Carbide end mills are your go-to for achieving precision when cutting cast iron. These tools offer superior hardness and heat resistance, making them ideal for tough materials. Learn how to select and use the right carbide end mill for consistent, accurate results in your cast iron projects.

Working with cast iron can feel a bit daunting at first. It’s a tough material, and getting clean, precise cuts sometimes feels like a puzzle. Many beginners worry about damaging their tools or ending up with less-than-perfect results. But with the right approach and the right cutting tool, machining cast iron can be surprisingly straightforward and rewarding. The key is understanding how specific tools interact with this material.

This guide is all about a fantastic tool for the job: the carbide end mill. We’ll explore why carbide is so well-suited for cast iron and how to pick the perfect one, like a “carbide end mill 3/16 inch 1/2 shank reduced neck for cast iron tight tolerance,” to ensure you achieve that sought-after precision. Get ready to machine cast iron with confidence!

Why Carbide End Mills Excel in Cast Iron

Cast iron isn’t like softer metals. It’s brittle and abrasive, which means it can really put a strain on your cutting tools. This is where carbide end mills shine.

Carbide, also known as tungsten carbide, is an extremely hard and dense material. It’s made by combining tungsten, a very heavy metal, with carbon. This combination creates a compound that’s significantly harder and more rigid than high-speed steel (HSS), the material most common drill bits and some end mills are made from.

Here’s why this matters for machining cast iron:

<ul<

<li<Superior Hardness: Cast iron contains graphite, which can act like sandpaper on softer cutting tools. Carbide’s hardness allows it to cut through this abrasive material without dulling too quickly.

<li<Heat Resistance: Machining generates heat. Carbide can withstand much higher temperatures than HSS before softening. This is crucial because cast iron is known to cause friction and heat buildup.

<li<Rigidity: Carbide is stiffer than HSS. This means the end mill is less likely to deflect under the cutting forces, leading to more accurate and predictable cuts – exactly what we need for “tight tolerance” work.

<li<Better Surface Finish: Because carbide stays sharp longer and deflects less, it can produce smoother surface finishes on cast iron compared to HSS tools.

<li<Faster Cutting Speeds: With its superior properties, you can often run carbide end mills at faster speeds and feed rates than HSS, which can significantly speed up your machining time.

</ul<

While carbide is fantastic, it’s also more brittle than HSS. This means it can chip or break if mishandled, especially if you’re plunging into the material too aggressively or if the workpiece isn’t held securely.

Choosing the Right Carbide End Mill for Cast Iron

When you’re looking for that perfect tool for cast iron precision, especially for specific needs like a “carbide end mill 3/16 inch 1/2 shank reduced neck for cast iron tight tolerance,” a few key features will guide your selection.

Key Features to Consider

<ul<

<li<Material: Look for end mills specifically rated for cast iron or general-purpose machining of ferrous metals.

<li<Coating: Coatings can dramatically improve tool life and performance. For cast iron, coatings like TiN (Titanium Nitride), TiAlN (Titanium Aluminum Nitride), or even AlTiN (Aluminum Titanium Nitride) are excellent choices. They add hardness, reduce friction, and improve heat resistance.

<li<Number of Flutes:

<ul<

<li<2 Flutes: Generally preferred for softer materials and for clearing chips effectively in slots.

<li<3-4 Flutes: Good all-around choices for cast iron. They offer a balance between rigidity and chip evacuation. For cast iron, often 4 flutes are preferred for better rigidity and surface finish.

<li<More than 4 Flutes: Usually reserved for finishing passes on softer materials or specific applications. For general cast iron work, 3 or 4 flutes are often the sweet spot.

</ul<

<li<Edge Preparation (Edge Pre-Treatments):

<ul<

<li<Corner Radii: A slight radius on the corner can strengthen the cutting edge, making it less prone to chipping on hard materials like cast iron.

<li<Corner Chamfers: Some end mills have a small chamfer instead of a radius. This can help initiate the cut and reduce chipping.

</ul<

<li<Helix Angle:

<ul<

<li<Standard Helix (30°): A versatile choice for many materials, including cast iron.

<li<High Helix (45°+): Can lead to a smoother, more shearing action, which can be beneficial in cast iron to reduce cutting forces and improve chip evacuation, especially at higher speeds.

</ul<

<li<Shank:

<ul<

<li<Weldon Shank: Features a flat or “hollo” ground into the side. This allows set screws in your tool holder to create a more positive drive, preventing slippage. Essential for any serious milling.

<li<Straight Shank: The most common type, but relies entirely on clamping force from the tool holder.

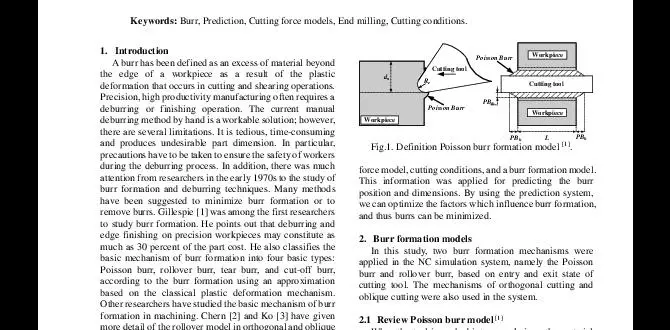

<li<Reduced Neck: As specified in “carbide end mill 3/16 inch 1/2 shank reduced neck,” this means the shank above the cutting flutes is smaller in diameter than the cutting flutes. This is incredibly useful for reaching into deep pockets or slots without the shank colliding with the workpiece. The “1/2 shank” refers to the diameter of the shank itself.

</ul<

</ul<

Understanding Specific Terminology

Let’s break down that specific example: “carbide end mill 3/16 inch 1/2 shank reduced neck for cast iron tight tolerance.”

Carbide End Mill: We know this means the tool is made of tungsten carbide for strength and heat resistance.

3/16 inch: This is the diameter of the cutting end of the mill. This is crucial for the size of the features you want to create.

1/2 Shank: This is the diameter of the main body of the tool holder that the end mill fits into. This tells you what collet or holder size you’ll need on your milling machine.

Reduced Neck: This feature, as mentioned, allows deeper reach. The neck diameter will be smaller than 3/16 inch.

For Cast Iron: This is a strong indicator that the end mill is designed with coatings, flute geometry, and edge treatments suitable for this abrasive material.

Tight Tolerance: This implies the end mill is manufactured to high precision standards to achieve accurate dimensions and surface finishes.

Recommended End Mill Types for Cast Iron

For general-purpose milling of cast iron, especially for beginners, consider:

Square End Mills: These create sharp, square corners. They are versatile for pocketing, profiling, and general surface milling.

Ball End Mills: These have a rounded tip, ideal for creating contoured surfaces, chamfers, and fillets.

Corner Round End Mills: These are like square end mills but have a radius put on the corners. This adds strength to the cutting edge and produces a fillet or radius in the inside corners of your cut. This is often a great choice for cast iron to prevent chipping.

A good starting point for a versatile carbide end mill for cast iron might be a 3 or 4-flute, uncoated or TiN coated, square-end mill with a standard helix angle and a Weldon flat on the shank. If you anticipate needing to machine deeper features, definitely look for that reduced neck option. Always ensure you’re buying from reputable manufacturers who specify the material suitability.

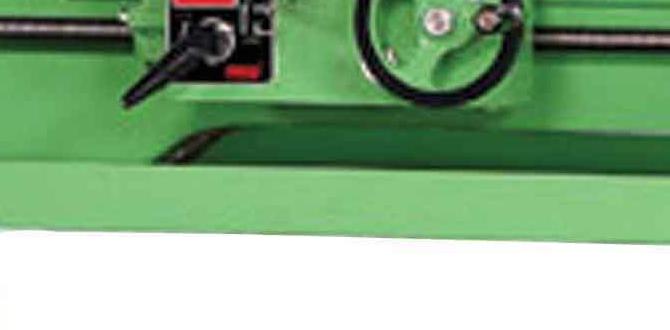

Setting Up Your Milling Machine for Success

Before you even touch the carbide end mill to the cast iron, setting up your milling machine correctly is vital. This ensures safety, tool longevity, and the best possible results.

Workholding is King

This is arguably the MOST important part of any machining operation, especially with abrasive materials. The workpiece must be held absolutely securely.

<ul<

<li<Vises: For smaller parts, a sturdy milling vise is essential. Ensure the vise jaws have good surface area contact with the workpiece and that the vise itself is mounted securely to the machine table. Use hardened vise jaws if possible for better grip and less marring of your part.

<li<Clamps: For larger or irregularly shaped parts, specialized clamping kits (toe clamps, strap clamps) are used to secure the workpiece to T-slots on the milling table.

<li<Fixtures: For repetitive operations or complex parts, a custom fixture might be necessary. This is often custom-made to hold the part precisely and securely.

</ul<

Never rely on just one point of contact or assume your part won't move. The forces involved in milling can be significant. A loose workpiece can lead to tool breakage, a damaged machine, or serious injury.

Tool Holder Selection

The tool holder connects the end mill to the spindle of your milling machine. The quality of this connection directly impacts rigidity, runout (how perfectly centered the tool spins), and accuracy.

<ul<

<li<Collet Chucks: These use individual collets to grip the shank of the end mill. They offer excellent runout accuracy and good gripping power. ER collet chucks are very common and versatile.

<li<End Mill Holders: These are specifically designed to grip end mills, often featuring a Weldon flat for positive drive (preventing rotation).

<li<Shrink Fit Holders: These offer the highest runout accuracy and best balance for high-speed operations, but require a special heating/cooling machine.

</ul<

Ensure your tool holder is clean, the collet is the correct size for your end mill shank, and that there are no nicks or burrs on either. A clean tool holder and spindle taper are crucial for accurate results.

Spindle Speed and Feed Rate Calculation (The Basics)

This is where things can get technical, but we’ll keep it simple. The goal is to find the right balance of how fast the end mill spins (spindle speed, RPM) and how fast it moves through the material (feed rate, inches per minute or mm per minute).

Surface Speed (SFM or m/min): This is the speed at which the cutting edge of the end mill is moving. Different materials and tool types have optimal surface speeds.

Chip Load: This is the thickness of the chip each flute of the end mill is designed to remove with each revolution. Too thick a chip can overload the tool; too thin a chip can lead to rubbing and heat buildup.

A simple formula for RPM:

RPM = (Surface Speed 12) / (Diameter of End Mill π)

While exact numbers depend on the specific carbide grade, coating, and machine rigidity, here are some

general starting points for carbide end mills in cast iron: Surface Speed (SFM): 150 – 300 SFM (can vary greatly)

Chip Load per Tooth: 0.001″ – 0.004″ (for a 3/16″ end mill)

The best approach for beginners is to use a milling calculator or consult manufacturer recommendations. Many tool manufacturers provide charts for their specific end mills. For example, for a 3/16″ carbide end mill in cast iron, you might start around 1000-2000 RPM and a feed rate that yields a chip load within that range. Always start conservatively and listen to the cut.

For a “carbide end mill 3/16 inch 1/2 shank reduced neck for cast iron tight tolerance,” you’ll want to find specs for a general-purpose carbide end mill suitable for cast iron and perhaps slightly adjust based on the specific tool’s geometry. If you can find data from the manufacturer of your specific end mill, that’s your best bet. Resources like the Machinist’s Handbook (while a physical book, its principles are online) or online calculators from tool manufacturers are invaluable.

The Machining Process: Step-by-Step

Now, for the action! Let’s walk through the process of using your carbide end mill on cast iron. Safety first – always wear safety glasses and appropriate work attire.

Step 1: Prepare the Workspace

Clean your milling machine table and the securing surface of your workpiece.

Ensure your end mill is the correct one for the job and is free of any damage.

Install the end mill securely into the collet and then into the spindle/tool holder. Ensure it’s seated properly.

Load your workpiece into the vise or under clamps. Check that it’s stable and won’t shift under cutting forces.

Step 2: Set Up Your Cutting Parameters

Using the calculations or manufacturer’s data, set your spindle speed (RPM) and feed rate.

Program these into your CNC mill, or set them manually on a manual mill. For manual milling, you’ll control the feed rate by hand.

Set your Z-axis zero point accurately. This is crucial for achieving the correct cutting depth.

Step 3: Perform a Dry Run (Optional but Recommended)

With the spindle off, move the end mill to just above the workpiece at your starting point.

Turn on spindle and coolant (if used).

Then, bring the end mill down to the surface and move it across the path of your intended cut.

This helps you ensure your setup is correct, your tool is running true, and your program/movements are as expected without an actual cut.

Step 4: The First Cut

Plunge (if necessary): If you need to plunge the end mill vertically into the material (e.g., starting a pocket), do so slowly and at a shallow feed rate. Avoid plunging straight down at a high feed rate, as this can break the tool. Some end mills have a “center cutting” feature, meaning they are designed for plunging, but even then, care is needed.

Engage the Material: Move the end mill into the workpiece at your programmed/calculated feed rate. Listen to the sound of the cut. A clean, crisp sound is good. A chattering or high-pitched squeal can indicate problems (too fast, too slow, or dull tool).

Full Depth of Cut: For cast iron, it’s usually best to take shallower cuts. Instead of trying to remove all the material in one go, take multiple passes. A common guideline for depth of cut is to take passes that are about 50% of the end mill’s diameter, or even less for very hard cast iron or when aiming for tight tolerances. This allows the tool to slice through efficiently without being overloaded. For your “carbide end mill 3/16 inch,” this might mean a depth of cut around 0.06″ to 0.09″ per pass.

Chip Evacuation: Poor chip evacuation is a major cause of tool failure. Ensure your flutes are clearing chips effectively. If chips are building up or recutting themselves, you may need to:

Reduce the depth of cut.

Increase the feed rate slightly to push chips out.

Use a coolant or lubricant.

Consider a higher helix angle end mill or one with improved chip breaker features.

For deep pockets, you might need to use helical interpolation or peck drilling/milling cycles.

Step 5: Continue Machining

Make multiple passes at the desired depth, proceeding with your programmed path or manual movements.

Periodically check the chips – they should be consistent and manageable. If they start to look powdery or change color significantly, it’s a sign of overheating or excessive friction.

For demanding operations, through tools (tools that spray coolant directly at the cutting edge) or flood coolant systems are highly beneficial for cast iron. They cool the cutting zone, lubricate the cut, and help flush chips away. Metalworking fluid specifically designed for cast iron can also help.

Step 6: Finishing Pass

For achieving “tight tolerance” finishes, a final “spring pass” or light finishing pass is often employed.

This involves taking a very light cut (e.g., 0.001″ to 0.003″ depth of cut) at the final desired dimension. This pass removes any minor inaccuracies from previous roughing passes and often results in a superior surface finish.

This is best done at a slightly slower feed rate than the roughing passes, with consistent depth.

Step 7: Inspection and Cleaning

Once machining is complete, carefully remove the workpiece and inspect your dimensions and finish.

* Clean all swarf (metal chips) from the workpiece, machine, and tooling.

Troubleshooting Common Issues

Even with the best tools and setup, you might encounter problems. Here are a few common ones when working with cast iron and carbide end mills:

<ul<

<li<Tool Chattering/Vibration:

<ul<

<li<Causes: Programmed feed rate is too low or too high, tool deflection, worn tool holder, loose workpiece, unbalanced tool, incorrect spindle speed.

<li<Solutions: Adjust feed rate, reduce depth/width of cut, ensure rigid workholding, check tool holder and spindle for wear, try a different spindle speed.

</ul<

<li<Poor Surface Finish:

<ul<

<li<Causes: Dull or chipped tool, incorrect feed rate or