Carbide end mills are versatile cutting tools essential for precise and efficient material removal in milling operations. Choosing the right one, understanding its types, and using it correctly will dramatically improve your project success and workpiece finish, especially for demanding materials like Inconel 718.

Welcome to Lathe Hub! If you’ve dipped your toes into metal machining, whether it’s on a lathe or a milling machine, you know that having the right tools makes all the difference. Today, we’re diving into a super important one: the carbide end mill. Ever looked at a piece of metal and wondered how to shape it with those spinning cutters on a mill? It can seem a bit intimidating at first, but understanding this one tool will unlock a whole world of possibilities for your projects. We’re going to break down exactly what a carbide end mill is, why it’s a workhorse, and how to pick the perfect one for your needs, even for tough stuff like Inconel 718. Stick around, and we’ll make sure you feel confident using these amazing tools.

What is a Carbide End Mill and Why Use One?

At its core, an end mill is a type of milling cutter, but it’s designed to cut sideways and axially. Think of it like a drill bit that can also create slots, pockets, and contours. End mills are the workhorses of CNC machining and manual milling alike. They come in many shapes and sizes, but carbide end mills stand out. Why?

Carbide, or tungsten carbide, is an incredibly hard and wear-resistant material. This means end mills made from it can tackle tougher materials, cut faster, and last much longer than their counterparts made from high-speed steel (HSS). For hobbyists and professionals alike, this translates to less downtime, better precision, and the ability to work with a wider range of metals, from soft aluminum to superalloys like Inconel 718.

The Power of Carbide

- Hardness: Carbide is significantly harder than HSS, allowing it to cut harder materials and maintain its cutting edge for longer.

- Heat Resistance: It can withstand higher cutting temperatures, which is crucial for preventing tool wear and maintaining dimensional accuracy during aggressive cuts.

- Rigidity: Carbide end mills are stiffer than HSS, leading to less chatter and vibration, which results in smoother surface finishes and tighter tolerances.

- Versatility: While the base material is hard, carbide end mills can be coated to further enhance their performance for specific applications, like cutting aluminum or exotic metals.

Common Uses for Carbide End Mills

Carbide end mills are used for a wide array of machining tasks:

- Slotting: Creating narrow grooves or channels in a workpiece.

- Pocketing: Machining out cavities or depressions to specific depths and shapes.

- Profiling: Cutting around the external or internal contours of a part.

- Face Milling: Creating a flat surface on the top or end of a workpiece.

- Drilling (with specialized end mills): Some end mills have center-cutting capabilities that allow them to plunge straight down like a drill.

Types of Carbide End Mills

The world of end mills can seem complex, but understanding the basic types will help you make an informed choice. The key differentiators are the number of flutes, the geometry of the cutting edges, and the material coatings.

By Number of Flutes

Flutes are the spiral grooves that run along the length of the end mill. They are crucial for chip evacuation. The number of flutes affects how the tool handles different materials and cutting speeds.

- 2-Flute End Mills: Often have a center-cutting tip, making them ideal for plunging and slotting. They provide more clearance for chips, making them great for softer materials like aluminum and plastics, or for general-purpose machining where chip evacuation is a concern.

- 3-Flute End Mills: Offer a good balance between chip clearance and rigidity. They are excellent for slotting, pocketing, and general milling in a wide range of materials, including steels and cast iron.

- 4-Flute End Mills: Provide maximum rigidity and a better surface finish. They are not typically center-cutting and are best for peripheral milling (cutting along the outside edge of a part) and faster metal removal in harder materials. The increased number of flutes means less chip space, so they are not ideal for deep slots in gummy materials.

- More than 4 Flutes (e.g., 5, 6, 8): These are often high-performance tools designed for specific applications like finishing or high-feed milling in softer non-ferrous materials. The reduced chip clearance means they rely heavily on flood coolant or MQL (Minimum Quantity Lubrication) to manage heat and chips.

By Geometry and Design

Beyond the number of flutes, the shape and design of the end mill’s cutting surfaces matter.

- Square End Mills: The most common type, featuring sharp 90-degree corners. They are versatile for a wide range of operations.

- Ball End Mills: Have a hemispherical tip, ideal for creating curved surfaces, 3D contours, and fillets.

- Corner Radius End Mills: Similar to square end mills but with a small radius at the cutting corners. This radius helps strengthen the cutting edge, reduce chipping, and create a small fillet at the bottom of a slot, which can be beneficial for stress concentration.

- Form (or Profile) End Mills: These are specialized tools designed to cut specific shapes, like T-slots or dovetails.

- Reduced Neck End Mills: These end mills have a portion of their shank ground down beneath the cutting diameter. This is extremely useful for reaching into deep pockets or undercuts where a standard shank would collide with the workpiece. A reduced neck end mill is often specified for complex geometries.

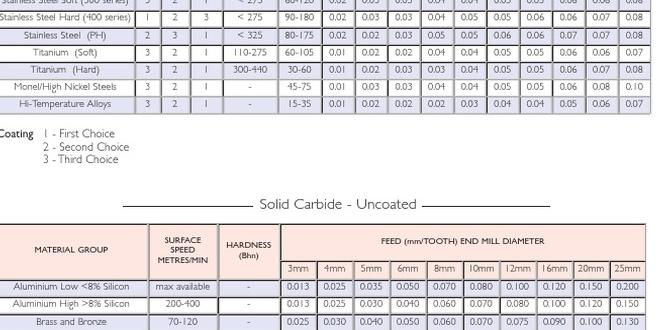

Coatings for Enhanced Performance

Coatings applied to the surface of carbide end mills can dramatically improve their performance:

- TiN (Titanium Nitride): A general-purpose coating that adds some hardness and lubricity, extending tool life in many applications.

- TiCN (Titanium Carbonitride): Harder than TiN, offering better wear resistance, especially when machining abrasive materials.

- TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications and machining harder metals like stainless steels and Inconel. It forms a protective aluminum oxide layer at high temperatures.

- ZrN (Zirconium Nitride): Offers good lubricity and is often preferred for machining aluminum and other non-ferrous materials as it prevents material buildup.

- Uncoated: While less common for carbide, some uncoated end mills are used, especially when cutting softer materials where buildup isn’t a major issue, or when specific coolant/lubrication strategies are employed.

Choosing the Right Carbide End Mill for Your Project

Selecting the correct end mill is crucial for efficiency, tool life, and the quality of your finished part. Several factors come into play, and for specific materials like Inconel 718, these considerations become even more critical.

Material to be Machined

This is the most significant factor. Different materials require different tool geometries, flute counts, and coatings.

- Aluminum and Soft Non-Ferrous Metals: Often benefit from high-flute count (4+) end mills or highly polished uncoated/ZrN coated tools. High flute counts reduce chip load per flute, leading to a better surface finish, but require good chip evacuation. A 2-flute, un-coated or ZrN coated end mill can also work well due to better chip clearance.

- Steel and Stainless Steel: Typically require 3 or 4-flute end mills. TiAlN or TiCN coatings are beneficial for handling the heat generated.

- Cast Iron: Often machined with 4-flute end mills. TiCN or uncoated carbide can perform well.

- Exotic Alloys (e.g., Inconel 718, Titanium): These are a class of their own. They are gummy, abrasive, and work-harden rapidly. They require special tooling with geometries designed for their properties and often benefit from TiAlN/AlTiN coatings. Machining these alloys with Inconel 718 demands robust setups, slow speeds, appropriate feeds, and excellent lubrication (often MQL or flood coolant).

Application Needs

What are you trying to achieve with the end mill?

- Finishing: For a smooth surface finish, a higher flute count (4+ or specialized finishing tools) often works best. Smaller step-overs and lower axial depth of cuts using tools like corner radius or ball end mills are typical.

- Roughing/Material Removal: For rapid material removal, you might use a low-flute count end mill (2-4) with larger chip loads. High-performance roughing end mills with serrated edges are also available.

- Slotting: 2-flute end mills are excellent, especially if you need to cut deep slots, due to their chip-carrying capacity.

- Pocketing: Depends on pocket depth and complexity. For deep pockets, a reduced neck end mill might be necessary.

Shank Diameter and Reduced Neck

The shank is the part of the end mill that is held in the collet or tool holder. For standard operations, the shank diameter is usually the same as the cutting diameter. However, if you need to machine deep features or reach into tight spaces, a carbide end mill 1/8 inch 6mm shank reduced neck becomes incredibly important.

Consider a scenario where you need to mill a slot that is 1 inch deep, but your end mill has a 1/4 inch cutting diameter. A standard 1/4 inch shank end mill would collide with the workpiece long before it reaches the desired depth. A reduced neck end mill allows the shank to be much smaller than the cutting diameter, providing the necessary clearance. A 1/8 inch (approx. 3mm) or 6mm shank on an end mill with a larger cutting diameter is a common configuration for reaching into intricate areas.

Tool Holder and Work Holding

Ensure your tool holder can grip the shank of the end mill securely. For reduced neck end mills, you might need specialized tool holders or collets that can accommodate the smaller shank diameter while still providing rigid support to the cutting portion.

Understanding Key Specifications for Your Carbide End Mill

Beyond the general types, a few specific details on an end mill’s packaging or description are vital for selection.

Cutting Diameter

This is the largest diameter of the cutting edges. It’s what determines the width of the slot or the size of the feature you can cut directly.

Number of Flutes

As discussed, this is crucial for chip evacuation and rigidity. For materials that produce long, stringy chips (like aluminum) or when plunging, fewer flutes (2) are often better. For harder materials or smoother finishes, more flutes (4+) can be advantageous.

Shank Diameter

The diameter of the portion that fits into the tool holder. Standard is often the same as the cutting diameter, but reduced necks are critical for deep cuts.

Overall Length (OAL)

The total length of the end mill from shank end to tip. This affects how deeply the tool can cut and the rigidity of the setup (longer tools are less rigid).

Length of Cut (LOC)

The portion of the end mill that has cutting flutes. This is important for determining how deep a slot or pocket you can machine without engaging the non-fluted portion of the shank.

Helix Angle

The steepness of the spiral of the flutes. Common helix angles are 30 degrees (general purpose), 45 degrees (good balance), and 60 degrees (more aggressive, better for softer materials). High helix (e.g., 60°) can improve surface finish and reduce chatter.

Coating

As detailed earlier, coatings like TiAlN, TiN, or ZrN offer specific benefits depending on the material and cutting conditions.

Reduced Neck Feature

This means a portion of the shank is ground down below the cutting diameter. This is a key feature if your operation requires reaching into deep recesses or undercuts, preventing collisions. For example, a 1/4″ end mill with a 6mm shank and significantly reduced neck would allow deeper reach than a standard 1/4″ shank.

A Deeper Dive: The Carbine End Mill 1/8 Inch 6mm Shank Reduced Neck for Inconel 718 MQL Friendly

Let’s break down this specific example of a tool. This is a highly specialized description, ideal for advanced or specific machining challenges:

- Carbide End Mill: The base material is tungsten carbide, known for its hardness and wear resistance.

- 1/8 Inch (approx. 3mm) 6mm Shank: This indicates two possible shank sizes: a very small 1/8 inch shank, or a standard 6mm shank. Both are relatively small diameters, suggesting the tool might have a proportionally larger cutting diameter or is designed for small-scale, high-precision work. A smaller shank can sometimes be used with specific collets or holders for very tight tolerances.

- Reduced Neck: This is the critical feature. It means the shank is ground down below the cutting diameter for a certain length. This is essential for reaching into deep pockets or undercuts without the shank hitting the workpiece. The 1/8” or 6mm shank is significantly thinner than the cutting head, allowing for considerable reach.

- For Inconel 718: This specifies the target material. Inconel 718 is a high-temperature nickel-chromium superalloy known for its strength, toughness, and resistance to corrosion and oxidation. Machining it is notoriously difficult, requiring robust machinery, optimized cutting parameters, and specially designed tooling. Carbides with TiAlN or similar high-temperature coatings are standard.

- MQL Friendly: MQL stands for Minimum Quantity Lubrication. This means the end mill is designed to work effectively with a fine mist of coolant and lubricant sprayed onto the cutting zone. MQL systems are efficient, reduce fluid waste, and are often preferred for machining difficult materials where controlling heat and providing lubrication is paramount. This often means the end mill will have internal coolant channels or a geometry optimized to work with external MQL delivery.

When machining Inconel 718, successful results are typically achieved with:

- Very rigid machines and workholding

- Lower spindle speeds (RPM)

- Specific feed rates that avoid work hardening

- High-performance carbide with specialized coatings (like TiAlN/AlTiN)

- Effective lubrication, such as MQL, to manage heat and friction.

A tool like this is engineered to tackle the extreme demands of machining this tough alloy, providing the reach needed for complex geometries and the durability to withstand high cutting forces.

Best Practices for Using Carbide End Mills

Even the best tool needs proper handling to perform optimally and safely. Here are some essential tips for using carbide end mills effectively.

Secure Tool Holding is Non-Negotiable

A carbide end mill, especially a small one or one with a reduced neck, needs to be held very securely. Use a high-quality collet chuck or tool holder designed for end mills. Ensure the shank is inserted deep enough into the collet to provide maximum support, but not so deep that it risks hitting the bottom of a deep hole if you’re not careful.

- Always clean the shank and the collet/holder before insertion.

- Tighten the collet with the appropriate wrench, applying firm and even pressure.

- Check for any runout (wobble) when the spindle rotates. Excessive runout will ruin the tool and the workpiece.

Understand Chip Load and Spindle Speed

Chip load is the thickness of the chip that each cutting edge removes. It’s a critical factor in tool life and surface finish. Higher chip loads generally mean faster material removal but can also increase cutting forces and heat. Spindle speed (RPM) controls how fast the tool rotates.

For carbide end mills, it’s common to run them at higher speeds than HSS, but this depends heavily on the material and the end mill’s design. Always refer to the manufacturer’s recommended cutting parameters or use online calculators. For harder materials like Inconel, speeds will be significantly lower.

Lubrication and Coolant are Key

Carbide cutting generates a lot of heat. Proper cooling and lubrication are essential to:

- Prevent the tool from overheating, which can lead to premature wear or catastrophic failure.

- Help evacuate chips from the cutting zone.

- Improve surface finish by reducing friction and preventing material buildup.

This can be through flood coolant, air blast, or MQL systems