Have you ever watched a machine spin and shape metal? It’s fascinating! The magic often happens thanks to a CNC metal lathe drive system. This drive system is like the heartbeat of the lathe. It powers the machine and makes it work smoothly.

Picture this: a block of metal sits on the lathe. With the right drive system, that block can turn into anything from a simple bolt to a complex part for a car. Isn’t it amazing how this system can help create so many objects we use every day?

But what makes a good CNC metal lathe drive system? How does it help the machine? These questions are key to understanding how these machines operate. Let’s dive deeper into the world of CNC lathes and discover more about their incredible drive systems!

Cnc Metal Lathe Drive System: Enhancing Precision And Efficiency

A CNC metal lathe drive system powers the machine to shape metal. It uses motors and gears to turn workpieces at high speeds. Have you ever wondered how precise cuts are made? The drive system helps achieve that perfection. This system also enhances speed and efficiency. It makes it easier to create complex designs. For hobbyists or professionals, understanding this system can boost your skills. Think about how much easier your projects could be with the right drive system!

What is a CNC Metal Lathe Drive System?

Definition and purpose of a CNC metal lathe drive system. Components and mechanics involved in the drive system.

A CNC metal lathe drive system functions like the engine of a race car. It powers the machine to cut and shape metal into precise parts. The main components include the motor, which drives the tool, and the gear mechanism, which helps control speed and rotation. Think of it as a dance: the motor leads, and the gears follow, ensuring everything moves smoothly.

| Component | Function |

|---|---|

| Motor | Powers the tool for cutting |

| Gear Mechanism | Controls speed and direction |

| Control System | Directs the cutting process |

In short, this drive system is vital for creating everything from tiny screws to big metal parts. Without it, your favorite robot would be sitting in a pile of metal scraps, probably asking, “What happened to my cool body?”

Key Features of an Effective CNC Metal Lathe Drive System

Discussion on torque, speed, and precision. Importance of reliability and durability in a drive system.

An effective drive system in a CNC metal lathe provides important benefits. It focuses on three main features: torque, speed, and precision. High torque gives machines more power. Fast speed helps complete tasks quickly. Precision ensures every cut is accurate.

Reliability and durability are also crucial. A strong drive system lasts longer and works better over time. This reduces the chance of breakdowns.

- Power from high torque

- Fast speeds save time

- Precision makes accuracy possible

- Reliable systems reduce repairs

- Durable parts enhance longevity

What are the benefits of precision in CNC metal lathe drive systems?

Precision ensures accuracy in every cut, which leads to better quality products. This saves time and money in production.

Benefits of Using CNC Metal Lathe Drive Systems

Enhanced productivity and efficiency in machining processes. Improved surface finish and dimensional accuracy.

Using a CNC metal lathe drive system can really boost how much work you get done! This tech magic speeds up machining processes, letting machines work faster and smarter. You’ll notice improved surface finishes that look like they were polished by a fancy jeweler. Plus, with better dimensional accuracy, your parts will fit together like puzzle pieces. It’s like having a fun robot friend who never gets tired of helping you, except you might have to pay it with some coolant!

| Benefit | Explanation |

|---|---|

| Enhanced Productivity | Faster machining means more parts made in less time. |

| Improved Surface Finish | Parts look shiny and smooth, just like new toys! |

| Dimensional Accuracy | Everything fits perfectly, no awkward wobbles! |

Factors to Consider When Selecting a CNC Metal Lathe Drive System

Power requirements and machine compatibility. Budget considerations and cost versus performance analysis.

Choosing the right drive system for your CNC metal lathe can feel a bit like picking a pet. You want something that fits just right! First, think about power requirements and machine compatibility. Make sure your system has enough oomph to handle your projects. Then, there’s the budget. Everyone loves a good deal! Remember, balancing cost with performance is key. Sometimes, spending a little more can save you a lot of headaches later on.

| Factor | Detail |

|---|---|

| Power Requirements | Match the drive’s power to your machine’s needs. |

| Machine Compatibility | Ensure parts fit together like puzzle pieces. |

| Budget | Find a balance between cost and features. |

| Cost vs. Performance | Sometimes you get what you pay for, so choose wisely! |

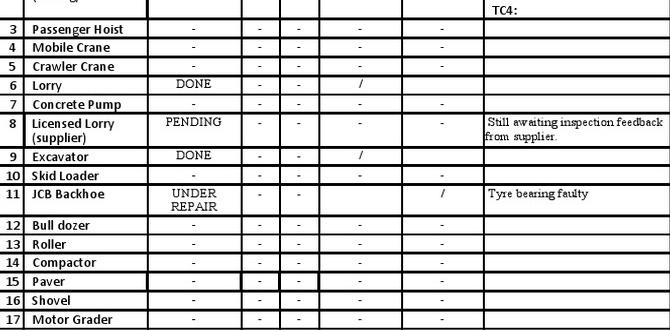

Maintenance and Troubleshooting for CNC Metal Lathe Drive Systems

Recommended maintenance practices to ensure longevity. Common issues and troubleshooting tips for drive systems.

Keeping your CNC metal lathe drive system in top shape is easier than you’d think. Regularly clean the drive components and check for wear and tear. Lubrication is key; think of it as giving your machine a good oil massage! Common issues include strange noises or erratic movements. For troubleshooting, always check the power supply and connections first. If those are okay, a look at the belts and pulleys might be in order!

| Issue | Possible Cause | Troubleshooting Tip |

|---|---|---|

| Strange noises | Worn bearings | Inspect and replace bearings. |

| Inconsistent speed | Loose belts | Tighten or replace belts. |

| Sudden stops | Power supply issue | Check connections and fuses. |

Future Trends in CNC Metal Lathe Drive Technologies

Innovations and advancements in drive system technologies. Impact of automation and smart technologies on drive systems.

New drive systems for CNC metal lathes are changing the game. Innovations like advanced servo motors make machining faster and more accurate. Automating these systems allows for better precision and control. Smart technologies use sensors and AI to monitor processes in real-time. This leads to less waste and higher quality. Drive systems are getting smarter, and that’s good news for everyone in manufacturing.

What are the latest trends in CNC metal lathe drive technologies?

Recent trends include:

- Eco-friendly power systems

- Enhanced automation features

- Integration of IoT

These advancements aim to improve efficiency while reducing energy costs.

Conclusion

In summary, CNC metal lathe drive systems are essential for precision machining. They control the speed and direction of the lathe, ensuring accuracy in shaping metal. Understanding these systems helps you appreciate their role in manufacturing. If you’re interested, consider exploring more about CNC technology or even trying it out yourself. You’ll discover a whole new world of possibilities!

FAQs

What Are The Key Components Of A Cnc Metal Lathe Drive System, And How Do They Work Together To Ensure Precise Machining?

A CNC metal lathe drive system has a few key parts. First, there’s a motor that gives power. This motor turns the spindle, which holds the metal piece. Then, we have gears that help control the speed and direction. All these parts work together to make sure we cut the metal accurately and smoothly. This teamwork helps us make precise shapes and designs.

How Does The Choice Of Motor Type (Stepper Vs. Servo) Affect The Performance And Accuracy Of A Cnc Metal Lathe Drive System?

When we choose a motor for a CNC metal lathe, we can pick either a stepper or a servo motor. A stepper motor moves in small steps, which helps with accuracy but can be slower. A servo motor is faster and can adjust better, making it great for smooth movements and more power. This means a servo motor usually makes the CNC lathe work faster and more accurately than a stepper motor. So, the type of motor you pick really changes how well the machine works!

What Factors Should Be Considered When Selecting A Power Supply For A Cnc Metal Lathe Drive System?

When choosing a power supply for a CNC metal lathe, think about the voltage and current it needs to run. You should also check how much power it uses while working. Make sure the supply matches your machine’s requirements. Finally, consider how safe it is to use, so we can avoid accidents.

How Can Maintenance And Regular Checks Of The Drive System Improve The Longevity And Reliability Of A Cnc Metal Lathe?

Taking care of the drive system in a CNC (Computer Numerical Control) metal lathe is very important. When we check it regularly, we can spot problems early. This helps to avoid bigger issues that can break the machine. By keeping it clean and well-oiled, the lathe will work better and last longer. Good maintenance means we can count on it to do its job without sudden failures.

What Role Do Software And Control Algorithms Play In Optimizing The Performance Of A Cnc Metal Lathe Drive System?

Software and control algorithms are like smart helpers for a CNC metal lathe. They tell the machine how fast to spin and how to move. This makes sure the metal is shaped perfectly. With good software, the lathe works better and saves time. It helps us make things more accurately and efficiently.