machining will lead to inaccurate dimensions.

3. Cutting Parameters (Speed and Feed Rate)

This is where experience and careful calculation come in. Consult manufacturer data, but generally:

- Cutting Speed (Spindle Speed): Carbide generally runs faster than HSS. For a 1/8 inch end mill, you might be looking at spindle speeds from 10,000 RPM to 25,000 RPM or even higher, depending on the material and the specific tool.

- Feed Rate: This is how fast the tool moves through the material. For tight tolerances, you often need to use a feed rate that is appropriate for the tool diameter and the number of flutes, ensuring you don’t overload the tool or the machine. It’s often better to take lighter, more frequent passes than one heavy pass. For small diameter tools like 1/8 inch or 6mm, the feed rate will be quite low.

A good starting point for feed rate can often be calculated using the formula: Feed Rate = (Chipload per tooth) x (Number of Flutes) x (Spindle Speed). Chipload is the thickness of the material each cutting edge removes on each revolution. For tight tolerance, you’ll often aim for a smaller chipload.

4. Depth of Cut

For very precise work, especially with smaller diameter end mills prone to deflection, take lighter depths of cut. Instead of trying to remove all the material in one go, make multiple shallow passes. This reduces the cutting forces on the tool, minimizing deflection and improving accuracy. For profiling or slotting to a very precise dimension, it’s common to leave a few thousandths of an inch for a final “cleanup” or “finishing” pass at a reduced feed rate.

5. Chip Evacuation

Ensure chips are being cleared away effectively. Clogged flutes can lead to tool breakage, poor surface finish, and inaccurate cuts. For deep pockets, consider using peck drilling (plunging and retracting the tool to clear chips) or using through-spindle coolant if your machine supports it. For FR4, sticky fiberglass dust can be an issue, so good chip management is key.

6. Coolant and Lubrication

While carbide can handle heat, proper cooling or lubrication can extend tool life, improve surface finish, and help with chip control, all of which benefit precision machining. For metals, a good cutting fluid is recommended. For plastics or composites like FR4, air blast or mist coolant can be effective.

7. Tool Length and Cantilever

The more the end mill extends beyond its holder (known as cantilever), the more it is susceptible to deflection. For demanding tight tolerance work, try to use the shortest possible end mill that will reach your target depth. If you must use an extra-long tool, be extra careful with speeds, feeds, and depth of cut.

Specific Considerations for “Carbide End Mill 1/8 inch 6mm Shank Extra Long for FR4 Tight Tolerance”

Let’s zoom in on this specific example. Machining FR4 for electronics or other precise applications requires careful handling:

- FR4’s Nature: FR4 is a composite material made of fiberglass and epoxy resin. It’s abrasive and can be brittle. The epoxy can also melt if too much heat is generated.

- Tooling for FR4: Specialized end mills for PCBs often feature: