Quick Summary:

Proper chip evacuation with carbide end mills is crucial for clean cuts and tool longevity. Good evacuation prevents overheating, reduces cutting forces, and ensures smooth material removal, especially vital when working with hardwoods or in deeper cuts. This guide will show you how to achieve it.

Carbide End Mill: Proven Wood Chip Evacuation for Smoother Cuts

Hey there, fellow makers and woodworking enthusiasts! Daniel Bates here from Lathe Hub. Have you ever been in the middle of a milling project, maybe shaping some intricate details or plunging into a deeper cut, and found yourself battling with a pile of wood chips jamming things up? It’s a frustrating problem, isn’t it? Those built-up chips can chatter your tool, bake into your workpiece, and even damage your expensive carbide end mill. But don’t worry, it’s a common hurdle, and today, we’re going to break down exactly how to get those chips flowing out of your way like magic. We’ll explore simple techniques and tool choices that’ll make your milling experience smoother and your projects cleaner. Stick around, and you’ll be achieving those crisp, professional finishes in no time!

Why Wood Chip Evacuation Matters

When your milling machine is working hard to cut wood, it creates tiny particles—chips! These chips are like the sawdust you get from sawing, but they’re produced right in the cutting zone. If these chips can’t escape, several problems can occur:

- Overheating: The chips act like an insulating blanket around the cutting edges of your carbide end mill. This traps heat, which can dull your tool much faster or even cause it to fail prematurely.

- Poor Surface Finish: Stuck chips mean the cutting edge is not making clean contact with fresh wood. This leads to rougher surfaces, tear-out, and a generally lower quality of finish.

- Increased Cutting Forces: When chips build up, the tool has to push through them as well as the wood. This requires more power, can cause vibration (chatter), and makes it harder to control your cut.

- Tool Damage: Excessive heat and stress from chip buildup can chip or break the delicate cutting edges of your carbide end mill, shortening its lifespan considerably.

Think of it like trying to eat with a mouthful of food; it’s much harder and messier than when you can clear your miệng between bites. For machinists, clear chip evacuation is the key to efficient and effective cutting.

Understanding Your Carbide End Mill’s Role

A carbide end mill is a fantastic tool for woodworking. Its hardness allows it to cut efficiently, and it can handle higher speeds and feeds than many other cutting tools. But for it to do its job well, especially in wood, we need to help it out. The design of the end mill itself plays a big part in how well chips are cleared.

Flute Design: The Chip’s Highway

The spirals or grooves on an end mill are called flutes. These aren’t just for show; they are designed to carry the chips away from the cutting point.

- Number of Flutes: For wood, end mills typically have fewer flutes than those used for metal. A 2-flute end mill is often ideal for wood. Why? More flutes mean less space between them. Less space means less room for chips to form and less space to carry them away effectively. A 2-flute design offers larger chip “gullets” or spaces for chips to exit.

- Helix Angle: This is the angle at which the flutes spiral around the cutter shaft. Higher helix angles (steeper spirals) are generally better for chip evacuation in softer materials like wood. They help “scoop” chips up and out of the cut more aggressively. Lower helix angles are often used for harder materials or for finishing passes where chip load is less of a concern.

- Chip Breakers: Some specialized end mills have small notches or serrations on the cutting edges called chip breakers. These are designed to break up long, stringy chips into smaller, more manageable pieces, which are easier to evacuate. While common in metal cutting, they can also be found on some wood-specific end mills and can be beneficial.

Material Matters: Softwood vs. Hardwood

The type of wood you’re cutting significantly impacts chip evacuation.

- Softwoods (like pine or fir) tend to produce long, stringy chips that can be very prone to getting stuck.

- Hardwoods (like oak or maple) produce shorter, more brittle chips, which are generally easier to evacuate but can still cause issues if not managed.

This is where understanding the principles of chip evacuation becomes even more critical. For woods that produce stringy chips, using tools and techniques that promote faster chip removal is paramount.

Mastering Chip Evacuation Techniques

Choosing the right end mill is only half the battle. How you use it is just as important. Here are some proven techniques to ensure your chips are swept away efficiently.

1. Tool Selection for Optimal Evacuation

When shopping for carbide end mills, look for features that promote good chip flow, especially if you plan on working with demanding woods or doing deeper cuts.

- 2-Flute Design: As mentioned, this is often the go-to for wood. More space for chips means better evacuation.

- High Helix Angle: Look for end mills with steeper helix angles (often 30 degrees or more) for better chip lifting.

- Up-Cut vs. Down-Cut vs. Straight Flutes: This is a crucial distinction.

- Up-Cut (Spiral): These mills rotate counter-clockwise and pull chips upward, away from the workpiece. They are excellent for clearing chips from the bottom of pockets and holes. They can cause some lifting of thin material at the top edge.

- Down-Cut (Reverse Spiral): These mills rotate clockwise and push chips downward. They are great for leaving a clean top surface and holding thin material down, but they can pack chips tightly into pockets. Not ideal for evacuation from deep cuts.

- Straight Flutes: These have no spiral. They are less common for general routing and milling in wood, as they don’t actively move chips out.

For excellent chip evacuation, especially from pockets and through cuts, the up-cut spiral end mill is generally preferred.

- “O-Flute” or Single Flute End Mills: Some very specialized end mills for plastics and specific wood applications come with a single, large flute. These offer the absolute best chip clearance but might not be suitable for all types of milling or materials.

- Longer Reach End Mills: For deeper cuts, you’ll need a longer end mill. When selecting a longer reach, such as a carbide end mill 3/16 inch 8mm shank long reach for wood chip evacuation, ensure the flute length is adequate for your intended depth of cut. The shank’s length means the cutting portion is further away from the collet, allowing for deeper access to your workpiece. Be mindful of rigidity—longer tools can be more prone to flexing.

A great resource for understanding tool geometry and its impact can be found on sites like the National Institute of Standards and Technology (NIST) which often provides data and research on manufacturing processes and tool standards.

2. Feed Rate Optimization

The speed at which your end mill moves through the material, known as the feed rate, has a direct impact on chip evacuation.

- Too Fast: If you feed too quickly, the end mill can’t effectively cut the material, and chips can become oversized and get jammed.

- Too Slow: Feeding too slowly can lead to the end mill rubbing rather than cutting, generating excessive heat and fine dust that doesn’t evacuate well.

Finding the “sweet spot” is key. You want chips that are relatively small and consistent, not long, stringy ribbons or fine powder. The ideal feed rate depends on your machine, the material, and the diameter of your end mill. Many CNC machines have calculators or software that can help determine recommended feed rates. For manual milling, it’s often about listening to the cut and observing the chip formation.

3. Spindle Speed (RPM) Adjustment

The rotational speed of your end mill is also critical. It dictates how much material each cutting edge removes with every rotation (chip load).

- High RPM, Low Chip Load: This means the tool is spinning fast, but each cutting edge is taking a very small bite. This can lead to heat buildup and poor chip formation if not managed.

- Low RPM, High Chip Load: This means the tool spins slower, but each bite is larger. This can be more efficient for chip evacuation if the machine can handle the forces and the tool can maintain its cutting edge.

Again, the ideal RPM is a balance. As a general rule for woodworking with a carbide end mill, you’ll often be in a range of 14,000 to 24,000 RPM, depending on the machine and the specific task. The goal is to create a chip load that is neither too small (which causes dusting and heat) nor too large (which overloads the tool).

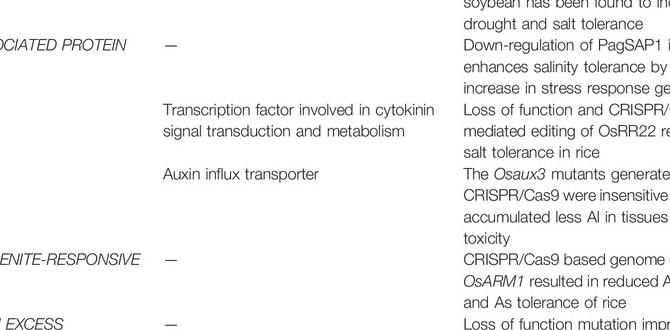

A Table of Recommended Starting Points (General Guidance)

This table provides generalized starting points. Always adjust based on your specific machine, material, and the sound/look of the cut.

| End Mill Diameter | Material | Recommended RPM (Range) | Typical Chip Load per Tooth (mm/tooth) | Feed Rate (mm/min) |

|---|---|---|---|---|

| 3/16″ (4.76mm) | Pine, Fir (Softwood) | 16,000 – 20,000 | 0.03 – 0.08 | 380 – 1280 |

| 3 H16″ (4.76mm) | Oak, Maple (Hardwood) | 14,000 – 18,000 | 0.02 – 0.06 | 224 – 864 |

| 1/4″ (6.35mm) | Pine, Fir (Softwood) | 15,000 – 19,000 | 0.04 – 0.10 | 480 – 1900 |

| 1/4″ (6.35mm) | Oak, Maple (Hardwood) | 13,000 – 17,000 | 0.03 – 0.08 | 312 – 1360 |

Note: Chip load is directly related to feed rate and RPM. The formula is: Feed Rate = RPM x Number of Flutes x Chip Load per Tooth.

4. Step-Down and Step-Over Settings (For Pocketing/Profiling)

When you’re not just cutting an edge but also removing material from a surface or creating a pocket, how deep you plunge and how wide your passes are makes a difference.

- Step-Down: This is the depth of cut for each pass. For aggressive material removal, you might use a larger step-down. However, in tougher woods or when chip evacuation is a concern, a smaller step-down is often better. This allows the flutes to clear chips more effectively on each pass.

- Step-Over: This is the width of your cutting path when clearing a pocket. A wider step-over means the end mill covers more area, but it also means the chips generated are dispersed over a larger area, potentially making evacuation harder. For difficult-to-evacuate materials, a narrower step-over might be beneficial.

For deep pockets, a strategy of using a smaller step-down and potentially a two-pass approach (a roughing pass with a larger step-down followed by a finishing pass with a smaller one) can significantly improve chip clearing.

5. Air Blast and Coolant (When Applicable)

While not always necessary for wood, sometimes a little extra help is needed.

- Air Blast: A directed stream of compressed air can blow chips away from the cutting zone. This is very effective in keeping the tool path clear, especially in 2D profiling or when working with very dusty materials like MDF. Many CNC routers have provisions for an air blast nozzle.

- Coolant/Lubricant: For most woodworking applications, water-based coolants are not generally used as they can warp the wood. However, in some specialized industrial settings or when cutting very hard, dense woods at high speeds, a minimal mist coolant system might be employed. For the hobbyist, air blast is usually the preferred method.

A good source for CNC machining best practices, which often include discussions on chip evacuation applicable to wood, can be found through educational institutions or CNC machining forums that focus on specific machine types.

6. Climb Milling vs. Conventional Milling

This refers to the direction the cutter rotates relative to the feed direction.

- Conventional Milling: The cutter rotates against the feed direction. This is generally more stable, produces smaller chips, and is easier for machines to handle.

- Climb Milling: The cutter rotates with the feed direction. This can result in a finer finish, lower cutting forces, and longer tool life if set up correctly, as chips are produced more efficiently and tend to be thicker and easier to evacuate. However, it requires a rigid machine to avoid chatter and “climbing” into the material.

For wood, climb milling can be very effective for chip evacuation, but it’s important to test on scrap first. Always ensure your machine has minimal backlash in its drives when attempting climb milling.

Troubleshooting Common Chip Evacuation Issues

Let’s say you’re still having trouble. What might be going wrong, and how can you fix it?

Problem: Chips are packing into pockets and not coming out.

Possible Causes:

Feed rate is too slow, creating fine dust instead of evacuating chips.

Step-down is too aggressive, not giving the flutes enough room.

Using a down-cut end mill when an up-cut is needed.

Spindle speed is too high for the feed rate, creating tiny chips that don’t exit.

The pocket is too narrow for the end mill diameter, limiting chip clearance.

Solutions:

Increase feed rate slightly.

Decrease step-down.

Switch to an up-cut end mill.

Adjust RPM or feed rate to achieve a more optimal chip load.

Consider a smaller diameter end mill if feasible for the pocket size.

Use an air blast to assist.

Problem: Overheating, smoking wood, or burning smell.

Possible Causes:

Feed rate is too slow.

Spindle speed is too high.

End mill is dull.

Poor chip evacuation is trapping heat.

Too much material is being removed in a single pass (aggressive step-down).

Solutions:

Increase feed rate or decrease RPM to achieve a proper chip load.

Ensure your RPM is suitable for the material and end mill diameter.

Inspect your end mill for dullness or damage; sharp tools cut cooler.

Implement better chip evacuation techniques (air blast, better tool path).

Reduce your step-down.

Problem: Rough surface finish or tear-out.

Possible Causes:

Dull end mill.

Chip buildup is causing the cutter to scrape rather than cut.

Feed rate is too slow.

Excessive runout (wobble) of the end mill.

Solutions:

Use a sharp carbide end mill.

Improve chip evacuation.

Increase feed rate.

* Check your collet and spindle for runout. Ensure the end mill is seated correctly.

Choosing the Right Carbide End Mill for Wood: A Quick Guide

When heading to the tool supplier or browsing online, keep these points in mind for wood chip evacuation specifically:

- Primary Material: Wood (hardwood or softwood).

- Ideal Flute Count: 2 flutes.

- Helix Angle: Aim for a moderate to high helix (e.g., 30 degrees) for better chip lifting.

- Cut Type: Up-cut spirals are generally best for evacuation from pockets.

- Special Features: Chip breakers can be beneficial, especially for stringy woods.

- Length: Ensure flute length is sufficient for your intended depth of cut, but beware of excessive length that reduces rigidity. Consider shanks like an 8mm shank for specific collet systems or a standard 1/4″ or 3/8″ for common routers.

This approach prioritizes tools that are designed to manage the unique challenges of milling wood, particularly when it comes to keeping those pesky chips out of the way.

FAQ: Your Carbide End Mill Chip Evacuation Questions Answered

Q1: What is the biggest mistake beginners make with chip evacuation?

The biggest mistake is often not paying attention to it at all! Beginners might use a general-purpose end mill not designed for wood, run at incorrect speeds/