Have you ever wondered how tiny gears are made? It’s fascinating to think about how much work goes into creating something so small yet so important. One of the machines that help create these gears is called a CNC metal lathe. This powerful tool shapes and cuts metal into precise, detailed parts.

CNC stands for Computer Numerical Control. This means that a computer controls the movements of the machine. Because of this technology, it’s easier to make gears that fit perfectly. Imagine a world without these precise gears. Many of our daily tools, toys, and even car engines rely on them.

Did you know that CNC metal lathes can create gears in many different sizes? From tiny clock gears to large industrial gears, these machines do it all. The next time you see a gear, think about the CNC metal lathe that helped make it. It’s a blend of art and science found in workshops all over the world!

Understanding Cnc Metal Lathe Gear: Key Features And Benefits

CNC Metal Lathe Gear

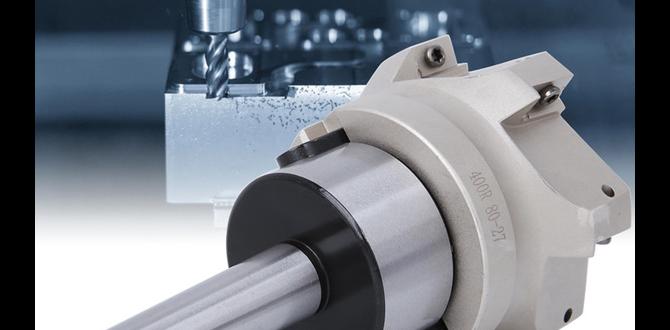

CNC metal lathe gear plays a crucial role in precision machining. These gears help shape and cut metal into desired forms. Did you know that the right gear can make a massive difference in the quality of your work? Understanding how gears interact in a CNC lathe can boost efficiency and accuracy. Proper maintenance of these gears is essential, too. A small issue can lead to bigger problems down the road. Make sure to choose the best gear for your projects!Understanding CNC Metal Lathes

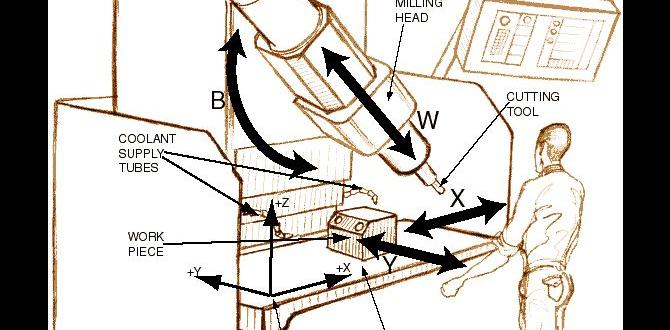

Definition and functionality of CNC metal lathes. Importance of CNC technology in metalworking.CNC metal lathes are special machines that shape metal into useful items. They use computer programs to control movements. This makes them very precise. With CNC technology, workers can create complex designs quickly and correctly. The importance of this technology in metalworking is huge. It helps save time, reduce errors, and improve quality. Many industries rely on CNC lathes for production.

- They speed up the manufacturing process.

- They allow for intricate designs that hand tools can’t manage.

- They improve safety by minimizing human error.

What is the role of CNC technology?

CNC technology allows machines to be more precise and efficient. It helps in creating many products like gears and parts for cars. This boosts productivity in factories.

Benefits of Using CNC Metal Lathe Gears

Enhanced precision and accuracy in machining. Improved efficiency and reduced operational costs.CNC metal lathe gears provide many benefits. They allow for enhanced precision in machining. This means parts fit together better. It also leads to improved efficiency. Machines work faster and save time. This reduces operational costs, making production cheaper. Companies can produce high-quality work without wasting materials or money.

What are some advantages of CNC metal lathe gears?

Using CNC metal lathe gears can help you by:

- Creating parts with exact measurements.

- Saving time during production.

- Lowering material waste.

- Reducing the need for manual labor.

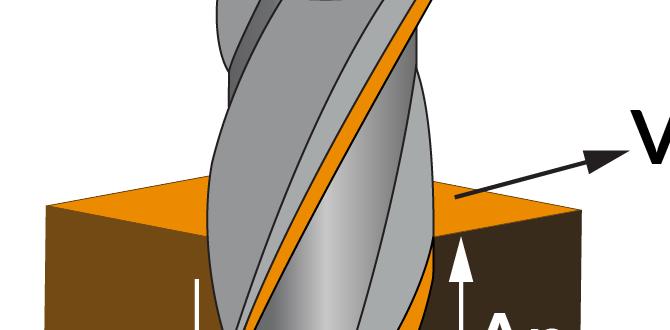

Key Components of CNC Metal Lathe Gears

Detailed analysis of critical gear components. Impact of gear design on machine performance.Understanding the parts of cnc metal lathe gears can help us see how machines work better. Each gear plays a vital role. Design matters a lot; it affects how well the machine performs. Here are some important parts:

- Teeth: They help gears connect and transfer power efficiently.

- Material: Strong materials ensure durability and reduce wear.

- Size: The size of gears can change speed and precision.

Clever designs can lead to smoother operations and higher accuracy. Knowing about these details can make you appreciate how machines create our world!

How does gear design affect machine performance?

The design impacts machine effectiveness. A well-designed gear leads to smoother movements and increased lifespan. It helps reduce errors. A bad design can make machines noisy and slow. Good design is crucial for success!

Maintenance and Care for CNC Metal Lathe Gears

Best practices for gear maintenance and troubleshooting. Signs of wear and when to replace gears.Keeping your CNC metal lathe gears in good shape is important. Regular maintenance helps them last longer. Check them for dirt or damage. Clean them with a soft cloth. Also, listen for strange noises. These can be signs of wear. Look for:

- Cracks or chips on the gears

- Increased vibrations during use

- Unusual sounds when operating

If any issues appear, you may need to replace the gears. Regular checks can save time and money!

What are the signs that you need to replace CNC metal lathe gears?

Common signs include visible cracks, strange noises, and increased vibrations. Check your gears often!

Choosing the Right CNC Metal Lathe Gear

Factors to consider when selecting gears (size, weight, load capacity). How to match gear specifications to machining requirements.Finding the right gear for a CNC metal lathe is key. First, think about the size. It must fit your machine perfectly. Next, consider the weight. A heavy gear can handle more pressure. Lastly, check the load capacity. Make sure it can lift the items you will be working on. Matching gear specs to your needs can help you work better and faster.

What are key factors in selecting CNC metal lathe gears?

Three main factors are size, weight, and load capacity.

1. Size

- Choose gears that match your lathe’s dimensions.

2. Weight

- Heavier gears often last longer and support greater loads.

3. Load Capacity

- Ensure it can handle the materials you will use.

In the world of CNC machining, selecting the right gear can make a big difference. A well-chosen gear can boost productivity and improve results.

Advancements in CNC Metal Lathe Gear Technology

Latest innovations in gear design and materials. The future of CNC metal lathe technology and its implications for gear development.CNC metal lathe gear technology is zooming ahead like a race car on a track. Recent innovations have led to better gear designs and stronger materials. Think of gears that are lighter but tougher, like a superhero in the metal world! Future advancements promise faster production and improved accuracy. This means smoother operations and more efficient machines. Gear development will become faster and smarter, almost as if they have a brain of their own.

| Innovation | Benefit |

|---|---|

| Advanced materials | Lighter and stronger gears |

| Smart technology | More efficient performance |

| Automated processes | Faster production |

Common Issues and Solutions in CNC Metal Lathe Gear Operations

Typical problems encountered during machining. Troubleshooting techniques and preventive measures.CNC metal lathes help create parts, but they can have issues. Some common problems during machining include irregular cuts, vibrations, and tool wear. These can happen due to improper settings or dull tools. Here are some troubleshooting tips:

- Check tool sharpness regularly.

- Ensure precise measurements.

- Use the correct speed and feed rates.

Preventive measures, like regular maintenance, can keep operations smooth. It helps to regularly inspect the equipment. This ensures your CNC metal lathe runs efficiently and produces quality parts.

What are typical problems in CNC machining?

Typical problems in CNC machining include bad surface finish, tool breakage, and noise. Addressing these issues early can save time and money.

Real-World Applications of CNC Metal Lathe Gears

Industries that utilize CNC metal lathes and gears. Case studies showcasing successful implementations.Many industries rely on CNC metal lathes and gears to keep things running smoothly. For example, in the automotive sector, these tools help create precise engine parts. Without them, your car might just be a fancy lawn ornament! A case study at a leading car manufacturer showed a 30% increase in production speed after they upgraded their CNC machinery. Imagine a world where your car wasn’t made with love, but with the precision of a robot chef.

| Industry | Key Benefits |

|---|---|

| Automotive | Higher precision and faster production |

| Aerospace | Lightweight components for fuel efficiency |

| Manufacturing | Cost-effective mass production |

In the aerospace industry, these gears are essential for crafting lightweight parts that help save fuel. So, while you’re soaring through the skies, think of the CNC machines making it possible.

Conclusion

In conclusion, a CNC metal lathe gear is an essential tool for precise metal shaping. It helps you create detailed parts faster and with more accuracy. Understanding how it works can improve your projects. Explore more about CNC technology and its benefits. You can discover more techniques and tips to master your skills. Let’s keep learning together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Cnc Metal Lathe Gears:Sure! Here are five questions about CNC metal lathe gears: 1. What is a CNC metal lathe? A CNC metal lathe is a machine that helps us shape metal. It uses a computer to guide the cutting tool. 2. How do gears work on a lathe? Gears help turn the metal piece in different ways. They make sure the metal spins at the right speed. 3. Why are gears important for cutting metal? Gears help control the speed and movement. This lets us make precise cuts and shapes. 4. Can you change gears on a CNC lathe? Yes, you can change gears to adjust the speed or power. This helps in making different types of cuts. 5. What materials can we use with a CNC metal lathe? We can use metals like steel and aluminum. These materials are strong and easy to shape.

Sure! Just ask me your question, and I’ll provide a simple answer for you.

What Are The Key Components Of A Cnc Metal Lathe And How Do They Interact To Produce Precision Parts?A CNC metal lathe has several important parts. The bed holds everything in place. The spindle spins the metal part very fast. The cutting tool moves in and out to shape the metal. All these parts work together to create smooth and accurate shapes. This teamwork helps us make precise parts for machines and other things.

How Do Gear Ratios Affect The Performance And Capabilities Of A Cnc Metal Lathe?Gear ratios change how fast and powerful a CNC metal lathe works. A high gear ratio means the lathe turns quickly, great for light tasks. A low gear ratio gives more power, perfect for tough jobs. So, depending on what you want to do, the gear ratio helps you pick the right speed and strength!

What Are The Common Materials Used For Making Gears In Cnc Metal Lathes, And How Do They Impact The Machining Process?Common materials for making gears in CNC (Computer Numerical Control) metal lathes include steel, aluminum, and plastic. Steel is strong and lasts a long time. Aluminum is lighter and easier to shape. Plastic is cheaper but not as strong. The choice of material affects how easy or hard it is to make the gears and how well they work together.

How Can One Optimize The Programming And Setup Of A Cnc Metal Lathe For Gear Manufacturing?To make a CNC metal lathe work better for making gears, you can follow a few steps. First, you should carefully design the gear shape on a computer. Next, you need to set up the machine so it can move in the right ways. This includes using the right tools and speeds for cutting the metal. Finally, you can run tests to check if the gears are made correctly and adjust as needed.

What Are The Advantages Of Using A Cnc Metal Lathe For Gear Production Compared To Traditional Gear-Making Methods?Using a CNC (Computer Numerical Control) metal lathe for making gears has many advantages. First, it works really fast, so we can make more gears in less time. Second, it’s very accurate, which means the gears fit together better and last longer. Third, a CNC lathe can make different shapes easily, so we can create many types of gears without much effort. Overall, it makes gear-making easier and better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Cnc Metal Lathe Gears:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about CNC metal lathe gears: 1. What is a CNC metal lathe? A CNC metal lathe is a machine that helps us shape metal. It uses a computer to guide the cutting tool. 2. How do gears work on a lathe? Gears help turn the metal piece in different ways. They make sure the metal spins at the right speed. 3. Why are gears important for cutting metal? Gears help control the speed and movement. This lets us make precise cuts and shapes. 4. Can you change gears on a CNC lathe? Yes, you can change gears to adjust the speed or power. This helps in making different types of cuts. 5. What materials can we use with a CNC metal lathe? We can use metals like steel and aluminum. These materials are strong and easy to shape.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask me your question, and I’ll provide a simple answer for you.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Cnc Metal Lathe And How Do They Interact To Produce Precision Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A CNC metal lathe has several important parts. The bed holds everything in place. The spindle spins the metal part very fast. The cutting tool moves in and out to shape the metal. All these parts work together to create smooth and accurate shapes. This teamwork helps us make precise parts for machines and other things.”}},{“@type”: “Question”,”name”: “How Do Gear Ratios Affect The Performance And Capabilities Of A Cnc Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratios change how fast and powerful a CNC metal lathe works. A high gear ratio means the lathe turns quickly, great for light tasks. A low gear ratio gives more power, perfect for tough jobs. So, depending on what you want to do, the gear ratio helps you pick the right speed and strength!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used For Making Gears In Cnc Metal Lathes, And How Do They Impact The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common materials for making gears in CNC (Computer Numerical Control) metal lathes include steel, aluminum, and plastic. Steel is strong and lasts a long time. Aluminum is lighter and easier to shape. Plastic is cheaper but not as strong. The choice of material affects how easy or hard it is to make the gears and how well they work together.”}},{“@type”: “Question”,”name”: “How Can One Optimize The Programming And Setup Of A Cnc Metal Lathe For Gear Manufacturing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a CNC metal lathe work better for making gears, you can follow a few steps. First, you should carefully design the gear shape on a computer. Next, you need to set up the machine so it can move in the right ways. This includes using the right tools and speeds for cutting the metal. Finally, you can run tests to check if the gears are made correctly and adjust as needed.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Cnc Metal Lathe For Gear Production Compared To Traditional Gear-Making Methods?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a CNC (Computer Numerical Control) metal lathe for making gears has many advantages. First, it works really fast, so we can make more gears in less time. Second, it’s very accurate, which means the gears fit together better and last longer. Third, a CNC lathe can make different shapes easily, so we can create many types of gears without much effort. Overall, it makes gear-making easier and better!”}}]}