Cutting Inconel 625 dry with a carbide end mill is achievable and efficient by using specific tools like stub length mills, optimizing speeds and feeds, and employing proper cooling strategies. This guide provides a beginner-friendly, step-by-step approach to master this challenging machining task for reliable results.

Machining Inconel 625 can feel like wrestling a bear made of steel – tough, frustrating, and downright exhausting. This superalloy is prized for its incredible strength, heat resistance, and corrosion protection. That’s why it’s used in everything from jet engines to deep-sea submersibles. But for us machinists? It’s a real challenge. Trying to cut it dry, especially with standard tools, often leads to rapid tool wear, poor surface finish, and a whole lot of wasted effort. Many beginners get discouraged, thinking Inconel is just too difficult. But what if I told you there’s a smart, almost genius way to tackle Inconel 625 dry machining using the right carbide end mill? Stick around, and I’ll walk you through it, step-by-step, making this seemingly impossible job surprisingly achievable.

The Secret Weapon: Your Carbide Carbide End Mill 1/8 Inch 8mm Shank Stub Length for Inconel 625 Dry Cutting

When you’re looking at machining Inconel 625, especially dry, you’re essentially looking for a tool that can handle extreme forces and heat without giving up. The standard tools you might use for aluminum or mild steel will likely be toast in seconds. That’s where specialized tooling comes into play. For dry cutting Inconel 625, the star of the show is a precisely engineered carbide end mill.

The keyword here is “carbide end mill 1/8 inch 8mm shank stub length for Inconel 625 dry cutting.” Let’s break down why each part of that description is so crucial:

- Carbide: Traditional High-Speed Steel (HSS) simply can’t handle the hardness and heat generated when cutting Inconel. Tungsten carbide, on the other hand, has superior hardness and heat resistance, making it the go-to material for these tough jobs.

- End Mill: This is the cutting tool itself. The geometry and number of flutes are critical for chip removal and surface finish. For Inconel, you’ll often find helical flutes designed to shear material effectively.

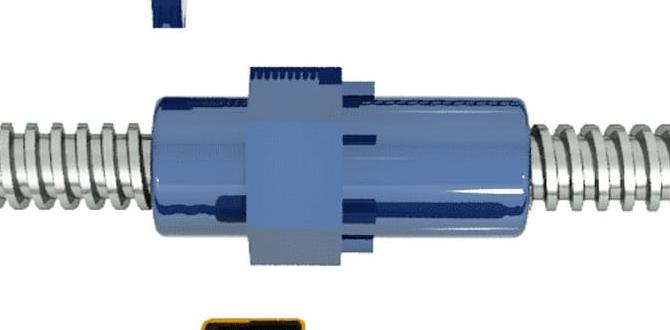

- 1/8 Inch / 8mm Shank: This refers to the diameter of the part of the tool that goes into your milling machine’s collet or tool holder. While the cutting diameter might vary, having a standard shank size like 8mm (which is roughly 5/16 inch, but specific tool manufacturers might use exact or slightly different conversions) ensures compatibility with common holders. A smaller shank might mean less rigidity for larger cuts, but for detailed work or smaller features, it’s perfectly fine. For Inconel, rigidity is king, so smaller diameter tools in this category are often designed to be very robust.

- Stub Length: This is perhaps the most critical feature for this application. “Stub length” means the tool is shorter than a standard end mill. Why is this a game-changer for Inconel?

- Increased Rigidity: A shorter flute length means less tool deflection and vibration. Inconel is notoriously prone to work hardening, and any chatter or vibration can quickly exacerbate this, leading to tool breakage or poor parts. A stub-length mill is inherently stiffer.

- Better Chip Evacuation: Shorter tools generally allow for more efficient chip removal, which is vital for managing heat and preventing recutting chips that can damage the tool and the workpiece.

- Reduced Tool Overhang: Less stick-out from the collet means a more stable setup.

- For Inconel 625 Dry Cutting: Manufacturers will specifically design these tools with coatings and geometries optimized for this challenging material and the dry machining condition. This isn’t just any stubby end mill; it’s a specialized tool. The coatings might include TiAlN (Titanium Aluminum Nitride) or similar advanced PVD coatings designed for high-temperature applications.

Why is Dry Cutting Inconel 625 So Tough?

Before we dive into the how-to, let’s quickly touch on why Inconel 625 is such a pain to machine, especially without coolant. It’s a nickel-chromium alloy, and its ‘superalloy’ status comes from:

- High Hardness: It’s significantly harder than steels like 304 stainless steel.

- Work Hardening: As you cut it, the material around the cutting edge gets even harder. This means each subsequent pass becomes more difficult if you’re not careful.

- Low Thermal Conductivity: Inconel doesn’t dissipate heat well. This means the heat generated by friction and deformation stays concentrated right at the cutting zone, rapidly dulling tools.

- Gummy Nature: It can sometimes behave like a “gummy” material, leading to built-up edge (BUE) on the tool, further reducing cutting efficiency and potentially causing tool failure.

When you try to cut this dry, all these factors are amplified. Without coolant to carry away heat and lubricate the cut, the tool experiences extreme thermal and mechanical stress. The specialized carbide end mill is designed to mitigate these issues.

Step-by-Step Guide: Machining Inconel 625 with Your Carbide End Mill

This guide assumes you have a milling machine capable of the necessary speeds and feeds, and you’re using a solid collet system. Safety first, always! Wear your eye protection and be aware of your machine’s operation.

Step 1: Selecting and Inspecting Your Carbide End Mill

You’ve got the right type – a carbide end mill 1/8 inch 8mm shank stub length for Inconel 625 dry cutting. But before you even think about putting it in the machine, give it a good once-over.

- Check for Damage: Look for any nicks, chips, or signs of wear on the cutting edges. Even a tiny chip can propagate and lead to catastrophic tool failure.

- Verify Coating: Ensure the coating is intact and hasn’t been damaged during handling.

- Cleanliness: Make sure the shank is perfectly clean. Any residue can affect how securely it grips in the collet.

Step 2: Setting Up Your Milling Machine for Dry Cutting

Dry cutting means managing heat and chips without a liquid flood. This requires careful setup.

- Secure Workpiece: Inconel 625 can exert significant forces. Ensure your workpiece is rigidly clamped. A loose part is incredibly dangerous and will ruin your part and potentially your tool. Vises with hardened jaws and ample clamping force are recommended.

- Tool Holder and Collet: Use a high-quality collet system. For an 8mm shank, a precision ER collet is ideal. Ensure the collet is clean and the tool is seated fully. Avoid long extensions if possible; a stubby end mill helps with this.

- Machine Rigidity: Make sure your milling machine itself is rigid. Check for any play in the ways, spindle bearings, or axes. A machine with a solid feel is crucial for Inconel.

- Chip Management System: While dry cutting, you won’t have coolant washing chips away. Some machines have integrated chip augers or blowers. If not, you’ll need to be prepared to clear chips frequently using compressed air or a brush.

Step 3: Determining Optimal Speeds and Feeds (The Heart of the Matter)

This is where the magic happens, and it’s where things get a bit intricate. For Inconel 625 dry cutting, you need to be aggressive enough to shear the material but gentle enough to avoid overheating or excessive tool wear. Generic numbers are risky; always refer to the tool manufacturer’s recommendations if available. However, here are some general principles and starting points for a typical carbide end mill designed for this purpose:

Key Concepts:

- Surface Speed (SFM or m/min): This is how fast the cutting edge is moving relative to the workpiece. For carbide on Inconel, this is typically lower than for softer materials.

- Feed Per Tooth (IPT or mm/tooth): This is how much material each cutting flute removes with each revolution. This is critical for managing chip load and heat.

- Depth of Cut (DOC) and Width of Cut (WOC): These determine how much material is being engaged at any given time.

General Starting Points (for a 1/8 inch or 3mm-ish diameter carbide end mill):

- Surface Speed: Start around 15-30 SFM (5-10 m/min). This is quite low compared to steels or aluminum, reflecting the difficulty.

- Feed per Tooth: For a 1/8 inch (3mm) end mill, a good starting point might be 0.0005 – 0.0015 inch/tooth (0.01 – 0.04 mm/tooth). You want a chip that’s thin but not powdery. Think small, consistent curls.

- Spindle Speed (RPM): This is calculated.

For Imperial: RPM = (SFM 3.82) / Diameter (inches)

For Metric: RPM = (m/min

1000) / (π Diameter (mm))Example: Using 20 SFM and a 1/8″ (0.125″) diameter tool: RPM = (20 3.82) / 0.125 = 611 RPM.

Example: Using 8 m/min and a 3mm diameter tool: RPM = (8 1000) / (3.14159 3) ≈ 848 RPM.

- Depth of Cut (DOC): For dry cutting Inconel, keep the axial DOC conservative. Start with around 0.25 to 0.5 times the tool diameter. So, for a 1/8″ (3mm) tool, aim for 0.030″ to 0.060″ (0.75mm to 1.5mm) axeial DOC.

- Width of Cut (WOC) / Stepover: This is critical for efficient machining. For roughing, you might use a radial stepover of 20-40% of the tool diameter. For a finishing pass, you might reduce this to 10-20%. High-efficiency machining (HEM) or trochoidal milling strategies with high radial engagement (e.g., 70%+) and very shallow axial DOC can also work, but require specialized CAM software and very robust setups.

Important Considerations:

- Tool Manufacturer Data: ALWAYS prioritize the recommendations from the carbide end mill manufacturer. They design their tools for specific applications and materials. Look up their cutting data charts.

- Material Thickness: Thicker material will generate more heat. You may need to adjust DOC and RPM accordingly.

- Machine Power: Inconel Drains power. If your spindle bogs down significantly, your feed rate is too high, or your DOC needs to be reduced.

- Sound and Chip Formation: Listen to the cut. A nice, consistent chirping sound is good. A high-pitched squeal or rattling indicates problems. Look at the chips: they should be small, consistent curls, not powdery dust or long, stringy spirals. Powdery chips mean you’re rubbing, and it’s too hot. Stringy chips mean you’re not cutting efficiently and could be work hardening.

Step 4: The Cutting Process – Dry and Deliberate

Now that you have your speeds and feeds dialed in, it’s time to make the cut.

- Plunge Carefully: When plunging straight down into Inconel dry, do it slowly. Use a peck drilling cycle if your CAM software supports it, or a manual peck with 0.050″ plunges. This helps clear chips and prevent overheating.

- Engage Smoothly: Start your milling path with a smooth engagement. Avoid sudden stops and starts. Use helical interpolation for internal pockets or ramping into cuts where possible.

- Monitor Heat: Even dry, you need to manage heat.

- Chip Evacuation: Use compressed air (low pressure so you don’t blast chips everywhere, but enough to clear) or a brush between passes, or even mid-pass on longer linear cuts if your machine setup allows.

- Brief Dwell: Sometimes, allowing the tool to dwell off the material for a few seconds can help it cool slightly. This is more of an advanced technique.

- Tool Changes: For longer operations, consider taking breaks to let the tool and workpiece cool down.

- Observe the Cut: Constantly monitor the sound, chip formation, and surface finish. If anything changes for the worse, stop the machine immediately.

- Feathered Passes for Finishing: For critical surface finishes, a final “spring pass” or “finishing pass” with a very light depth of cut (e.g., 0.001″ – 0.003″) and a slightly higher feed rate (but still within tight chip load limits) can help smooth out any minor imperfections. This pass should be a full-width cut to clean up any subtle tool runout or deflection marks.

Step 5: Post-Machining Inspection

Once your part is complete, it’s time for the final check.

- Tool Inspection: Immediately after the job, inspect your end mill. How do the cutting edges look? Is the coating intact? This will give you valuable feedback for your next Inconel job. If the edges are rounded or chipped, your speeds/feeds or DOC might have been too aggressive.

- Part Inspection: Check your part for dimensional accuracy and surface finish. Are there any signs of chatter, burning, or rough patches?

- Refine Parameters: Based on your inspection, adjust your machining parameters for future Inconel parts. Small tweaks can make a big difference.

Essential Tools and Accessories for Dry Inconel Machining

Beyond the specialized carbide end mill, a few other items will make your life easier and your machining safer and more effective:

| Tool/Accessory | Reason for Use | Beginner Tip |

|---|---|---|

| Carbide End Mill (Stub Length, Specific for Inconel): e.g., 1/8 inch 8mm shank | The primary cutting tool, designed for hardness, heat, and rigidity. | Don’t compromise here. Buy from a reputable tooling supplier known for exotic material tooling. |

| High-Quality Collet Chuck/ER Collets | Ensures a precise, rigid grip on the end mill shank, minimizing runout. | Clean your collets and tool holder before every use. A bit of dirt can ruin accuracy. |

| Rigid Vise | Securely holds the workpiece, preventing movement under cutting forces. | Ensure the vise is properly aligned with your machine’s axes. |

| Dial Indicator/Test Indicator | For verifying spindle runout and workpiece tramming. | Learn how to indicate your workpiece. A perfectly positioned part is half the battle. |

| Compressed Air Blower/System | For clearing chips away from the cutting zone during dry machining. | Use a regulated pressure. Too high can displace chips unpredictably; too low won’t clear effectively. |

| Deburring Tools | To safely clean up sharp edges after machining. | Inconel edges can be extremely sharp. Always deburr cautiously. |

| Coolant (Optional but Recommended for Certain Steps) | While this guide is for dry cutting, a mist coolant or specialized high-pressure coolant system can dramatically improve tool life and surface finish on Inconel if dry cutting proves too challenging or for less critical finish passes. | If implementing coolant, research Inconel-specific coolant formulas and

|