Quick Summary: A 1/8 inch, 6mm shank reduced neck carbide end mill for HRC60 hardened steel offers extended tool life by minimizing vibration and improving chip clearance. This specialized design is crucial for precision work on tough materials, ensuring cleaner cuts and less wear.

Carbide End Mill: The Secret Weapon for Hardened Steel on Your Mill

Ever feel frustrated when your end mill struggles with tough materials, leaving rough cuts or breaking prematurely? It’s a common pain point, especially when you’re working with hardened steel. The good news is, with the right tool, tackling these challenging materials becomes much simpler and more effective. We’re going to dive deep into a specific type of carbide end mill that can make a world of difference for anyone using milling tools, from hobbyists in their home workshops to seasoned machinists. Get ready to discover how a specialized carbide end mill can boost your success and confidence with even the hardest metals.

Understanding the Challenge: Hardened Steel and End Mills

Working with hardened steel can feel like trying to cut concrete – it’s tough, unforgiving, and can quickly wear down your tools. Standard end mills often struggle. They might chatter, overheat, or even snap under the pressure. This leads to scrapped parts, wasted time, and a lot of frustration. The key to success lies in using tools specifically designed for these demanding applications.

When we talk about hardened steel, we’re usually referring to materials that have been heat-treated to increase their strength and hardness, often reaching Rockwell hardness ratings of HRC 60 or more. This makes them incredibly durable but also very difficult to machine. Traditional cutting tools can’t handle the abrasive nature and toughness of these steels.

Introducing the Specialized Carbide End Mill

This is where a specially designed carbide end mill shines. We’re focusing on a particular type: a 1/8 inch (or 6mm shank) carbide end mill with a reduced neck, engineered for hardened steel up to HRC 60, and built for a long tool life. Let’s break down what each of these features means:

- Carbide Material: Tungsten carbide is incredibly hard – much harder than high-speed steel (HSS). This makes it ideal for cutting harder materials and resisting wear.

- 1/8 Inch (6mm Shank): This refers to the diameter of the part of the end mill that fits into your milling machine’s collet or tool holder. A smaller shank can sometimes be advantageous for reaching into tight spaces or for smaller profiling jobs.

- Reduced Neck: This is a critical design feature. The neck is the part of the end mill between the cutting flutes and the shank. Reducing this diameter increases the clearance behind the cutting edges.

- For Hardened Steel (HRC 60): The end mill is specifically designed and coated (often) to perform optimally on materials hardened to a Rockwell hardness of 60.

- Long Tool Life: The combination of these features aims to extend how long the end mill can be used effectively before needing replacement or resharpening.

Why These Features Matter for Cutting Hardened Steel

Let’s dig a little deeper into why these specific attributes make a difference when you’re milling hardened steel:

1. The Power of Carbide

Carbide tools are the go-to for machining tough materials. Their inherent hardness means they can withstand the abrasive forces and higher temperatures generated when cutting hardened steel. While carbide is brittle compared to steel, modern manufacturing techniques create carbide grades that offer excellent toughness alongside hardness.

2. The Significance of the Reduced Neck

This is often the most overlooked but vital feature for certain applications. On a standard end mill, the neck is the same diameter as the flutes. However, on a reduced neck end mill, this section is ground smaller. Here’s why that’s a game-changer:

- Increased Clearance: The reduced neck provides increased clearance behind the cutting flutes. This is crucial in deep slots or pockets where a standard end mill’s neck could rub against the walls of the cut. Rubbing generates heat, which can dull the tool, deform the workpiece, and potentially cause tool breakage.

- Vibration Dampening: A reduced neck can sometimes help to dampen vibrations. When machining hard, brittle materials, chatter (vibration) is a major enemy. It leads to poor surface finish, tool wear, and potential breakage. The slight flexibility or different mass distribution in the neck area can help absorb some of these vibrations, leading to smoother cuts.

- Improved Chip Evacuation: In some designs, the reduced neck can also facilitate better chip evacuation, especially in narrower slots, preventing chips from clogging the cutting area.

For more information on understanding tool geometry, you can check out resources from the National Institute of Standards and Technology (NIST), which often provides foundational data on materials and machining.

3. Targeting HRC 60 Hardened Steel

Not all carbide end mills are created equal. Those designed for HRC 60 have specific flute geometries, coatings, and carbide grades optimized for this hardness level. Using an end mill not rated for this hardness could lead to rapid tool failure.

4. Achieving Long Tool Life

The ultimate goal is to make your tools last. A carbide end mill with a reduced neck, designed for hardened steel, achieves long tool life through:

- Reduced Heat Generation: Efficient cutting and clearance mean less heat is transferred to the tool.

- Minimized Wear: The hardness of carbide and optimized geometry resist abrasion and chipping.

- Prevented Breakage: Better chip management and vibration dampening reduce stress on the tool.

Key Specifications to Look For

When you’re hunting for this type of end mill, here are the crucial details to confirm:

| Specification | Importance | What to Look For |

|---|---|---|

| Shank Diameter | Tool holder compatibility, reach | 1/8 inch (3.175mm) or 6mm |

| Flute Diameter | Size of the cut | Often the same as shank for square end, or smaller for ball/corner radius |

| Neck Diameter | Clearance, vibration | Significantly smaller than flute/shank diameter (e.g., may be 1/8″ or 4mm for a 1/4″ flute) |

| Material Hardness Rating | Suitability for workpiece | Up to HRC 60 / 62 |

| Number of Flutes | Chip clearance, surface finish, suitability for finishing vs. roughing | Typically 2 or 4 for hardened steel; 2 for better chip evacuation in slots. |

| Coating | Wear resistance, heat resistance, lubricity | TiAlN (Titanium Aluminum Nitride), AlTiN (Aluminum Titanium Nitride), or similar dark coatings are common for high-temp applications. |

| Tool Type | Specific cutting application | Square (flat), Ball end, Corner Radius |

It’s important to note that a 1/8 inch (or 6mm) shank can hold a small cutting diameter, which is ideal for detailed work. However, for very deep cuts with a small shank, rigidity can become a factor. Always ensure your machine setup provides adequate support.

Choosing the Right End Mill for Your Project

Before you buy, consider your specific needs:

- What material hardness are you actually cutting? HRC 60 is very hard. If you’re working with something softer, a less specialized tool might suffice.

- What is the depth of cut? If you need to cut deep slots, the reduced neck is essential.

- What kind of finish do you need? For fine finishing, a higher number of flutes (like 4) might be preferred, but for hardened steel, 2-flute is often recommended for better chip clearing to avoid re-cutting chips.

- What is your coolant/lubrication strategy? Proper lubrication is key for tool life.

Setting Up Your Milling Machine for Success

Even with the best tool, proper setup is crucial. Poor setup can negate all the benefits of a high-quality carbide end mill.

1. Collet and Holder Tightness

Ensure your collet is clean, properly sized for the shank, and tightened securely. A loose tool is a recipe for disaster. For small shank tools like 1/8 inch, a good quality ER collet chuck is recommended for runout accuracy and holding power.

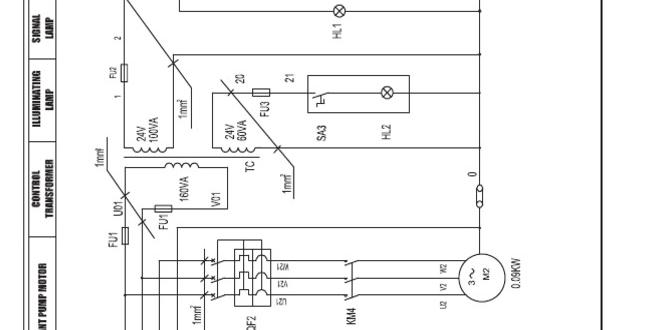

2. Spindle Speed and Feed Rate (SFM/IPM)

This is critical. You can’t just guess. You need to calculate your speeds and feeds based on the specific end mill, material, and machine capabilities. Consult the end mill manufacturer’s recommendations. A good starting point for hardened steel with carbide tooling is often:

- Surface Speed (SFM): Typically lower than for softer materials, perhaps 150-300 SFM, depending on the coating and coolant.

- Feed Per Tooth (IPT): This needs to be precise. Too light, and you’ll rub; too heavy, and you’ll break the tool or overload the machine.

For example, to calculate spindle speed (RPM):

RPM = (SFM 3.82) / Diameter (inches)

And for feed rate (IPM):

IPM = RPM Number of Flutes * IPT

Many online calculators and resources can help with this. For instance, Machinery Magazine offers some useful tools for calculating speeds and feeds.

3. Depth of Cut (DOC) and Stepover

Don’t try to hog out large amounts of material at once. For hardened steel, especially with a small tool, shallow depths of cut and stepovers are generally recommended for both roughing and finishing. This reduces the load on the tool and allows for better chip control.

- Depth of Cut (DOC): Start conservatively, perhaps 0.010″ to 0.050″ (0.25mm to 1.2mm), depending on the tool diameter and machine rigidity.

- Stepover: For perimeter cuts, a stepover of 20-40% of the tool diameter is common. For pocketing, this can be higher.

4. Coolant and Chip Evacuation

Hardened steel generates heat. Proper coolant or lubrication is vital to prevent the tool from overheating and to help flush away chips. Flood coolant is ideal, but a good quality cutting fluid applied directly to the cutting zone can also work for lighter operations. Ensure your machine’s coolant system is functioning correctly and that chips are being effectively cleared from the flutes and the workpiece. Clogged flutes are a primary cause of tool failure.

A Comparison: End Mills for Hardened Steel

Let’s look at how our specialized reduced neck end mill stacks up against common alternatives when machining hardened steel (HRC 60):

| End Mill Type | Suitability for HRC 60 Steel | Key Advantages | Key Disadvantages |

|---|---|---|---|

| Standard HSS End Mill | Poor | Inexpensive, tough | Too soft, dulls very quickly, generates excessive heat. |

| Standard Carbide End Mill (Uncoated) | Fair to Good | Harder than HSS, higher heat resistance | Can still chatter, limited tool life without coating, can chip |

| Coated Carbide End Mill (e.g., TiAlN/AlTiN) | Good to Very Good | Excellent wear resistance, high-temperature stability | Can still rub in deep cuts, potential for chatter without specific geometry |

| Reduced Neck Carbide End Mill for HRC60 (e.g., 1/8″ shank) | Very Good to Excellent | Reduced vibration, significantly improved clearance in slots, long tool life | Can be more expensive, requires precise speed/feed setups, shank diameter limits reach/rigidity in some deep applications. |

The reduced neck design fundamentally addresses the clearance and vibration issues that plague deeper cuts in hardened materials, making it a premium choice for professionals.

Safety First: Always!

Machining, especially with hard materials, demands respect for safety. Always:

- Wear safety glasses or a face shield.

- Ensure your workpiece is securely clamped.

- Keep hands and loose clothing away from moving parts.

- Understand your machine’s emergency stop procedures.

- Use proper coolant and chip management to avoid hazardous dust or splashes.

- Never force a tool. If it’s struggling, stop the machine and reassess.

The Occupational Safety and Health Administration (OSHA) provides extensive guidelines on machine safety that every shop should follow.

Troubleshooting Common Issues

Even with the right tool, problems can arise. Here’s how to tackle them:

Frequently Asked Questions

Q1: What is the main benefit of a reduced neck on an end mill?

A1: The primary benefit is increased clearance behind the cutting flutes, preventing the neck from rubbing against the workpiece in deep or narrow cuts. This reduces heat, wear, and the risk of tool breakage.

Q2: Can I use a 1/8 inch reduced neck end mill for roughing?

A2: Yes, but with caution. For hardened steel, aggressive roughing with a small diameter, reduced neck end mill can be challenging. It’s often better for semi-finishing or finishing operations where precision and surface finish are paramount, or for shallow roughing passes. Always follow manufacturer recommendations and start conservatively.

Q3: How do I know if my steel is HRC 60?

A3: Hardness is typically measured using a Rockwell hardness tester. If you’re unsure, consult documentation for the steel you’re using or have it tested. Machining steel above its rated hardness will lead to rapid tool failure.

Q4: What kind of coating is best for hardened steel?

A4: Coatings like TiAlN (Titanium Aluminum Nitride) and AlTiN (Aluminum Titanium Nitride) are excellent for high-temperature applications like cutting hardened steel. They provide exceptional hardness and thermal resistance, significantly extending tool life.

Q5: My end mill is chattering. What can I do?

A5: Chatter can be caused by several factors: insufficient spindle rigidity, loose tool holder, incorrect speeds/feeds, light depth of cut, or worn tooling. For a reduced neck end mill, ensure your machine’s setup is as rigid as possible, verify your DOC and stepover are appropriate, and experiment slightly with spindle speed and feed rates. Sometimes, a slightly larger DOC can help damp vibrations.

Q6: Is a 6mm shank the same as 1/8 inch?

A6: No, 6mm is approximately 0.236 inches, while 1/8 inch is 0.125 inches. They are significantly different. Make sure you are ordering the correct shank diameter for your collets and tool holders. Many tools are specified in both metric and imperial measurements, so always check the exact dimensions.

Conclusion: Empowering Your Machining with the Right Tool

Tackling hardened steel on your milling machine doesn’t have to be a daunting task. By understanding the specific advantages of precision-engineered tools like the 1/8 inch (or 6mm shank) reduced neck carbide end mill designed for HRC 60 materials, you equip yourself with a powerful solution. The careful design of these end mills addresses the critical challenges of reduced vibration, superior chip clearance, and enhanced tool life, leading to cleaner cuts, less wasted material, and a more enjoyable machining experience. Remember that the tool is only one part of the equation; proper machine setup, calculated speeds and feeds, and diligent safety practices are equally important. With this knowledge, you’re well on your way to mastering those tough-to-machine metals and bringing your intricate project designs to life with confidence.