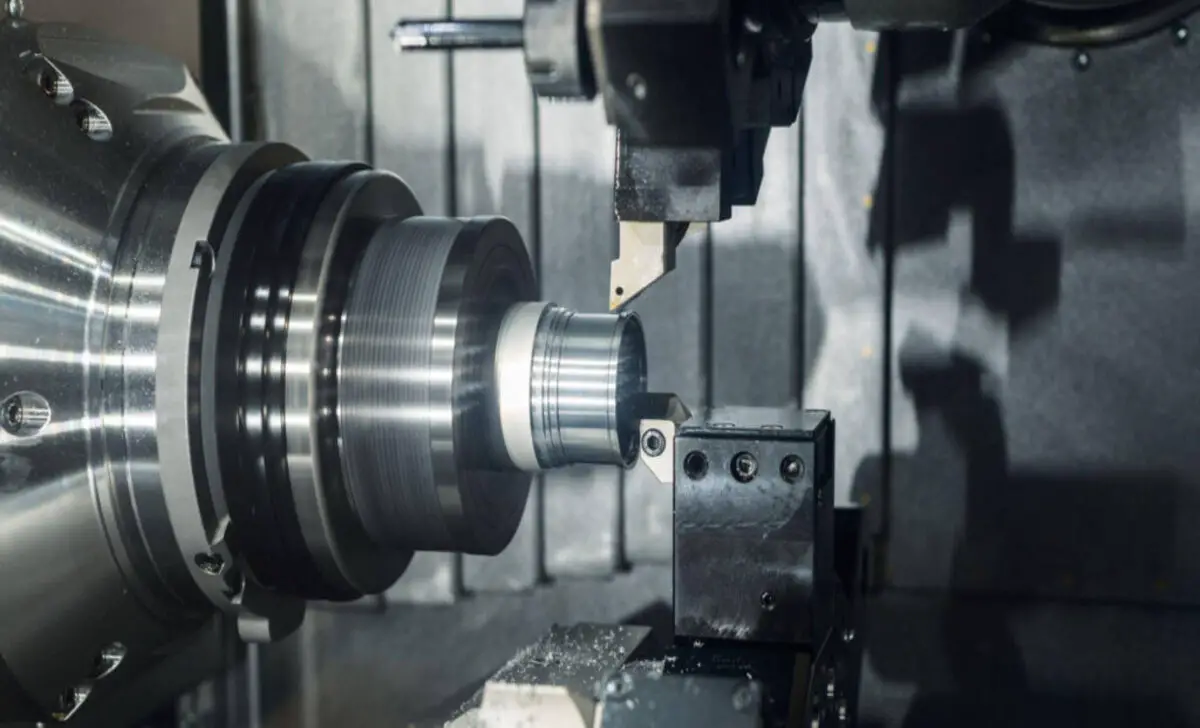

CNC lathe machines are crucial tools in the manufacturing industry, providing precision and efficiency in producing various components.

However, chatter is one common issue that can disrupt the smooth functioning of a CNC lathe machine. Chatter is the vibration or bouncing of the tool against the workpiece, resulting in poor surface finish and dimensional accuracy.

This affects the quality of the end product and leads to increased tool wear and tear, resulting in higher production costs. As such, machine operators and manufacturers must understand the causes of chatter and learn effective methods to prevent and eliminate it.

Here, we will discuss the different types of chatter, explore the reasons behind CNC lathe machine chatter, and provide a step-by-step guide on how to stop chatter on a CNC lathe machine in 7 easy steps.

Different Types Of Chatter In CNC Machining

Chatter can be a frustrating issue when operating a CNC lathe machine. It refers to the vibration or noise that occurs during machining, which can negatively impact the quality of the finished product. Different types of chatter can occur, including:

- Check And Adjust Cutting Parameters: Ensure that I use optimal cutting speeds, feeds, and depths of cut for my specific material and tooling.

- Use A Stable Workpiece Setup: Ensure the workpiece is properly secured and balanced on the machine to minimize external forces that can cause vibrations.

- Check Tool Condition: Inspect the cutting tool regularly to ensure it is sharp and in good condition.

- Implement Vibration-Dampening Techniques: Use tool holders or inserts with built-in vibration-dampening properties to reduce chatter during machining.

- Use Cutting Strategies Designed To Minimize Chatter: Employ trochoidal or high-speed machining techniques, which can help minimize vibrations and chatter.

- Consider Using Cutting Fluids: Using appropriate cutting fluids can help reduce heat and friction, which can contribute to chatter.

- Seek Professional Assistance If Necessary: If chatter persists despite implementing these measures, consult a CNC machining expert for further analysis and troubleshooting.

Exploring The Reasons For CNC Lathe Machine Chatter

Exploring the root causes of chatter leads to targeted solutions. Understanding the reasons for chatter involves analyzing cutting parameters. Factors like cutting speed, feed rate, and tool wear contribute to chatter.

Spindle speed variation, excessive cutting forces, and poor surface finish also lead to chatter. Resolving the reasons for chatter enhances machining stability and surface finish. Addressing these factors optimizes CNC machine performance by mitigating resonant vibration and resonant frequency, ultimately minimizing chatter problems and achieving high-performance machining outcomes.

How To Stop Chatter On A CNC Lathe Machine: Step-By-Step Guide

Exploring the reasons for CNC lathe machine chatter and understanding the type of chatter is crucial before implementing the step-by-step guide on how to stop chatter on a CNC lathe machine. Start by diagnosing the chatter type, then adjust the spindle speed accordingly. Check and realign the cutting edge, reduce machine tool deflection, and inspect parts regularly.

Using suitable cutting tools, maintaining the lathe machine, and ensuring centralized force is vital to reducing chatter. These steps will effectively address the chatter problem without loud noises or great impact on the workpiece. Implementing these measures will positively impact the performance of the CNC machine, helping to control chatter in CNC lathe machines.

Step 1: Diagnose The Type Of Chatter

Understanding the characteristics of different types of chatter is crucial for accurately diagnosing and resolving machining issues. By identifying the specific type of chatter, precise corrective measures can be implemented to address the root cause effectively. Accurate diagnosis ensures the selection of appropriate solutions, ultimately leading to targeted and effective control of chatter.

Properly diagnosing chatter types guides the diagnostic process and allows for the implementation of tailored solutions, minimizing unwanted vibrations and improving machining stability. The ability to diagnose chatter types effectively directly impacts the cutting process’s overall quality and the cutting tools’ service life.

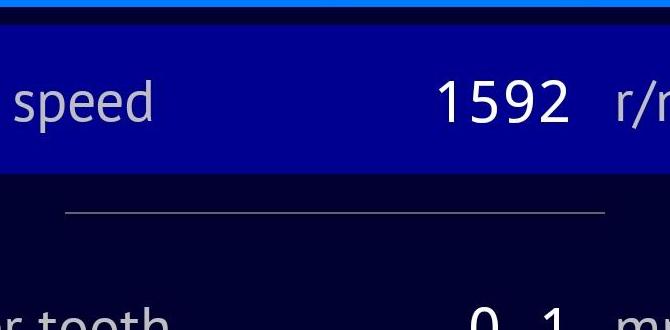

Step 2: Adjust The Spindle Speed

Fine-tuning the spindle speed based on cutting conditions and material minimizes resonant vibration, reducing chatter frequency and impact. Varied control of the machine’s axis effectively mitigates the occurrence of loud noises while adhering to constant surface speed principles decreases the risk of chatter.

Adjusting the speed to the sweet spot decreases the likelihood of chatter vibration and greatly impacts CNC turning and milling. Using the right tool with a positive rake angle minimizes chatter problems and maximizes the machine’s overall performance, specifically in workpiece machining.

Step 3: Check And Realign The Cutting Edge

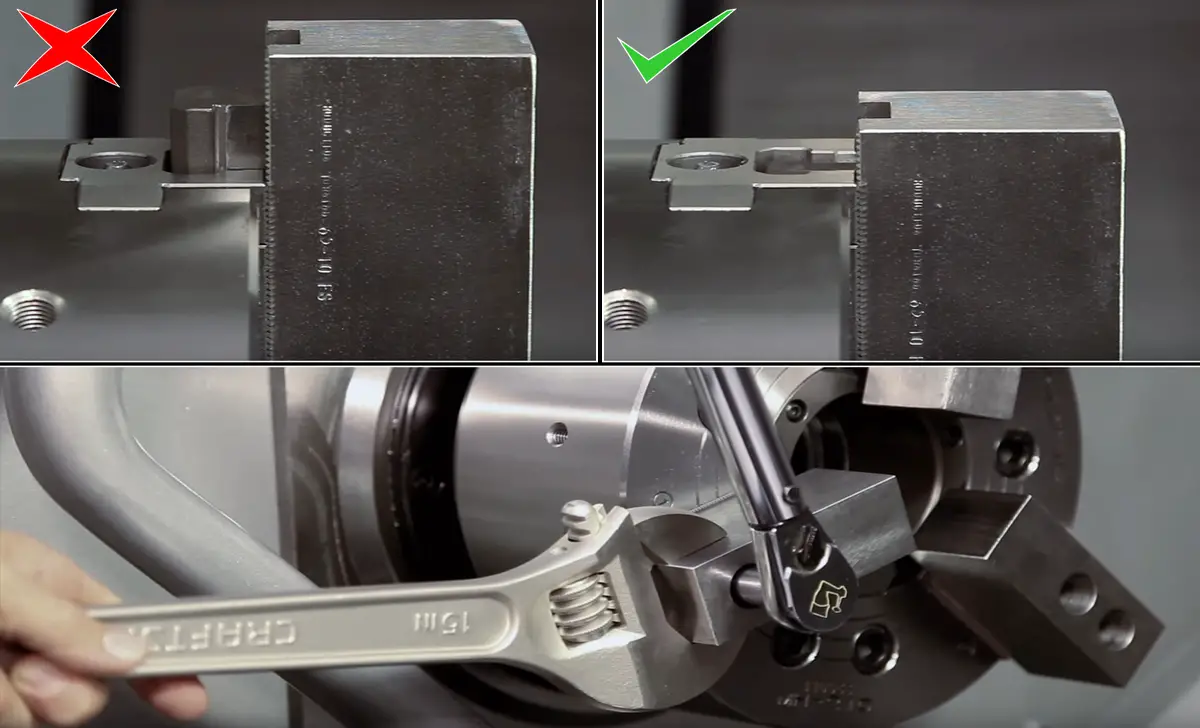

Maintaining proper cutting-edge alignment is crucial to prevent chatter and ensure consistent cutting. Regularly checking and realigning the cutting edge will minimize chatter vibration and uphold tool performance.

This alignment reduces the risk of tool chatter, promoting machining stability and mitigating chatter frequency based on the workpiece material. Achieving correct alignment minimizes the impact of tool chatter on the workpiece, resulting in improved machining stability and reduced operational noise.

Step 4: Reduce Machine Tool Deflection

By ensuring proper setup to minimize machine tool deflection, the frequency of chatter can be reduced effectively. This mitigation of deflection also plays a crucial role in improving the surface finish of the workpiece, contributing to enhanced machining stability.

Addressing machine tool deflection is a key factor in controlling chatter vibration during the cutting process, ultimately impacting the overall performance of CNC machining. Implementing measures to reduce machine tool deflection significantly enhances the overall efficiency and effectiveness of the machining process, leading to higher quality production.

Step 5: Inspect Your Parts Regularly

Regular part inspection identifies wear and tear, maintains product quality, and ensures machining accuracy. It also helps prevent unexpected tool breakage, minimizing the risk of poor surface finish. By inspecting parts regularly, manufacturers can address potential issues early on, avoiding any adverse effects on the machining process.

Additionally, thorough inspection reduces the impact of excessive cutting forces, unwanted vibration, and rigidity issues, promoting a steady machining environment. Advanced techniques such as resonance frequency analysis and centralized force measurement during part inspection can provide valuable insights into the root causes of chatter problems, enabling operators to make data-driven decisions to enhance machining performance and service life.

Step 6: Use Suitable Cutting Tools

Choosing the appropriate cutting tools is crucial for achieving high-quality results in CNC machining. It contributes to the improved performance and lifespan of the tools, minimizing wear and breakage. Proper selection of cutting tools also aids in reducing resonant vibration during the cutting process, thereby addressing the chatter problem effectively. Utilizing the right tool plays a significant role in achieving the desired surface finish of the workpiece, greatly impacting the machining process’s overall quality.

Step 7: Maintain Your Lathe Machine Regularly

Proper maintenance of the lathe machine is crucial for prolonging its service life and ensuring consistent cutting performance. Regular upkeep helps prevent machine chatter, excessive cutting forces, and rigidity issues, minimizing the risk of tool chatter and vibration.

By maintaining the lathe machine regularly, you can mitigate the impact of centralized forces and resonant vibrations, contributing to high performance and efficient CNC turning or milling. Additionally, regular maintenance reduces the likelihood of loud noises and chatter problems, enhancing the overall quality of workpiece machining.

The Effects Of Reduced Chatter In CNC Machining

Reduced chatter has a significant impact on CNC machining. It improves tool life, surface finish, and overall cutting performance. By minimizing chatter, productivity and machining accuracy are increased, while the service life of cutting tools and workpieces is enhanced.

Additionally, optimized cutting parameters resulting from reduced chatter lead to efficient material removal. Eliminating chatter vibration ensures the production of high-quality machined parts. These effects underscore the importance of effectively controlling chatter in CNC machining processes.

Advanced Tips To Control Chatter In CNC Lathe Machines

Controlling chatter in CNC lathe machines can significantly improve the quality of your machining operations. Chatter occurs when the cutting tool vibrates against the workpiece, resulting in poor surface finishes and dimensional inaccuracies. Here are some advanced tips to help you control chatter in CNC lathe machines:

- Optimize Cutting Parameters: Adjusting the cutting speed, feed rate, and depth of cut can help minimize chatter.

- Use High-Quality Cutting Tools: Investing in high-quality cutting tools specifically designed for lathe operations can reduce vibration and chatter.

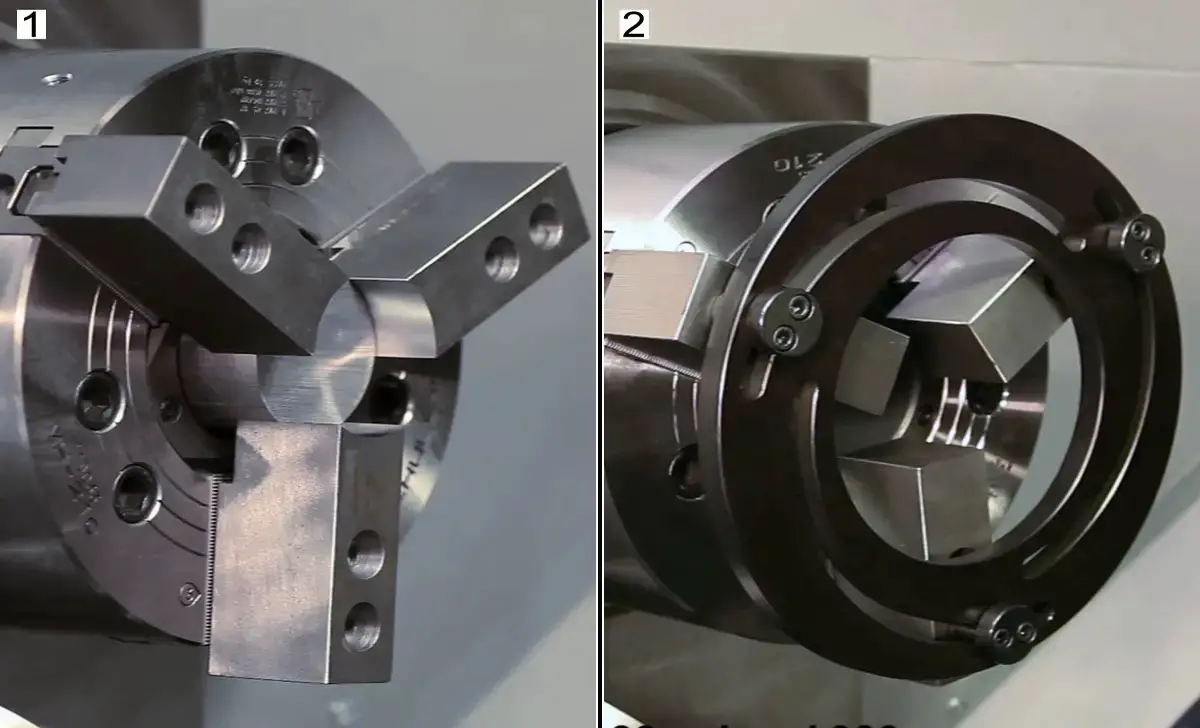

- Check Workpiece Stability: Ensure the workpiece is securely clamped and supported during machining.

- Minimize Tool Overhang: Longer tool overhang increases the risk of chatter.

- Consider Vibration-Damping Solutions: Implementing vibration-damping technologies, such as anti-vibration boring bars or tool holders, can help absorb vibrations and reduce chatter during machining.

By implementing these advanced tips, you can effectively control chatter and achieve better results in your CNC lathe operations. Remember to continuously monitor and adjust your processes to optimize performance and ensure smooth, chatter-free machining.

What Happens When Chatter Is Not Addressed?

Chatter issues are a serious concern in CNC machining, and ignoring them can have severe consequences. Neglecting these issues can lead to poor surface finish, reduced tool life, excessive cutting forces, unwanted vibration, compromised machining performance, and even machine tool breakage. It is crucial to address chatter issues to maintain the quality and efficiency of CNC lathe machines.

This can be done by optimizing the cutting parameters like spindle speed, feed rate, and depth of cut and using appropriate tooling systems that minimize vibration. Additionally, implementing modern control systems with advanced algorithms that predict and prevent chatter can help mitigate these issues and improve overall productivity.

Conclusion

Addressing chatter in CNC lathe machines is essential for achieving optimal machining results. By following the step-by-step guide on how to stop chatter on a CNC lathe machine, you can diagnose the type of chatter, adjust spindle speed, realign cutting edges, reduce machine tool deflection, inspect parts regularly, use suitable cutting tools, and maintain your lathe machine.

These measures reduce chatter and improve the overall quality and precision of your machining operations. Remember, reduced chatter leads to improved surface finish, increased tool life, and enhanced productivity. Implementing advanced tips and regularly addressing chatter issues will help you achieve exceptional machining results and ensure the longevity of your CNC lathe machine.

Frequently Asked Questions

1.How Do I Get Rid Of Chatter On My Lathe?

Ans: To eliminate chatter on your lathe, start by checking the condition of the tool and adjusting the spindle speed. Consider trying a different cutting fluid and ensuring your workpiece is properly centered and secured. Additionally, inspect for loose parts or damaged bearings in the lathe machine.

2.What Causes Chatter On A CNC Lathe?

Ans: Chatter on a CNC lathe occurs due to vibrations in the machine or workpiece. Factors like cutting speed, feed rate, and depth of cut contribute to chatter. Other causes include worn tools, improper tool holder setup, or incorrect coolant use. Preventing chatter requires proper machine maintenance and operator training.

3.How Can Chatter Be Reduced?

Ans: To reduce chatter on a CNC lathe machine, consider decreasing the cutting speed or increasing the feed rate. Using a sharper tool or reducing the depth of the cut can also help. Secure the workpiece properly and check for damage or wear on machine components like the spindle or bearings.

4.How Can Machine Tool Chatter Be Eliminated?

Ans: You can reduce cutting speed, increase feed rate, and use a sharp cutting tool to eliminate machine tool chatter. Another way is to increase the setup’s rigidity and properly support the workpiece. Using vibration-dampening tools or inserts can also help reduce machine tool chatter.

5.What Causes Chatter In Machining Operations?

Ans: The chatter in machining operations occurs due to vibrations between the tool and the workpiece. Improper cutting parameters, worn tools, and inadequate machine rigidity are common causes. Chatter can lead to poor surface finish, reduced tool life, and decreased accuracy.