Have you ever wondered how metal parts are made? It’s fascinating! One key tool in this process is the CNC metal lathe. A CNC lathe helps shape metal with precision. But wait, there’s something very important that usually gets overlooked: the chuck key.

What is a chuck key, you ask? It’s the tool that helps hold the metal piece tightly in place. Without it, the metal could slip or spin uncontrollably. Imagine trying to ride a bike with a loose wheel! It just wouldn’t work.

Using a CNC metal lathe without a chuck key can lead to mistakes and wasted time. That’s why understanding this small but mighty tool is vital. Curious about how it all works? Let’s explore the world of CNC lathes and the role of the chuck key in making perfect metal parts.

Understanding The Cnc Metal Lathe Chuck Key Functionality

Have you ever wondered how a CNC metal lathe holds pieces perfectly? The CNC metal lathe chuck key is essential for this job. It helps tighten and loosen the chuck that grips the metal. Without it, you couldn’t easily change materials. Fun fact: some lathe designs let you use a standard wrench instead! Knowing about this tool helps you appreciate the precision of metalworking. Understanding the chuck key’s role can inspire new projects and spark creativity.

What is a CNC Metal Lathe Chuck Key?

Definition and purpose of a CNC metal lathe chuck key. Types of CNC metal lathe chucks that utilize keys.

A CNC metal lathe chuck key is a special tool used to tighten or loosen a chuck on a lathe. This device holds and secures different materials for shaping. Without it, jobs would be messy and unsafe. There are different types of CNC lathe chucks that use keys:

- Self-centering chucks

- Independent jaw chucks

- Expanding chucks

Each type helps in various projects, making work easier and more precise.

What are CNC metal lathe chuck keys used for?

CNC metal lathe chuck keys are used to operate the lathe. They help secure materials in place during the machining process. This ensures better accuracy and safety while working with metal.

Choosing the Right Chuck Key for Your CNC Lathe

Factors to consider: size, compatibility, and material. Common mistakes to avoid when selecting a chuck key.

Selecting the perfect chuck key for your CNC lathe feels like picking the right pizza topping: it can make or break your project! First, consider the size—a key that’s too small may slip away, while a giant one can be unwieldy. Next, check for compatibility with your lathe model. Not every key can fit every lathe, like a cat in a dog park! Lastly, think about the material: sturdier keys usually last longer. Avoid common mistakes like picking a key without checking its specifications. That could lead to some slapstick moments in the workshop!

| Factor | What to Consider |

|---|---|

| Size | Make sure it fits snugly without being too big or small. |

| Compatibility | Check it’s the right match for your lathe model. |

| Material | Opt for durable materials for long-lasting use. |

How to Properly Use a CNC Metal Lathe Chuck Key

Stepbystep instructions for using a chuck key effectively. Safety tips during operation to prevent injury.

Using a cnc metal lathe chuck key is simple if you follow these steps:

- First, check your chuck key for damage.

- Next, insert the key into the chuck securely.

- Turn the key in the direction needed to tighten or loosen.

- After adjusting, remove the key to avoid accidents.

Always remember safety:

- Wear safety glasses to protect your eyes.

- Keep your hands clear of moving parts.

- Work in a well-lit area for better visibility.

Each step ensures smooth operation. Following these tips helps keep you safe while working.

What are key safety tips for using a chuck key?

Always wear safety gear and keep hands away from moving parts. Make sure the area is clear before starting your machine.

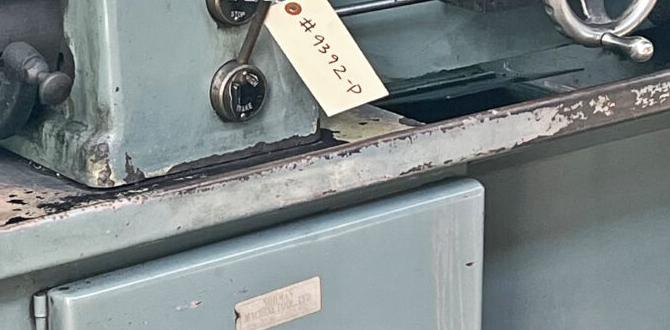

Maintenance of CNC Chuck Keys

Best practices for ensuring longevity and performance. Signs of wear and when to replace your chuck key.

Taking care of your cnc metal lathe chuck key is important for smooth operations. Here are simple ways to ensure it lasts longer:

- Keep it clean and dry.

- Regularly check for cracks or bends.

- Store it in a safe place to avoid damage.

Look for these signs of wear to know when to replace your chuck key:

- Difficulty tightening.

- Visible rust or corrosion.

- Squeaking sounds when used.

Regular checks increase performance and safety. A little care goes a long way!

How often should you check your cnc chuck key?

Check your chuck key once a month for signs of wear. This helps keep your machine running well and prevents accidents.

Common Issues and Troubleshooting

Identifying issues such as slippage or damage. Solutions to common problems related to chuck keys.

Sometimes, things don’t go as planned with your lathe and chuck key. Slippage can turn your project into a wobbling mess. If that key isn’t fitting snugly, it might be damaged! Check for cracks or wear. Solutions? Start by tightening that key! If it’s still acting like a slippery eel, you might need a replacement. Here’s a quick table to help you spot problems and fix them:

| Issue | Solution |

|---|---|

| Chuck key slips | Tighten or replace the key |

| Key shows wear | Get a new key |

| Inconsistent cutting | Check all parts for alignment |

Keep an eye on these issues, and you’ll be turning metal into art like a pro!

Frequently Asked Questions (FAQs)

Answers to common queries about CNC metal lathe chuck keys. Resource recommendations for further learning.

CNC metal lathe chuck keys might seem tricky, but they aren’t so scary! People often ask things like, “What’s a chuck key for?” and “Do I need one for my lathe?” The answer is simple: they tighten and loosen the chuck on the lathe. Without them, you might end up with a flying piece of metal! For more learning, check out some great resources online. Books and videos can make things really clear and fun, just like your favorite cartoons!

| Common Questions | Answers |

|---|---|

| What is a chuck key? | A tool to open or close the chuck on a lathe. |

| Can I use any key? | Not really! Each chuck has its own key size. |

| Why does it matter? | A wrong size can cause chaos and mess! |

Conclusion

In summary, a CNC metal lathe chuck key is essential for operating lathes safely and effectively. It helps you tighten and loosen workpieces. Understanding how to use it boosts your machining skills. We encourage you to practice using a chuck key and explore more about CNC lathes. This knowledge can make your projects more successful and enjoyable!

FAQs

What Are The Different Types Of Cnc Metal Lathe Chucks And How Do They Differ In Terms Of Functionality And Application?

CNC metal lathe chucks hold the metal while it spins. The most common types are three-jaw chucks and four-jaw chucks. Three-jaw chucks grip round objects tightly, making them great for simple shapes. Four-jaw chucks hold different shapes and are better for tricky pieces. Each type works best for certain jobs, depending on the shape of the metal.

How Do You Properly Use A Chuck Key To Ensure Safe And Effective Operation Of A Cnc Metal Lathe?

To use a chuck key safely, first make sure the lathe is turned off. Place the chuck key into the holes on the chuck, which holds the tool. Turn the key to tighten or loosen the tool. Always remove the chuck key after you finish. This prevents accidents and helps you work safely.

What Are The Common Issues That Can Arise With Chuck Keys On Cnc Metal Lathes, And How Can They Be Resolved?

Chuck keys can sometimes get lost, which makes it hard to tighten or loosen the chuck. You can fix this by keeping the chuck key in a special spot on the machine. Sometimes, the chuck key can get stuck. If that happens, gently wiggle it until it comes free. Lastly, the chuck key might not fit perfectly, so make sure it matches your lathe correctly.

How Do You Determine The Appropriate Size Of A Chuck Key For A Specific Cnc Lathe Chuck?

To find the right size of a chuck key for a CNC lathe chuck, you need to check a few things. First, look at the chuck itself. There should be a size listed on it. Next, measure the hole where the key fits. It should match the size of your key. You can also ask a worker or check the manual for help.

What Maintenance Practices Are Recommended For Chuck Keys To Extend Their Lifespan And Ensure Optimal Performance?

To keep your chuck key in good shape, always clean it after use. Wash off any dirt or chips with warm soapy water. Dry it well to prevent rust. Store it in a dry place where it won’t get damaged. Lastly, check it for any wear and tear before you use it.