Have you ever watched a metal lathe in action? It’s like magic! A block of metal turns and transforms into something useful. But what makes this process so smooth and precise? The answer lies in the cnc metal lathe compound rest.

This special part helps the lathe cut metal easily. It slides and moves, letting you shape the metal just right. Imagine trying to carve a statue from a rock. You need the right tools to get the job done. The compound rest is one of those essential tools.

Did you know that the first lathes date back thousands of years? Even back then, craftsmen used simple designs to create beautiful objects. Today, cnc lathes are much more advanced. They make it easier to work with metal.

Have you ever wanted to create your own metal project? Understanding the cnc metal lathe compound rest could be your first step. With the right knowledge, you can turn your ideas into reality!

Cnc Metal Lathe Compound Rest: Essential Guide And Tips

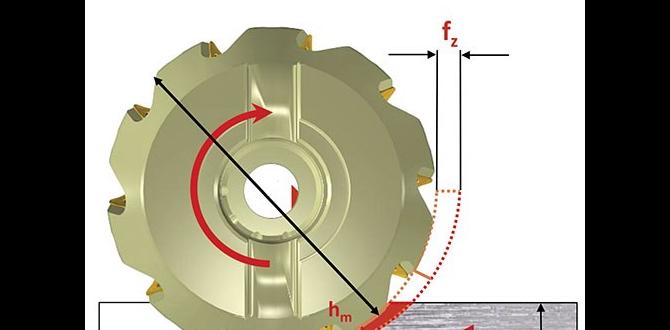

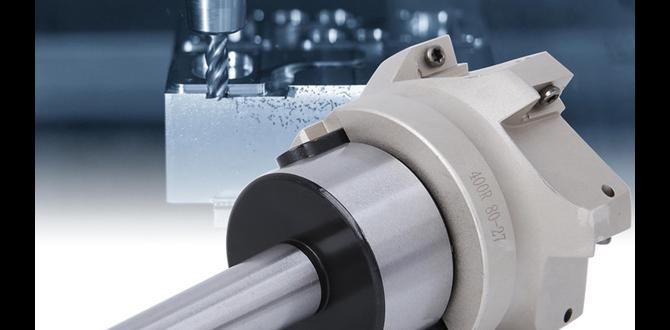

The CNC metal lathe compound rest is a vital part of machining. It helps position the cutting tool accurately, ensuring precise cuts. This tool moves in two directions, allowing for intricate designs and details in metalworking. Think about crafting a decorative piece; a stable compound rest makes all the difference. Fun fact: many skilled machinists often say a solid compound rest can create pieces that seem impossible to achieve. Want to try precise metal shaping? The compound rest is your key tool!

Benefits of Using a Compound Rest in CNC Machining

Enhanced precision and control for complex cuts. Increased versatility for machining various materials.

Using a compound rest gives you superpowers in CNC machining! With it, you gain enhanced precision, allowing for complex cuts that would make a straight line jealous. Need a curve? No problem! Plus, it offers increased versatility for handling various materials like wood, plastic, and metal. Imagine being able to turn a block of steel into a fancy art piece without breaking a sweat. The compound rest makes that happen, while you look like a machining wizard.

| Benefit | Description |

|---|---|

| Precision | Allows for accurate and complex cuts. |

| Versatility | Works with different materials effortlessly. |

Common Features of CNC Metal Lathe Compound Rests

Detailed description of adjustable angles and movements. Materials and construction quality contributing to durability.

The cnc metal lathe compound rest is essential for precise work. It offers adjustable angles and movements. This means you can tilt or rotate the tool to fit the project perfectly. Such flexibility allows for various designs and cuts.

Durability comes from using strong materials. High-quality steel or aluminum ensures the rest lasts a long time. Good construction means fewer repairs. This way, you can focus on creating instead of fixing.

- Adjustable angles: Helps in precise cutting.

- Strong materials: Provides better durability.

- Easy movements: Ensures smooth operation.

What makes a cnc metal lathe compound rest durable?

Durability comes from high-quality materials, like steel or aluminum, and solid construction.

Different Types of Compound Rests

Comparison of fixed vs. swiveling compound rests. Specialized compound rests for specific machining tasks.

When comparing compound rests, you have fixed and swiveling options. Fixed rests hold the tool steady like an old friend. Swiveling rests can twist and turn, offering flexibility for tricky cuts. It’s like choosing between a sturdy chair and a fun swivel seat at school!

There are specialized compound rests crafted for specific machining tasks, making it easier to achieve perfect results. Think of them as superhero tools, equipped for different missions. Some are great for fine details, while others work wonders on bigger projects.

| Type | Advantages | Disadvantages |

|---|---|---|

| Fixed Compound Rest | Sturdy, reliable | No flexibility for angles |

| Swiveling Compound Rest | Flexible, versatile | Can be less stable |

| Specialized Rests | Targeted for tasks | May not fit all machines |

Choosing the right one depends on your project’s needs. It’s like picking the right outfit for a party—comfort or style!

How to Set Up a CNC Metal Lathe Compound Rest

Stepbystep guide on installation and calibration. Tips for aligning the compound rest for optimal performance.

Setting up your CNC metal lathe compound rest can be as easy as pie—assuming you don’t confuse your screwdrivers with a pastry fork! First, install the compound rest onto the cross-slide. Make sure it’s snug, not loose like your favorite pair of socks after laundry day. Next, calibrate it by adjusting the angle and position to ensure it moves freely. For a perfect align, check if the tool holder is level; this makes cutting smooth and less whiny. Remember, a happy machine is a productive machine!

| Step | Action |

|---|---|

| 1 | Install the compound rest to the cross-slide. |

| 2 | Calibrate the angle and position to ensure free movement. |

| 3 | Align the tool holder to make it level. |

Maintenance Tips for CNC Metal Lathe Compound Rests

Regular cleaning and lubrication practices. Troubleshooting common issues and when to seek repairs.

Keeping your CNC metal lathe compound rest in top shape is like feeding a pet; it needs regular care! Clean it often to remove dust and debris. A little lubrication goes a long way, like oiling squeaky hinges. Having fun with your tools is great, but don’t ignore signs of trouble—like strange noises or rough movement. If things get too weird, it’s time to call a pro. After all, even the best machines need a doctor sometimes!

| Issue | Solution |

|---|---|

| Sticking parts | Lubricate and clean |

| Strange noises | Inspect for damage |

| Inaccurate cuts | Check settings |

How to Troubleshoot Common Compound Rest Issues

Identifying signs of wear or misalignment. Solutions for restoring functionality and precision.

Watch out for signs that your compound rest is getting tired. If you notice strange noises, wobbling, or a lack of precision while working, it’s time to investigate. Look for wear or misalignment. A quick check can save you a lot of headaches! If you find issues, *fixing them can be simple*. Tighten screws or realign parts. Remember, a happy lathe makes for happy projects! Here’s a handy table to help you spot and solve common problems:

| Issue | Signs | Solution |

|---|---|---|

| Wobbling | Uneven cuts, shaking | Realign and tighten |

| Noise | Grinding, squeaking | Lubricate parts |

| Lack of Precision | Inconsistent measurements | Check for wear, recalibrate |

Real-World Applications of CNC Metal Lathe Compound Rests

Examples of industry use cases in manufacturing. Custom projects and creative uses in hobbyist machining.

CNC metal lathe compound rests are like magic tools in many industries. They help create precise shapes in manufacturing, like the parts inside your favorite toys or appliances. For example, car makers love them for making engine components that fit perfectly together. Hobbyists stumble upon their wonders too, crafting everything from custom furniture knobs to shiny jewelry. Imagine turning a simple piece of metal into something fabulous with just a twist! Even the most serious engineers can admit—it’s satisfying to see a project come to life.

| Industry Use Case | Example | Hobbyist Project |

|---|---|---|

| Automotive | Engine Parts | Custom Knobs |

| Aerospace | Brackets and Components | Jewelry Making |

| Electronics | Casings for Gadgets | Unique Penholders |

Future Trends in CNC Technology and Compound Rests

Innovations in design and material science. Predictions for the evolution of CNC machining practices.

New designs and materials are sprouting in CNC technology, much like wildflowers in spring. Engineers are getting creative, using advanced composites and lightweight metals to improve tools like the cnc metal lathe compound rest. Predictions suggest that future CNC practices may lean towards more automation and smarter software. This means less human error and possibly more coffee breaks for machinists!

| Innovation | Description |

|---|---|

| Advanced Materials | Using lightweight and durable materials for better performance. |

| Smart Software | Aiming for more automation to reduce mistakes. |

Conclusion

In summary, the CNC metal lathe compound rest supports precise machining. It helps you control the tool’s position for better accuracy. Understanding its parts and functions is essential for successful projects. We encourage you to explore tutorials and guides on using a CNC lathe. This knowledge will boost your confidence and skills in metalworking. Happy machining!

FAQs

What Is The Function Of The Compound Rest In A Cnc Metal Lathe?

The compound rest on a CNC (Computer Numerical Control) metal lathe helps you cut shapes at different angles. It moves side to side and up and down. This allows you to make things like cones or grooves easily. You can adjust it to get the exact cut you want. It makes your work more accurate and creative!

How Does The Design Of A Compound Rest Influence The Precision Of Machining Operations?

The design of a compound rest helps us control the tool’s position better. This means we can cut materials more accurately. If the rest is solid and stable, it reduces mistakes. With a good design, we can make precise shapes and sizes in our work. Overall, it helps us do a better job when we’re machining.

What Are The Key Differences Between Manual And Cnc-Operated Compound Rests?

Manual compound rests need you to move them by hand. You control the tools and how they work. CNC-operated compound rests use a computer to do the moving for you. This makes them faster and often more precise. So, one is hands-on while the other is high-tech.

How Can Users Modify Or Adjust The Compound Rest For Specific Machining Tasks Or Angles?

You can adjust the compound rest by turning its handles. This lets you change the angle of the tool. First, loosen the lock knobs, so the rest can move easily. Then, set the angle you need for your task. Finally, tighten the knobs again to keep it in place.

What Materials Are Commonly Used In The Construction Of Compound Rests For Cnc Metal Lathes, And How Do These Materials Affect Their Performance?

Common materials used for compound rests in CNC (Computer Numerical Control) metal lathes are metal and high-strength plastic. Metal is very strong and helps the machine work well. High-strength plastic is lighter but still durable. Using these materials can make the CNC lathe more accurate and easier to move. This helps us create better metal parts quickly.