Carbide end mills, especially those with a reduced neck for titanium, are key to stopping chatter and deflection when machining tough materials like Grade 5 titanium. Using the right tool, proper speeds and feeds, and smart cutting strategies will keep your workpiece stable and give you clean cuts.

Machining titanium can feel like wrestling a bear – it’s tough, springs back, and loves to chatter. One of the biggest headaches for beginners is cutter deflection. This happens when your end mill bends or wobbles under the cutting pressure, leading to inaccurate cuts and a rough finish. When you’re trying to machine materials like Grade 5 titanium, the problem is even more pronounced. But don’t worry, there’s a clever solution that many experienced machinists rely on: the specialized carbide end mill. This guide will walk you through how using the right carbide end mill can be your secret weapon against titanium deflection, making your machining smoother and more precise. We’ll cover why this type of tool is so effective and how to use it to get fantastic results.

Why Does Titanium Deflection Happen, and Why Is It a Problem?

Titanium is a super strong metal, but it’s also quite “gummy” and prone to work hardening. When your end mill bites into it, the metal resists. This resistance can cause the cutting tool to bend, or “deflect,” away from its intended path. Think of it like pushing on a rubbery object – it bends instead of breaking. This bending is deflection.

When an end mill deflects, several frustrating things can happen:

- Inaccurate Dimensions: Your part won’t be the size you designed. The walls might be thinner or thicker than planned.

- Poor Surface Finish: The deflection often leads to a rough, wavy surface on your part, which is hard to clean up.

- Chatter: This is that horrible, noisy vibration you hear and feel when the tool is bouncing in and out of the cut. Chatter ruins the finish and can damage your cutter and workpiece.

- Tool Breakage: Excessive deflection puts a lot of stress on the end mill, increasing the risk of it breaking off inside your workpiece – a very costly and time-consuming problem.

For beginners, encountering these issues can be really disheartening. It makes you question your setup, your machine, or your skills. But often, the biggest culprit is simply not using the right tool for the job. That’s where the specific design of a “carbide end mill with a reduced neck for titanium” comes in.

Understanding the “Genius” Carbide End Mill for Titanium

When we talk about a “carbide end mill: genius way to minimize titanium deflection,” we’re usually referring to a specific type of tool engineered to combat the unique challenges of machining titanium. This isn’t just any end mill; it’s designed for strength and rigidity.

What Makes It Special?

These specialized end mills typically have a few key features:

- Carbide Material: Solid carbide tools are much harder and more rigid than high-speed steel (HSS) tools. This means they can withstand higher cutting forces and temperatures without deforming as much.

- Reduced Neck: This is the magic part for titanium. The shank (the part that goes into the collet) of the end mill is often made slightly thinner than the cutting diameter. This “reduced neck” allows the tool to have a much stronger core, meaning it’s far less likely to bend under pressure. Imagine a pencil with a thick lead and a thin wooden casing – it’s much harder to snap the lead than the pencil itself.

- Specific Geometry: These end mills are often designed with fewer flutes (cutting edges) and a specific helix angle. For titanium, you might see tools with 2 or 4 flutes. Fewer flutes allow chips to evacuate more easily, which is crucial because titanium chips can be sticky and clog up the flutes. A higher helix angle can help with chip evacuation and reduce cutting forces.

A common example we’ll focus on is the carbide end mill 3/16 inch 1/4 shank reduced neck for titanium grade 5. This combination is popular because a 3/16 inch cutting diameter is versatile for many detail-oriented tasks, while the 1/4 inch shank, being thicker than the cutting diameter, provides that essential rigidity. Grade 5 titanium is one of the most common and challenging types to machine, so tools designed for it offer great benefits for both Grade 5 and similar alloys.

Why the Reduced Neck “Genius”?

The reduced neck design is a clever engineering solution. By making the cutting diameter (e.g., 3/16 inch) larger than the shank diameter (e.g., 1/4 inch), you’re essentially creating a stronger, more robust tool. When the 3/16 inch diameter is cutting, if it experiences sideways force, the thicker core of the tool (which might be around 1/4 inch or slightly more, depending on the exact design for the reduced neck) resists bending much better than a standard end mill where the shank and cutting diameter are the same. This increased rigidity is what directly combats deflection.

Choosing the Right Carbide End Mill: Key Specifications

Not all carbide end mills are created equal, especially when aiming to minimize titanium deflection. Here’s what to look for:

1. Material: Solid Carbide

Always opt for solid carbide for machining titanium. It offers superior hardness and heat resistance compared to High-Speed Steel (HSS). This means it stays sharp longer and can handle the higher forces and temperatures involved in titanium machining.

2. Diameter and Shank Size

For the “genius” approach to titanium, you want a tool with a reduced neck. This means the shank diameter will be slightly larger than the cutting diameter. For instance, a 3/16 inch diameter end mill might have a 1/4 inch shank. The 1/4 inch shank provides more rigidity than a tool with a 3/16 inch shank. The specific cutting diameter you need will depend on the features you are machining.

3. Number of Flutes

This is critical for gummy materials like titanium.

- 2 Flutes: Generally the best choice for titanium. They provide ample space for chip evacuation, which is essential to prevent chip buildup and overheating.

- 4 Flutes: Can sometimes be used in lighter cuts or when better surface finish is paramount, but require more careful management of chip load and cooling to avoid clogging.

- Avoid tools with more than 4 flutes for roughing titanium, as they tend to pack with chips very quickly.

4. Helix Angle

A higher helix angle (e.g., 30 to 45 degrees) is often preferred for titanium. This design:

- Improves Chip Evacuation: The steeper angle helps curl and throw chips away from the cutting zone.

- Reduces Cutting Forces: It results in a more gradual engagement of the cutting edge, leading to less vibration and deflection.

- Enhances Surface Finish: Can lead to a smoother finish on tough materials.

5. Coating

For titanium, coatings can significantly improve tool life and performance. While not always mandatory, coatings like:

- TiN (Titanium Nitride): Offers good hardness and reduces friction.

- AlTiN (Aluminum Titanium Nitride): Excellent for high-temperature applications and is very effective on titanium alloys.

- ZrN (Zirconium Nitride): Similar benefits to TiN but can sometimes offer better lubricity.

A coating provides an extra layer of protection against heat and wear, which is beneficial when machining a demanding material like titanium.

6. Corner Radius/Chamfer

Some end mills have a small radius or chamfer on their cutting corners. This can help strengthen the cutting edge against chipping and improve finish. A small corner radius is often beneficial in titanium to support the edge.

When to Use a Reduced Neck End Mill for Titanium

A reduced neck carbide end mill is your go-to tool in several scenarios when machining titanium:

1. Machining Grade 5 Titanium

As mentioned, Grade 5 (often designated as Ti-6Al-4V) is the workhorse of titanium alloys. It’s tough, strong, and difficult to machine. A reduced neck end mill is almost essential for achieving reliable results without excessive deflection.

2. Deep Pocketing or Slotting

When you need to mill a deep cavity or a narrow slot, the end mill has to work harder and has more opportunity to deflect. The rigidity of a reduced neck tool is particularly beneficial here.

3. High Aspect Ratio Features

If you’re creating features where the depth is significantly greater than the width, deflection will be a major concern. The reduced neck design directly addresses this by increasing the tool’s effective stiffness.

4. Minimizing Vibrations and Chatter

Even in shallower cuts, if you’re experiencing chatter with standard end mills, switching to a reduced neck carbide end mill can be a game-changer. The increased rigidity helps dampen vibrations.

5. Achieving Tight Tolerances

If your project requires high precision, minimizing deflection is non-negotiable. The reduced neck tool helps ensure the tool stays on its intended path, leading to more accurate parts.

How to Implement This Genius Solution: Step-by-Step

Using your specialized carbide end mill effectively involves more than just putting it in the collet. Here’s how to maximize its benefits:

Step 1: Select the Right Tool and Holder

Ensure you have a solid carbide end mill with a reduced neck, designed for titanium. For the 3/16 inch diameter, 1/4 shank, you’ll need a collet that can hold a 1/4 inch shank securely. A high-quality collet chuck or ER collet system is recommended for maximum rigidity and runout accuracy. Avoid using a worn or oversized collet.

Step 2: Set Up Your Machine Correctly

Ensure your milling machine is rigid. Check for any play in the machine’s ways or spindle. A solid setup is the foundation for successful machining. Clean your spindle taper and collet nut thoroughly.

Step 3: Determine Your Cutting Parameters (Speeds and Feeds)

This is where many beginners struggle. Titanium requires slower spindle speeds (RPM) and a higher feed rate (in inches per minute, IPM) than steel or aluminum. The goal is to achieve the correct chip load – the thickness of the material being removed by each cutting edge. Too small a chip load leads to rubbing and overheating; too large a chip load can overload the tool.

For a 3/16 inch diameter, 2-flute carbide end mill with a reduced neck, designed for titanium Grade 5, a good starting point might be:

- Spindle Speed (RPM): 300 – 800 RPM

- Feed Rate (IPM): 3 – 8 IPM

- Chip Load per Flute: 0.002″ – 0.005″ (This is critical. Calculate Feed Rate = RPM Number of Flutes Chip Load per Flute)

- Depth of Cut (DOC): For roughing, start conservatively, perhaps 0.050″ to 0.100″. For finishing, much shallower.

- Width of Cut (WOC): For slotting, 100% of the tool diameter. For profiling, start with 25-50% of the tool diameter and adjust.

Important Note: These are starting points! Always consult the tool manufacturer’s recommendations if available. Machining titanium is highly dependent on the specific alloy, machine rigidity, coolant, and tool geometry.

Here’s a helpful resource for understanding speeds and feeds: The National Institute of Standards and Technology (NIST) provides valuable research on machining parameters.

Step 4: Utilize Coolant or Lubricant

Titanium generates a lot of heat. Using a suitable coolant or lubricant is essential.

- Flood Coolant: A strong flow of a good quality coolant is ideal. It cools the cutting zone, lubricates the cut, and helps flush chips away.

- MQL (Minimum Quantity Lubrication): Specialized mist coolant systems can also work well.

- Never Machine Titanium Dry: It will lead to rapid tool wear and poor finishes.

Step 5: Employ Smart Cutting Strategies

Even with the best tool, how you cut matters.

- Climb Milling (Conventional Milling in CNC terms): For most titanium machining, climb milling is preferred. In climb milling, the cutter rotates in the same direction as its feed. This results in a thinner, shallower cut at the beginning of engagement and a thicker cut at the end. This can reduce chatter and improve chip formation.

- Helical Interpolation: For creating holes or large pockets, using a helical motion (like drilling with the end mill) can be more effective than plunging straight down, as it keeps the tool engaged in a more controlled, sweeping motion.

- Step-Overs: When profiling (milling around the outside or inside of a shape), don’t take aggressive side steps. For finishing passes, a very light step-over (e.g., 10-20% of the tool diameter) will yield the best surface finish with minimal deflection.

Step 6: Perform a Test Cut

Before committing to a full machining operation, always perform a test cut on a scrap piece of titanium or an inconspicuous area of your workpiece. Listen for any unusual noises (chatter) and visually inspect the chip formation. Adjust your feed rate or spindle speed slightly based on your observations.

Comparing Standard vs. Reduced Neck End Mills

To truly appreciate the “genius” of the reduced neck design, let’s compare it side-by-side with a standard end mill.

| Feature | Standard End Mill (e.g., 3/16″ diameter, 3/16″ shank) | Reduced Neck End Mill (e.g., 3/16″ diameter, 1/4″ shank) |

|---|---|---|

| Shank Diameter | Same as cutting diameter | Larger than cutting diameter (e.g., 1/4″ shank for 3/16″ cutting diameter) |

| Core Rigidity | Lower | Higher |

| Deflection Resistance | Moderate, prone to deflection in tough materials like titanium | Significantly higher, designed to resist bending under load |

| Ideal For | Softer metals, lighter cuts, general milling | Tough alloys (titanium, Inconel), deep pocketing, high-precision cuts, chatter reduction |

| Risk of Chatter/Breakage | Higher, especially in titanium | Lower, due to increased rigidity |

| Chip Evacuation | Standard | Often enhanced with specialized flute geometry (e.g., higher helix) and space created by the reduced neck. |

As you can see, the reduced neck design is a deliberate engineering choice to address the specific problem of deflection in challenging materials. It’s not just a marketing term; it’s a functional advantage.

Troubleshooting Common Issues

Even with the right tool, you might run into problems. Here’s how to solve them:

Problem: Still getting chatter

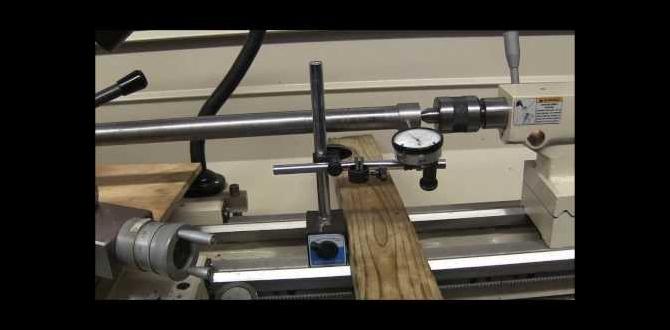

- Check tool runout: Ensure your collet and holder are clean and gripping the tool perfectly concentric. Even a small amount of runout can induce chatter. Search for information on “collet chuck runout testing” for guides.

- Adjust feed rate: Try increasing the feed rate slightly. This increases the chip load, which can sometimes help the tool push through the material rather than scraping.

- Reduce spindle speed: If increasing the feed rate doesn’t help, try lowering the RPM. This also affects chip load and vibration.

- Change depth of cut: Experiment with shallower depths of cut.

- Verify machine rigidity: Is there any play in the machine itself? Tighten gibs if necessary and appropriate for your machine.

Problem: Poor surface finish

- Check spindle speed: Too slow a speed can lead to a poor finish.

- Check feed rate: Too slow a feed rate can cause rubbing and glazing, leading to a bad finish.

- Tool wear: Even carbide wears out. Inspect the end mill for signs of dullness or chipping.

- Chip recutting: Ensure chips are being cleared effectively. If chips are packing in the flutes or aren