A 1/8 inch carbide end mill is your key to achieving precise, tight tolerances when machining Delrin, making it a reliable choice for detailed work in your CNC projects.

Hey there, workshop friends! Daniel Bates here from Lathe Hub. Ever stared at a piece of Delrin, ready to machine it, and wondered about the best tool for super accurate cuts? It can feel a bit daunting when you’re aiming for those really tight tolerances, especially with plastics that can sometimes have a mind of their own. Many folks run into trouble trying to get consistent, precise results with Delrin. The good news is, it doesn’t have to be complicated. We’re going to dive into why a specific type of tool – the 1/8 inch carbide end mill – is a real champion for this job. Stick around, and we’ll break down exactly what you need to know to get those perfect, accurate cuts every single time.

Why Choose a 1/8 Inch Carbide End Mill for Delrin?

Let’s get straight to the point: when you need reliable, tight tolerance machining in Delrin, reaching for a 1/8 inch carbide end mill is a smart move. Why this specific tool? It boils down to a few key features that play perfectly with Delrin’s unique properties.

Understanding Delrin (Acetal)

Before we talk tools, it’s helpful to know a little about our workpiece, Delrin. Formally known as acetal or polyoxymethylene (POM), Delrin is a popular engineering thermoplastic. It’s known for its high stiffness, low friction, and excellent dimensional stability. These qualities make it fantastic for parts that need to be strong, precise, and wear-resistant. However, Delrin can also be a bit tricky to machine. It melts relatively easily under high heat, and if you don’t get your settings right, you can end up with gummy, inaccurate cuts or even melt the material. This is where the right end mill becomes crucial.

The Advantages of Carbide

Carbide is a super-hard material, much harder than high-speed steel (HSS). This hardness translates directly to better heat resistance and edge retention. When machining plastics like Delrin, which can generate heat, carbide’s superior heat resistance means the tool stays sharper for longer, preventing that dreaded melting and material buildup. This keeps your cutting edges clean and effective, which is vital for precise results.

The Significance of the 1/8 Inch Diameter

The 1/8 inch size is particularly well-suited for achieving tight tolerances. Smaller diameter tools have higher rotational speeds (RPMs) available on most CNC machines, allowing for efficient material removal without generating excessive heat. This smaller size also enables you to create finer details and tighter corner radii, essential for intricate parts. When precision is paramount, a smaller, sharper tool often outperforms its larger counterparts.

Why “Stub Length” Matters

You might see terms like “stub length” when looking at end mills. A stub length end mill is shorter than a standard one. This shorter length reduces tool deflection and vibration. Less deflection means the tool stays on its intended path more accurately, leading to better dimensional control and tighter tolerances. For Delrin, where maintaining accuracy is key, a stub length end mill is often the preferred choice.

So, when you combine the hardness and heat resistance of carbide with the precision offered by a 1/8 inch diameter and the stability of a stub length, you get a tool perfectly engineered for the demands of machining Delrin to tight tolerances. It’s not just about picking a tool; it’s about picking the right tool for the job.

Key Features of a 1/8 Inch Carbide End Mill for Delrin

When you’re out shopping for the perfect end mill, there are a few specific features to look for that will make your Delrin machining much smoother and more accurate. Think of these as your checklist for success.

Material Composition

Tungsten Carbide: This is the standard and what you want. It’s exceptionally hard and resistant to the heat generated during cutting.

Coatings (Optional but helpful): While not always necessary for Delrin, some coatings like TiAlN (Titanium Aluminum Nitride) can further enhance heat resistance and tool life, though they might add to the cost. For Delrin, a plain, uncoated carbide end mill is often more than sufficient and can prevent potential adhesion issues.

Geometry and Design

Number of Flutes: For plastics like Delrin, 2-flute or 3-flute end mills are generally recommended.

2-Flute: Offers excellent chip clearance. This is very important for Delrin, as it helps prevent chips from packing up and melting into the cut. It also allows for higher feed rates.

3-Flute: Can sometimes offer a smoother finish than a 2-flute due to more cutting edges engaging the material. However, chip clearance can be a bit more restricted, so you need to ensure your chip evacuation is good. For Delrin, a 2-flute is often the go-to for its superior chip handling.

Helix Angle: Look for a moderate helix angle, typically around 30-45 degrees. A steeper helix can help with chip evacuation in softer materials, but too steep can lead to chatter. A standard angle works well for Delrin.

End Cut Type: Most 1/8 inch tools will be square end mills, which are standard for general-purpose milling and slotting. For achieving sharp internal corners, you might occasionally need a ball end mill, but for general tolerance work, a square end is your best bet.

Shank Diameter vs. Cutting Diameter: Ensure you’re getting an 1/8 inch cutting diameter. Most 1/8 inch end mills will have an 1/8 inch shank as well, especially stub length ones. This common size is easy to find and fits standard collets.

Specific Terminology to Watch For:

“Stub Length”: As mentioned, this means the tool is shorter than average. This reduces deflection and vibration, which is gold for tight tolerances.

“Single End”: This means the tool has cutting edges on one end only, standard for milling operations.

“Up-cut” vs. “Down-cut” vs. “Straight Flute”: For Delrin, up-cut end mills are common as they help pull chips up and out of the cut. Straight flute (0-degree helix) can be used but offer less chip control. Down-cut mills push chips down, which you generally want to avoid in plastics that can melt.

Example Specification You Might See:

“1/8″ Carbide End Mill, 2 Flute, Stub Length, Square End, 30° Helix”

This description hits all the key points for successful Delrin machining.

Setting Up Your CNC for Success with a 1/8 Inch End Mill

Getting the right tool is only half the battle. How you set it up in your CNC machine and the parameters you use are just as critical for achieving those prized tight tolerances in Delrin.

Spindle Speed (RPM): Finding the Sweet Spot

Delrin machines best at higher spindle speeds. This is because faster speeds allow the tool to cut the material cleanly before it has a chance to melt. A good starting point for a 1/8 inch carbide end mill in Delrin is often between 18,000 and 24,000 RPM.

Why higher RPM? It allows for a higher Surface Feet per Minute (SFM) or Surface Meters per Minute (SMM) without excessive chip load, leading to a cleaner cut.

Experimentation is Key: Always start conservatively and listen to your machine. If you hear squealing, it might be too fast or you have a chip packing issue. If you see melting or a gummy surface, you might need to increase RPM or surface speed if your machine allows, or reduce your feed rate.

Feed Rate: The Balance of Speed and Finish

The feed rate is how fast the cutting tool moves through the material. This is directly linked to your spindle speed and the number of flutes. The goal is to remove material efficiently without overloading the tool or causing melting.

Chip Load: This is the thickness of the chip that each flute cuts. For a 1/8 inch carbide end mill in Delrin, a chip load of 0.001 to 0.003 inches per flute is a common starting point.

Calculating Feed Rate: Your feed rate is essentially:

`Feed Rate (inches per minute) = Spindle Speed (RPM) × Number of Flutes × Chip Load (inches per flute)`

For example, with a 2-Flute end mill at 20,000 RPM and a chip load of 0.002 inches/flute:

`Feed Rate = 20,000 RPM × 2 flutes × 0.002 in/flute = 80 inches per minute (IPM)`

Plunge Rate: When the tool feeds straight down into the material (plunging), use a much slower rate, usually about 25-50% of your standard feed rate, to avoid damaging the tool or the material.

Depth of Cut (DOC): Taking It Easy

For tight tolerance work and to manage heat, it’s best to take lighter cuts.

Radial Depth of Cut (WOC – Width of Cut): When slotting or profiling, don’t try to cut the full 1/8 inch at once. Aim for a radial depth of cut that’s about 25-50% of the tool’s diameter. So, for a 1/8 inch tool, cut to a width of 1/32 inch to 1/16 inch. This helps prevent the tool from flexing and overheating.

Axial Depth of Cut (DOC): This is how deep the tool cuts into the material in a single pass. For Delrin, shallower DOCs are generally better. Start with cuts around 0.0625 inches (1/16 inch) or even less, especially for initial testing. You can gradually increase this if your machine and setup handle it well, but prioritizing accuracy means staying conservative.

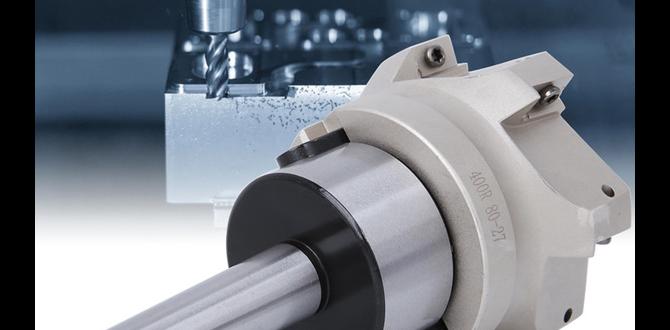

Tool Holding: The Foundation of Precision

A tight tolerance starts with a solid grip on your tool.

Collet Chuck: Using a high-quality collet chuck (like a ER collet system) is highly recommended. This provides a consistent and accurate grip on the end mill shank. Ensure the collet size matches your shank diameter (e.g., using a 1/8 inch ER collet).

Cleanliness: Always ensure the collet and the tool shank are clean and free of oil or debris. Any contamination can lead to runout (wobble) and inaccurate cuts.

Shank Runout: Minimize runout. Even a few thousandths of an inch of runout can significantly impact your part’s accuracy and surface finish.

Workholding: Keep It Solid!

Just as important as holding the tool is holding the workpiece.

Rigid Clamping: Delrin parts need to be held firmly without flexing. Use clamps specifically designed for CNC machining. Avoid relying on just friction or weak hold-downs.

Support: Ensure there’s good support underneath the material being cut, especially around the tool path. This prevents the material from lifting or vibrating, which can lead to inaccurate dimensions. For thin parts, consider a vacuum table or a spoilboard that provides even clamping pressure.

By carefully managing these settings and ensuring your tool holding and workholding are robust, you’re setting yourself up for consistent, repeatable results and the tight tolerances you’re aiming for with your 1/8 inch carbide end mill in Delrin.

Step-by-Step Machining Process for Delrin with a 1/8 Inch End Mill

Let’s walk through a typical workflow for machining Delrin with your 1/8 inch carbide end mill. This guide assumes you have your design ready in CAD/CAM software and your CNC machine set up.

Step 1: Prepare Your Design and CAM Toolpaths

1. Model the Part: Ensure your CAD model is accurate.

2. Define Machining Strategy: Decide if you’re profiling (cutting the outside shape), pocketing (removing material from an area), or slotting.

3. Select the Tool in CAM: Choose a 1/8 inch, 2-flute (or 3-flute), carbide end mill.

4. Input Machining Parameters: Use conservative starting values for spindle speed, feed rate, depth of cut, and width of cut, based on the recommendations we discussed. A 2-flute with a 1/8″ shank, stub length, is ideal.

Example Parameters for a 2-Flute, 1/8″ Carbide End Mill:

Spindle Speed: 18,000 – 24,000 RPM

Feed Rate: 60 – 100 IPM (calculated based on chip load)

Plunge Rate: 20 – 40 IPM

Axial Depth of Cut (DOC): 0.0625″ (1/16″)

Radial Depth of Cut (WOC): 0.031″ – 0.062″ (25-50% of tool diameter)

5. Generate Toolpaths: Let your CAM software create the G-code. A common strategy for profiling is to use a “left-of-cut” tool compensation to ensure the final dimension is accurate to your CAD model. For pocketing, concentric or spiral toolpaths can work well.

6. Simulate: ALWAYS simulate your toolpaths in the CAM software to check for collisions, unexpected movements, or potential issues.

Step 2: Machine Setup

1. Securely Fixture the Delrin: Clamp your Delrin stock firmly to your CNC machine bed. Ensure it is perfectly flat and won’t move during machining. Use appropriate clamps or workholding.

2. Install the End Mill: Insert your 1/8 inch carbide end mill into a clean ER collet and securely tighten it in your spindle. Ensure it’s seated properly and the runout is minimal.

3. Set Work Origin (Zero): Carefully set your X, Y, and Z zero points on the workpiece according to your CAM program. Use a digital indicator or a probe for precision, especially for the Z-axis. Ensure the tool tip is touching the surface accurately for the Z-zero.

Step 3: First Cut and Verification

1. Dry Run (Optional but Recommended): With the spindle off, run the G-code through its motions to visually check if everything is clear.

2. First Pass (Air Cut): If your machine allows, perform a “dry run” or “air cut” with the spindle rotating but the Z-axis set slightly above the material. This helps you hear if the spindle speed and feed rate sound reasonable.

3. Initiate Machining: Start the actual machining process. Stand by and monitor the machine closely, especially during the first few passes.

Listen: Pay attention to the sound of the cut. A clear, crisp sound is good. Squealing, grinding, or excessive chatter can indicate problems.

Watch for Chips: Ensure chips are being evacuated effectively and not building up or melting. If you see melting, you might need to slightly slow down the feed rate or increase the spindle speed.

Observe Surface Finish: Look for a clean, smooth finish on the cut surfaces.

4. After the First Layer: Once the first axial depth of cut is complete, pause the machine and carefully inspect the result.

Check Dimensions: Use calipers or a micrometer to measure key dimensions. Are they within your tolerance?

Inspect Finish: Look for any signs of melting, burrs, or poor surface finish.

Step 4: Fine-Tuning Parameters

If your initial results aren’t perfect, don’t panic! This is where fine-tuning comes in.

If you have melting or gummy residue:

Increase spindle speed.

Slightly decrease the feed rate (or increase chip load if you have room).

Ensure good chip evacuation. A 2-flute end mill is usually best here.

If you have chatter or poor surface finish:

Decrease spindle speed.

Decrease feed rate.

Reduce the depth and width of cut.

Ensure rigid workholding and tool holding.

Check for tool wear.

If dimensions are slightly off:

Double-check your CAM tool compensation. Are you using “left of cut” correctly for profiling?

Verify your machine’s backlash settings.

* Ensure your workholding isn’t shifting.

Step 5: Finishing Passes (Optional for Extreme Tolerance)

For incredibly tight tolerances, you might perform a final “finishing pass” at a very high feed rate and very light depth of cut. This pass essentially just cleans up the surface and refines dimensions without removing significant material. For Delrin and a 1/8 inch end mill, this might involve a DOC of 0.002″ – 0.004″ at a high feed rate.

Step 6: Part Removal and Inspection

1. Clean Part: Once machining is complete, carefully remove the part from the machine.

2. Deburr: Gently deburr any sharp edges if necessary, though Delrin often produces minimal burrs.

3. Final Inspection: Thoroughly inspect the part for dimensions, surface finish, and any defects. Measure critical features to confirm you’ve met your tolerance requirements.

This step-by-step approach, combined with careful observation and willingness to tweak settings, will empower you to consistently achieve excellent results when machining Delrin with your 1/8 inch carbide end