Quick Summary: For routing wood, carbide end mills are generally the superior choice over High-Speed Steel (HSS) end mills. Carbide offers much greater hardness, wear resistance, and heat tolerance, leading to cleaner cuts, longer tool life, and faster machining speeds, especially in hardwoods and CNC applications.

Choosing the right cutting tool can make a world of difference when you’re working with wood. You might have heard terms like HSS and Carbide being thrown around when talking about end mills, and wondered which one is best for your woodworking projects. It’s a common question for beginners, and the confusion is understandable! Don’t worry, though. As a machinist and tool enthusiast, I’ve spent countless hours with different cutters, and I’m here to break down the difference between Carbide and HSS end mills for wood, so you can make the best choice for your workshop. We’ll explore what makes them different and when to use each one.

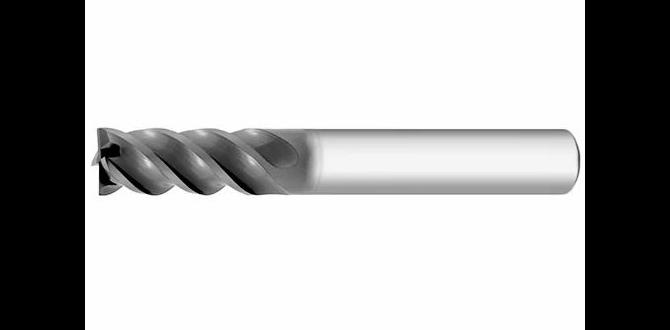

Carbide End Mill vs HSS End Mill For Wood: What’s The Big Deal?

When you’re shaping wood, the end mill is your best friend. It’s the business end of your router or CNC machine, carving out details and creating your designs. But not all end mills are created equal. The two main types you’ll encounter are High-Speed Steel (HSS) and Carbide. Understanding their strengths and weaknesses is key to getting smooth cuts, preserving your tools, and actually enjoying your woodworking process.

Think of it like choosing between a regular screwdriver and a high-quality electric one. Both can turn a screw, but one will get the job done faster, cleaner, and with less effort. That’s a good analogy for Carbide versus HSS in woodworking!

High-Speed Steel (HSS) End Mills: The Classic Choice

HSS end mills have been around for a long time, and for good reason. They are made from a type of tool steel that can withstand higher temperatures than regular steel. This is important because cutting tools generate heat through friction.

Pros of HSS End Mills for Wood:

- Cost-Effective: HSS cutters are generally much cheaper than carbide ones. This makes them a great starting point for hobbyists or for projects where tool wear isn’t a major concern.

- Toughness and Flexibility: HSS has a certain amount of toughness and can flex slightly without breaking. This can be an advantage when dealing with very hard knots or occasional impacts, as they are less brittle than carbide.

- Easier to Sharpen (Relatively): While sharpening any end mill requires care, HSS can sometimes be sharpened with standard grinding wheels if needed, though specialized bits are still recommended for best results.

- Good for Softer Woods: For softer woods or less demanding cuts, HSS can perform admirably and provide a decent finish at a lower cost.

Cons of HSS End Mills for Wood:

- Slower Cutting Speeds: Because HSS can’t handle heat as well as carbide, you’ll need to run your router or CNC at slower speeds and feed rates to prevent overheating and premature dulling.

- Faster Wear: HSS will dull much faster than carbide, especially when cutting hardwoods or abrasive materials like plywood or MDF. This means more frequent replacements or resharpening.

- Less Edge Retention: The cutting edges on HSS mills won’t stay sharp as long, leading to a decline in cut quality over time. You might notice tear-out or burning more quickly.

- Can Burn Material: If you push an HSS bit too hard or it gets dull, it’s more prone to burning the wood, leaving unsightly scorch marks.

Carbide End Mills: The Modern Workhorse

Carbide, specifically Tungsten Carbide, is a ceramic composite material known for its extreme hardness and strength. When used in end mills, it offers significant advantages over HSS for many woodworking applications.

Pros of Carbide End Mills for Wood:

- Superior Hardness and Wear Resistance: This is the biggest advantage. Carbide is significantly harder than HSS, meaning it resists wear much better. Your carbide end mill will stay sharp for a lot longer, even when cutting tough materials.

- Higher Cutting Speeds: Thanks to its heat resistance and hardness, you can run carbide tools at much faster speeds and feed rates. This translates to quicker project completion times, especially on CNC machines where efficiency is key.

- Cleaner Cuts and Better Finish: A sharp carbide edge cuts more cleanly, reducing tear-out and splintering. This means you often get a smoother finish right off the machine, potentially saving you sanding time.

- Excellent for Hardwoods and Composites: If you work with hardwoods like oak, maple, or walnut, or with materials like plywood, MDF, or particleboard, carbide is almost essential for good results and tool longevity. These materials are more abrasive and harder on cutting edges.

- Longer Tool Life: Because they stay sharper for so much longer, carbide end mills offer a much better return on investment over time, despite their higher initial cost.

Cons of Carbide End Mills for Wood:

- Higher Initial Cost: Carbide end mills are typically more expensive than HSS end mills. This can be a barrier for some hobbyists just starting out.

- Brittleness: While incredibly hard, carbide is also more brittle than HSS. This means they can chip or break if subjected to sudden impacts, like hitting a screw or a knot that’s not properly accounted for, or if dropped.

- Difficult to Sharpen: Sharpening carbide requires specialized grinding equipment (like diamond wheels) and expertise. It’s generally not a DIY sharpening task for most home users; resharpening is usually best left to professionals.

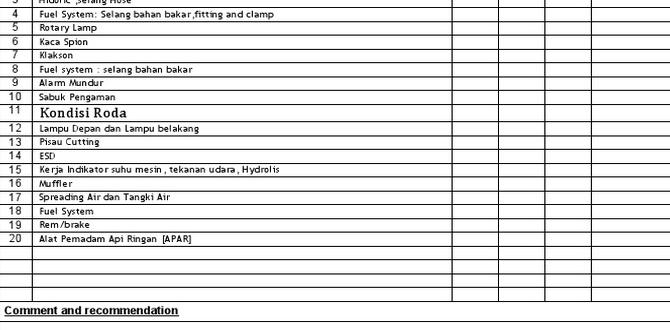

When to Use Which: A Practical Guide for Woodworkers

The choice between Carbide and HSS for your wood projects often comes down to a few key factors: the type of wood, the complexity of the cut, your machinery, and your budget. Here’s a breakdown to help you decide:

Choose HSS If:

- You’re on a tight budget: HSS is more affordable upfront.

- You work mostly with softwoods: Pine, cedar, and similar softwoods are less abrasive and HSS can handle them reasonably well if you’re not pushing the tool too hard.

- You’re doing simple, shallow cuts: For basic tasks like rounding edges or light profiling, an HSS bit might be sufficient, especially if you’re not in a hurry.

- Your machine has limited spindle speed: If your router or CNC can’t spin very fast, the benefit of carbide’s higher speed capabilities is reduced.

- You anticipate occasional impacts: If you’re worried about accidentally hitting a nail or a very hard knot where a bit might take a hit, HSS’s slight flexibility might be considered safer for the tool.

Choose Carbide If:

- You work with hardwoods: Oak, maple, cherry, walnut – carbide slices through these with ease and stays sharp.

- You work with man-made materials: Plywood, MDF, particleboard, and solid surface materials are abrasive. Carbide is essential to avoid rapid dulling and burning. For more information on machining MDF, check out resources from organizations like the Woodworking Network which often discuss material-specific tooling.

- You want the best finish: Carbide’s sharpness leads to cleaner cuts and less tear-out, reducing your sanding time.

- You’re using a CNC router: CNC machines are designed for efficiency and higher speeds. Carbide allows you to take advantage of this, leading to much faster machining times.

- You want long-term value: Even though they cost more upfront, the extended lifespan and better performance of carbide often make them more economical in the long run.

- You’re doing detailed or intricate work: The precision and sharpness of carbide are invaluable for fine details and complex carvings.

Types of End Mills and Cuts for Wood

Beyond the material (HSS vs. Carbide), the design of the end mill also matters. For wood, you’ll typically encounter a few common types, each suited for different tasks:

Common End Mill Types for Wood

- Straight Flute End Mills: These have straight cutting edges. They are versatile and good for general-purpose cutting, slotting, and pocketing. They can be good at clearing chips, which is important in wood.

- Spiral (or Helix) Flute End Mills: These have helical flutes. They provide a smoother cutting action and are excellent for chip evacuation, especially in softer woods or when doing deeper cuts.

- Up-cut Spiral: Flutes spiral upward. They pull chips up and out of the cut, which is great for clearing material but can cause some lifting or tear-out on the top surface. Good for pocketing.

- Down-cut Spiral: Flutes spiral downward. They push chips down and away from the top surface. This results in a very clean top finish but can pack chips into the bottom of a deep cut. Excellent for finish passes.

- Compression Bits: These have a combination of up-cut and down-cut flutes. They engage the material from both directions, providing a clean cut on both the top and bottom surfaces simultaneously. These are a favorite for sheet goods like plywood where you want a perfect edge on both sides.

- Ball Nose End Mills: These have a rounded tip. They are perfect for creating rounded profiles, 3D carving, and creating smooth, flowing surfaces.

- V-Groove Bits: These have a conical shape, creating V-shaped cuts. They are ideal for lettering, chamfering, and decorative grooving.

Understanding Flutes

The “flutes” are the spiral grooves that run along the cutting edge of the end mill. They serve two primary purposes: providing the cutting surfaces and clearing away the material (chips) that is being removed. The number of flutes can influence performance:

- 2-Flute: Generally preferred for wood. They offer good chip clearance, which is crucial to prevent overheating and burning.

- 3-Flute: Can offer a smoother finish than 2-flute bits but may have slightly reduced chip clearance.

- 4-Flute: More common in metalworking. They offer excellent finish but can be prone to clogging with wood chips if not used carefully, potentially leading to burning or increased load on the machine.

For most woodworking, especially in CNC applications, 2-flute up-cut or compression bits are very popular. For 3D carving, ball-nose bits are essential, and their flute count will depend on the material and desired finish speed.

Carbide vs. HSS: A Direct Comparison Table

To make it even clearer, let’s look at a direct comparison. This will help you visualize the key differences at a glance as you choose your next tool.

| Feature | Carbide End Mill | HSS End Mill |

|---|---|---|

| Hardness | Very High | Moderate |

| Wear Resistance | Excellent | Good |

| Heat Resistance | Excellent | Good |

| Edge Retention | Very Long | Shorter |

| Cutting Speed (for Wood) | Fast | Moderate to Slow |

| Material Suitability | Hardwoods, Plywood, MDF, Softwoods | Primarily Softwoods, occasional hardwoods if careful |

| Finish Quality | Excellent, Clean | Good, can get rougher as it dulls |

| Brittleness | Higher (can chip) | Lower (more impact resistant) |

| Initial Cost | Higher | Lower |

| Tool Life | Longer | Shorter |

| Sharpening Difficulty | Difficult (requires special tools/expertise) | Easier (can be done with standard equipment if skilled) |

Best Practices for Using End Mills in Wood

Regardless of whether you choose HSS or Carbide, using your end mills correctly is crucial for safety, performance, and longevity. Here are some essential tips:

Safety First!

This is the most important part of any workshop activity. Always remember:

- Wear Safety Glasses: Always protect your eyes from flying debris.

- Secure Your Workpiece: Ensure your wood is firmly clamped down. A slipping workpiece can cause dangerous kickbacks or inaccurate cuts.

- Keep Hands Clear: Never place your hands in the path of the cutting tool.

- Use Dust Collection: Wood dust can be a health hazard and also interfere with your machine’s cooling and your vision. Connect a dust hose to your router or dust collection system.

- Understand your Machine: Know the limits of your router, CNC, or spindle. Don’t push it beyond its capabilities.

Optimizing Your Cuts

- Feeds and Speeds: This is critical. For HSS, you’ll run slower RPMs and feed rates. For Carbide, you can run faster. While specific recommendations vary greatly by wood type, bit diameter, and machine power, a good starting point for softwood with a 1/4″ carbide bit on a CNC might be around 18,000-20,000 RPM at a feed rate of 30-50 inches per minute. Harder woods will require slower feed rates or lower RPMs. A fantastic resource for learning more about feeds and speeds, especially for CNC, is the Inventables Easel Feed and Speed Calculator – while focused on their machines, the principles apply broadly.

- Chip Load: This is the thickness of the material removed with each tooth of the end mill per revolution. For wood, you generally want a higher chip load for efficient material removal and less burning. Too high a chip load can overload your machine or break the bit.

- Depth of Cut: Don’t try to remove too much material in a single pass. For roughing cuts, especially in hardwoods, making multiple passes with increasing depth is better. A common rule of thumb is to not cut deeper than your bit’s diameter in a single pass, though this can be adjusted based on material and bit design.

- Cooling and Lubrication: While not as critical in wood as in metal, good airflow and dust collection help keep the cutting area cool. Avoid letting chips build up, as this is a primary source of heat and burning.

- Clean Your Bits: Periodically clean any resin or wood dust buildup from your end mills, especially if you’ve been cutting pine or other sticky woods. This helps maintain their cutting efficiency.

When Carbide is the Undisputed Champion

If you’ve ever struggled with tear-out on plywood edges, burned your way through a hardwood project, or found your HSS bits dulling after just a few hours of work, you’ve experienced why carbide is often considered the best for wood. Its ability to maintain a sharp edge through thousands of feet of material is unparalleled. For professional woodworkers, furniture makers, and serious hobbyists using CNC machines, carbide end mills aren’t just an upgrade; they are a necessity for achieving high-quality results efficiently.

Consider the materials handled by the U.S. Forest Products Laboratory. Their research highlights the varying densities and properties of wood, informing best practices for machining. Materials like dense hardwoods or engineered wood products like MDF put significant stress on cutting tools. Carbide’s superior hardness and wear resistance are specifically designed to combat this, offering a cutting edge that endures where HSS would quickly falter.

When you’re looking for clean, crisp lines, minimal sanding, and the ability to tackle a wide variety of wood types and composites, carbide stands out as the proven best choice. It allows your machine to perform to its potential and gives you the confidence that your tools will keep up with your creativity.

Frequently Asked Questions (FAQ)

Q1: Can I use a metal-cutting end mill on wood?

A: Yes, you can use end mills designed for metal on wood, but it’s not always ideal. Many metal-cutting end mills are made of HSS or Carbide. For wood, we generally prefer end mills with fewer flutes (like 2-flute) to help with chip evacuation. Metal-cutting bits often have more flutes, which can increase the risk of clogging and burning in wood if not used carefully. However