Quick Summary: A 3/16 inch carbide end mill with a 1/4 inch shank and reduced neck is your secret weapon for clean, precise cuts in tough 304 stainless steel. Choosing the right one ensures accuracy and makes machining this challenging material surprisingly manageable.

Working with stainless steel can sometimes feel like trying to cut through a brick. It’s a fantastic material for durability and corrosion resistance, but it can be a real headache for machinists, especially beginners. The common problem is that stainless steel work-hardens quickly, leading to dull tools, poor surface finish, and frustration. But what if I told you there’s a specific tool designed to conquer this challenge with ease? Today, we’re diving deep into the world of carbide end mills, focusing on a particular hero: the 3/16 inch carbide end mill with a 1/4 inch shank and a reduced neck, specifically for 304 stainless steel.}

You’ll soon discover why this tool is so essential, how to pick the right one for tight tolerances, and how to use it like a pro. Let’s get your machining projects running smoothly!

Decoding the “Perfect” Carbide End Mill for Stainless Steel

When you hear “carbide end mill,” it sounds pretty technical, right? Don’t worry! Let’s break down what makes a carbide end mill so special and why the specific features matter when you’re tackling something as stubborn as 304 stainless steel.

Why Carbide? The Hard Truth about Cutting Tools

End mills are basically rotating cutting tools used in milling machines to create slots, pockets, and profiles in metal or wood. They come in various materials, but for tough jobs like stainless steel, carbide is king. Here’s why:

- Hardness: Carbide is incredibly hard, much harder than high-speed steel (HSS). This means it can withstand higher cutting temperatures and pressures, which are common when machining stainless steel.

- Heat Resistance: Stainless steel generates a lot of heat when cut. Carbide tools can handle these high temperatures without losing their sharpness as quickly as softer materials.

- Edge Retention: Because it’s so hard and resistant to heat, carbide holds its cutting edge for much longer. This is crucial for consistent results and fewer tool changes.

The Anatomy of Your Stainless Steel Workhorse: 3/16 Inch Carbide End Mill, 1/4 Inch Shank, Reduced Neck

Now, let’s look at the specific features mentioned in our target keyword, as they are all vital for success with 304 stainless steel:

- 3/16 Inch Diameter: This refers to the cutting portion of the end mill. A 3/16 inch size is versatile for many projects, allowing for fine details and smaller pockets.

- 1/4 Inch Shank: The shank is the smooth, un-fluted part of the tool that goes into the tool holder or collet chuck. A 1/4 inch shank is common and fits many standard milling machine collets. This size offers a good balance of rigidity and ease of use for smaller machines.

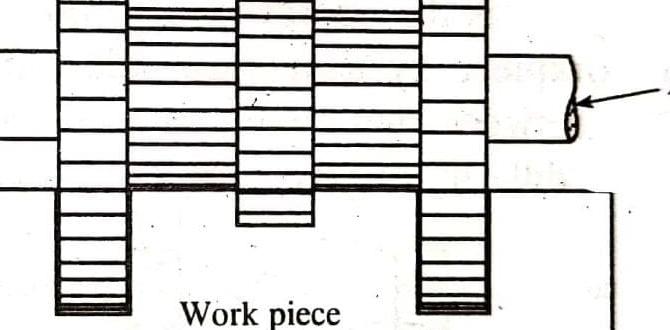

- Reduced Neck: This is a key feature for stainless steel. The neck is the tapered section between the cutting flutes and the shank. A “reduced neck” means this area has a smaller diameter than the cutting diameter. Why is this a game-changer for stainless steel?

- Chip Clearance: Stainless steel chips can be gummy and sticky. The reduced neck provides extra space for chips to evacuate from the cutting area, preventing them from re-cutting and causing tool breakage or poor finishes.

- Vibration Dampening: The slight flex in the reduced neck can help absorb vibrations, leading to quieter cuts and smoother surfaces.

- Access: It can allow the flutes to reach deeper into a pocket or slot without the non-fluted shank rubbing against the workpiece.

- For Stainless Steel (304): Not all carbide end mills are created equal when it comes to specific materials. Tools designed for stainless steel often have specific flute geometries (like higher helix angles or more flutes) and special coatings to handle the material’s toughness and tendency to work-harden. 304 is one of the most common stainless steel alloys, known for its excellent corrosion resistance and formability, but it can still be challenging to machine.

- Tight Tolerance: This implies the need for a high-quality tool that maintains its size and geometry. When you’re aiming for tight tolerances, you need an end mill that’s precisely manufactured and won’t deflect easily. This often means looking for tools with very straight shanks, accurate flute geometry, and good balancing.

Why 304 Stainless Steel is Tricky (and How the End Mill Helps)

Before we get too deep into how to use the tool, let’s quickly touch on why 304 stainless steel is notorious. It’s an austenitic stainless steel, which means it has a face-centered cubic (FCC) crystal structure. This structure is great for ductility and corrosion resistance but makes it harder to machine:

- Work Hardening: As the tool cuts, the metal immediately around the cut gets harder. This means subsequent cuts must deal with even harder material.

- Low Thermal Conductivity: Stainless steel doesn’t transfer heat very well. This means most of the heat generated during cutting stays right at the cutting edge, where it can cause premature tool wear.

- Gummy Chips: The material tends to form long, stringy chips that can clog flutes and lead to tool breakage.

This is where our specialized carbide end mill shines. The hardness of carbide resists the increased forces and temperatures. The reduced neck design helps manage those gummy chips, and knowing the right cutting parameters ensures you’re not pushing the material into extreme work hardening.

Choosing Your Proven Carbide End Mill: What to Look For

Not all “3/16 inch carbide end mills for stainless steel” are created equal. To get those “tight tolerances” and a “proven” outcome, keep these points in mind:

Key Specifications for Your End Mill

| Feature | Importance for 304 Stainless Steel | What to Look For |

|---|---|---|

| Material | Essential for durability and heat resistance. | Solid Carbide (ensure it’s full carbide, not just coated HSS). Look for grades like YG8 or similar, often indicated by manufacturer specifications. |

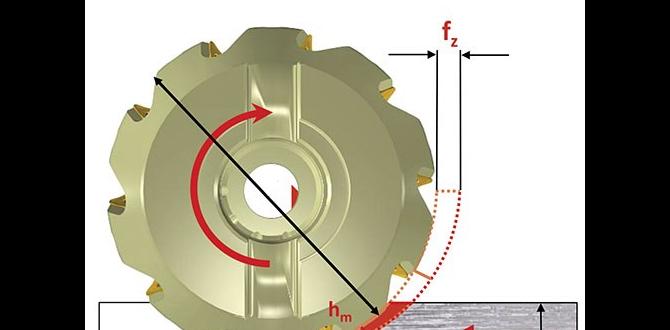

| Number of Flutes | Affects chip evacuation and surface finish. | 3 or 4 flutes are generally good for stainless steel. 2 flutes offer maximum chip clearance but can lead to vibration on harder materials. 4 flutes are great for finishing and can handle moderate slotting. For 304, 4 flutes are often a sweet spot for rigidity and finish. |

| Helix Angle | Impacts cutting action and chip ejection. | Higher helix angles (30-45 degrees) are excellent for stainless steel. They provide a sharper cutting action, helping to shear the material rather than rub it, and effectively eject chips away from the cut. |

| Coating | Adds surface hardness and lubricity, reducing friction and heat. | TiCN (Titanium Carbonitride) or AlTiN (Aluminum Titanium Nitride) are excellent choices for stainless steel. TiCN offers superior hardness and abrasion resistance, while AlTiN handles higher temperatures very well. Some prefer uncoated carbide for certain applications to avoid built-up edge, but for beginners with 304, a good coating is often more forgiving. |

| End Type | Determines the shape of the cut. | Square end mills are standard for general profiling, slotting, and pocketing. For specific applications, you might consider corner radius end mills to add a fillet and strengthen corners. For beginners targeting general use, a sharp square end is perfect. |

| Tolerance (Manufacturing Precision) | Crucial for achieving repeatable, accurate cuts. | Look for end mills with tight runout specifications and a precise cutting diameter. Reputable brands will often list these tolerances. A “precision ground” tool is a good indicator. |

Where to Find Real-World Guidance

For detailed specifications and comparisons, including material compatibility charts, the National Institute of Standards and Technology (NIST) provides valuable information on machining fundamentals. While they don’t specify brands, their research on cutting tool performance offers a solid foundation. You can often find machining handbooks or technical guides from reputable tool manufacturers online that provide recommended parameters for cutting stainless steel.

Always check the manufacturer’s specifications for their recommended speeds and feeds for your specific end mill when machining stainless steel. This is your best guide to avoiding frustration!

Step-by-Step: Using Your Carbide End Mill on 304 Stainless Steel

Alright, you’ve got your specialized end mill. Let’s get it into your milling machine and make some clean cuts!

Safety First! Always.

Before you even power up:

- Wear Safety Glasses: Non-negotiable. Metal chips can fly unexpectedly.

- Secure Your Workpiece: Use a vise, clamps, or fixture to ensure the 304 stainless steel piece cannot move.

- Secure Your Tool: Make sure the end mill is properly seated in the collet or tool holder and tightened down.

- Clear the Area: Remove any unnecessary items, scrap material, or clutter from your machine and the surrounding workspace.

- Know Your Machine: Understand how to operate your milling machine safely, including emergency stops.

Step 1: Setting Up the Material and Machine

Secure the Stainless Steel: Place your piece of 304 stainless steel in your milling machine vise or a robust fixture. Ensure it’s well-supported and clamped firmly. Make sure the surface you intend to machine is accessible and relatively flat to start.

Install the End Mill: Insert your 3/16 inch carbide end mill into a high-quality collet chuck. Tighten the collet firmly. Ensure the shank is well-supported within the collet without being excessively long, which can reduce rigidity. Double-check that the tool is spinning true (low runout).

Step 2: Finding Your Cutting Parameters (Speed & Feed)

This is WHERE the magic happens for stainless steel. Too fast, and you’ll burn up your tool. Too slow, and you’ll rub and work-harden the material. For a 3/16 inch carbide end mill on 304 stainless steel, here are starting points. Always consult your tool manufacturer’s recommendations if available! (Note: RPM is revolutions per minute, IPT is inches per tooth, SFM is surface feet per minute).

General Starting Parameters for 3/16″ Carbide End Mill on 304 Stainless Steel

| Parameter | Recommended Value | Notes |

|---|---|---|

| Surface Speed (SFM) | 50-100 SFM | This is a general range. Start lower and adjust upwards. |

| Spindle Speed (RPM) | (~SFM 3.82) / Diameter (inches) = RPM (~75 3.82) / 0.1875 = ~1528 RPM |

For 3/16″ (0.1875″), using 75 SFM as a mid-range value gives approximately 1528 RPM. Start around low to mid-1000s for safety. |

| Chip Load (IPT) | 0.001 – 0.002 inches per tooth (IPT) | For a 4-flute end mill, this translates to a feed rate. |

| Feed Rate (IPM) | RPM Flutes Chip Load (IPT) = IPM 1500 (RPM) 4 (flutes) 0.0015 (IPT) = 9.0 IPM |

This is the linear speed your machine’s axis moves. Start on the lower end. |

| Depth of Cut (Axial) | 0.060 – 0.120 inches | Start with a shallower “step” for the first pass. |

| Width of Cut (Radial) | 20% – 50% of the end mill diameter (0.037″ – 0.094″) | Avoid full-width slots with a high-power milling operation if possible. Slotting can be tough. |

| Coolant/Lubrication | Essential! Flood coolant, mist, or a good machining paste/fluid. | Crucial for chip evacuation and heat management. Use a dedicated metalworking fluid. |

Explanation:

The formula for RPM is a handy way to convert the recommended surface speed (how fast the edge of the tool is moving) into a spindle speed your machine can achieve. For a 3/16 inch diameter tool, using a mid-range SFM of 75, you’d aim for around 1500-1600 RPM. However, for stainless steel and beginners, it’s VERY safe to start lower, maybe 1000-1200 RPM, and listen to the cut.

Chip load (IPT) is how much material each tooth of the end mill is supposed to remove. For stainless steel, you want a small chip load to avoid overloading the tool and causing work hardening. A chip load of 0.001 to 0.002 inches is typical for this size and material. The feed rate (IPM) is the actual feed speed of the machine, calculated from RPM, number of flutes, and chip load.

Step 3: Making the First Cut (The “Talking” Cut)

Set Your Z-Axis: Carefully bring the end mill down to just touch the surface of your workpiece. Use your machine’s DRO (Digital Readout) or a dial indicator to set your Z-zero. Alternatively, touch off on a known height gauge or surface plate.

Engage the Spindle: Start your spindle before the end mill touches the material.

Plunge or Ramp In: For simple cuts, you might plunge straight down. However, for stainless steel, a ramp cut is much better. This means the end mill enters the material at an angle. Most CNC machines can do this with G02/G03 (arc) commands. If you’re on a manual mill, you can carefully feed down while also feeding in at an angle. This significantly reduces the force on the tool.

Watch and Listen: This is your most important tool! As the end mill enters the material, pay close attention to the sound and feel.

- Good Cut: A consistent, “sweet” humming or mild cutting sound.

- Bad Cut: A high-pitched squeal, chattering, or a heavy grinding sound usually means something is wrong – feed is too slow, depth of cut is too high, or the tool is dull.

Feed with Purpose: Once engaged, feed at your calculated IPM. If it sounds good, slowly increase your feed rate slightly. If it sounds bad, slow down the feed rate or reduce the depth of cut. It’s about finding that sweet spot.

Step 4: Machining Operation (Profiling, Pocketing, Slotting)

For Pocketing: Use a series of passes, taking a reasonable depth of cut (don’t try to remove all the material at once!). For a 3/16 inch end mill, a DOC of 0.060″ to 0.120″ is a good starting point, depending on your machine’s rigidity. Make full-width cuts at the bottom of pockets and step over radially (side of the end mill) by about 20-40% of its diameter for each pass.

For Profiling/Slotting: If you’re cutting a slot, ensuring good chip evacuation is key. The reduced neck helps here beautifully. If you’re profiling an outside edge, take lighter passes, especially on full-width cuts. If possible, try to take less than 50% of the tool’s diameter in width for slotting operations to reduce the cutting load.

Coolant is Your Friend: Keep a steady stream of cutting fluid on the tool and workpiece. This cools the cutting edge, lubricates the cut, and flushes chips away.

Step 5: Finishing the Cut and Inspection

Finishing Pass: Once you’ve reached your final depth, often it’s beneficial to take a “finishing pass” on the final contour or pocket bottom. This pass can be slightly faster in feed rate and with a shallower depth of cut (e.g., 0.005″ – 0.010″). This will usually yield a much smoother surface finish.

Retract and Inspect: Retract the tool to clear the part. Turn off the spindle