3/16-inch carbide end mills are precision tools essential for achieving accurate cuts in various materials. They offer superior hardness and heat resistance, making them ideal for demanding milling tasks, even in tight tolerances, and working with tough materials like PVC. This guide simplifies their use for beginners.

Welcome to Lathe Hub! If you’ve ever stared at a milling project and felt a little overwhelmed by the tiny, sharp tools involved, you’re in the right place. Today, we’re going to talk about a real workhorse: the 3/16-inch carbide end mill. It might seem small, but this little tool packs a punch when it comes to precision. We’ll explore why it’s a must-have in your workshop, how to pick the right one, and most importantly, how to use it safely and effectively. Get ready to add some serious accuracy to your projects!

What is a 3/16-Inch Carbide End Mill?

At its core, an end mill is a type of milling cutter. Think of it like a drill bit that can also cut sideways. Unlike a drill, which mostly makes holes, an end mill is designed to cut into the side of a material to create slots, pockets, or profiles. The “3/16-inch” refers to its cutting diameter – how wide the part of the tool that actually does the cutting is. A 3/16-inch end mill is small but mighty, perfect for detailed work.

The “carbide” part is crucial. This refers to the material the end mill is made from – tungsten carbide. Carbide is incredibly hard and can withstand high temperatures, which means it can cut tougher materials and hold a sharp edge for much longer than, say, a high-speed steel (HSS) end mill. This hardness and durability make it a favorite for achieving those “tight tolerances” we often need in precision machining.

Why 3/16-Inch? The Sweet Spot for Precision

So, why this specific size? The 3/16-inch (which is roughly 4.76mm) diameter strikes a fantastic balance for many common workshop tasks. It’s small enough to get into tight corners and create fine details, but not so tiny that it’s overly delicate or prone to breaking if handled with reasonable care. This size is particularly useful for:

- Creating narrow slots.

- Machining small pockets for components.

- Engraving detailed designs.

- Working with materials like plastics (including PVC), softer metals, and wood.

- Achieving precise contouring and edge breaks.

When you’re aiming for that “essential precision,” a 3/16-inch carbide end mill often becomes your go-to tool for jobs that require a high degree of accuracy. It’s an excellent choice for beginners because it offers good performance without being overly intimidating.

Understanding the Anatomy of a Carbide End Mill

Before we dive into using one, let’s quickly look at its parts. Knowing these will help you understand its function and care:

- Flutes: These are the spiral grooves running up the cutting end. They do two main jobs: they carry away the chips (swarf) created during cutting and provide the cutting edges. A 3/16-inch end mill can have 2, 3, or 4 flutes.

- Cutting Diameter: This is the 3/16-inch measurement. It defines the width of the material the end mill can remove in a single pass.

- Shank: This is the unsharred part that fits into your milling machine’s chuck or collet. For specific applications, you might see descriptions like “10mm shank,” meaning the shank diameter is 10 millimeters. This is important for ensuring a secure fit in your machine’s tooling.

- Helix Angle: This is the angle of the flutes. A steeper helix angle generally results in a smoother cut and better chip evacuation, often preferred for softer materials.

- End Cut Design: Some end mills are “center cutting,” meaning they can plunge straight down into the material like a drill. Others are “non-center cutting” and are only meant for side milling. For versatility, especially for beginners, a center-cutting end mill is usually a good bet.

When to Choose a 3/16-Inch Carbide End Mill

This versatile tool shines in a variety of scenarios, especially when accuracy and durability are key. Here’s when you’ll likely reach for one:

Specific Applications

- Pocketing: Creating recessed areas in a workpiece. A 3/16-inch end mill is perfect for making pockets that are 3/16-inch wide or larger, or for finishing contours of larger pockets to achieve tight tolerances.

- Slotting: Machining narrow channels. If your design calls for a slot that’s 3/16-inch wide, this is your direct solution. It can also create narrower slots by taking multiple shallow passes.

- Profiling: Cutting out 2D shapes from sheet material or shaping edges.

- Engraving: For detailed work, especially with CNC machines, a 3/16-inch end mill can be used for larger engraving passes or as a starting point for more intricate designs.

- Chamfering/Deburring: While specialized tools exist, a 3/16-inch end mill can be used to create small chamfers (angled edges) or to clean up minor burrs after other machining operations.

Material Suitability

Carbide end mills are excellent for a range of materials due to their hardness and heat resistance. A 3/16-inch carbide end mill is particularly well-suited for:

- Plastics: Including PVC, ABS, acrylic, and polycarbonate. Carbide cuts clean and minimizes melting or chipping compared to HSS.

- Aluminum: Carbide offers good performance in softer metals like aluminum, allowing for faster cutting speeds than HSS.

- Wood: While wood can be machined with less expensive bits, carbide offers superior durability and provides cleaner cuts, especially in denser hardwoods or when fine detail is required.

- Softer Steels and Cast Iron: For lighter-duty applications or when high feed rates aren’t necessary, carbide can handle these materials effectively, though specialized tooling might be better for heavy-duty work.

The keyword phrase “carbide end mill 3/16 inch extra long for pvc” highlights a specific use case. “Extra long” versions provide greater reach, which can be crucial for accessing parts of a workpiece that are deep or hard to get to. PVC, being a plastic, benefits from the clean, sharp cutting action of carbide, reducing the risk of melting or fuzziness common with less effective tools.

Choosing the Right 3/16-Inch Carbide End Mill

Not all 3/16-inch carbide end mills are created equal! To get the best results and ensure you’re buying the right tool for your job, consider these factors:

Number of Flutes

- 2 Flutes: Best for softer materials like plastics and aluminum. They offer excellent chip clearance, which is vital for preventing melting or gumming up.

- 3 Flutes: A good all-around choice. They provide a balance between chip clearance and edge engagement, working well for many materials including some steels and wood.

- 4 Flutes: Ideal for harder materials like steel and cast iron. They offer a smoother finish due to more cutting edges engaging the material, but chip clearance is reduced. Not usually the first choice for plastics.

For PVC and general beginner use, 2-flute or 3-flute end mills are often recommended.

Coating

Carbide end mills can come with various coatings that enhance their performance. Common ones include:

- Uncoated: Good for general-purpose use, especially in softer materials. They are the most affordable option.

- TiN (Titanium Nitride): A common, gold-colored coating that increases hardness and lubricity, offering better tool life and allowing for slightly higher cutting speeds in many materials.

- AlTiN (Aluminum Titanium Nitride): A darker coating that provides excellent heat resistance, making it suitable for machining steels and other high-temperature alloys at higher speeds.

- ZrN (Zirconium Nitride): Often used for plastics and non-ferrous metals, providing a slick surface to prevent material buildup.

For PVC, an uncoated carbide end mill or one with a slick coating like ZrN can be very effective.

End Cut Type

- Center Cutting: As mentioned, these can plunge vertically. Essential if you need to drill holes with the end mill or create pockets starting from the surface.

- Non-Center Cutting: These cannot plunge. They are designed purely for cutting horizontally along the material’s surface.

For most beginner projects and versatility, a center-cutting end mill is the way to go.

Length of Cut and Overall Length

When you see “extra long” in a product description, it refers to the flute length or the overall length of the tool. For instance, a standard end mill might have flutes that are 1/2 inch long, while an “extra long” version might have 1 inch or more of cutting flute. This is crucial when you need to machine deep pockets or slots.

Consider your machine’s rigidity and power. Longer end mills are more prone to vibration and deflection, so they require slower cutting speeds and feed rates, and a rigid machine setup is essential. For smaller hobby machines, standard length might be more appropriate unless an extra-long reach is absolutely necessary.

Shank Diameter

The shank is the part that holds the end mill. While the cutting diameter is 3/16 inch, the shank could be 3/16 inch, 1/4 inch, or even 10mm (as in your keyword). Your milling machine’s collet or chuck must match the shank diameter exactly for a secure and accurate grip. A 10mm shank on a 3/16-inch end mill indicates that the tool holder system uses metric sizes, and you would need a 10mm collet. This ensures maximum rigidity and prevents slippage.

Safety First: Working with End Mills

Machining involves sharp tools and powerful machines. Safety is paramount. Always follow these guidelines:

- Wear Safety Glasses: Absolutely non-negotiable. Always.

- Secure Your Workpiece: Use clamps or a vise to ensure the material won’t move during machining.

- Use the Correct Spindle Speed (RPM): Too fast can break the tool or melt the material; too slow can lead to chatter or poor finish.

- Use Appropriate Feed Rate: This is how fast you push the material into the spinning end mill. Too fast can break the tool; too slow can burn the workpiece or tool.

- Ensure Proper Tool Holding: Use the correct collet size for the end mill shank. Never use an end mill with a shank that’s too small for the collet.

- Clear Chips: Use compressed air or a brush (never your fingers!) to clear chips as you work, especially in plastics.

- Run the Spindle in the Correct Direction: Most milling machines have variable speed and direction. Ensure it’s set for “conventional milling” unless you’re intentionally set up for “climb milling” (which is generally more advanced).

- Keep Guards in Place: If your machine has safety guards, use them.

- Understand Material Properties: Different materials require different approaches. For PVC, avoid excessive heat to prevent melting.

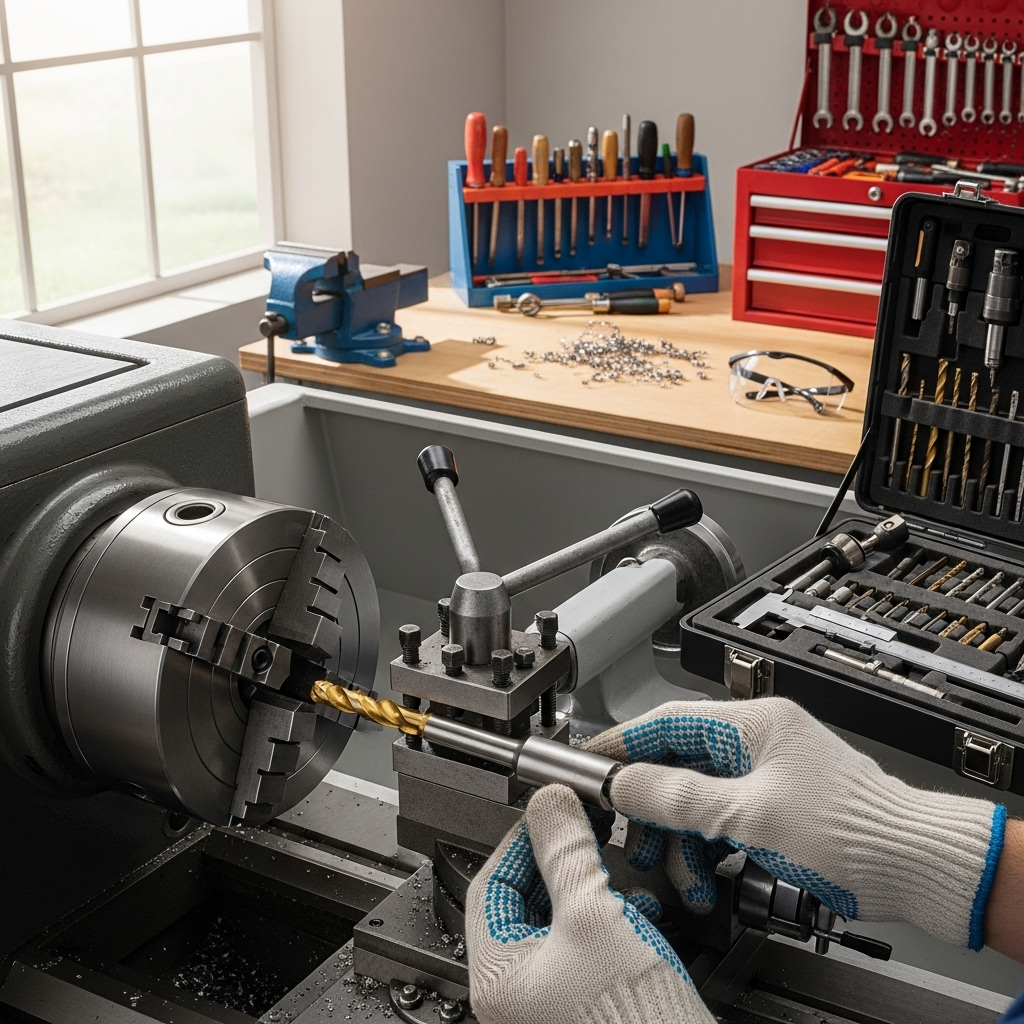

How to Use a 3/16-Inch Carbide End Mill: A Beginner’s Guide

Let’s walk through using your 3/16-inch carbide end mill. We’ll assume you have a basic milling machine setup (like a small desktop CNC or a milling attachment for a metal lathe, or a rotary tool with a milling fixture). For this example, let’s imagine we’re cutting a slot in a piece of PVC.

Step 1: Preparation and Setup

- Choose Your End Mill: Select a 3/16-inch carbide end mill. For PVC, a 2-flute, center-cutting end mill is ideal. If you need to cut deep, consider an “extra long” version, but be mindful of machine rigidity. Ensure the shank (e.g., 10mm) matches your collet.

- Secure the Workpiece: Place the PVC sheet on your milling machine’s table. Clamp it down firmly using vises or clamps. Ensure the surface you’re milling is flat and level with the table.

- Install the End Mill: Insert the end mill into the correct collet (e.g., 10mm). Tighten the collet securely in the milling machine’s spindle.

- Set the Z-Axis Zero: Lower the end mill until it just touches the surface of your workpiece. This is your Z-axis zero point. Lock the Z-axis. Many machines have electronic probes for this, or you can use a feeler gauge or edge finder. For beginners, a simple touch-off with a piece of paper can work for less critical applications.

Step 2: Determine Cutting Parameters

This is where experience comes in, but for beginners, starting conservatively is key. For a 3/16-inch carbide end mill in PVC:

- Spindle Speed (RPM): Start around 10,000 – 20,000 RPM. PVC can melt easily, so a higher speed with a fast feed rate can sometimes work better to prevent heat buildup, but higher RPM also increases risk. It’s best to check manufacturer recommendations or start conservatively. For example, a typical recommendation for carbide in plastics might be high RPM. Let’s aim for 15,000 RPM as a starting point.

- Feed Rate: This is how fast you move the tool through the material. For PVC, a relatively fast feed rate is good to prevent melting. Something in the range of 15-30 inches per minute (IPM) or 380-760 mm/minute. Start on the lower end of this.

- Depth of Cut (DOC): This is how deep the end mill cuts in each pass. For a 3/16-inch end mill, don’t try to cut the full depth in one go, especially if it’s a softer material. A good starting depth might be 0.050 inches (about 1.27mm) or even less. You can always take more passes if needed.

- Stepover: If you’re cutting a wider slot or pocket, this is how much the end mill moves sideways between passes. For a 2-flute end mill, a 40-50% stepover is common.

Important Note: Always consult specific charts for carbide end mills and materials if available. Websites like Iscar or Sandvik Coromant provide excellent resources for cutting data, though they might be complex for absolute beginners.

Step 3: Making the Cut

- Engage the Spindle: Turn on your milling machine spindle at the chosen RPM.

- Plunge (if center cutting): If you’re starting a pocket or slot from the surface, carefully plunge the spinning end mill down to your desired depth of cut. Go slowly for the first plunge.

- Feed the Material: Move the workpiece (or the milling head, depending on your machine) at your set feed rate to create the slot or pocket.

- Clear Chips: Periodically pause the feed and use compressed air to blow away the plastic shavings. This is crucial for preventing buildup and overheating.

- Take Multiple Passes: If your desired slot depth is greater than your initial depth of cut, raise the end mill slightly above the workpiece, increase the Z-axis depth setting for the next pass (by the amount of your DOC), and repeat the cutting process. Continue until you reach the full desired depth.

- Finishing Pass: For extra smooth surfaces, you can make a final pass at a shallower depth (e.g., 0.010 inches) with a slightly slower feed rate.

Step 4: Post-Machining

- Retract the Tool: Once the cut is complete, carefully retract the end mill from the workpiece.

- Turn Off Spindle: Stop the spindle.

- Remove Workpiece: Unclamp and remove your finished part.

- Clean Up: Carefully clean your end mill and work area. For plastics, sometimes a bit of rubbing alcohol helps remove residue.

Tips for Working with PVC

PVC can be tricky because it’s prone to melting if too much heat is generated. Using a 3/16-inch carbide end mill helps, but keeping these tips in mind