A 3/16-inch carbide end mill is an excellent tool for eliminating chatter in CNC machining, especially when working with aluminum. Using the right type and applying correct cutting parameters are key to achieving smooth finishes and longer tool life.

Ever heard that annoying buzzing or vibrating sound when your milling machine is working? That’s called chatter, and it’s a common frustration for anyone using a CNC or even a manual mill. It leaves ugly marks on your workpiece and can quickly damage your tools. The good news is, often, a simple change in your cutting tool can make a world of difference. We’re going to talk about a fantastic solution: the 3/16-inch carbide end mill. This little tool is a workhorse for killing chatter. We’ll explore why it’s so effective and how you can start using it to get those super smooth finishes you’ve been dreaming of on your projects.

Why Chatter Happens (and Why It’s So Annoying)

Chatter. It’s that teeth-grinding vibration that your workpiece makes while the cutting tool is trying to do its job. Think of it like trying to play a musical instrument that’s out of tune – it just sounds wrong and can damage the instrument. In machining, chatter is caused by a harmonic resonance. This happens when the cutting forces, the rigidity of your machine, the material you’re cutting, and the tool itself get into a natural vibration frequency. When these frequencies align, they amplify, causing the tool to bounce in and out of the cut. This results in those characteristic wavy lines on your surface, often called “chatter marks.”

Why is this a big deal? For starters, chatter ruins the finish on your part. If you’re aiming for a smooth, precise surface, chatter marks can be incredibly difficult, if not impossible, to remove without taking an extra, often deep, cut. This wastes material and time. Worse still, the constant hammering and vibration puts excessive stress on your cutting tool, leading to premature wear, chipping, or even catastrophic failure. It also stresses your machine’s spindle bearings and other components. In short, chatter is bad for your part, your tools, and your machine.

The Right Tool for the Job: Enter the 3/16-Inch Carbide End Mill

So, if harmonic resonance is the culprit, how do we break that cycle? One of the most effective ways is by using a cutting tool designed to disrupt that resonance. This is where the 3/16-inch carbide end mill shines, particularly in its ability to handle specific materials like aluminum alloys (think 7075, a popular, strong aluminum). Here’s why it’s a chatter killer:

- Material Properties: Carbide is a super hard, brittle material that can withstand higher cutting speeds and temperatures than High-Speed Steel (HSS). This allows for more efficient material removal. Its density also helps dampen vibrations.

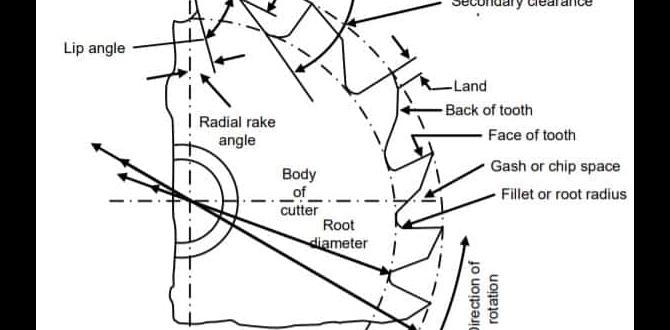

- Tool Geometry: End mills aren’t just simple spinning rods. They have specific flute designs, helix angles, and cutting edge geometries. For chatter reduction, especially in softer metals like aluminum, end mills with specific characteristics are used.

- Diameter and Length: The 3/16-inch diameter is a sweet spot for many detail-oriented tasks and for fitting into tighter spaces. When combined with a “standard length,” it offers a good balance between rigidity and reach. A shorter, stockier tool is generally more rigid and less prone to vibration than a longer, more slender one.

- Number of Flutes: For aluminum, end mills with fewer flutes (like 2 or 3) are often preferred. They have larger chip gullets, which are crucial for evacuating the soft, gummy aluminum chips. This prevents chip recutting and the buildup of heat that can lead to chatter.

Choosing Your 3/16″ Carbide Chatter Killer

Not all 3/16-inch carbide end mills are created equal when it comes to fighting chatter. To get the best results, you’ll want to look for specific features. This is where understanding your end mill’s geometry becomes important.

Key Features to Look For:

- Coating: While not always necessary for aluminum, specialized coatings like ZrN (Zirconium Nitride) or AlTiN (Aluminum Titanium Nitride) can improve lubricity, reduce friction, and increase tool life, indirectly helping to prevent chatter by maintaining a sharp edge. For general aluminum machining, an uncoated carbide end mill is often perfectly fine and can be very effective.

- Helix Angle: A higher helix angle (e.g., 45 degrees or more) can help shear the material more cleanly and improve chip evacuation, which is vital for aluminum. Some specialized “high-performance” end mills for aluminum even feature variable helix angles or unequal flute spacing to break up harmonic vibrations.

- Number of Flutes: As mentioned, 2 or 3 flutes are ideal for aluminum. They provide ample space for chips to escape. Avoid 4-flute end mills for soft, gummy materials like aluminum unless they are specifically designed with chip breakers or high-performance geometry for this purpose.

- End Mill Type:

- Standard End Mills: These are the most common. Look for 2 or 3 flutes with a standard helix angle (often around 30 degrees) for general-purpose use.

- “Aluminum” End Mills: These are specifically designed for non-ferrous materials. They typically have a higher polish, a high helix angle (often 45-60 degrees), and larger chip gullets. They are usually 2-flute. These are often your best bet for chatter reduction in aluminum.

- Variable/Unequal Index End Mills: These are the premium chatter killers. Their flutes are not spaced equally, which means the cutting edge hits the workpiece at slightly different intervals, effectively breaking any harmonic resonance that tries to build up. They are often more expensive but can provide incredibly smooth finishes.

- Shank: A 3/8-inch shank is a common size that offers good rigidity for a 3/16-inch cutting diameter. Ensure the shank is well-made and compatible with your tool holders.

- Length: Standard length end mills offer a good compromise between reach and rigidity. For chatter reduction, avoid unnecessarily long “extended reach” end mills unless your part geometry demands it.

Optimizing Your Machine Settings for Chatter-Free Machining

Even with the perfect end mill, incorrect machine settings can lead to chatter. Your CNC machine or mill needs to be dialed in to work with your tool and material.

Understanding Chip Load and Stepover

Two critical parameters that directly influence cutting forces and tool engagement are Chip Load and Stepover. Getting these right is paramount for smooth cutting.

- Chip Load: This is the thickness of the material removed by each tooth of the cutting tool as it rotates. A chip load that’s too small can lead to rubbing and excessive heat, while one that’s too large can overload the tool. For chatter reduction, a slightly larger chip load is often beneficial, as it allows the tool to “bite” deeper and more effectively shear the material, rather than lightly scraping.

- Stepover: This is the distance the tool moves sideways in each pass. A smaller stepover means you’re taking lighter cuts axially across the surface. This is often used for finishing passes to achieve a smooth surface. For roughing, a larger stepover is more efficient but can sometimes induce chatter if not managed properly.

Calculating and Setting Your Parameters

The formula for calculating the feed rate based on chip load is:

Feed Rate (IPM) = Chip Load (inch/tooth) × Number of Flutes × Spindle Speed (RPM)

When figuring out these numbers, it’s crucial to consult the manufacturer’s recommendations for your specific end mill and material. Websites like G-Wizard Calculator or Machining Doctor can be invaluable resources for accurately calculating optimal machining parameters and understanding tool engagement.

For instance, when machining 7075 aluminum with a 3/16″ 2-flute carbide end mill, you might start with parameters like:

- Spindle Speed (RPM): 12,000 – 20,000 RPM (can vary based on tool quality and machine capability)

- Chip Load (IPT): 0.002 – 0.005 inches per tooth (this is a common range for aluminum, adjust based on your specific tool and desired finish)

- Feed Rate (IPM): Calculated using the formula above. If RPM = 15,000 and IPT = 0.003, then Feed Rate = 0.003 × 2 × 15,000 = 90 IPM.

- Axial Depth of Cut (DOC): This is how deep the tool cuts into the material. For roughing, it might be 0.100″ or more depending on rigidity. For finishing, it’s very shallow, perhaps 0.010″ – 0.020″.

- Radial Depth of Cut (Stepover): For roughing, this might be 0.060″ – 0.120″. For finishing, it’s usually much smaller, like 0.005″ – 0.010″ for a smooth surface.

Important Note: These are starting points. Always listen to your machine and the sound of the cut. If you hear chatter, adjust your feed rate (often slightly increasing it or decreasing it), spindle speed, or depth of cut. Sometimes a small change can cure chatter.

Table: Common 3/16″ Carbide End Mill Specifications for Aluminum

This table outlines typical specifications you’ll find for 3/16-inch carbide end mills suitable for machining aluminum and reducing chatter. Always verify with the manufacturer’s data.

| Feature | Typical Specification for Aluminum | Impact on Chatter Reduction |

|---|---|---|

| Material | Tungsten Carbide (e.g., Sub-micron grain) | Higher hardness and rigidity compared to HSS, dampens vibration. |

| Number of Flutes | 2 or 3 | Larger chip gullets for efficient aluminum chip evacuation. Prevents chip recutting. |

| Helix Angle | 45°, 50°, 60° or Variable Helix | Improved shearing action, better chip evacuation and surface finish. Variable helix actively breaks resonance. |

| Coating | Uncoated (highly polished), ZrN, or TiB2 (for some applications) | Uncoated with good polish is often best for aluminum. Coatings can reduce friction and heat, maintaining a sharp edge. |

| Side Relief / Clearance | Adequate | Prevents rubbing against the cut wall, reducing heat and chatter. |

| End Cut Type | Flat or Square End | Standard for most milling operations. Ball nose for contours. |

| Shank Diameter | 3/8 inch | Provides good rigidity for the cutting diameter. |

| Overall Length | Standard (e.g., 2-4 inches) | Balances reach with rigidity. Shorter is generally more rigid. |

Step-by-Step Guide to Using Your 3/16″ Carbide End Mill to Kill Chatter

Let’s walk through how to get the best results and eliminate chatter with your new 3/16-inch carbide end mill.

Step 1: Inspect Your Tool and Machine

Before you even think about cutting, take a moment to ensure everything is in good condition.

- End Mill Inspection: Check the 3/16-inch carbide end mill for any signs of damage, chipping, or wear on the cutting edges. A damaged tool is a guaranteed path to poor performance and chatter.

- Tool Holder: Make sure your tool holder (collet or chuck) is clean and in good condition. A worn or dirty tool holder can run out, inducing vibration.

- Spindle Taper: Ensure the spindle taper is clean. Any debris here can cause runout.

- Workholding: Verify that your workpiece is securely held. A loose part will vibrate and contribute to chatter.

- Machine Rigidity: Check that all access lock nuts on your machine (if applicable) are tightened. Ensure your machine is on a stable surface.

Step 2: Select the Right End Mill Type (If You Have Options)

If you have multiple 3/16″ carbide end mills, choose the one best suited for aluminum and chatter reduction:

- Prefer a 2 or 3-flute “aluminum” specific end mill with a high helix angle (45°+).

- If available, a variable index end mill is the premium choice.

- Ensure it has a sharp, polished cutting edge.

Step 3: Set Up Your CAM or Manual Machining Parameters

This is where we apply the knowledge about chip load and feed rates.

- Material: Select your material (e.g., 7075 Aluminum).

- Tool: Input the 3/16-inch carbide end mill details (flutes, diameter, etc.).

- Spindle Speed (RPM): Start with a recommended high RPM for aluminum (e.g., 15,000-20,000 RPM), but be within your machine’s capabilities.

- Chip Load (IPT): Begin with a conservative, but effective chip load for aluminum (e.g., 0.003 IPT).

- Calculate Feed Rate: Use the formula: Feed Rate = IPT × Flutes × RPM.

- Depth of Cut (DOC): For roughing, start with an axial DOC appropriate for your machine’s rigidity and tool length (e.g., 0.100″ to 0.250″). For finishing, use a shallow DOC (e.g., 0.010″ to 0.020″).

- Stepover: For roughing, a radial stepover of 40-70% of tool diameter (e.g., 0.075″ to 0.130″) is common for efficiency. For finishing, aim for a small stepover (e.g., 0.005″ to 0.010″) for a mirror-like finish.

- Coolant/Lubrication: For aluminum, a mist coolant or a good quality cutting fluid specifically for aluminum is highly recommended to prevent chip welding and reduce heat.

You can find resources and calculators online to help with these calculations. For example, Machinetoolhelp.com’s Feed Rate Calculator can be a helpful starting point.

Step 4: Dry Run (Optional but Recommended)

If you’re using a CNC, perform a dry run without the cutting tool engaged in the material. This allows you to verify the tool path and ensure everything is moving as expected without any risk of crashing.

Step 5: Make the Cut and Listen

Start your machining operation. Pay close attention to the sound the tool is making. A smooth, consistent cutting sound is ideal. A high-pitched squeal, a low rumble, or a distinct buzzing are all signs of chatter.

Step 6: Adjust Parameters if Chatter Occurs

If you hear chatter, don’t panic! Here’s what to try:

- Feeder Rate Adjustment:

- Try slightly increasing the feed rate. This makes each tooth take a slightly bigger bite, potentially breaking the harmonic.

- Alternatively, try slightly decreasing the feed rate. This can sometimes move the cutting frequency out of resonance.

- Spindle Speed Adjustment: Try a small increase or decrease in RPM.

- Depth of Cut:

- Reduce the axial depth of cut.

- If possible, try a different stepover strategy. Sometimes a smaller stepover with a shallower depth can work wonders, as can a larger stepover with a shallower depth.

- Engage Coolant: Ensure your coolant is flowing effectively. For aluminum, proper lubrication is key.

- Tool Holder/Tool: If adjustments don’t help, re-check your tool and holder. Is the tool seated properly? Is there any runout?

Step 7: Finishing Passes

Once you have a chatter-free roughing pass, use a very shallow depth of cut (0.010″ – 0.020″) and a small stepover (0.005″ to 0.010″) for your finishing passes. At this point,