Have you ever wondered which milling tool is best for your project? Climb milling and conventional milling tools each have their own special powers. Choosing the right one can change everything about your work.

Imagine carving out the perfect piece of metal. You pick up a tool and get started. Suddenly, you realize that not all tools can do the job well. Climb milling tools cut differently than conventional ones, and that can make a huge difference.

Did you know that using the wrong tool can lead to mistakes and wasted materials? Many people don’t realize that the choice between climb and conventional is not just about preference; it can affect the quality of your work. In this article, we will explore these two types of milling tools. You might be surprised by what you learn!

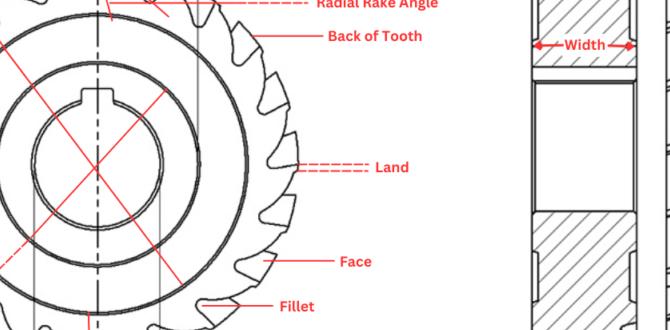

Climb Vs Conventional Milling Tools: Understanding The Differences Climb Milling And Conventional Milling Are Two Important Techniques In The Realm Of Machining, Particularly When It Comes To Milling Operations. Each Method Has Its Unique Advantages And Applications, Making It Crucial For Machinists And Engineers To Understand The Differences Between Them. What Is Climb Milling? Climb Milling, Also Known As Down Milling, Occurs When The Cutter Rotates In The Same Direction As The Feed Of The Workpiece. This Means That The Cutting Edge Engages The Material At The Top And Exits At The Bottom. The Primary Benefits Of Climb Milling Include: – **Reduced Tool Wear**: Since The Cutter Experiences Less Friction And Drag, It Typically Lasts Longer. – **Improved Surface Finish**: Climb Milling Often Results In Smoother Surfaces Because Of The Way The Material Is Removed. – **Higher Efficiency**: The Technique Allows For Faster Material Removal Rates, Making It Suitable For Production Settings. However, Climb Milling Can Also Pose Challenges, Particularly During The Initial Engagement With The Material. If The Cutter Is Not Properly Set Or If The Workpiece Is Not Securely Clamped, It Can Lead To Climb Milling Chatter Or Even Tool Breakage. What Is Conventional Milling? Conversely, Conventional Milling (Or Up Milling) Occurs When The Cutter Rotates Against The Direction Of The Feed. In This Technique, The Cutting Edge Engages The Material At The Bottom And Exits At The Top. Key Aspects Of Conventional Milling Include: – **Better Stability**: This Method Is Often More Stable Because The Cutting Action Tends To Push The Workpiece Down Onto The Table, Reducing The Risk Of Movement. – **Easier For Beginners**: Many Operators Find Conventional Milling More Intuitive, Particularly For Less Experienced Machinists. – **Suitability For Hard Materials**: Conventional Milling Can Be Preferable When Working With Harder Materials That Require More Control During The Cutting Process. Despite Its Advantages, Conventional Milling Can Also Lead To Increased Tool Wear And Less Favorable Surface Finishes Compared To Climb Milling. When To Choose Climb Vs Conventional Milling Choosing Between Climb And Conventional Milling Largely Depends On The Specific Requirements Of A Given Project: – **Material Type**: For Softer Materials, Climb Milling May Be Preferable; For Harder Materials, Conventional Milling Might Be The Better Option. – **Tooling And Machine Capability**: Some Machines Are Better Equipped For One Technique Over The Other, Influencing The Decision. – **Desired Finish**: When Surface Finish Is A Priority, Climb Milling Might Be The Better Choice. Conclusion In Conclusion, The Choice Between Climb And Conventional Milling Tools Can Significantly Affect The Outcome Of Machining Projects. Understanding The Differences, Benefits, And Limitations Of Each Method Allows Engineers And Machinists To Make Informed Decisions That Lead To Better Efficiency, Longer Tool Life, And Superior Workpiece Quality. By Analyzing The Material Requirements And Desired Outcomes, Professionals Can Determine Which Milling Approach Best Suits Their Specific Needs.

Climb vs Conventional Milling Tools

Climb milling and conventional milling have different approaches to cutting materials. Climb milling feeds the cutter in the same direction as the material, providing a smoother finish. This method reduces tool wear and requires less power. On the other hand, conventional milling cuts against the feed, resulting in a rougher surface. Did you know? Climb milling is often preferred for softer materials. Understanding these differences helps machinists choose the best tool for their projects!What is Climb Milling?

Definition and explanation of climb milling.. Key advantages of climb milling in machining processes..Climb milling is a machining method where the cutter moves in the same direction as the table feed. This technique allows for a smoother finish and less wear on tools. When the cutter engages the material, it tends to pull itself into the workpiece. This can make it more efficient and faster than other methods. Do you know that climb milling can reduce the risk of tool breakage? It’s like a ninja stealthily slicing through butter! The key advantages include improved surface finish and less power consumption.

| Advantages | Description |

|---|---|

| Smoother Finish | Produces a finer surface on the material. |

| Reduced Tool Wear | Decreases the rate of tool degradation. |

| Greater Efficiency | Allows for quicker machining times. |

What is Conventional Milling?

Definition and explanation of conventional milling.. Key advantages of conventional milling in machining processes..Conventional milling is a common machining method used to shape materials. In this process, the cutting tool moves against the material. It removes material in a series of rotations. This type of milling offers several benefits, such as:

- Better control over the cutting action.

- Lower tool wear compared to other methods.

- Ability to produce smoother finishes.

These advantages make conventional milling a go-to choice for many manufacturers.

What are the key benefits of conventional milling?

Some key benefits of conventional milling include:

- Improved surface finish.

- Reduced tool wear.

- Greater flexibility in machining different materials.

Comparative Analysis of Climb and Conventional Milling

Differences in cutter movement and chip formation.. Impact on tool wear and surface finish..Understanding how milling tools work helps you choose the right one for your project. In climb milling, the cutter moves down the workpiece, removing material efficiently and creating smoother finishes. This movement forms smaller, more manageable chips. On the other hand, conventional milling moves upward against the cutter’s rotation. It creates larger chips, leading to increased tool wear and rougher surfaces.

| Aspect | Climb Milling | Conventional Milling |

|---|---|---|

| Cutter Movement | Downward | Upward |

| Chip Formation | Small chips | Large chips |

| Tool Wear | Less wear | More wear |

| Surface Finish | Smoother finish | Rougher finish |

Choosing the right method can make your projects more successful. Remember, climb milling is like a ninja, quietly slicing through materials, while conventional milling stomps through with loud chips and wear.

Applications of Climb Milling

Industries and scenarios where climb milling is preferred.. Specific materials that benefit from climb milling techniques..In various industries, climb milling shines for its smooth finish and precision. This method is often used in places like:

- Automotive manufacturing

- Aerospace engineering

- Woodworking shops

It works well with materials such as:

- Aluminum

- Plastics

- Soft metals

Climb milling decreases tool wear and improves surface quality. Many experts prefer this technique for these reasons.

How does climb milling benefit specific materials?

Climb milling is best for aluminum and soft metals. It helps create better finishes and less tool damage. This makes it easier to work with these materials.

Applications of Conventional Milling

Industries and scenarios where conventional milling is preferred.. Specific materials that benefit from conventional milling techniques..Many industries use conventional milling for various reasons. This method works well in manufacturing and automotive sectors. It helps create precise parts from materials like metal and plastic. Conventional milling is also great for small projects, where fine details matter. Some specific materials that benefit from this technique include:

- Aluminum

- Steel

- Copper

- Wood

Each of these materials gets a polished finish. Properly using conventional milling can lead to high-quality products. This method remains popular for its reliability.

Why choose conventional milling?

Conventional milling provides consistent results on soft materials. This makes it a trusted choice in many workshops.

Factors Influencing the Choice of Milling Technique

Discussion of material properties and part complexity.. Consideration of tool life and machining efficiency..Choosing a milling technique depends on several factors. First, consider the material’s properties and how complex the part is. Harder materials need stronger tools. More intricate shapes may require finer cutting techniques. Tool life also matters. Durable tools save money over time. Efficient machining can mean faster production, which is great for business. Understanding these elements helps in picking the best milling method.

What influences the choice of milling technique?

Material properties, part complexity, tool life, and machining efficiency greatly influence milling choices.

Key Factors:

- Material hardness affects tool selection.

- Complex parts might need special tools.

- Long-lasting tools cut costs.

- Efficient machines speed up production.

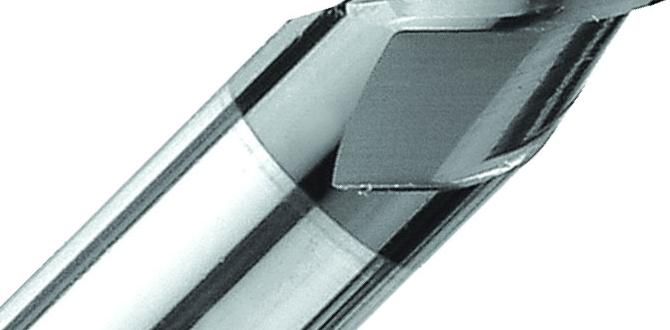

Choosing the Right Tools for Each Technique

Recommended tools for climb milling.. Recommended tools for conventional milling..For climb milling, you should use tools that work well with the material you’re cutting. Recommended tools include:

- High-speed steel (HSS) end mills

- Carbide end mills

For conventional milling, focus on durable tools. Here are some great choices:

- Fluted drills

- High-speed steel (HSS) cutters

Picking the right tool makes a big difference in your milling results!

What are some tools to choose for climb milling?

High-speed steel and carbide end mills work best for climb milling.

What tools are recommended for conventional milling?

Use fluted drills and HSS cutters for effective conventional milling.

Common Misconceptions About Climb and Conventional Milling

Addressing myths and misunderstandings in milling choices.. Clarifying when to use each method effectively..Many people confuse climb and conventional milling. They think climb is always better, but that’s not true. Each method has its strengths. Knowing when to use each can make a big difference.

Some common myths include:

- Climb milling is always faster.

- Conventional milling is outdated.

- Climb milling can only be used on certain materials.

Using climb milling is best for softer materials with less resistance. Meanwhile, conventional milling works well with harder materials, as it avoids creating problematic chips. Choose wisely!

What are the differences in climb and conventional milling?

Climb milling pulls the cutter into the material, while conventional milling pushes it out. This affects the finish and chip removal.

Future Trends in Milling Technology

Innovations affecting climb and conventional milling.. Predictions for the evolution of milling techniques..The world of milling technology is buzzing with exciting changes. Innovations are popping up like popcorn in a microwave! Climb milling and conventional milling tools are evolving, making tasks faster and easier. Machines are getting smarter, using fancy software to help operators make better cuts. Experts predict that automation and AI will soon lead the way, pushing traditional methods to the sidelines. Imagine a robot doing your boring milling while you snack on cookies!

| Innovation | Effect on Milling | Future Prediction |

|---|---|---|

| Smart Technology | Improves precision | Increased efficiency |

| AI Integration | Automates tasks | Reduces human errors |

| Advanced Materials | Enhances tool durability | Longer tool life |

Conclusion

In summary, climb milling tools offer smooth finishes and reduced tool wear, while conventional milling provides stability and control. You should choose based on your project needs. Experiment with both methods to see what works best for you. For more tips, consider reading about milling techniques and tools to enhance your skills. Happy milling!FAQs

What Are The Key Differences Between Climb Milling And Conventional Milling In Terms Of Chip Formation And Cutting Forces?Climb milling and conventional milling are two ways to cut metal or wood. In climb milling, the tool cuts into the material, making chips that are thin at the start and thicker at the end. This usually means the cutting forces are smaller, which helps the tool last longer. In conventional milling, the tool cuts in the opposite direction, making chips that start thick and get thinner. This can create more cutting force and can wear the tool out faster.

In Which Situations Is Climb Milling Preferred Over Conventional Milling, And Why?Climb milling is better when you want a smooth finish on metal or wood. It cuts more efficiently, making your tools last longer. You should use it when the machine can handle it, like with stronger materials. Also, it’s good for making precise shapes and sizes. Overall, it helps you work faster and better.

How Do The Tool Wear Patterns Differ Between Climb Milling And Conventional Milling?In climb milling, the tool moves with the material, which usually makes it last longer. The cutting edge helps pull itself into the work, causing less wear. In conventional milling, the tool moves against the material, leading to more wear and tear. This can make the tool dull faster. So, climb milling is often better for keeping tools sharp.

What Impact Do Climb And Conventional Milling Have On The Surface Finish Of The Machined Components?Climb and conventional milling affect how smooth a surface looks after we cut it. In climb milling, the tool moves with the material, often making a smoother finish. In conventional milling, the tool moves against the material, which can leave a rougher surface. So, if you want a nice finish, climb milling is usually the better choice.

Are There Specific Materials Or Tooling Configurations That Make One Milling Technique More Advantageous Than The Other?Yes, some materials and tools can make one milling technique better than another. For example, hard materials need stronger tools. If you use the right tool, it cuts faster and lasts longer. You also want to match the tool’s shape to the job. This way, you get cleaner cuts and save time.