Quick Summary: A 3/16″ carbide end mill with a 1/2″ shank is a versatile tool for dry cutting in milling machines like the PMM-A, offering precision and durability without the need for coolant, making it ideal for hobbyists and professionals alike.

Mastering Your 3/16″ Carbide End Mill: The Genius of Dry Cutting

Ever stared at a project, ready to mill, but felt a bit stuck on how to get that perfect cut? Specifically, when you’ve got that handy 3/16″ carbide end mill? It’s a common scenario for us makers, especially when we want precise results without the mess of coolant. Many beginners find machining a little daunting, and figuring out the right tool and technique can add to that pressure. But here’s the good news: using a 3/16″ carbide end mill for dry cutting is not only achievable, it’s often a brilliant solution for many common milling tasks. We’re going to walk through exactly how to get the most out of this fantastic tool, ensuring you feel confident and ready to tackle your next project.

In this guide, we’ll break down everything you need to know about dry cutting with your 3/16″ carbide end mill. We’ll cover what makes carbide special, the advantages of going coolant-free, and the step-by-step process to achieve clean, precise cuts. You’ll learn how to select the right end mill, set up your machine, and operate safely. By the end, you’ll be an ace at dry cutting, ready to create amazing things with confidence.

Why Carbide? The Secret Behind a Sharp Cut

Carbide, or tungsten carbide, is a super-hard material created by bonding tungsten atoms with carbon atoms. Think of it as a ceramic metal. This unique composition gives it some truly impressive properties that make it a top choice for cutting tools.

- Extreme Hardness: Carbide is significantly harder than high-speed steel (HSS). This means it can withstand higher temperatures and pressures during cutting without getting dull or deforming.

- Wear Resistance: Because it’s so hard, carbide end mills resist wear for much longer than HSS. This translates to more consistent cuts over time and less frequent tool changes.

- Heat Resistance: Machining generates heat, especially at high speeds. Carbide can handle much higher temperatures before losing its cutting edge, which is crucial for efficient dry cutting.

- Stiffness: Carbide is also stiffer than HSS, meaning it deflects less under load. This leads to more accurate and precise machining.

These qualities make carbide end mills ideal for cutting a wide range of materials, from softer plastics and aluminum to harder steels and composites, often with fewer issues and better surface finishes, especially when speed and feed rates are optimized.

The Genius of Dry Cutting: Benefits and Considerations

Dry cutting might sound a bit aggressive, but with the right tools and techniques, it’s a remarkably effective and often preferred machining method for many situations. When we talk about dry cutting with a carbide end mill, we mean machining without the use of a liquid coolant or cutting fluid.

Advantages of Dry Cutting:

- Cleanliness: This is the big one! No coolant means no messy chips mixed with fluid, no cleaning up spills, and no need for coolant filtration systems. This is a huge advantage for home workshops, educational settings, or anywhere cleanup is a major concern.

- Reduced Costs: You save money by not having to buy, store, and maintain cutting fluids.

- Simpler Setup: No need for coolant pumps, hoses, or nozzles. This simplifies machine setup and reduces potential points of failure.

- Material Compatibility: Some materials, like certain plastics or composites, can be damaged or degraded by certain cutting fluids. Dry cutting eliminates this risk.

- Chip Evacuation: With proper technique, dry cutting can lead to excellent chip evacuation, as chips are often blown away by the air around the cutting zone.

- Environmentally Friendly: No spent coolant to dispose of properly, which can be a significant environmental benefit.

Potential Considerations for Dry Cutting:

While dry cutting is great, it’s important to be aware of its limitations and how to manage them:

- Heat Management: Without a liquid coolant to carry heat away, the cutting tool and the workpiece can get hotter. This is where the heat resistance of carbide really shines. However, you must manage chip load and feed rates to prevent overheating.

- Tool Life: While carbide is robust, excessive heat without coolant can still shorten tool life over very long production runs. For hobbyist and typical workshop use, it’s usually not a major issue.

- Chip Control: Proper chip evacuation is crucial. If chips don’t clear the flutes, they can recut material, leading to poor finishes and potential tool breakage.

- Dust and Fumes: Machining certain materials dry can create fine dust particles or fumes, especially plastics. Adequate ventilation and personal protective equipment (PPE) are essential.

For a 3/16″ carbide end mill, dry cutting is frequently the go-to method for metals like aluminum, brass, and plastics, as well as some softer steels, when heat can be managed effectively through appropriate speeds and feeds.

Your 3/16″ Carbide End Mill: What to Look For

Not all 3/16″ carbide end mills are created equal. When you’re aiming for successful dry cutting, selecting the right type of end mill is crucial. For a general-purpose 3/16″ carbide end mill with a 1/2″ shank, here are the key features to consider:

Key Features:

- Material: Ensure it’s solid carbide or carbide-tipped. Solid carbide is generally preferred for its toughness and ability to handle higher cutting forces.

- Number of Flutes: This specifies how many cutting edges the end mill has.

- 2-Flute: Excellent for chip evacuation because it leaves more space in the flutes for chips to exit. This is often the best choice for dry cutting softer materials like aluminum and plastics, as it helps prevent chip recutting and melting.

- 3 or 4-Flute: These offer a smoother finish and better stability due to more cutting edges engaging the material. They are generally better suited for harder materials or when a superior surface finish is paramount, and can be used for dry cutting, but require more careful management of heat and feed rates.

For general dry cutting of aluminum and plastics, a 2-flute is a fantastic starting point.

- Coating: While not always necessary for dry cutting softer metals, coatings can significantly improve performance and tool life, especially if you’re pushing the limits or cutting slightly harder materials. Common coatings include:

- Uncoated: Standard for many all-purpose end mills. Works well for aluminum with proper speeds/feeds.

- TiN (Titanium Nitride): A general-purpose coating that adds some hardness and lubricity, offering moderate protection against heat and wear.

- AlTiN (Aluminum Titanium Nitride) or TiAlN (Titanium Aluminum Nitride): Excellent for high-temperature applications, making them very suitable for dry cutting tougher materials where heat buildup is a concern.

- ZrN (Zirconium Nitride): Offers good lubricity and wear resistance, particularly good for aluminum.

- Shank: You specified a 1/2″ shank. This is common and provides a good amount of rigidity. Ensure it’s a straight shank for most milling applications, or a Weldon shank if your collet system prefers it for positive locking.

- Length: For a “standard length” end mill, its cutting length will typically be around 1 to 1.5 times its diameter. This is versatile. Longer end mills are for reaching deeper into workpieces but are more prone to deflection.

- End Shape:

- Square End: Most common, creates sharp 90-degree corners.

- Ball End: Creates rounded internal corners, useful for 3D profiling and carving.

- Corner Radius: A slightly rounded corner to add strength and prevent chipping.

For general machining, a square end is the most versatile.

For typical beginner use and dry cutting applications like aluminum or plastics on a PMM-A style mill, a 2-flute, uncoated or ZrN coated, solid carbide, square-end 3/16″ end mill with a 1/2″ shank is an excellent, cost-effective choice.

Preparing for Dry Cutting: Machine and Material Setup

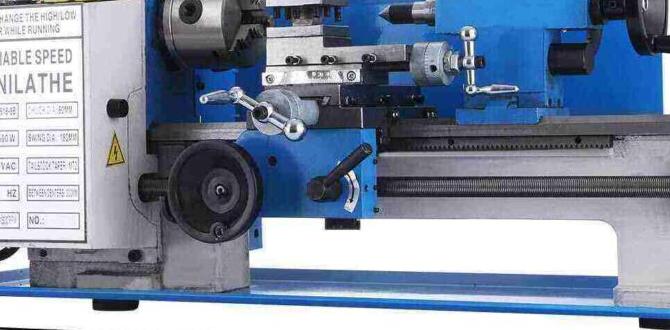

Before you even think about making a cut, proper preparation is key. This ensures safety, accuracy, and a good result. For dry cutting with your 3/16″ carbide end mill, especially on a machine like a PMM-A (which implies a small benchtop milling machine), you need to pay attention to a few things:

1. Secure the Workpiece:

This is paramount for safety and accuracy. No matter what material you’re cutting or how you’re cutting it, your workpiece must be held firmly. The last thing you want is for the workpiece to shift mid-operation.

- Vise: A good quality machine vise is the most common way to hold stock. Ensure the vise jaws are clean and that your workpiece is seated squarely in the vise.

- Clamps: Depending on your machine table and workpiece shape, clamps can be used. Always use T-nuts and bolts to fix clamps securely to the machine table.

- Squaring: Make sure your workpiece is perfectly square to the machine’s axes. This is crucial if you need parallel or perpendicular features. Use a machinist’s square.

A loose workpiece can lead to dangerous chatter, broken tools, poor finishes, and inaccurate dimensions. Always go for robust workholding.

2. Machine Spindle Setup:

For a 3/16″ end mill with a 1/2″ shank, you’ll need a collet or tool holder that accepts a 1/2″ shank. The PMM-A is often equipped with an R8 spindle or similar, requiring a specific collet for your end mill.

- Collet Selection: Use a properly sized collet. A 3/16″ collet is ideal. Avoid using an adapter or a collet that is too large; this reduces rigidity and accuracy.

- Collet Nut: Ensure the collet nut is clean and free from debris.

- Tightening: Tighten the collet nut securely according to the manufacturer’s recommendations. A loose end mill can wobble, leading to poor cuts and potential disaster.

3. Spindle Speed (RPM):

Determining the correct spindle speed is critical for dry cutting. It depends on the material being cut, the diameter of the end mill, and the type of end mill (flute count, coating). For a 3/16″ carbide end mill, particularly in aluminum, you’ll typically want higher speeds than you would with HSS.

A good starting point for 3/16″ carbide in aluminum is often in the range of 5,000 to 15,000 RPM. For harder materials, you might need to decrease RPM. Always consult a machining calculator or manufacturer’s recommendations if available. For example, a common formula for surface speed (SFM or SMM) is:

$$ text{RPM} = frac{text{Surface Speed} times 12}{pi times text{Diameter (inches)}} $$

Or for metric:

$$ text{RPM} = frac{text{Surface Speed} times 1000}{pi times text{Diameter (mm)}} $$

Here’s a table of approximate surface speeds (SFM) for carbide end mills.

| Material | Approximate Surface Speed (SFM) for Carbide |

|---|---|

| Aluminum | 400 – 800+ |

| Brass | 300 – 600 |

| Mild Steel | 150 – 300 |

| Tool Steel | 100 – 200 |

| Plastics (e.g., Delrin, ABS) | 400 – 800+ |

Let’s calculate a starting RPM for aluminum with a 3/16″ (0.1875″) end mill, aiming for 600 SFM using a 2-flute uncoated carbide end mill. Use an online calculator or the formula:

$$ text{RPM} = frac{600 text{ SFM} times 12}{pi times 0.1875 text{ inches}} approx 12,230 text{ RPM} $$

This is a high speed; ensure your machine can achieve it reliably. For many smaller mills, you might be limited to a lower RPM, which means you’ll have to adjust your feed rate accordingly.

4. Feed Rate and Chip Load:

Feed rate is how fast the tool moves through the material. Chip load is the thickness of the chip removed by each cutting edge per revolution. For dry cutting, especially with fewer flutes like a 2-flute end mill, you want a feed rate that allows chips to clear easily and prevents excessive heat buildup.

A good rule of thumb is to set a feed rate that results in a healthy chip load. For a 3/16″ carbide end mill in aluminum, a chip load might be around 0.002″ to 0.005″ per tooth. Again, use a calculator:

$$ text{Feed Rate (IPM)} = text{Chip Load} times text{Number of Flutes} times text{RPM} $$

Example: Assuming a chip load of 0.003″ per tooth and RPM of 10,000:

$$ text{Feed Rate} = 0.003″ times 2 text{ flutes} times 10,000 text{ RPM} = 60 text{ IPM} $$

You should test this. If chips are too fine or you hear rubbing, increase chip load (higher feed rate or lower RPM). If you hear excessive chatter or the tool struggles, decrease chip load (lower feed rate or higher RPM).

5. Plunge Rate:

When plunging the end mill directly into the material (drilling a hole, for example), use a slower plunge rate than your standard feed rate. A good starting point is 1/3 to 1/2 of your typical feed rate.

6. Depth of Cut (DOC):

For dry cutting, especially on smaller machines or with harder materials, it’s often best to take lighter depths of cut. This helps manage heat and reduces the load on the end mill and machine.

- Radial Depth of Cut (RDOC): This is how much the end mill cuts across its diameter. For full slotting (cutting a channel the full width of the end mill), you might take 50% or less of the diameter. For profiling (cutting around a shape), you can often take a larger RDOC.

- Axial Depth of Cut (ADOC): This is how deep the end mill cuts into the material along its axis (Z-axis). For dry cutting, taking lighter passes, say 1/10th to 1/4th of the end mill diameter, is generally safer and more effective at managing heat. You can always make multiple passes to reach your final depth.

7. Machine Stability and Alignment:

Ensure your milling machine is on a stable surface and that there’s no excessive play in the machine’s axes (leadscrews, gibs). Proper alignment is also crucial for accurate results.

8. Ventilation and Dust Collection:

Even when dry cutting, dust and fine particles can be generated. For plastics and some composites, this can be significant. Ensure you have good general ventilation, consider a dust collection system if available, and always wear safety glasses and a dust mask or respirator.

Referencing resources like the NIST Precision Engineering Education can provide deeper insights into machining principles and best practices.

The Step-by-Step Dry Cutting Process

Now that you’re prepared, let’s get down to the actual cutting. This process will build on the preparations we’ve discussed. For this example, let’s assume we are cutting a slot in a piece of aluminum stock using a 3/16″ 2-flute carbide end mill on a PMM-A style mill.