A 1/8 inch carbide end mill is your best friend for achieving incredibly precise cuts on hardened steel up to HRC60, minimizing unwanted wobble and ensuring clean, accurate results in your milling projects.

Have you ever struggled to get that perfectly clean edge or that tight tolerance on a metals project? It’s a common frustration for anyone diving into machining, especially when you’re aiming for the kind of accuracy that screams “professional.” You’ve got your machine ready, your material is clamped down, but the tool just isn’t cooperating. That’s where the right tool makes all the difference. Specifically, the 1/8 inch carbide end mill with features designed to combat deflection is a game-changer for hobbyists and aspiring machinists alike. We’re going to walk through exactly what makes this little tool so special and how you can use it to achieve the kind of precision that will make your projects shine.

Why a 1/8 Inch Carbide End Mill is Your Precision Powerhouse

So, what exactly makes a 1/8 inch carbide end mill, especially one designed for hardened steel, such a sought-after tool for delicate and precise work? It all comes down to a combination of material science, geometry, and specific design features. Let’s break down what gives these tiny tools their mighty capabilities.

The Magic of Carbide

First off, let’s talk about carbide. Carbide, also known as tungsten carbide, is a super hard composite material. It’s significantly harder and more rigid than high-speed steel (HSS), which is another common material for cutting tools. This inherent hardness is what allows carbide end mills to:

- Cut Harder Materials: They can easily take on materials that would quickly dull or even shatter an HSS tool, like hardened steels up to HRC60 (a significant level of hardness!).

- Maintain Sharpness: Carbide edges stay sharp for much longer, meaning fewer tool changes and more consistent results over time.

- Handle Higher Cutting Speeds: Because they resist heat buildup better, you can often run carbide tools at faster speeds, leading to quicker machining times.

For a beginner, this means more forgiving cuts and less worrying about ruining your tool on tougher materials. You get cleaner cuts and a longer tool life, which is a win-win.

The Significance of the 1/8 Inch Diameter

Why 1/8 inch specifically? This small diameter is ideal for a wide range of detailed work. Think about:

- Intricate Details: Engraving, creating small pockets, chamfering tiny edges, or machining intricate patterns becomes much more manageable with a smaller diameter tool.

- Tight Tolerances: Smaller tools often allow for finer adjustments and more control when you need to hit very specific dimensions.

- Accessing Small Spaces: Some workpieces have tight internal corners or areas that only a small tool can reach effectively.

This size strikes a fantastic balance between being substantial enough to remove material efficiently but small enough for detailed manipulation.

The “Proven Precision” Factor: Minimizing Deflection

This is where the “Proven Precision” in our title really comes into play. When you’re cutting, especially with smaller diameter tools or in harder materials, there’s a force that tries to push the tool away from your intended path. This is called deflection. If a tool deflects too much, your cuts won’t be accurate, and you can even break the tool. So, how does a 1/8 inch carbide end mill combat this?

- Rigidity of Carbide: As mentioned, carbide is inherently more rigid than HSS. This reduces the amount it bends under cutting forces.

- Specific Geometry: Many specialized end mills, even at 1/8 inch, feature designs to enhance rigidity. This can include:

- Higher Number of Flutes: While sometimes counter-intuitive, more flutes on a small end mill can provide more support and chip evacuation paths, contributing to stability. However, for harder materials and smaller chip loads, fewer flutes can sometimes be more robust. It’s a balance!

- Center Cutting Design: Most end mills are center-cutting, meaning they can plunge straight down into the material. This is standard but crucial for versatility.

- Strong Core Diameter: The internal diameter of the end mill shank where the flutes meet is a critical factor in its strength. A robust core resists bending.

- Shorter Overall Length / Shorter Effective Cutting Length: Tools that are “extra long” give you more reach but also more opportunity to deflect. When precision is paramount and you don’t need extreme reach, selecting a standard or even a stub-length cutter can dramatically increase rigidity and reduce deflection, leading to that “proven precision.”

When you see a specification like “extra long for hardened steel HRC60,” it’s a clue that the manufacturer has invested in designing this tool to perform exceptionally well in demanding situations. This means it’s engineered to cut hard materials accurately without excessive bending.

Choosing the Right 1/8 Inch Carbide End Mill

Not all 1/8 inch carbide end mills are created equal. To get that “Proven Precision,” you’ll want to look for specific features when making your purchase. This is where understanding a few key terms will save you time and frustration.

Key Specifications to Look For

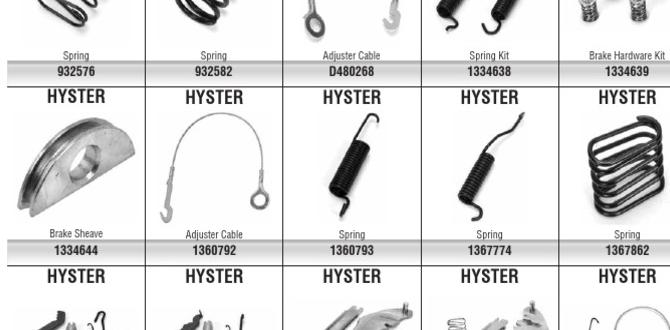

When shopping for your 1/8 inch carbide end mill, keep an eye out for these important details:

- Material Compatibility: Ensure it’s rated for the type of material you’ll be machining. For hardened steel up to HRC60, you need a tool specifically designed for that.

- Number of Flutes: For general-purpose milling in harder materials, 4 flutes are often a good starting point. These provide a good balance of cutting action and rigidity. For very hard materials or when minimizing vibration, sometimes 2-flute or 3-flute designs are preferred as they offer larger chip gullets and less chatter.

- Coating: Some end mills come with specialized coatings (like TiN, TiAlN, or AlTiN). These coatings can improve wear resistance, reduce friction, and handle higher temperatures, further enhancing performance and tool life when cutting tough materials.

- Helix Angle: A standard helix angle (around 30 degrees) is common. Higher helix angles can sometimes offer a smoother cut but might be less rigid. Lower helix angles can be more robust but might chatter more. For hardened steels, a moderate to high helix angle is often favored for achieving a good surface finish.

- Shank Type: Most end mills have a plain cylindrical shank. Ensure it will securely grip in your collet or tool holder. A Weldon flat (a machined groove on the shank) can provide extra locking security in some holders, preventing the mill from being pulled out.

- Length: As we’ve discussed, “extra long” means more reach but less rigidity. For maximum precision and minimal deflection, a standard or even stub-length end mill might be necessary if your project allows. The “effective cutting length” (how far the flutes extend from the shank) is also important.

Defining the Shank Size

You’ll notice end mills are often described by their flute diameter and their shank diameter. While we’re focusing on a 1/8 inch cutting diameter, the shank is also crucial. A 1/8 inch end mill typically comes with a 1/8 inch shank. However, you might also see 1/8 inch end mills with a larger shank (e.g., 1/4 inch or 6mm). This slightly larger shank can add a touch more rigidity to the overall tool assembly, even if the cutting edge is only 1/8 inch.

For the specific keyword “carbide end mill 1/8 inch 8mm shank extra long for hardened steel hrc60,” this implies a tool that has an 8mm (approximately 0.315 inches) shank and a 1/8 inch (0.125 inches) cutting diameter. This combination is interesting: it suggests a tool designed for maximum rigidity where the 8mm shank provides a much sturdier connection to your milling machine’s collet compared to a standard 1/8″ shank. The “extra long” aspect allows for deeper cuts or reaching further into a workpiece.

Setting Up for Success: Your Milling Machine Checklist

Before you even think about engaging the carbide end mill with your workpiece, proper machine setup is paramount. A solid foundation ensures that the precision your end mill promises can actually be realized.

Machine Readiness

Your milling machine needs to be in top shape. Here’s what to check:

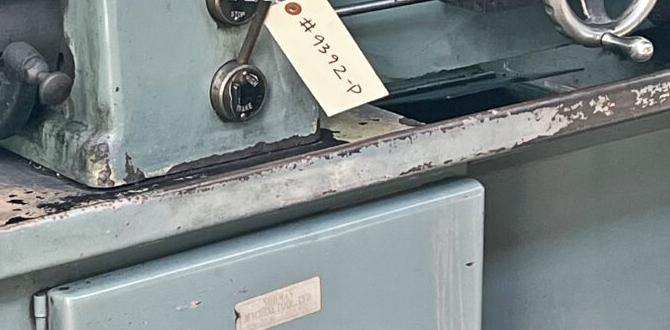

- Cleanliness: Ensure the spindle, collet, and tool holder are spotlessly clean. Any debris can cause runout (wobble) and lead to poor finishes or tool breakage.

- Spindle Runout: Ideally, your machine should have minimal spindle runout. This can be checked with a dial indicator inserted into the spindle. Less than 0.0005 inches is acceptable for most work, and aim for even less if possible.

- Rigidity of the Machine: Is your milling machine itself sturdy? A wobbly machine will amplify any cutting forces. Ensure all axis locks are engaged where appropriate and that the machine base is stable.

- Lubrication: Make sure all ways and moving parts are adequately lubricated. Smooth movement is essential for controlled cutting.

Collet and Holder Selection

The way you hold the end mill is critical for precision.

- High-Quality Collet: Use a precision collet that matches your shank diameter (in this case, 8mm). A cheap or worn collet will introduce runout. Look for reputable brands for your collets. Standards organizations often define machining tolerances and tool holding best practices, which can guide your choices.

- Secure Grip: Tighten the collet nut firmly to ensure the end mill is held securely and won’t slip or pull out during operation.

- Protrusion Length: Minimize the amount of the end mill that is sticking out of the collet. The less overhang, the less chance of deflection. If your collet can grip further up the 8mm shank, do so. Only let enough flute length extend to make your cut.

The Step-by-Step Guide to Using Your 1/8 Inch Carbide End Mill

Now that you’re equipped and your machine is ready, let’s get to the actual machining. We’ll focus on achieving that “Proven Precision” when cutting hardened steel.

1. Material and Machine Settings

This is where we translate the tool’s capabilities into actual cutting parameters. Cutting hardened steel requires care and appropriate settings.

- Material: You’re working with hardened steel up to HRC60. This is tough stuff!

- Speeds and Feeds: This is the most critical part for a beginner. Too fast, and you’ll burn up the tool or break it. Too slow, and you risk chatter and a poor finish. For a 1/8 inch carbide end mill in hardened steel, you’ll typically need relatively high spindle speeds (RPM) and relatively slow feed rates.

- Spindle Speed (RPM): Aim for a surface speed (SFM) that’s appropriate for carbide in hardened steel. A good starting point might be anywhere from 100-250 SFM, depending on the specific steel alloy and any coatings on the end mill. To calculate RPM: RPM = (SFM 3.82) / Diameter (inches). So for a 1/8″ (0.125″) end mill and 150 SFM: RPM = (150 3.82) / 0.125 = 4576 RPM. You need a machine that can achieve these higher RPMs.

- Feed Rate (IPM): This is how fast the cutter moves through the material. For small carbide end mills in hard materials, you want a lighter chip load to reduce stress on the tool and machine. A good starting point for a 2-flute end mill might be 0.001 to 0.002 inches per tooth per revolution (IPT). To calculate IPM: IPM = IPT Number of Flutes RPM. So for 0.0015 IPT, 2 flutes, and 4500 RPM: IPM = 0.0015 2 4500 = 135 IPM.

- Depth of Cut (DOC) and Width of Cut (WOC): Because you’re using a small end mill and working with hard material, keep your cuts shallow.

- Depth of Cut (DOC): Start very conservatively, perhaps 0.020 inches (0.5mm) or less for a typical 1/8″ end mill like this. You can increase this if the machine is rigid and the cut is clean.

- Width of Cut (WOC): For a full slotting operation (taking a full 1/8″ width), the load is higher. For pocketing or profiling, try to take a partial width. For example, using a 1/8″ end mill, take a series of closer passes to achieve a wider channel rather than one aggressive pass. A WOC of 25-50% of the tool diameter is a safe bet to start.

- Coolant/Lubrication: Machining hardened steel generates heat. Using a cutting fluid or mist coolant is highly recommended. It helps to cool the tool, lubricate the cut, and evacuate chips, all of which extend tool life and improve finish.

Disclaimer: These are starting points. Always consult the end mill manufacturer’s recommendations if available and be prepared to adjust based on sound and chip formation as you cut.

2. Setting the Z-Axis Zero

Accurate Z-axis setting is crucial for the correct depth of cut.

- Using a Height Gauge or Edge Finder: Carefully bring the tip of the end mill down to the top surface of your workpiece. Use a height gauge or a digital readout to set your Z-axis zero point. An electronic edge finder can also be very useful for precisely locating the center of a hole or the edge of a feature relative to your workpiece.

- Electronic Indicator: For absolute best results, especially on machines with electronic readouts, use an electronic Z-axis setter tool. These tools allow you to accurately set your Z-zero by touching the tool to the tool and then to the workpiece surface.

3. Engaging the Cut

This is the moment of truth. Take your time and observe.

- Plunge Cut (if necessary): If you need to plunge the end mill straight down, do so slowly. Some end mills are better designed for plunging than others; check the manufacturer’s specs. Start by plunging to a small depth (e.g., 0.020 inches) and then begin your milling path.

- Ramping In: If possible, it’s often better to ramp the end mill into the material rather than plunging. This means entering the material at an angle. Most modern CAM software can generate ramp moves automatically.

- Maintain Feed Rate: Once the tool is engaged, maintain a consistent feed rate. Avoid stopping or slowing down mid-cut, as this can increase friction and heat.

- Listen and Watch: Pay close attention to the sound of the cut. A smooth, consistent hum indicates a good cut. A squealing or chattering sound suggests you need to adjust your speeds, feeds, or depth of cut. Watch the chips being produced – they should be small and consistent, not long and stringy or powdery.

4. Machining Strategy: Pockets, Profiles, and Details

The way you plan your tool paths greatly influences precision and tool life.

- Pocketing: For pockets larger than 1/8 inch, you will need to take multiple passes. A common strategy is “climb milling” (where the cutter rotation direction is the same as the feed direction), which tends to produce a better surface finish and exert less force on the workpiece. However, for very hard materials or less rigid machines, “conventional milling” (opposite directions) might be more stable, though it can lead to a rougher finish. Modern CNC controllers often have options like “high-efficiency milling” (HEM) or “adaptive clearing” that optimize toolpaths to maintain a consistent chip load and tool engagement, making them ideal for this kind of work.

- Profiling (Contouring): When cutting the outside of a shape, take light finishing passes. You can often leave a small amount of material (e.g., 0.005 to 0.010 inches) on the final pass and then perform a full-depth, light-width finishing pass to achieve a very accurate and smooth edge.

- Small Details: For intricate details, focus on slow, controlled movements. Use the smallest possible depth of cut. If you are engraving, a very light depth of cut is essential.

- Managing Heat: If machining for an extended period, pause the machine periodically to allow the tool and workpiece to cool. Ensure your coolant system is functioning properly.

Tool Wear and Maintenance

<p