A 3/16 inch carbide end mill is your precision tool for intricate milling tasks, offering superior hardness, heat resistance, and edge retention. It’s ideal for detailed work in both hard and soft materials, making challenging cuts smoother and more accurate for hobbyists and professionals alike.

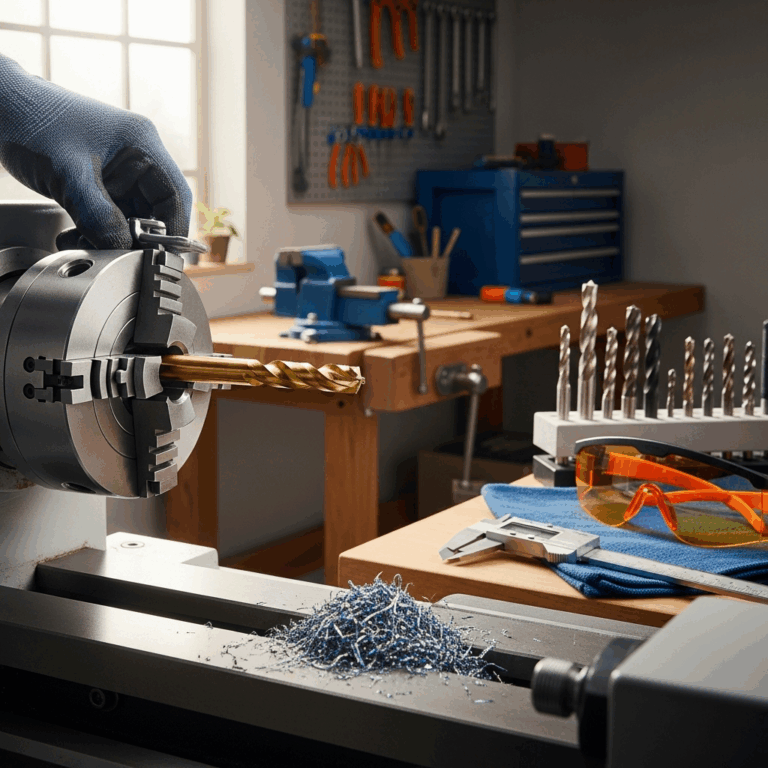

Ever found yourself wrestling with a milling project, wishing for a tool that just works? Maybe you’re trying to create a detailed slot, a precise pocket, or an intricate contour in metal or plastic. Often, the frustration comes down to the cutting tool. A small, but mighty, tool can make all the difference. That’s where the humble 3/16 inch carbide end mill steps in. It’s more than just a size; it represents a smart choice for accuracy and durability, especially when you need to tackle stubborn materials or achieve a fine finish. Let’s demystify this versatile tool and see how it can become your go-to solution for a whole range of workshop challenges.

Why a 3/16 Inch Carbide End Mill is Your Secret Weapon

When we talk about milling, we’re talking about shaping materials with rotating cutting tools. And when we talk about the sharp end of those tools, carbide is often the star. A 3/16 inch carbide end mill might seem small, but its impact on your projects can be huge. It’s the sweet spot for a lot of detailed work, offering a balance of precision and capability that larger or less robust tools just can’t match. Let’s break down why this specific type of end mill deserves a prime spot in your toolbox.

The Brilliance of Carbide

Carbide, specifically tungsten carbide, is incredibly hard and dense. This material is significantly harder than high-speed steel (HSS), which is commonly used for other cutting tools. What does this mean for you? It means:

- Longer Tool Life: Carbide resists wear much better than HSS. You’ll get more cuts out of a carbide end mill before it needs sharpening or replacement.

- Higher Cutting Speeds: Because carbide can withstand higher temperatures generated by friction, you can often run your milling machine at faster spindle speeds. This translates to quicker material removal and shorter project times.

- Improved Surface Finish: The rigidity and sharpness of carbide tools lead to cleaner, smoother cuts and a better finished surface on your workpiece.

- Toughness for Hard Materials: Carbide is excellent for cutting harder metals like stainless steel, hardened steel, and even exotic alloys. It can also handle materials like composites and some plastics with finesse.

For a 3/16 inch end mill, these properties are particularly beneficial. Smaller tools can be more prone to chatter or breakage under stress. Carbide’s inherent strength helps mitigate these issues, allowing you to push the boundaries of what you can achieve with such a small cutting diameter.

The Magic of 3/16 Inch

The 3/16 inch (0.1875 inch) diameter is a very common and useful size in machining. It’s large enough to remove material efficiently for many common tasks, yet small enough for intricate details. Consider these scenarios:

- Pocketing: Creating small, precise pockets for electronics components, fasteners, or decorative elements.

- Engraving and Lettering: Machining fine details, text, or patterns onto a surface.

- Slotting: Cutting narrow slots for keyways, hinges, or alignment features.

- Contouring: Following complex outlines or creating rounded corners with a specific radius.

- Deburring: Cleaning up edges on small parts where larger tools would be too clumsy.

When you combine the hardness and heat resistance of carbide with the versatile 3/16 inch size, you get a tool that’s incredibly effective for a wide spectrum of precision machining tasks. It’s a problem-solver for anyone looking to elevate the quality and complexity of their work.

Choosing Your 3/16 Inch Carbide End Mill: What to Look For

Not all 3/16 inch carbide end mills are created equal. To make sure you’re getting the right tool for your job, consider these key features. This will save you time, frustration, and potential damage to your workpiece or machine.

Shank Diameter

The shank is the part of the end mill that the collet or chuck grips. While we’re focusing on a 3/16 inch cutting diameter, the shank diameter can vary. The most common shank size for a 3/16 inch end mill is, unsurprisingly, 3/16 inch. However, you might also find end mills with a 1/4 inch shank. A larger shank (like 1/4 inch) provides more rigidity and can help prevent vibration and deflection, which is especially useful when milling harder materials or taking heavier cuts. For precision 3/16 inch work, a 3/16 inch shank is often perfectly adequate and allows for smaller workholding setups.

Number of Flutes

Flutes are the helical grooves that run along the cutting edges of the end mill. The number of flutes affects how well it clears chips and the type of material it’s best suited for.

- 2-Flute End Mills: These have larger chip gullets (the space between the flutes), making them excellent for clearing chips efficiently. They are generally preferred for softer materials like aluminum, plastics, and wood, as they reduce the risk of chip recutting and melting. They also offer the most aggressive material removal rate and are good for slotting.

- 3-Flute End Mills: A good compromise. They offer better rigidity and higher feed rates than 2-flute mills while still providing reasonable chip clearance. They are suitable for a broader range of materials, including some steels and softer hardwoods.

- 4-Flute End Mills: With smaller chip gullets, 4-flute end mills are best for harder materials like alloy steels and steels hardened to around Rockwell 40. They offer the highest rigidity and allow for finishing passes where chip evacuation is less of a concern than surface finish and tool strength. They are also good for ramping and plunging.

For general-purpose use with a 3/16 inch carbide end mill on common materials like aluminum, plastics, or mild steel, a 2 or 4-flute design is often recommended. If you plan on working with tougher steels, a 4-flute is highly advisable. For very specific work on materials like aluminum where chip evacuation is key, a 2-flute is excellent.

Length of Cut and Overall Length

Consider how deep you need to mill. The “length of cut” refers to the portion of the end mill that has cutting edges. If you need to mill deep slots or pockets, you’ll need an end mill with a sufficient length of cut. Standard end mills usually have a length of cut roughly equal to their diameter, or slightly more. For deeper work, you might need an “extended reach” or “long flute” end mill.

The “overall length” is the total length of the tool. This matters for machine Z-axis travel limitations and for ensuring there’s enough tool shank to get a good grip in your collet or chuck.

Coating

While basic uncoated carbide is excellent, coatings can enhance performance. For general milling of steels and other common metals, a TiAlN (Titanium Aluminum Nitride) coating can provide additional hardness and thermal resistance, extending tool life and allowing for higher cutting speeds. For aluminum and non-ferrous metals, a bright (uncoated) or DLC (Diamond-Like Carbon) coating is often preferred to prevent material buildup.

End Type (Flat, Ball, Corner Radius)

The shape of the end mill’s tip determines the geometry of the cut:

- Flat End Mills: These have a flat cutting surface at the end and are used for creating square-bottomed slots, pockets, and profiles. They are the most common type.

- Ball End Mills: These have a fully rounded cutting tip, ideal for creating 3D contoured shapes, fillets, and ball-nosed slots.

- Corner Radius End Mills: These have a slight radius at the corner where the side cutting edge meets the end. This helps to strengthen the corners, reduce stress concentration, and leave a small radius in the corners of pockets or slots, which can be beneficial for strength.

For general-purpose 3/16 inch work, a flat end mill is usually the go-to. If you’re doing 3D carving or need smooth internal corners, a ball or corner radius end mill would be your choice.

Practical Applications of a 3/16 Inch Carbide End Mill

Let’s get hands-on and see where this versatile tool truly shines. Its size and material properties make it perfect for a range of detailed and demanding tasks.

Precision Pocketing

Creating accurate recesses for components, such as in enclosures for electronics, mounts for sensors, or seats for bearings, is a common need. A 3/16 inch end mill allows you to mill these pockets with high precision. For instance, if you need to mill a pocket for a specific fitting or a small set screw, this diameter is often ideal. Using a 4-flute carbide end mill in steels, or a 2-flute in aluminum, allows for smooth pocketing without excessive chatter.

Intricate Slotting

Need to mill a narrow slot? Whether it’s for a keyway in a shaft, a sliding mechanism, or a decorative groove, a 3/16 inch end mill can do the job. For materials like aluminum or plastics, a 2-flute carbide end mill can efficiently clear chips, leaving a clean slot. If you’re in mild steel, a 4-flute will provide the rigidity needed. For slots that require a specific width and depth, precise control from a carbide end mill is invaluable. This is also where the longevity of carbide means you can produce many identical slots without worrying about the tool wearing out.

Engraving and Text Machining

For adding labels, serial numbers, or decorative patterns to parts, you might think of specialized engraving tools. However, a small diameter (often 1/8 inch or even smaller) ball-nosed end mill is used for detailed engraving. A 3/16 inch end mill, particularly a ball-nosed one, can also be used for slightly larger lettering or for milling out areas around engraved text for a bolder look. Its precision can ensure clean edges on letters and symbols.

Contouring and Profile Machining

When you need to create specific external shapes or internal profiles, a 3/16 inch end mill can be your primary tool. If you’re cutting out a part from sheet material or creating curved edges on a block, this size can be perfect for achieving the desired contour. Using CAM software to program toolpaths will allow you to leverage the full capability of the end mill for complex curves and radiuses.

Working with Specific Materials

While we’ve touched on this, it’s worth reiterating. A 3/16 inch carbide end mill is your friend when dealing with materials that are tough on HSS tools:

- Aluminum: Lightweight and easy to machine, but can gum up tools. A 2-flute carbide end mill with high rake angles is excellent for chip evacuation, preventing buildup and ensuring a good finish.

- Steels (Mild to Medium Hardness): For steels up to around Rockwell 35-40, a 4-flute carbide end mill provides the necessary rigidity. You’ll get a good balance of material removal and surface finish.

- Plastics and Composites: Many plastics machine well, but some can melt or chip undesirably. Carbide’s sharpness and heat resistance help create clean cuts in most plastics, including acrylics, ABS, and nylon. For composites, it’s crucial to use appropriate feeds and speeds to avoid delamination, but carbide’s hardness is beneficial.

- Wood (for specific applications): While wood is softer, a carbide end mill can be used for very fine detail work in hardwoods, especially when a clean, crisp edge is paramount, or for certain composite materials that are wood-like. However, it’s generally overkilled for common woodworking and can lead to splintering if not used carefully. For general wood, specialized wood bits are better.

When to Consider a “Long Reach” or Extended Length End Mill

Sometimes, the standard length of cut just isn’t enough. This is where an extended reach or “long reach” carbide end mill comes into play. These tools have a significantly longer cutting flute section, allowing you to mill deeper into a workpiece without the shank interfering. They are essential for:

- Deep Slotting: Creating long, deep slots where standard end mills would bottom out.

- Machining into Cavities: Accessing recessed areas inside a workpiece.

- Reducing Setups: By using a longer tool, you might avoid the need for multiple setups or special fixturing to reach deeper features.

If you find yourself consistently needing to machine deeper than a standard tool allows, the 3/16 inch carbide end mill in a long reach variant could be a game-changer for your projects.

Machining with Your 3/16 Inch Carbide End Mill: Best Practices

Now that you have your perfect 3/16 inch carbide end mill, let’s talk about using it effectively and safely. Machining, especially with precision tools, requires attention to detail. Following these guidelines will help you achieve great results and extend the life of your tool.

Understanding Cutting Speeds and Feeds

This is perhaps the most critical aspect of milling. Cutting speed (surface speed, SFM or m/min) is how fast the cutting edge moves relative to the material. Feed rate (IPM or mm/min) is how fast the tool advances into the material.

- Cutting Speed: Carbide generally allows for higher cutting speeds than HSS. For a 3/16 inch (0.1875 inch) carbide end mill in aluminum, you might start around 300-600 SFM (90-180 m/min). For mild steel, you might be in the 200-400 SFM (60-120 m/min) range. These are starting points; always consult manufacturer data or online calculators.

- Feed Rate: This depends heavily on the Number of Flutes and the Chip Load per Tooth (CLT). A common starting point for CLT in aluminum with a 2-flute end mill might be 0.002-0.005 inches per tooth. In mild steel with a 4-flute, it might be 0.001-0.003 inches per tooth. Multiply your CLT by the number of flutes and your spindle RPM to get your feed rate.

Rule of Thumb: Start conservatively. If your tool is chattering, the finish is poor, or chips are melting, slow down your feed rate or adjust your spindle speed. If chips are too light and feathery, you can often increase the feed rate or adjust spindle speed.

For more detailed information on calculating speeds and feeds, resources like the Metal Cutting Facts website offer comprehensive guides and calculators.

Proper Workholding is Key

Your workpiece needs to be held securely. Any movement during machining will lead to inaccuracy, tool breakage, or a dangerous situation.

- Vise: For most small to medium-sized parts, a good quality milling vise is essential. Ensure the vise jaws are clean and the workpiece is snug against the fixed jaw.

- Clamps: If milling directly onto a machine table or into a fixture, use appropriate clamps. Ensure clamps don’t interfere with the toolpath.

- Tooling: Use the correct collet for your spindle and ensure the end mill is seated properly and securely. A small amount of runout can magnify errors significantly.

Coolant and Lubrication

Even with carbide’s heat resistance, maintaining proper cooling and lubrication is crucial, especially when milling harder materials or taking heavier cuts.

- Air Blast: For aluminum and plastics, a blast of compressed air can help clear chips and prevent melting.

- Cutting Fluid/Mist: For steels and tougher alloys, a flood coolant or mist system is highly recommended. This lubricates the cut, cools the tool and workpiece, and flushes away chips. It dramatically extends tool life and improves surface finish.

- Cutting Paste/Stick: For very small workshops or manual machines, a small amount of specialized cutting paste or stick can be applied to the cutting area to provide localized lubrication.

Step-by-Step Milling Process (General)

Here’s a simplified process. Always refer to your specific machine’s manual for detailed operation.

- Secure the Workpiece: Ensure your part is firmly clamped in a vise or fixture.

- Install the End Mill: Insert the 3/16 inch carbide end mill into the correct collet and tighten it securely in the spindle.

- Set the Z-Axis Zero: Carefully touch off on the top surface of your workpiece to establish your zero point for depth.

- Set the X and Y Zero: Position the end mill over your start point and set your