A 1/8 inch, 6mm shank carbide end mill with a reduced neck is ideal for plastics like PVC, effectively minimizing chatter for cleaner cuts and better finishes.

Welcome to Lathe Hub! If you’re diving into the world of metalworking or woodworking, you’ve likely encountered terms that sound like a secret code. But don’t worry, we’re here to demystify them. Today, let’s talk about a specific tool that can make a big difference when you’re working with materials like PVC: a “carbide end mill, 1/8 inch, 6mm shank, reduced neck, for PVC, reduce chatter.” It sounds like a mouthful, but each part of that description tells us something important about how this tool works and why it’s so handy for beginner machinists and DIY enthusiasts. Getting the right tool for the job isn’t just about efficiency; it’s also about making your projects safer and much more enjoyable. We’ll break down exactly what this tool is, why its features matter, and how you can use it to achieve fantastic results, especially when cutting plastics. Stick around, and you’ll be cutting with confidence in no time!

Understanding Your Carbide End Mill: The Basics

Let’s break down that specific end mill description piece by piece. This will help you understand why it’s so effective for certain tasks.

What is an End Mill?

An end mill is a type of cutting tool used in milling operations. Think of it as a drill bit that can also cut sideways. While a drill bit is primarily designed to make holes, an end mill can be used to create slots, pockets, profiles, and contour surfaces. They are essential for shaping materials in both metal and plastic machining.

Carbide: The Material Matters

The “carbide” in the description refers to the material the end mill is made from: tungsten carbide. Carbide is an extremely hard and durable material. This hardness means it can cut through tough materials, maintain a sharp edge for longer, and withstand higher temperatures generated during machining compared to high-speed steel (HSS) tools. For beginners, using a carbide tool often means less tool wear and a more consistent cutting experience, which can reduce frustration.

Size: 1/8 Inch and 6mm Shank

1/8 Inch Cutting Diameter: This refers to the diameter of the cutting edges at the very tip of the end mill. A 1/8 inch end mill is quite small. This size is perfect for intricate work, detailed engravings, cutting out small parts, or creating fine slots where precision is key.

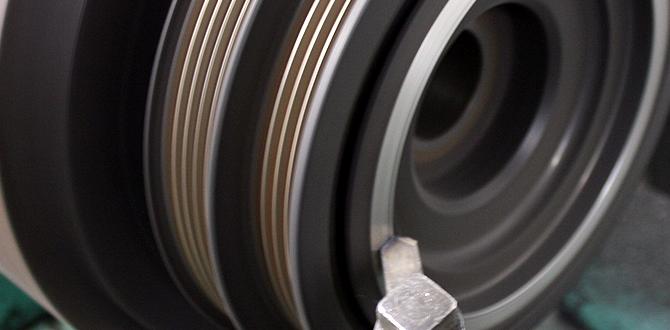

6mm Shank Diameter: The shank is the part of the tool that fits into the tool holder (like a collet or chuck) on your milling machine. A 6mm shank is a common size, especially for smaller machines or for use in specific collet systems. It’s important that the shank size matches your machine’s tool holder. Using an adapter can sometimes be necessary, but it’s always best to have the shank fit directly for maximum rigidity.

Reduced Neck: The Chatter Buster

This is a crucial feature for reducing vibration, commonly known as “chatter.” A “reduced neck” means that the diameter of the shank is made smaller than the cutting diameter for a portion of the tool’s length, usually just below the cutting flutes.

Why does this help reduce chatter? Chatter often occurs when the cutting forces cause the end mill to vibrate. A reduced neck allows the end mill to flex slightly, absorbing some of these vibrations. It also helps to clear away chips more effectively from the flutes, preventing material buildup that can lead to increased cutting forces and further chatter. This feature is particularly beneficial when cutting softer materials like PVC, which can be prone to melting or vibrating if cut improperly.

For PVC and Reducing Chatter

Targeting “PVC” means this end mill is designed with features suitable for cutting this type of plastic. PVC (polyvinyl chloride) is a relatively soft plastic. It can melt easily under friction and is prone to gumming up cutting tools. An end mill designed for PVC will typically have:

Polished Flutes: Smooth flutes help prevent plastic from sticking to the tool, reducing buildup.

Specific Tooth Geometry: The shape of the cutting edges (teeth) is optimized to shear the plastic cleanly, rather than pushing or melting it.

Cooling Considerations: While not explicit in the name, tools designed for plastics often work best with appropriate speeds and feeds that don’t generate excessive heat.

The “reduce chatter” part reinforces what we discussed about the reduced neck feature. Chatter is a common problem when milling any material, but it can be particularly noticeable and detrimental when working with plastics. It results in a rough surface finish, can damage the workpiece, and puts undue stress on the cutting tool and the machine.

Why This Specific End Mill is Great for Beginners Working with PVC

As Dan from Lathe Hub, I see a lot of folks starting out, and sometimes the sheer variety of tools can be overwhelming. This particular end mill is a smart choice for several reasons when you’re cutting PVC:

Simplicity: You don’t need to be a seasoned pro to get good results. The reduced neck design actively helps you avoid one of the most common problems: chatter. This means fewer headaches and a higher chance of success on your first try.

Forgiveness: PVC can be a bit tricky. It’s soft, and heat management is key. An end mill designed for it, like this one, will cut more cleanly. The reduced neck also provides a little more flexibility, making you less likely to break a tiny, delicate tool if you hit a slightly harder spot or your feed rate isn’t perfect.

Precision: The 1/8 inch size is fantastic for detailed work common in DIY projects, model making, or creating custom fixtures. You can achieve fine lines and intricate shapes that larger tools just can’t manage.

Durability: Carbide is tough. This means your tool will last longer, stay sharper, and require less frequent replacement, which is always a win for the workshop budget.

How to Use Your 1/8 Inch Carbide End Mill on PVC

Let’s get practical. Using this end mill effectively on PVC involves a few key considerations. Remember, slow and steady often wins the race, especially with plastics.

Setting Up Your Machine

1. Secure the Workpiece: Always ensure your PVC workpiece is firmly clamped to the milling machine’s table. Any movement can lead to inaccurate cuts, tool breakage, or injury. Use appropriate clamps that won’t damage the material if possible.

2. Install the End Mill: Insert the 6mm shank of the end mill into a compatible collet. Ensure it’s seated properly for maximum rigidity. A loose tool is dangerous.

3. Set the Depth of Cut: For PVC, it’s often best to take shallower depths of cut. This reduces the strain on the tool and the machine, and helps manage heat. You can always make multiple passes to reach your final depth.

Speeds and Feeds – The Sweet Spot

This is where many beginners struggle, but for PVC with this type of end mill, we can simplify.

Spindle Speed (RPM): Plastics like PVC generally benefit from higher spindle speeds compared to metals. However, too high a speed generates heat, which can melt the plastic. For a 1/8 inch carbide end mill on PVC, a good starting point is often in the range of 12,000 to 20,000 RPM. You’ll need to experiment. The goal is to create a clean chip, not a melted mess.

Feed Rate (IPM or mm/min): This is how fast the tool moves through the material. You want to feed fast enough to create a proper chip. If you feed too slowly, the tool will rub and generate heat, melting the plastic. For a 1/8 inch end mill, a good starting point might be between 10 to 25 inches per minute (IPM). Again, listen to the machine and observe the chips.

Chip Evacuation: Ensure your flutes are clear. If you’re doing a deep cut or slotting, you might need to “peck” – retracting the tool periodically to clear chips. Some end mills designed for plastics have improved chip evacuation geometry.

Pro Tip: A common rule of thumb when starting out is to aim for a chip load of about 0.001 to 0.003 inches per tooth for plastics. For a two-flute end mill (which this likely is), you can calculate your feed rate: Feed Rate = Spindle Speed (RPM) × Number of Flutes × Chip Load.

Example: 15,000 RPM × 2 flutes × 0.002 inch/tooth = 60 IPM. You might start a bit lower and increase if it feels right and the chips look good.

Cooling and Lubrication

While not always necessary for PVC on a small scale, a little bit of lubricant can help.

Air Blast: A jet of compressed air directed at the cutting area can be very effective at cooling the tool and workpiece and blowing away chips.

Cutting Fluid/Lubricant: For plastics, a light spray of a specialized plastic cutting fluid or even a bit of soapy water can help reduce friction and prevent melting. Avoid heavy petroleum-based lubricants, as they can react with PVC.

Making the Cut

Climb Milling vs. Conventional Milling: For plastics, climb milling (where the cutter rotates in the same direction the feed is moving) often gives a better finish and reduces the chance of chipping the edge. However, it can also put more stress on the tool and machine if not set up perfectly. Conventional milling is safer for beginners as it tends to push the material away from the cutter. With a reduced neck end mill, you might find climb milling works very well to mitigate chatter. Always test on a scrap piece first!

Edgebreaks and Chamfers: If you’re cutting pockets, you might end up with small, sharp corners. You can use the same end mill at a reduced depth to create a small radius or chamfer.

When to Choose a Reduced Neck End Mill

While we’re focusing on PVC, the benefits of a reduced neck end mill extend to other scenarios:

Reducing Chatter on Any Material: If you’re experiencing vibration and a rough surface finish on wood, plastics, or even softer metals, a reduced neck end mill can often solve the problem.

Improved Chip Clearance: In narrow slots or deep pockets, the reduced neck can allow chips to escape more easily, preventing them from packing up and causing issues.

Flexibility for Delicate Operations: The slight flexibility can be beneficial when precise control is needed and you want to minimize any abrupt forces.

Alternatives and Variations

While the 1/8 inch, 6mm shank, reduced neck carbide end mill is great, it’s good to know about alternatives:

Standard End Mills: For less critical applications or materials that don’t chatter as much, a standard 1/8 inch carbide or HSS end mill might suffice.

Different Shank Sizes: If your machine uses a different collet size (e.g., 1/4 inch, 8mm), you’ll need an end mill with that shank diameter.

Single-Flute vs. Multi-Flute: For plastics, single-flute end mills are often recommended because they provide better chip clearance and faster material removal rates without overheating. However, multi-flute (like two-flute) end mills can offer a smoother finish. For this specific reduced-neck chatter-reducing tool, two flutes are common.

Ball-Nose or Corner-Radius End Mills: If you need to create rounded internal corners or specific profiles, you’d choose a ball-nose or corner-radius end mill of an appropriate size.

Safety First! Always!

Working with machinery can be dangerous if not approached with the right mindset and precautions.

Eye Protection: Always wear safety glasses or a full face shield. Flying debris is a real hazard.

No Loose Clothing or Jewelry: Anything that can get caught in rotating machinery must be removed. Tie back long hair.

Machine Guarding: Ensure all machine guards are in place and functioning.

Tooling Security: Double-check that your end mill is securely held in the collet.

Controlled Operation: Never leave a running machine unattended. Be aware of your surroundings.

Emergency Stop: Know where the emergency stop button is on your machine and how to use it.

For more detailed safety guidelines, especially concerning milling machines, I highly recommend consulting resources from organizations like the Occupational Safety and Health Administration (OSHA), specifically their publications on machine guarding.

Troubleshooting Common Issues

Even with the right tool, you might run into problems. Here’s how to tackle them:

Excessive Heat/Melting Plastic:

Cause: Spindle speed too low, feed rate too fast, depth of cut too high, dull tool, poor chip evacuation.

Solution: Increase spindle speed, decrease feed rate, take shallower cuts, use air blast or coolant, ensure flutes are clean.

Chatter/Vibration:

Cause: Loose tool, worn tool, rigid workpiece setup, feed rate too slow, spindle speed too high or too low, tool not suited for material.

Solution: Ensure tool is tight, try a different end mill (like the reduced neck one for plastics!), adjust feed/speed, increase depth of cut slightly (sometimes this stabilizes cutting), ensure workpiece is rigidly clamped. The reduced neck design should already be helping here!

Poor Surface Finish:

Cause: Incorrect speeds/feeds, worn tool, chatter, or incorrect tool geometry.

Solution: Refine speeds and feeds, try a new end mill, address chatter, ensure tool is appropriate for plastic.

Tool Breakage:

Cause: Taking too deep a cut, feeding too fast, workpiece moving, weak tool, hitting an obstruction.

Solution: Reduce depth of cut, reduce feed rate, ensure workpiece is very secure, use a quality tool, check for obstructions.

Projects Perfect for This End Mill

What can you actually make with a 1/8 inch, 6mm shank, reduced neck carbide end mill on PVC?

Custom Fixtures and Jigs: Create precise holders, guides, or templates for other projects.

Model Making: Cut out intricate parts for scale models, dioramas, or display pieces.

Electronics Enclosures: Mill precise openings for buttons, ports, or ventilation in custom cases.

Sign Making and Engraving: Create detailed lettering or decorative patterns.

Prototypes: Quickly mill out small prototype parts for testing.

* Educational Projects: Practice machining techniques in a forgiving material.

You can find excellent resources on project ideas and advanced techniques at sites like Instructables or Make: Magazine, which often feature projects involving CNC milling and DIY fabrication.

Frequently Asked Questions (FAQ)

Q1: What is the main benefit of a “reduced neck” end mill?

A1: A reduced neck end mill is designed to flex slightly and help absorb vibrations. This significantly reduces chatter, leading to a smoother finish on your workpiece and extending tool life.

Q2: Is a 1/8 inch end mill too small for most jobs?

A2: Not at all! A 1/8 inch end mill is perfect for fine details, intricate designs, small pockets, and engraving. For larger areas, you might need multiple passes or a larger tool, but for precision work, it’s ideal.

Q3: What’s the best way to avoid melting PVC when milling?

A3: The key is managing heat. Use appropriate cutting speeds and feeds (often higher RPM, moderate feed), take shallow cuts, ensure good chip evacuation, and consider using an air blast or a suitable coolant.

Q4: Can I use this end mill on materials other than PVC?

A4: While optimized for plastics like PVC, a carbide end mill with these features can be used on other softer plastics or even some very soft woods. For harder materials like aluminum or steel, you’d need a different type of end mill with specific geometry and use drastically different speeds and feeds.

Q5: How do I know if my feed rate is correct for PVC?

A5: Observe the chips being produced. They should be small, clean chips. If you’re getting wispy, melted-looking material, your feed rate might be too slow or your speed too high. If the tool is chattering or struggling, the feed rate might be too fast or the depth of cut too high.

Q6: My end mill is vibrating a lot, what can I do?

A6: First, ensure the end mill is securely tightened in the collet. Check for any runout (wobble) in your spindle. If the problem persists, you might be taking too deep a cut, your feed/speed settings could be off, or the tool geometry might not be ideal. For plastics, a reduced neck end mill, like the one we’re discussing, is specifically designed to combat this.

Conclusion

So there you have it! That seemingly complex tool description – “carbide end mill, 1/8 inch, 6mm shank, reduced neck, for PVC, reduce chatter” – is actually a fantastic guide to a very useful tool for beginners. By understanding each part, you can see why it’s perfectly