Have you ever wondered how metal parts get their perfect shape? Imagine a machine that can do this for you. That’s where the CNC metal lathe comes in. It is a powerful tool that shapes metal using a special part called a lead screw.

But what exactly is a lead screw? It’s like a magic wand that helps the lathe move smoothly. The lead screw helps make precise cuts. With it, small errors turn into perfectly crafted projects.

Did you know that the lead screw has been used for decades? Yes, it has a rich history in helping machines work better. Many people love to use CNC lathes because they save time and effort. Think about building your own projects. Could a CNC metal lathe help you bring your ideas to life?

A CNC metal lathe can be your best friend in the workshop. In this article, we will explore how the lead screw works and why it is so important. Get ready to dive deeper into the world of metal shaping!

Understanding Cnc Metal Lathe Lead Screw: Functions And Benefits

The CNC metal lathe’s lead screw is vital for precise movement. It translates motor action into smooth, linear motion. Have you ever wondered how a machine can make such accurate cuts? This simple yet crucial part allows the lathe to position tools perfectly. A well-maintained lead screw can enhance machining quality and life span. It’s fascinating how this small component plays a key role in creating everything from intricate parts to large metal pieces.

Understanding CNC Metal Lathes

Definition and functionality of CNC metal lathes. Importance of lead screws in CNC operations.

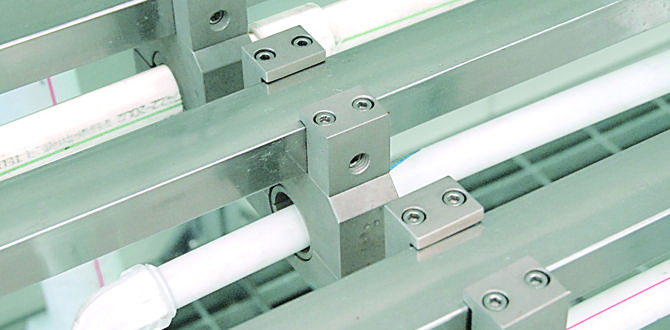

CNC metal lathes are machines that shape metal parts. They use a computer to control the tools. This makes them precise and efficient. One important part in these lathes is the lead screw. It helps move the tool smoothly along the metal. This leads to better cuts and designs.

What is the role of lead screws in CNC operations?

The lead screw is key in CNC machines. It ensures the tool moves correctly. This enhances accuracy and productivity. Without it, making complex shapes would be hard. Precision is crucial when working with metals.

The Role of Lead Screws in CNC Machining

How lead screws influence precision and accuracy. Comparison of lead screws with other drive mechanisms.

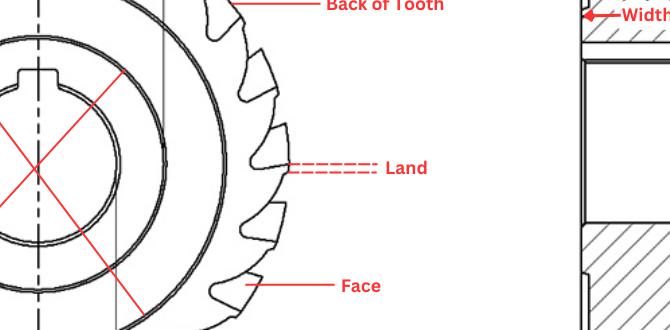

Lead screws are like the superheroes of CNC machining. They help machines move with precision and accuracy. When a lead screw turns, it moves the part being worked on exactly where it needs to go. This means the finished product fits perfectly, like a puzzle piece! Compared to other drive systems, lead screws shine in stability and less noise. Want to hear a funny fact? If lead screws were on a reality show, they’d win “most reliable!”

| Drive Mechanism | Precision | Noise Level |

|---|---|---|

| Lead Screw | High | Low |

| Ball Screw | Very High | Medium |

| Belt Drive | Medium | High |

In short, lead screws are great for keeping CNC machines on point and noise-free, making them the unsung heroes of metal lathe operations!

Factors to Consider When Choosing a Lead Screw

Material and durability characteristics. Thread pitch and its impact on performance.

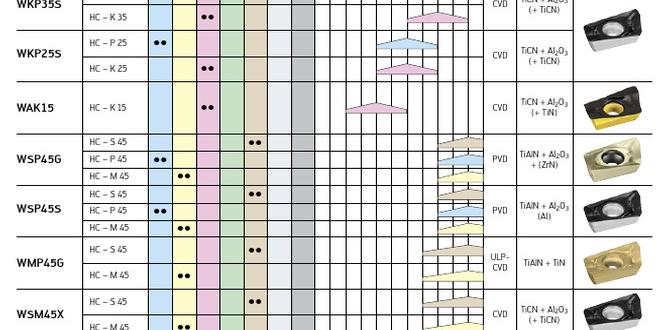

Choosing a lead screw can feel like picking a favorite ice cream flavor – so many options! First, the material matters. Strong materials like stainless steel last longer and handle tough jobs. Next, consider the thread pitch. This affects how smooth your machine runs. A fine pitch gives precision, while a coarse one can handle heavy loads better. So, think about what you need more – finesse or muscle!

| Attribute | Fine Thread Pitch | Coarse Thread Pitch |

|---|---|---|

| Performance | More precision | Better load handling |

| Durability | Wears out faster | Lasts longer |

Maintaining CNC Metal Lathe Lead Screws

Regular maintenance practices for longevity. Common issues and troubleshooting tips.

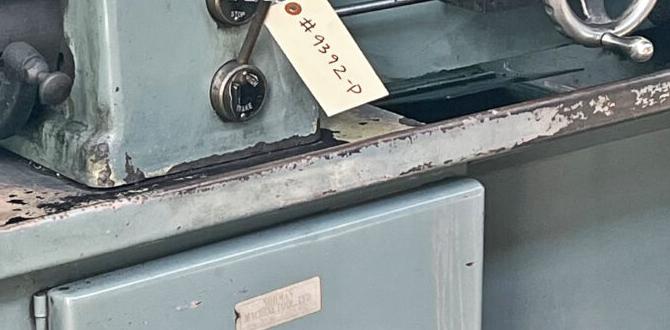

To keep your CNC metal lathe lead screws running smoothly, regular maintenance is key! Inspect them often to spot any wear and tear, which is like checking your favorite video game for bugs before going for a high score. Clean the screws and apply a good lubricant. It’s like giving your machine some oil for a refreshing spa day!

Some common hiccups include wear from use and loose fittings. If you hear weird sounds or notice bumps, check for dirt or damage. Adjust or tighten as needed—your lathe deserves some love too! Remember, a well-maintained lead screw can last a long time, almost like your favorite pet that doesn’t chew on your shoes!

| Issue | Tip |

|---|---|

| Wear and Tear | Inspect and replace damaged parts. |

| Loose Fittings | Tighten screws and bolts regularly. |

| Unusual Noises | Clean and lubricate for smoother operation. |

Upgrading Your CNC Lathe Lead Screw

Signs that indicate a need for an upgrade. How to select and install a new lead screw.

Noticing wobble or play in your lathe? That’s a sign your lead screw might need an upgrade! Other signs include inconsistent finishes or unexpected tool wear. If you’re ready to shop, pick a screw made from durable materials and check compatibility with your machine.

Installing the new lead screw is simpler than teaching a cat to fetch! Just follow the included instructions (or your cat will take over). Remember, proper alignment is key for smooth operation. Give it a whirl, and you’ll be back to crafting metal masterpieces in no time!

| Signs of Upgrade | Actions |

|---|---|

| Wobble or play | Replace immediately! |

| Inconsistent finishes | Upgrade for better results. |

| Excess wear on tools | Select a sturdy lead screw. |

Innovative Technologies in Lead Screw Design

Recent advancements in lead screw technology. Future trends in CNC metal lathe lead screws.

New ideas in lead screw design are changing how CNC metal lathes work. These advancements help machines become faster and more accurate. The use of materials like carbon fiber makes screws lighter yet stronger. Digital controls are also improving performance. They ensure smoother operations and better precision.

Looking ahead, we can expect more changes. Automation and smart technology will make lead screws easier to manage. Engineers are already testing self-adjusting screws. These could reduce wear and tear, saving time and money.

- Lightweight materials boost efficiency.

- Smart tech will enhance user control.

- Self-adjusting systems may extend lifespan.

What are the recent advancements in lead screw technology?

Recent advancements include the use of lightweight materials and digital control systems that enhance speed and precision.

What are the future trends for CNC metal lathe lead screws?

Future trends involve automation, self-adjusting systems, and smarter technologies to improve efficiency.

Cost Analysis of CNC Metal Lathe Lead Screws

Price ranges for different types of lead screws. Longterm cost benefits of investing in quality lead screws.

Buying lead screws for your CNC metal lathe can feel like shopping for ice cream. There are many flavors and prices! Basic lead screws start at around $50, while high-quality options can cost over $300. But remember, investing in quality parts can save money in the long run. Quality lead screws last longer and need fewer replacements. This means less hassle and more time for ice cream! Here’s a quick view of the different price ranges:

| Type of Lead Screw | Price Range |

|---|---|

| Basic Lead Screw | $50 – $100 |

| Standard Lead Screw | $100 – $200 |

| High-Quality Lead Screw | $200 – $300+ |

In conclusion, spending a little more now can save headaches later. Just like a good scoop of ice cream, the best lead screws make everything better!

Conclusion

In summary, a CNC metal lathe lead screw is essential for precise machining. It helps move the tool accurately along the metal. Understanding how it works can improve your projects. If you’re interested, consider researching different types of lead screws. You can also practice with a CNC lathe to see its benefits firsthand. Happy machining!

FAQs

What Is The Function Of A Lead Screw In A Cnc Metal Lathe?

A lead screw in a CNC metal lathe helps move the cutting tool. It turns to make the tool slide back and forth. This helps shape the metal into the right form. Without the lead screw, the tool wouldn’t move correctly. So, it’s very important for making precise parts.

How Do Lead Screw Specifications Affect The Accuracy And Precision Of Cnc Machining Operations?

Lead screws help move parts of a machine accurately. If the lead screw is well-made, it makes the machine more precise. This means that what you design will match what the machine makes. If the lead screw has issues, things may not fit together right. So, good lead screw specifications lead to better results in CNC machining.

What Materials Are Commonly Used For Lead Screws In Cnc Lathes, And How Do They Impact Performance?

CNC lathes often use lead screws made of metal, like steel or aluminum. Steel is strong and lasts a long time, while aluminum is lighter and easier to move. These materials help the machine move quickly and smoothly, making better parts. The right material helps us work faster and with more precision.

How Can Lead Screw Wear And Tear Affect The Longevity Of A Cnc Metal Lathe?

When the lead screw of a CNC metal lathe wears out, it can cause problems. The lathe might not move smoothly or accurately anymore. This can make your projects less precise. If the lead screw keeps getting worse, it could even break. Taking care of the lead screw helps the lathe last longer.

What Are Some Common Methods For Maintaining And Lubricating Lead Screws To Ensure Optimal Performance In Cnc Lathes?

To keep lead screws working well in CNC lathes, you can do a few things. First, clean the screws regularly to remove dust and dirt. Next, use the right lubricant, like oil or grease, to make them move smoothly. You should also check for any damage or wear and fix it. Lastly, keep everything tight so nothing is loose during use.