A 3/16-inch carbide end mill, especially one with a 1/2-inch shank and an extra-long flute designed for softer materials like Delrin, is a fantastic solution to combat chatter. By understanding its features and using it correctly, you can achieve smooth, precise cuts.

Dealing with chatter when machining can be a real head-scratcher. You’ve got your setup just right, you’re feeding the material, and suddenly, that annoying vibration starts. It ruins your finish, wears down your tools, and frankly, it’s frustrating! For beginners, chatter can feel like a mysterious force. But often, the right tool for the job is all you need to tame it. That’s where specific types of end mills come into play. We’re going to dive deep into how a specially designed 3/16-inch carbide end mill can be your new best friend against chatter, especially when working with materials like Delrin. Get ready to learn how to select, use, and maintain this powerful little tool to get those clean, precise cuts you’re after.

Understanding the 3/16 Inch Carbide End Mill for Chatter Reduction

So, what exactly makes a 3/16-inch carbide end mill such a champion against chatter, especially when we’re talking about materials like Delrin? It’s a combination of factors related to its material, size, geometry, and how it’s designed for specific tasks. Let’s break it down.

What is a Carbide End Mill?

First off, “carbide” refers to tungsten carbide, a very hard and durable material that’s fantastic for cutting tools. Unlike High-Speed Steel (HSS) tools, carbide end mills can handle higher cutting speeds and temperatures, which means they cut faster and last longer, especially in tougher materials. This hardness is key to reducing chatter because a sharp, rigid tool is less likely to be deflected by the cutting forces, which is a major cause of vibration.

Why 3/16 Inch?

The 3/16-inch size is quite common for a variety of projects, from intricate detail work to smaller-scale production runs. In milling, smaller diameter tools can sometimes be more susceptible to chatter due to their lower rigidity compared to larger tools. However, when a 3/16-inch end mill is properly designed and used, it can be very effective. The trick is often in its other features.

The Importance of a 1/2 Inch Shank

You’ll often see 3/16-inch end mills with a variety of shank diameters, but a 1/2-inch shank offers several advantages for chatter reduction:

Increased Rigidity: A larger shank diameter provides more material to support the cutting edge. This increased stiffness means the tool is less likely to flex or vibrate under load, which is a primary source of chatter.

Better Grip: A 1/2-inch shank provides a more substantial surface area for your milling machine’s collet or tool holder. This ensures a more secure and stable grip, preventing any slippage or wobble that could lead to chatter.

Compatibility: Many common milling machines have tool holders designed for 1/2-inch shanks, making this a versatile choice.

The “Extra Long” Flute and its Role

This is where things get really interesting for chatter solutions. An “extra long flute” on an end mill means the cutting portion of the tool extends further down the shank than on a standard end mill. This might seem counterintuitive for chatter, as longer tools can be more prone to deflection. However, for specific applications and materials, extra-long flutes are designed with chatter reduction in mind:

Controlled Engagement: For materials like Delrin, which can be gummy, an extra-long flute can allow for deeper cuts where the chip load (the amount of material removed per tooth per revolution) can be better managed. By taking a slightly deeper pass, you can sometimes achieve a more consistent cutting action and avoid the shallow, high-frequency vibrations that cause chatter.

Custom Geometries: End mills designed with extra-long flutes for specific materials often incorporate advanced helix angles or coatings. These aren’t just about length; they’re engineered to disrupt harmonic vibrations. For example, variable-helix or variable-pitch end mills have flutes that are not evenly spaced. This design breaks up the cutting rhythm, preventing the tool and workpiece from resonating at a specific frequency, which is a common cause of chatter.

Material-Specific Design: When we talk about an “extra long” flute specifically for Delrin, it implies the tool manufacturer has considered the gummy nature of Delrin. These flutes are often designed with higher rake angles and polished surfaces to help the material flow off the cutting edge smoothly, reducing the tendency for chips to pack up and cause chatter.

Why Delrin?

Delrin (also known as Acetal) is a popular engineering thermoplastic known for its low friction, high stiffness, and excellent dimensional stability. It machines very well, but it can also be prone to producing long, stringy chips that can pack in the flutes, leading to poor surface finish and chatter. Tools designed specifically for plastics like Delrin often have fewer flutes (e.g., 2 or 3 flutes instead of 4) and polished flutes to help manage these sticky chips.

Keyword Focus: “Carbide End Mill 3/16 Inch 1/2 Shank Extra Long for Delrin Reduce Chatter”

When you put all these elements together – carbide hardness, a common 3/16-inch cutting diameter, robust 1/2-inch shank for rigidity, and an extra-long flute optimized for a material like Delrin – you have a tool engineered precisely to combat the specific challenges that lead to chatter in this scenario.

Choosing the Right 3/16 Inch Carbide End Mill

Not all 3/16-inch carbide end mills are created equal, especially when you’re targeting chatter reduction in materials like Delrin. Here’s what to look for:

Key Features to Inspect:

Number of Flutes: For plastics like Delrin, fewer flutes are generally better. A 2-flute or 3-flute end mill is ideal. More flutes can overload the chip pockets with plastic shavings, leading to chip packing and increased friction, which exacerbates chatter.

Helix Angle: This is the angle of the cutting edge relative to the axis of the tool.

High Helix Angles (30-45 degrees): These are excellent for plastics. They provide a sharper cutting action, help evacuate chips more effectively, and generally reduce cutting forces, all of which contribute to reducing chatter.

Standard Helix Angles (around 30 degrees): Still good, but high helix is often preferred for sticky materials.

Coatings: While not strictly necessary for plastics if the carbide is good quality and the flutes are polished, certain coatings (like TiCN or even specialized plastic coatings) can further reduce friction and improve chip evacuation. However, for Delrin, a simple, highly polished uncoated carbide end mill is often superior as coatings can sometimes increase friction with plastics.

Flute Finish: Look for end mills with polished or mirror-finished flutes. This is crucial for plastics as it allows the material to slide off the cutter instead of sticking, preventing buildup that causes instability and chatter.

End Geometry:

Square End: The most common type, good for general milling.

Corner Radius: A small radius on the corner can add strength and reduce the tendency for chattering at the corner of a cut or in sharp internal corners. However, for general flat milling, a square end is typical.

Material Specificity: Many manufacturers label their tools for specific materials. An end mill explicitly marketed for “plastics” or “non-ferrous materials” is often a good bet.

Understanding “Extra Long” in Practical Terms

When we say “extra long,” what does that mean for a 3/16-inch end mill? A standard end mill might have a flute length that is 2-3 times its diameter. An “extra long” one could have a flute length of 4-6 times the diameter, or even more.

Example: A standard 3/16″ end mill might have a 1/2″ flute length. An “extra long” version could have a 3/4″ or 1″ flute length.

This extra length allows for deeper slotting or profiling in a single pass. However, with increased length comes increased potential for deflection. This is why the rigidity of the 1/2-inch shank and the specific geometry of the cutting edges become so critical.

Where to Find Them:

You can find these specialized end mills at most reputable industrial tool suppliers, both online and brick-and-mortar stores. Look for brands known for their quality in milling tools. Consider resources like:

McMaster-Carr: A massive supplier for all sorts of tools and hardware, often with detailed specifications.

Grainger: Another industrial supplier with a broad range of cutting tools.

Specialized CNC machine tool suppliers.

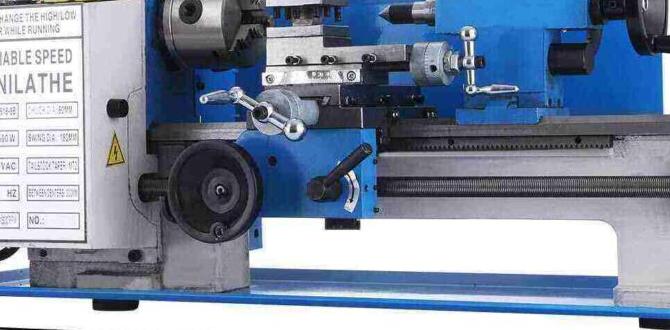

Setting Up for Success: Mounting and Machine Considerations

Even the best end mill won’t perform if it’s not set up correctly. Vibration, and therefore chatter, can be introduced at many points before the cut even happens.

Mounting the End Mill:

1. Tool Holder/Collet: Ensure you are using a high-quality collet or tool holder that matches the 1/2-inch shank of your end mill. A worn or cheap collet can introduce runout (wobble), which is a guaranteed chatter-inducer. For precise work, ER collets are highly recommended.

2. Cleanliness: Absolutely critical! Make sure the Shank of the end mill and the inside of the collet/holder are perfectly clean. Any dirt, oil, or coolant residue can prevent a secure grip and cause runout.

3. Proper Insertion: Insert the end mill fully into the collet/holder. Don’t just lightly grip it. Ensure the shank is seated as far as it will comfortably go. Tighten the collet nut securely, but avoid over-tightening, which can damage the collet or shank.

4. Check for Runout: If your machine has a dial indicator, use it to check the runout of the end mill shank in the spindle. Ideally, it should be very close to zero (less than 0.0005 inches is great). Excessive runout is a major cause of chatter.

Machine Stability:

Solid Base: Your milling machine needs to be on a stable, solid surface. A wobbly bench or frame will amplify vibrations. Many machinists bolt their machines to a heavy workbench or a dedicated steel stand.

Machine Balance: If you have a particularly large or heavy workpiece, ensure it’s securely clamped and balanced on the machine table.

Spindle Bearings: Worn spindle bearings can introduce vibration into the system. If you suspect this, it might be time for a service.

Workpiece Clamping:

Secure Fastening: The workpiece must be clamped down firmly. Use appropriate clamps, vises, or fixtures. Loosely held workpieces will move and vibrate, directly causing chatter.

Avoid Overhang: Minimize any unsupported overhang of the workpiece or the fixture. A long, unsupported section can act like a tuning fork.

Optimizing Cutting Parameters for Delrin with a 3/16 Inch End Mill

This is where we get into the nuts and bolts of making the cut and minimizing chatter. The right parameters are often specific to the material and the tool. Since we’re focusing on Delrin and a 3/16-inch end mill, here are some starting points. Always consult your end mill manufacturer’s recommendations if available.

Speeds and Feeds: A Balancing Act

Getting the right balance between spindle speed (RPM) and feed rate (how fast the tool moves through the material) is crucial. Too slow a feed rate for the RPM can lead to rubbing, heat buildup, and chatter. Too fast a feed rate can overload the tool.

Surface Speed (SFM): This is the speed at which the cutting edge is moving through the material. For Delrin, a good starting point for carbide end mills is typically between 300-600 SFM (Surface Feet per Minute).

Calculating RPM:

`RPM = (SFM 3.82) / Diameter (inches)`

For a 3/16″ (0.1875″) end mill:

`RPM = (SFM 3.82) / 0.1875`

If SFM = 400: `RPM = (400 3.82) / 0.1875 ≈ 8192 RPM`

If SFM = 500: `RPM = (500 3.82) / 0.1875 ≈ 10187 RPM`

Note: Many hobby machines might not reach these higher RPMs. You may need to adjust SFM downwards if your machine is slower.

Chip Load (CL): This is the thickness of the chip removed by each cutting edge on the tool. For Delrin, with a 2 or 3-flute end mill, a starting chip load might be around 0.001 to 0.003 inches per tooth.

Calculating Feed Rate (IPT – Inches Per Tooth): This is directly the chip load.

Calculating Feed Rate (IPM – Inches Per Minute):

`IPM = RPM Number of Flutes Chip Load (CL)`

Using the example of 500 SFM (approx. 10187 RPM), a 2-flute end mill, and a chip load of 0.002″:

`IPM = 10187 2 0.002 ≈ 40.7 IPM`

Table: Example Cutting Parameters for 3/16″ Carbide End Mill in Delrin

| Parameter | Value Range | Notes |

| :—————– | :——————— | :———————————————————————— |

| Material | Delrin (Acetal) | |

| Tool Diameter | 3/16″ (0.1875″) | |

| Shank Diameter | 1/2″ | For rigidity |

| End Mill Type | 2 or 3 Flute, High Helix | Polished flutes ideal |

| Carbide Grade | Standard | Uncoated carbide often best for plastics |

| Cutting Speed (SFM) | 300 – 600 | Start lower, increase if clean cuts |

|

| Chip Load (CL) per Tooth | 0.001″ – 0.003″ | Start small, .0015 is a good initial value. |

| Calculated IPM | For your RPM, Flutes & CL | See calculation above. Aim for a consistent, audible cut. |

| Axial Depth of Cut | 0.0625″ – 0.125″ | Start shallow, especially with extra-long flute. Experiment with deeper. |

| Radial Depth of Cut | Adaptive or 0.0625″ | For slotting, full radial engagement. For profiling, adaptive is best. |

Note: These are starting points. Always listen to your machine and tool. If you hear chatter, adjust parameters (usually increase feed or decrease RPM slightly).

Depth of Cut:

Axial Depth of Cut (AOC): This is how deep the end mill cuts into the material along its length. For an extra-long flute, especially when first starting, it’s wise to keep the axial depth of cut relatively shallow. Start around half the flute length or less (e.g., 0.0625″ to 0.125″ for a 3/16″ end mill). As you get comfortable and confirm no chatter, you can incrementally increase this.

Radial Depth of Cut (ROC): This is how much of the tool’s diameter engages the material sideways.

Slotting: When cutting a full slot, the radial depth of cut is equal to the tool’s diameter (0.1875″ in this case). This is a high-engagement cut and more prone to chatter.

Profiling/Contouring: For cutting around a shape, you can use lighter radial passes. Adaptive clearing strategies in CAM software are excellent for this. They use a constant tool engagement angle, which is much more stable and less prone to chatter than traditional pocketing or contouring.

Coolant/Lubrication:

While Delrin is a thermoplastic, some form of lubrication or cooling can still be beneficial, especially at higher speeds or for smoother finishes:

Air Blast: A strong blast of compressed air directed at the cutting zone is often sufficient. It helps clear chips and cool the tool.

Mist Coolant: A mist coolant system can provide both cooling and lubrication. Use a lubricant specifically designed for machining plastics. Avoid flooding with liquid coolant, which can sometimes make Delrin brittle or swell.

No Lubrication:** In many cases, for Delrin, especially on lower-power machines, simply running dry with good chip evacuation (air blast) is perfectly fine and can prevent gumming up.

Techniques to Further Reduce Chatter

Sometimes, even with the right tool and decent parameters, chatter can sneak in. Here are