Quick Summary: A 3/16 inch carbide end mill is an excellent choice for wood cutting, offering precision, durability, and heat resistance. Its small diameter excels at detailed work and engraving, making it a versatile tool for hobbyists and professionals alike when used correctly with appropriate speeds and feeds. It is a proven wood master for intricate projects.

Hey makers! Daniel Bates here from Lathe Hub. Ever stared at a piece of wood, brimming with ideas, but felt held back by your tools? You’re not alone. Sometimes, a small tool can make a monumental difference. Today, we’re diving into the world of the 3/16 inch carbide end mill, a tool that truly deserves the title “Proven Wood Master.”

This little powerhouse might seem unassuming, but it’s capable of incredible detail and precision in your woodworking projects. Whether you’re carving intricate designs, adding fine details to a project, or working with a CNC machine, understanding how to use this specific end mill can elevate your work to a whole new level. We’ll break down exactly why it’s so good, what to look for, and how to wield it safely and effectively. Let’s get your workshop buzzing with new possibilities!

Why a 3/16 Inch Carbide End Mill is Your Woodworking Ally

When you’re working with wood, especially for detailed or intricate projects, the size and material of your cutting tool are paramount. The 3/16 inch size is where many woodworking enthusiasts find themselves reaching for their tools. It’s small enough for fine lines and delicate cuts, yet robust enough for a variety of woodworking tasks. But what makes it a “master” and why “carbide”? Let’s break it down.

The Power of Carbide

Carbide, specifically tungsten carbide, is a super-hard material formed by combining tungsten and carbon. It’s known for its exceptional hardness and wear resistance. Here’s why this matters for your wood projects:

- Durability: Carbide tools last significantly longer than their high-speed steel (HSS) counterparts under similar conditions. This means fewer tool changes and a more consistent cut over time.

- Heat Resistance: Woodworking can generate heat, especially at higher speeds. Carbide excels at handling higher temperatures without losing its sharpness or structural integrity, reducing the risk of burning your wood.

- Sharpness Retention: Carbide edges stay sharp for longer, allowing for cleaner cuts and reducing tear-out, which is crucial for a smooth finish.

- Precision: The inherent hardness allows for incredibly precise edge geometry, leading to very accurate material removal.

The Sweet Spot: 3/16 Inch Diameter

So, why 3/16 of an inch? This specific diameter hits a sweet spot for many woodworking applications:

- Detail Work: It’s perfect for engraving, V-carving, lettering, and creating fine decorative patterns that larger bits would obliterate.

- Small Projects: For miniature models, intricate inlays, or small signs, a 3/16 inch end mill offers the finesse required.

- CNC Routing: On CNC machines, this size is incredibly versatile for pocketing, profiling, and creating detailed features without needing to switch to an even smaller, potentially less rigid bit.

- Balance of Strength and Detail: While small, 3/16 inch is substantial enough to remove material efficiently without being overly fragile, especially when made from carbide.

The “8mm Shank” Consideration

You might also see “8mm shank” mentioned. An 8mm shank is approximately 0.315 inches. This is a common shank size, especially for tools used in European-made CNC machines and some routers. It’s important to ensure the shank diameter of your end mill matches the collet or chuck in your router or milling machine for a secure fit. A 1/4 inch (0.250 inch) shank is also very common in North America. If your machine uses 1/4 inch collets, you might need an adapter if your end mill has an 8mm shank, or vice-versa. Always check your machine’s specifications!

Choosing the right end mill, like a 3/16 inch carbide one, is the first step. The next is understanding how to use it effectively and safely. Let’s move on to what you’ll need and how to actually get started cutting.

Essential Tools and Setup for Using Your 3/16 Inch Carbide End Mill

Before you can unleash the “Proven Wood Master” on your project, gathering the right supporting tools and setting up your workspace correctly is crucial. This ensures safety, efficiency, and the best possible results. Think of it as preparing your stage for a star performance.

Your Workstation Checklist

Here’s what you’ll want to have ready:

- The 3/16 Inch Carbide End Mill: Make sure it’s clean and free from any damage.

- Your Router or CNC Machine: Ensure it’s in good working order and suitable for the task.

- Appropriate Collet/Chuck: This must be the correct size for your end mill’s shank (e.g., 8mm, 1/4 inch) and your machine.

- Workholding System: This is how you’ll secure your workpiece. Options include:

- Clamps

- Vise (for milling machines)

- Double-sided tape (for very light cuts on CNC)

- Vacuum table (for CNC machines)

- Safety Gear: Non-negotiable!

- Safety Glasses or a Full Face Shield: Protect your eyes from flying debris.

- Hearing Protection: Routers and mills can be loud.

- Dust Mask or Respirator: Wood dust can be harmful.

- Vacuum Dust Collection: Highly recommended to keep your workspace clean and improve visibility.

- Measuring Tools: Calipers, ruler, or tape measure to set depths and positions.

- Cutting Fluid or Lubricant (Optional for Wood): While not always necessary for wood, some specialized operations or harder woods might benefit. For general woodworking, it’s usually not required.

CNC Machine Setup Considerations

If you’re using a CNC (Computer Numerical Control) machine, pay extra attention to these points:

- Secure Workholding: This is paramount. Movement during a CNC cut can ruin your project and damage your machine. Ensure your workpiece is firmly held down.

- Accurate Zeroing: Set your X, Y, and Z axes accurately. The Z-zero point is especially critical for controlling cutting depth. Learn more about establishing accurate zeros from resources like this guide on coordinate systems and transformations from UCSD Mechatronics, which can help understand spatial referencing.

- Correct Speeds and Feeds: This is crucial and often the trickiest part for beginners. We’ll cover this next.

- Tool Path Generation: Ensure your CAM (Computer-Aided Manufacturing) software generates appropriate tool paths for a 3/16 inch end mill, taking into account its diameter for inside corners.

Handheld Router Setup Considerations

For handheld routers, safety and control are key:

- Secure Base Plate: Ensure the router is firmly attached to its base and that the base plate is clean and smooth.

- Depth Adjustment: Set your desired cutting depth precisely.

- Steady Grip: Always maintain a firm, two-handed grip on the router.

- Direction of Cut: Be mindful of the router’s direction of rotation and feed direction to avoid kickback. Generally, you want to feed against the rotation where possible, but this can be machine-dependent.

With your tools ready and your setup in place, you’re almost ready to make some sawdust (or wood chips!). The next section is about the brainwork: speeds, feeds, and techniques.

Mastering Speeds and Feeds for Your 3/16 Inch Carbide End Mill

This is where the magic happens – and where beginners often feel a bit lost. Speeds and feeds might sound technical, but they’re really just about controlling how fast the tool spins (speed) and how fast you push it through the material (feed rate). Getting this right is the secret sauce for clean cuts, tool longevity, and a happy workshop.

Understanding Spindle Speed (RPM)

Spindle speed, measured in Revolutions Per Minute (RPM), is how fast your end mill spins. For carbide end mills in wood, you generally want to run them at higher RPMs compared to metal machining. A good starting range for a 3/16 inch carbide end mill is often between 18,000 and 24,000 RPM.

Why higher RPMs for wood? Wood is relatively soft, and a faster spin helps create a cleaner shearing action rather than rubbing, which can cause burning. However, running too fast can lead to burning and increased chatter.

Understanding Feed Rate

Feed rate is how fast you move the end mill through the material. It’s usually measured in inches per minute (IPM) or millimeters per minute (mm/min).

The Goal: Chip Load. The ideal feed rate creates the right “chip load.” Chip load is the thickness of the material each cutting edge of the end mill removes with each revolution. For wood, you’re generally looking for a chip load that’s a bit larger than you might use for metal.

A good starting chip load for a 3/16 inch carbide end mill in softwoods might be around 0.003 to 0.005 inches. For hardwoods, you might stick to the lower end or slightly less. A 3/16 inch end mill has two flutes (cutting edges) typically, so:

- High Speed: 18,000 RPM

- Chip Load: 0.004 inches

- Feed Rate Calculation: Speed (RPM) Number of Flutes Chip Load = Feed Rate (IPM)

- Example Calculation: 18,000 RPM 2 flutes 0.004 inches/flute = 144 IPM

Important Note: This is a starting point! Factors like the specific type of wood, the rigidity of your machine, and the tool’s length will influence the ideal feed rate.

Step-by-Step Guide to Setting Speeds and Feeds

- Identify Your Wood Type: Softwoods (pine, cedar) require slightly faster feed rates or larger chip loads than hardwoods (oak, maple).

- Choose a Starting RPM: For 3/16 inch carbide on wood, begin around 18,000-20,000 RPM.

- Estimate Chip Load: Start with 0.003-0.004 inches for hardwoods, and 0.004-0.005 inches for softwoods.

- Calculate Initial Feed Rate: Use the formula: RPM Flutes Chip Load = Feed Rate (IPM).

- Perform a Test Cut: Always test on a scrap piece. Make a shallow cut (e.g., 1/8 inch deep) first.

- Listen and Observe:

- If you hear loud screeching/screaming or see burning: Your feed rate is likely too slow, or your RPM is too high. Increase the feed rate!

- If you hear loud chattering or the cut looks rough and torn: Your feed rate might be too high, or your RPM too low. Try reducing the feed rate or increasing RPM.

- If you get clean chips and a smooth cut: You’re in the right ballpark!

- Adjust Gradually: Make small adjustments to either RPM or feed rate and re-test until you achieve the desired result.

- Consider Depth of Cut (DOC): For deeper cuts, you might need to “step” down. Instead of one deep pass, make several shallower passes. For a 1/2 inch desired cut, you might make 3-4 passes of 1/8 to 1/6 inch each. This reduces the load on the tool and machine.

“Heat Resistant” Feature Explained

Carbide’s “heat resistance” means it won’t melt or lose its hardness at the temperatures generated by cutting wood at typical speeds. This is a key advantage over softer materials that would quickly dull or deform. For wood, this primarily translates to maintaining a sharp edge for longer and preventing burn marks from friction heat.

Pro Tip: When using a handheld router, your hand speed is your feed rate! It’s harder to be precise, so keeping a consistent, moderate pace is essential. For CNCs, dialing in those numbers pays dividends in finish quality.

Common Applications for a 3/16 Inch Wood-Cutting End Mill

Once you’ve got the hang of speeds and feeds, you’ll find that your 3/16 inch carbide end mill opens up a world of possibilities. Its size and precision make it ideal for a variety of detailed woodworking tasks. Let’s look at some of the most popular and rewarding applications.

Detailed Engraving and Text

This is where the 3/16 inch size truly shines. Whether you’re adding your signature to a custom piece, creating nameplates, or personalizing gifts, this end mill delivers crisp, clean lines for lettering and fine details.

- Sign Making: Perfect for lettering on smaller signs or adding decorative borders.

- Artistic Engraving: For intricate patterns, portraits, or any detailed artwork on wood.

- Personalization: Engraving names, dates, or messages on furniture, cutting boards, or keepsake boxes.

V-Carving and Chamfering

V-carving uses a V-shaped (conical) bit to create angled grooves. While dedicated V-bits exist, an end mill can be used effectively, especially if your software supports V-carving tool paths with a standard end mill. Even without specific V-carving software, a 3/16 inch end mill can create angled channels by plunging at an angle for decorative effects.

- Decorative Grooves: Create elegant channels that add depth and visual interest.

- Chamfering Edges: A precise way to break sharp edges on smaller pieces for a softer look and feel.

Intricate Inlays and Joinery

For precise inlay work or small-scale joinery, the accuracy of a 3/16 inch end mill is invaluable. It can cut small mortises, rebates, or shaped pockets that require a high degree of precision.

- Creating Pockets: Perfect for inlaying metal, resin, or contrasting wood pieces.

- Small Dovetails/Mortises: With careful CAM programming, it can create pieces of very fine joinery.

Model Making and Miniatures

Hobbyists building scale models, dioramas, or miniature furniture will find this size indispensable for cutting fine details, shaping small components, and achieving realistic appearances.

- Cutting Delicate Parts: Shaping tiny pieces for models.

- Adding Fine Textures: Creating realistic textures on surfaces for dioramas or miniatures.

CNC Routing of Small Parts

For hobbyist CNC users, this end mill is a workhorse for cutting out small parts from sheet goods, creating templates, or carving detailed faces on projects.

- Profile Cutting: Cutting the outline of small, intricate shapes.

- Pocketing: Removing material to create recessed areas for components or decorative inserts.

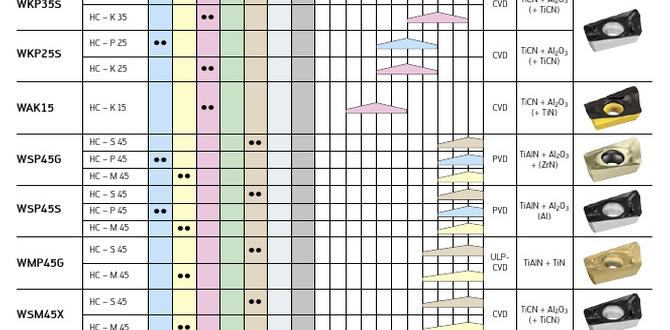

Carbide End Mill Geometry Types for Wood

While the 3/16 inch diameter is key, the geometry of the end mill also matters. For woodworking, you’ll typically encounter:

- Two-Flute (2-Flute): This is very common and often ideal for wood. It provides good chip clearance and works well at higher speeds.

- Single-Flute (1-Flute): Even better chip clearance, often used for softer plastics and woods where you want to ensure debris gets evacuated quickly. Can sometimes run faster.

- Compression Bits / Combination Bits: These have an ‘up-cut’ section and a ‘down-cut’ section. They are excellent for achieving a clean finish on both the top and bottom of plywood or laminates, as the down-cut section pushes chips down, preventing fuzzies.

When purchasing, look for end mills specifically marketed for wood or plastics, as they often have geometries optimized for these materials, such as higher helix angles and specific flute designs for better chip evacuation. For example, a “Sign Making Bit” or “Engraving Bit” at 3/16 inch is often exactly what you need for these detailed applications