3/16 Inch Carbide End Mills are crucial for successfully machining tough Inconel. This guide breaks down why and how to use them effectively for beginners.

Machining Inconel, a superalloy known for its strength and heat resistance, can feel like a daunting task, especially for those just starting out. Many beginners hit a wall when trying to cut this material, often leading to tool breakage and frustration. The good news is, with the right tools and techniques, Inconel is manageable. A key player in this process is the humble 3/16 inch carbide end mill. It’s not just any end mill; when chosen correctly, it becomes your secret weapon for tackling this challenging metal. We’ll walk through everything you need to know to make your Inconel machining projects a success.

Why 3/16 Inch Carbide End Mills Shine for Inconel

Inconel is famously tough. It’s designed to withstand extreme temperatures and corrosive environments, which also means it’s incredibly hard to machine. Traditional high-speed steel (HSS) tools often struggle, dulling quickly or even failing catastrophically. This is where carbide, and specifically a 3/16 inch carbide end mill, comes into its own.

The Power of Carbide

Carbide, or tungsten carbide, is a compound of tungsten and carbon atoms. It’s significantly harder and stiffer than HSS. This superior hardness means it can cut through tough materials like Inconel with less wear and tear. Carbide also offers better heat resistance, which is crucial because machining Inconel generates a lot of heat.

The 3/16 Inch Sweet Spot

Why 3/16 inch? This size offers a great balance for many Inconel applications, especially for hobbyists or those working on smaller parts. It’s small enough to allow for precise cuts and intricate details while large enough to handle the forces involved in machining Inconel without being overly fragile. For many common operations, a 3/16 inch shank provides sufficient rigidity for a carbide end mill to bite into the material effectively.

When looking for the right tool, you’ll often see specifications like “carbide end mill 3/16 inch 1/4 shank stub length for inconel 718 low runout.” Let’s break that down:

- Carbide End Mill: As we discussed, this tells you the material.

- 3/16 Inch: This is the diameter of the cutting edge.

- 1/4 Shank: The shank is the part that holds the end mill in your machine’s collet or tool holder. A 1/4 inch shank is common and fits many standard tool holders.

- Stub Length: This refers to the overall length of the end mill. Stub length end mills are shorter and stouter than standard length ones. This reduced length-to-diameter ratio makes them much more rigid and less prone to vibration, which is critical for stable cutting in tough materials like Inconel.

- For Inconel 718: This indicates it’s specifically designed or recommended for Inconel 718, a very common and notoriously difficult-to-machine grade of Inconel.

- Low Runout: Runout is the slight wobble or deviation of the cutting tool as it spins. Low runout means the tool spins very accurately, which is essential for precise cuts and extending tool life.

Key Features to Look For in Your 3/16 Inch Inconel End Mill

Not all carbide end mills are created equal, especially when it comes to exotic alloys like Inconel. Here are the features that make a 3/16 inch carbide end mill ideal for this job:

1. Material and Coating

Solid Carbide: Always go for solid carbide. This means the entire tool is made of tungsten carbide, offering maximum hardness and heat resistance. Avoid “carbide tipped” end mills for this application.

Coatings: Coatings add another layer of protection and performance. For Inconel, look for coatings rich in:

- Titanium Nitride (TiN): A good all-around coating that improves hardness and reduces friction.

- Titanium Aluminum Nitride (TiAlN) or AlTiN: Excellent for high-temperature applications like Inconel machining. They form a hard, heat-resistant layer that performs exceptionally well at elevated temperatures.

- Diamond-Like Carbon (DLC): Offers superior hardness and wear resistance, often beneficial for very abrasive materials.

A TiAlN or AlTiN coating is usually the best bet for Inconel.

2. Geometry and Flute Design

Number of Flutes: For Inconel, fewer flutes are generally better. While 2-flute end mills are common, for very tough materials, 3-flute or even 4-flute end mills can be used, but with careful consideration of chip evacuation. A minimum of 2 flutes is recommended to allow for good chip clearance. More flutes can sometimes lead to chip packing in sticky materials.

Helix Angle: A higher helix angle (e.g., 35-45 degrees) can help to shear the material more aggressively and improve chip evacuation. However, extremely high helix angles can reduce rigidity. For Inconel, a moderate to high helix angle is often preferred.

Center Cutting: Ensure the end mill is “center cutting.” This means it has cutting edges on the end face, allowing you to plunge or drill into the material vertically, not just cut sideways. This is essential for most milling operations.

3. Length and Shank

Stub Length: As mentioned, stub length end mills are highly recommended. Their shorter profile significantly reduces deflection and vibration, leading to cleaner cuts and longer tool life. This is paramount when dealing with the forces required to cut Inconel.

Shank Tolerance: Look for end mills with tight shank tolerances. Tight tolerances ensure a better grip in your collet or tool holder, minimizing runout. ER collets are a good choice for achieving low runout. For precision work, consider tool holders specifically designed for minimal runout, like those found in some .gov machining guides on precision machining.

Setting Up Your Machine for Inconel Machining

Successfully machining Inconel isn’t just about the end mill; it’s about how you set up your machine. Here’s what beginners need to focus on:

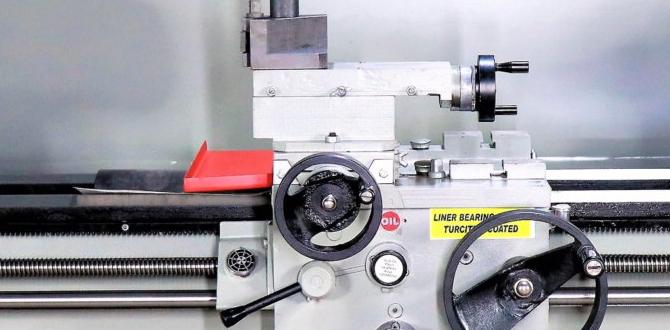

1. Rigidity is King

Inconel is tough, and it fights back. Your entire setup must be as rigid as possible. This means:

- Secure Workholding: Ensure your workpiece is clamped down TIGHTLY. Use a sturdy vise or appropriate fixtures. Any movement will lead to poor surface finish, tool breakage, or lost parts.

- Minimize Overhang: Keep the end mill’s cutting portion as close to the tool holder as possible. This is where the stub length comes in handy.

- Solid Machine Base: Make sure your milling machine itself is on a stable base.

2. Coolant and Lubrication

Machining Inconel generates extreme heat. Without proper cooling, your tool will overheat, lose its hardness, and fail. Flood coolant is ideal. If you don’t have a flood coolant system, consider:

- MQL (Minimum Quantity Lubrication): A system that sprays a fine mist of lubricant and air directly at the cutting zone.

- Cutting Pastes or Gels: These can be applied directly to the cutting area to supplement air cooling or when flood coolant isn’t feasible. They are thicker than liquid coolants but provide good lubrication.

Use cutting fluids specifically designed for exotic alloys or high-temperature machining. These often have additives that help with lubrication and cooling under extreme conditions.

3. Machine Settings (The Sweet Spot)

This is where many beginners struggle. Inconel requires slower speeds and faster feed rates than softer metals. This might seem counterintuitive, but it’s about shearing the material rather than rubbing it, and it helps manage heat by moving material away quickly.

General Starting Point for 3/16 Inch Carbide End Mill in Inconel 718:

These are starting points and will vary based on your specific machine, tool, and coolant. Use them as a guide and be prepared to adjust.

| Operation | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (DOC) | Width of Cut (WOC) |

|---|---|---|---|---|

| 2D Contour/Profiling | 500 – 1500 | 3 – 10 | 0.010″ – 0.030″ (Radial & Axial) | 0.040″ – 0.100″ (for 3/16″ end mill, this is about 20-50% of tool diameter) |

| Slotting (Full Width Cut) | 400 – 1000 | 2 – 8 | 0.010″ – 0.020″ (Axial) | 0.187″ (Full Width of 3/16″ end mill) |

| Face Milling (small areas, use with care) | 600 – 1200 | 5 – 15 | 0.005″ – 0.015″ (Axial) | ~0.050″ (Radial) |

Understanding Feed and Speed:

- Surface Speed (SFM): This is a property of the material and tool. For Inconel with carbide, it’s typically in the range of 50-150 SFM. To convert SFM to RPM, you use the formula: RPM = (SFM 3.82) / Diameter (inches). So for a 3/16″ (0.1875″) end mill at, say, 100 SFM: RPM = (100 3.82) / 0.1875 ≈ 2037 RPM. This is a high-end limit, and for Inconel, you’ll usually be at the lower end or even below that calculation.

- Feed Per Tooth (IPT): This is the amount of material each flute cuts. For a 3/16″ carbide end mill in Inconel, this might range from 0.001″ to 0.003″ IPT. The feed rate (IPM) is then IPT Number of Flutes RPM.

Important Notes on Settings:

- Chip Thinning: When taking very shallow radial cuts (less than 50% of the tool diameter), chip thinning can occur, leading to higher temperatures. You might need to adjust your feed rate upwards to maintain chip load.

- Always Start Conservatively: Begin with slower speeds and lighter depths of cut. Listen to the machine and observe the chips.

- Listen to the Cut: A healthy cut sounds like a continuous “chirping” or light “singing.” A loud, grinding, or chattering sound means something is wrong.

- Observe the Chips: For Inconel, you want small, manageable chips – not long, stringy ones, and definitely not dust (which indicates the tool is rubbing or too slow). Nice, broken chips are a good sign.

Consulting manufacturer data sheets for your specific end mill model and Inconel grade can provide more precise recommendations. Websites like the Machine Tool Help portal offer extensive resources on machining parameters for various materials. Even the Naval Air Warfare Center Aircraft Division publishes technical documents related to materials processing which can be insightful.

Step-by-Step: Machining Inconel with Your 3/16 Inch End Mill

Let’s walk through a typical workflow. Imagine you need to cut a simple profile into a block of Inconel 718.

Step 1: Preparation and Fixturing

- Inspect Your Tool: Double-check your 3/16 inch carbide end mill for any signs of wear or damage. Use a clean tool for the best results.

- Secure the Workpiece: Mount your Inconel block in a sturdy vise. Use soft jaws if you’re concerned about marring the surface, but ensure the grip is absolutely firm. Use parallels to lift the workpiece off the vise jaws for clearance and stability.

- Set Z-Zero: Carefully find your Z-axis zero point on the top surface of the workpiece. A touch probe or a simple edge finder works well here.

- Set X/Y Origin: Find your X and Y zero point using your machine’s method – edge finder, probe, or indicator.

Step 2: Loading Your Program and Setting Parameters

- Load Your G-code: If you’re using CAM software (like Fusion 360, Mastercam, or even simpler ones like Estlcam), generate your toolpath and load the resulting G-code program into your CNC controller.

- Set Tool and Offsets: Ensure your selected tool (the 3/16″ carbide end mill) is correctly loaded in your tool changer or turret and that its length and diameter offsets are accurately set in the controller.

- Double-Check Speeds and Feeds: Re-verify the spindle speed, feed rate, and depth of cut programmed for your operation. Refer to the table and your experience.

Step 3: Coolant and Lubrication Setup

- Turn on Coolant: Activate your flood coolant system, MQL, or manual application of cutting paste. Ensure it’s directed precisely at the cutting zone.

- Prepare for Chip Evacuation: Make sure your chip removal method is clear. Compressed air can help blast chips away if coolant isn’t perfectly covering the area, but avoid using it if it blows chips back into the cut or tool path.

Step 4: The First Cut

- Dry Run (Optional but Recommended): Many CNC controllers allow for a “dry run” where the machine moves through the programmed path without the spindle rotating or the tool cutting. This is a great way to catch any sudden collisions or major errors in your G-code.

- Jog to Starting Position: Manually jog your machine to the start of the programmed toolpath.

- Engage Spindle and Feed: Start the spindle at the programmed speed, then engage the feed.

- Observe and Listen:

- Sound: Listen for a consistent, relatively quiet cutting sound. Loud banging or grinding means trouble.

- Vibration: Excessive chatter or vibration is a sign you need to adjust your speeds, feeds, or depth of cut.

- Chips: Watch the chips being produced. They should be relatively small and broken, not long and stringy.

- Heat: While it’s hard to see directly, if your coolant starts to steam excessively, you’re generating too much heat.

Step 5: Subsequent Passes and Finishing

- Incremental Cuts: For Inconel, it’s standard practice to take multiple shallow passes rather than one deep pass. This reduces the cutting forces and manageable chip generation. For a profile cut, this might involve taking, for example, 0.020″ deep passes until you reach your final depth.

- Finishing Pass: On your final pass, you might want to:

- Reduce Feed Rate Slightly: A slight reduction in feed rate (e.g., by 10-20%) can help improve surface finish.

- Shallow Depth of Cut: Take a very shallow axial depth of cut (e.g., 0.005″ to 0.010″) for the final path.

- Tool Life Monitoring: Keep an eye on your end mill. If you notice chatter developing on later passes, or if the chips start to look different (more like dust), it might be time to change the tool or re-evaluate your parameters.

Step 6: Ejecting the Part and Inspection

- Retract Tool: Safely retract the tool to its home position.

- Turn off Coolant/Spindle: Once the tool is clear of the workpiece.

- Remove Workpiece: Carefully remove the machined part from the vise.

- Inspect: Check the dimensions, surface finish, and look for any signs of tool breakage or damage to the workpiece.