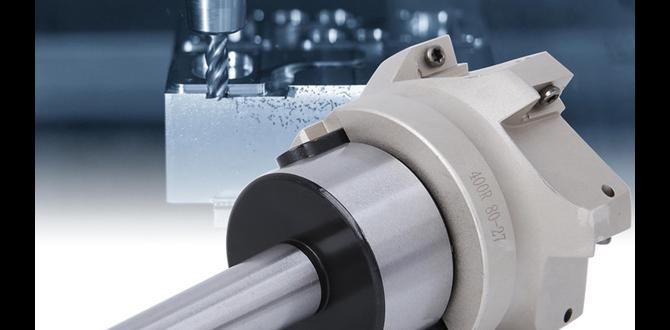

Have you ever wondered how metal pieces are created with such precision? Many people are surprised to learn that a CNC metal lathe bench is the answer to this mystery. This machine helps turn raw metal into beautiful parts with incredible accuracy.

Imagine sitting at a workbench, transforming a simple piece of metal into a unique creation. A CNC metal lathe does just that! By carefully removing material, it shapes metal like a sculptor with clay. What could you create with a machine like this?

Fun fact: CNC stands for Computer Numerical Control. This means that computers guide the lathe, making it easy and fun to use! You don’t need to be an expert to start your journey with a CNC metal lathe bench.

Getting started might seem tricky, but it opens a world of possibilities. Whether you dream of building tools, art, or even toy parts, the CNC metal lathe bench can help you bring those ideas to life!

Essential Guide To Choosing A Cnc Metal Lathe Bench

A CNC metal lathe bench is an essential tool for metalworking projects. Imagine turning raw metal into precise shapes with ease! These benches allow users to create intricate designs for parts and products. This machine combines speed and accuracy, making it perfect for hobbyists and professionals alike. Did you know CNC stands for Computer Numerical Control? This means machines can automate tasks, reducing effort. With a CNC metal lathe bench, you can unleash your creativity and produce amazing results.

Key Features of CNC Metal Lathe Benches

Size and capacity considerations. Control systems and software compatibility.

Choosing the right CNC metal lathe bench is important. Size matters! You need to know how big your workspace is and what machines you’ll use. Consider these points:

- Bench length and width for machine placement.

- Weight capacity for tools and materials.

Another key feature is the control systems. Many benches support different software. Check compatibility to make sure your tools work well with the bench. This ensures smooth operation and better results!

What size should my CNC metal lathe bench be?

The size of your CNC metal lathe bench should fit in your work area while providing enough space for your lathe and tools. Aim for at least 4 to 6 feet in length for most projects.

What type of control systems do CNC metal lathe benches have?

CNC metal lathe benches typically use computer software to control movement. Make sure the bench is compatible with popular programs, like Mach3 or LinuxCNC, for seamless operation.

Benefits of Using a CNC Metal Lathe Bench

Enhanced precision and repeatability in machining. Increased efficiency for small to medium production runs.

Imagine having a new best friend in your workshop! A CNC metal lathe bench makes machining easy-peasy apple squeezy. With this handy tool, you’ll achieve enhanced precision and repeatability that will leave your friends in awe. It’s like having a magic wand that knows exactly what you want every time. Plus, it works faster than your favorite superhero for small to medium production runs. More pieces, less time—no capes required!

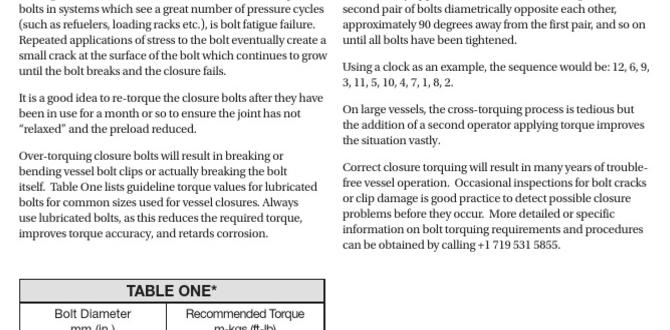

| Benefits | Details |

|---|---|

| Precision | Delivers exact measurements every time. |

| Efficiency | Perfect for quick production of items. |

Choosing the Right CNC Metal Lathe Bench

Factors to consider: budget, workload, and space. Comparison of leading brands and models in the market.

Getting the perfect cnc metal lathe bench is like choosing the right pizza toppings. First up: budget. You don’t want to end up broke like a rusty old tool, right? Next, think about your workload. Are you making tiny parts or giant sculptures? Finally, consider your space. A massive lathe in a tiny garage is like a hippo in a bathroom! Check out leading brands and models in the market for the best fit.

| Brand | Model | Price | Workload Capacity |

|---|---|---|---|

| Brand A | Model 1 | $1,000 | Light |

| Brand B | Model 2 | $1,500 | Medium |

| Brand C | Model 3 | $2,000 | Heavy |

Choosing wisely can save you money and headaches. Remember, a lathe is a long-term investment, so choose a bench that suits your needs!

Essential Accessories for CNC Metal Lathe Benches

Tooling, fixtures, and workholding devices. Maintenance tools and software upgrades.

Setting up a CNC metal lathe bench is fun but also needs some smart choices in accessories. First, let’s talk about tooling. High-quality cutters and tools can save you time and make your work shine like a new penny. Fixtures and workholding devices are also super important; they hold your materials tight, so they don’t play hide-and-seek while you’re cutting. And don’t forget about maintenance tools! They help keep everything in tip-top shape. Oh, and software upgrades are like giving your lathe a brain boost, making it smarter and faster!

| Accessory | Function |

|---|---|

| Tools | Cut materials precisely |

| Fixtures | Secure workpieces |

| Workholding devices | Prevent movement during cutting |

| Maintenance tools | Ensure longevity |

| Software upgrades | Improve performance |

Common Applications for CNC Metal Lathes

Industries that benefit from CNC metal lathes. Examples of products and components manufactured.

CNC metal lathes play a big role in many industries. They help create items daily that we often take for granted. From car parts to medical devices, these machines are like the superheroes of manufacturing. They shape metals with precision that would make a ruler jealous!

| Industry | Product Examples |

|---|---|

| Automotive | Engine blocks, axles |

| Medical | Surgical instruments, implants |

| Aerospace | Turbochargers, landing gear |

So, the next time you ride in a car or visit the doctor, remember that CNC lathes helped make the magic happen. Who knew metal could be so much fun?

Tips for Operating a CNC Metal Lathe Bench Effectively

Best practices for setup and programming. Safety precautions and maintenance routines.

To use a CNC metal lathe bench like a pro, start with the setup and programming. Make sure all settings are correct and the materials are ready. This is like laying out your toys before a fun day of play! Next, think safety first. Wear protective gear and make sure the area is tidy. Did you know that keeping your lathe clean can increase its lifespan? Now, check out this handy table for quick tips:

| Best Practices | Safety Precautions | Maintenance Routines |

|---|---|---|

| Calibrate the machine | Wear goggles and ear protection | Clean after every use |

| Use proper feeds and speeds | Keep hands away from moving parts | Lubricate parts regularly |

| Double-check your program | Work only in well-lit areas | Inspect for wear and tear |

Remember, practice makes perfect, and a little humor makes the day brighter. So, keep those lathes spinning and smiles shining!

Future Trends in CNC Metal Lathe Technology

Innovations in control systems and automation. The impact of AI and IoT on machining practices.

Exciting changes are coming in the world of CNC metal lathes! New control systems are making machines smarter, almost like they have brains. Automation helps these machines work faster and with fewer mistakes. Then, we have AI and the Internet of Things (IoT) stepping in like superhero sidekicks. They connect machines to the internet, helping them share data. Imagine your lathe sending you a text to alert you when it needs a coffee break! That’s modern machining for you!

| Trend | Description |

|---|---|

| Smarter Control Systems | Enhanced programming makes lathes easier to use and more accurate. |

| Automation | Machines now handle tasks more efficiently and with less effort. |

| AI & IoT | They make machines share info and improve their performance. |

Resources for Learning More About CNC Metal Lathes

Online courses and certifications. Community forums and support groups.

If you’re eager to dive into the world of CNC metal lathes, plenty of resources await you! Online courses can teach you everything about programming and operating these machines, even while you munch on your favorite snacks. Plus, certifications can give your skills a shiny stamp of approval. Want some social interaction? Join community forums and support groups. You might find friends who share your love for shavings and chips!

| Resource Type | Description |

|---|---|

| Online Courses | Learn from home with step-by-step guides. |

| Certifications | Boost your resume and skills. |

| Community Forums | Connect with fellow enthusiasts and share tips. |

| Support Groups | Get help and advice from experienced users. |

Conclusion

In conclusion, a CNC metal lathe bench is essential for precision metalworking. It streamlines tasks and improves accuracy. Investing in one can enhance your projects and skills. To get started, explore different models and their features. Practice regularly to master your technique. Keep learning about tools and techniques to make the most of your CNC experience!

FAQs

What Are The Key Features To Look For When Purchasing A Cnc Metal Lathe Bench For Home Use?

When buying a CNC (Computer Numerical Control) metal lathe for home, look for size and weight. Make sure it fits your space and is easy to move. Check its power and speed options; you want something strong for different projects. Look for good safety features to keep you safe while working. Finally, see if it has a user-friendly control panel for easy operation.

How Can You Effectively Maintain And Calibrate A Cnc Metal Lathe Bench To Ensure Its Longevity And Performance?

To keep a CNC metal lathe bench in good shape, you should clean it after each use. Check for loose parts and tighten them if needed. You can oil the moving parts to keep everything running smoothly. Calibrate, or adjust, the machine regularly to make sure it works right. Lastly, always follow the manufacturer’s instructions for best results.

What Types Of Projects Are Best Suited For A Cnc Metal Lathe Bench, And What Materials Can It Work With?

A CNC metal lathe bench is great for making round shapes like rods, pipes, and bowls. You can also create parts for machines and tools. This lathe works best with materials like metal, plastic, and wood. You can use it to make things for school projects or repairs at home.

How Does The Setup Process For A Cnc Metal Lathe Bench Differ From That Of A Traditional Metal Lathe?

Setting up a CNC (Computer Numerical Control) metal lathe is different from a traditional lathe. With a CNC lathe, you need to program it using a computer. This tells the machine what to do. In contrast, a traditional lathe is set up by hand. You adjust the tools yourself and work on the metal directly. This means CNC lathes can be more precise and need less manual work.

What Safety Precautions Should Be Taken While Operating A Cnc Metal Lathe Bench In A Workshop Environment?

When using a CNC metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear snug clothes to avoid getting caught in the machine. Make sure to keep your hands away from moving parts. Always check that tools are secure before starting the machine. Finally, follow all safety rules and listen closely to your teacher or supervisor.